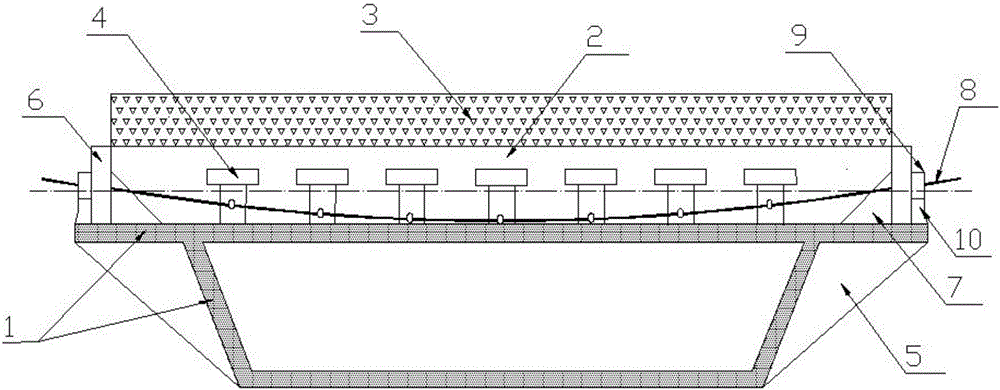

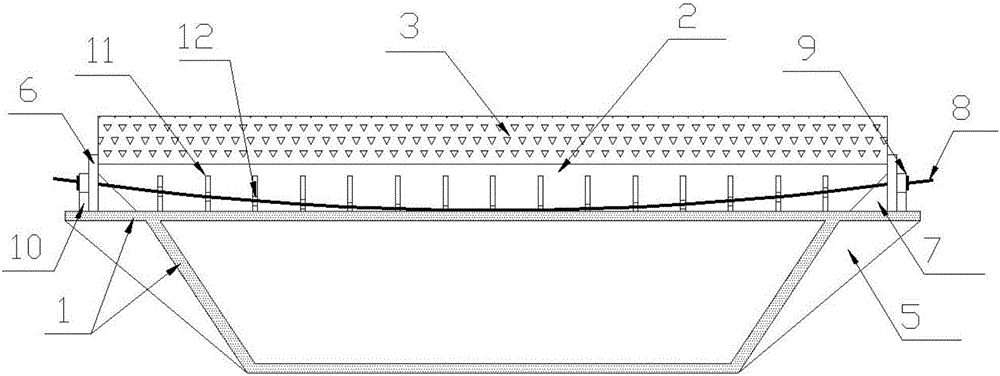

A kind of bridge deck pavement method

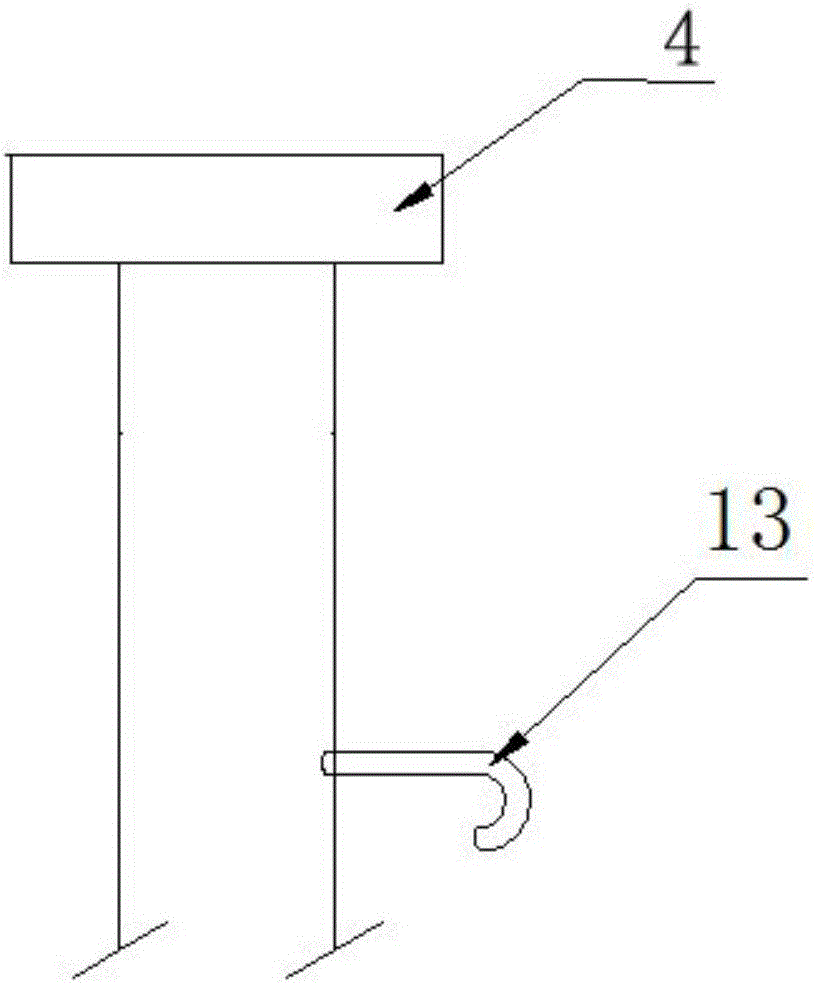

A bridge deck pavement and anchoring device technology, which is applied in the field of material science and engineering, can solve problems such as poor bonding performance, cracking of the concrete layer, and excessive flexibility of the bridge deck, so as to improve road performance, service life, and rigidity and durability, and the effect of improving the overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following examples further illustrate the technical solutions of the present invention, but are not intended to limit the protection scope of the present invention.

[0031] Bridge deck pavement method of the present invention is as follows:

[0032] 1) Steel bridge deck pretreatment

[0033] Check the appearance of the bridge deck, polish and remove the welding slag, burrs and spatter on the surface of the steel plate, then use a high-pressure water gun or surface cleaner to remove dirt, oil and grease on the surface of the steel plate, and perform sandblasting and rust removal after the surface of the steel plate is dry , Rust removal operations are prohibited in case of rain and snow.

[0034] In order to prevent secondary pollution of the steel plate, the spraying of the zinc-rich primer should be completed immediately within 4 hours of sandblasting and derusting, and then the adhesive should be sprayed on the steel plate with anti-rust coating to realize the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com