Non-quenched and tempered steel and method for manufacturing automobile steering knuckle through non-quenched and tempered steel

A technology of automobile steering knuckle and non-quenched and tempered steel, which is applied to vehicle parts, transportation and packaging, etc., to achieve the effects of reducing costs, improving cutting performance, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

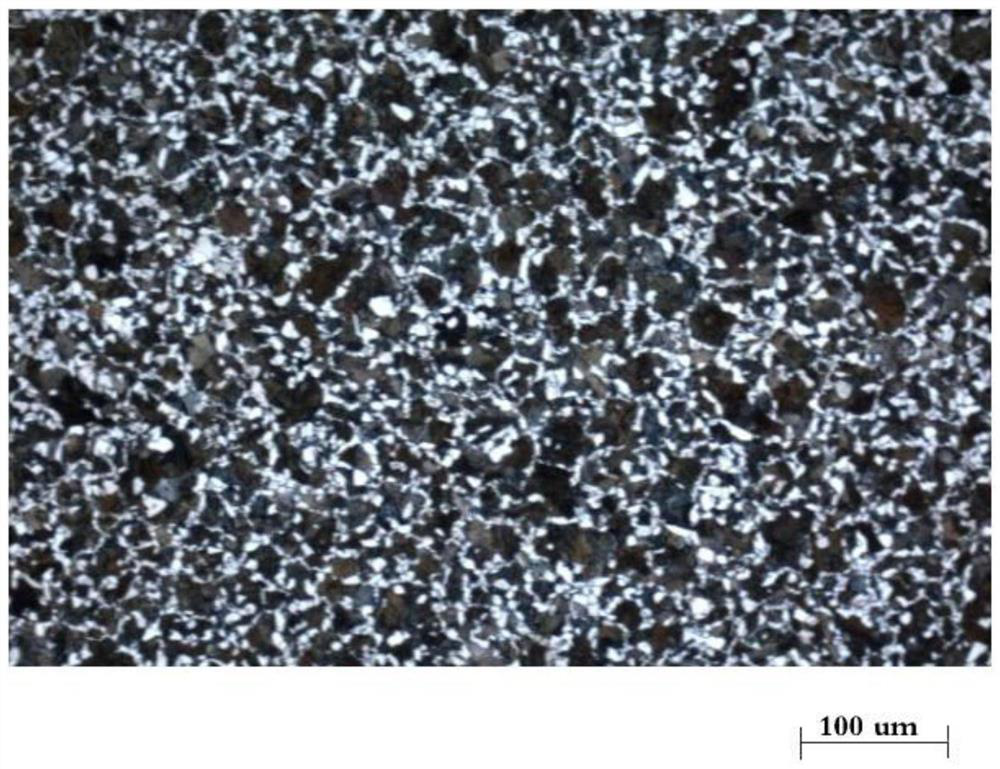

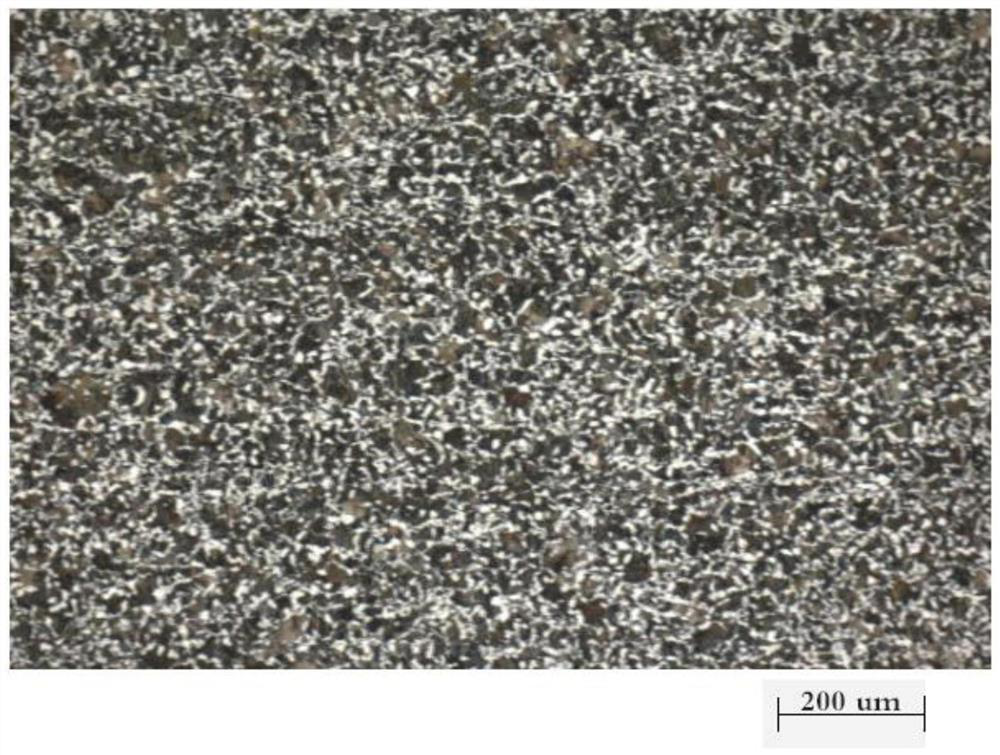

Image

Examples

Embodiment 1

[0042] A kind of non-quenched and tempered steel 37MnSiVSQ, the mass percent of each component is:

[0043] C: 0.35-0.39%; Si: 0.50-0.70%; Mn: 1.30-1.55%; P≤0.015%; S: 0.015-0.060%; Cr: 0.10-0.30%; ~0.05%; Nb: 0.020~0.035%; Ti: 0.015~0.035%; N: 0.015~0.020%; Ni≤0.25%; Mo≤0.10%; Avoid impurities.

[0044] Further, the composition also contains H and O, the content of which is: H≤2.0ppm, O≤15ppm.

[0045] Its composition design principle is as follows:

[0046] C: 0.35% to 0.39%, an important element determining the strength of non-quenched and tempered steel (37MnSiVSQ). To ensure the strength of steel, carbon is the most effective and cheap element, which can combine with strong carbide-forming elements V, Ti, Nb, Mo, etc. to form carbides to play the role of precipitation strengthening and fine-grain strengthening, which is beneficial to the strength of steel Increasing the carbon content is beneficial to prevent recrystallization and increase the recrystallization temper...

Embodiment 2

[0084] Use a kind of non-quenched and tempered steel 37MnSiVSQ of the present invention to manufacture the method for automobile steering knuckle:

[0085] Smelting non-quenched and tempered steel 37MnSiVSQ: steelmaking by electric furnace or converter → ladle refining LF → ladle vacuum degassing VD → continuous casting → controlled rolling and controlled cooling preparation round steel;

[0086] Controlled forging and controlled cold forging of the non-quenched and tempered steel 37MnSiVSQ produced by the above smelting:

[0087] The manufactured non-quenched and tempered steel 37MnSiVSQ round steel is sawed and blanked→induction heating→upsetting→preforming→forming→edge trimming→correction→controlled cooling→stack cooling→shot blasting, in which forging controlled forging and controlled cooling process, After the forging correction, the workpiece is immediately cooled by strong wind, and the cooling rate is controlled to cool to 550 ℃ ~ 650 ℃ stack cooling and slowly coole...

Embodiment 3

[0094] The difference from Example 2 is that the mass percent of the non-quenched and tempered steel 37MnSiVSQ is: C: 0.39; Si: 0.56; Mn: 1.36; P: 0.010; S: 0.04; Cr: 0.26; V: 0.15; Al: 0.02; N: 0.0150; Nb: 0.020; Ti: 0.015, Ni≤0.25; Mo≤0.10; Sn≤0.03; Cu≤0.20, the rest is Fe and unavoidable impurities.

[0095] 【O】=15.7ppm,【H】=1.1ppm; the final forging temperature is 1000~1050℃, and the mechanical properties are tested and analyzed: tensile strength Rm=970MPa, yield strength Re0.2=673MPa, elongation A=18 %, reduction of area Z=24%, impact energy AKu=38J.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com