High-strength and high-toughness titanium alloy pipe for oil and gas development and preparation method thereof

A titanium alloy and high-strength technology, which is applied in the field of high-strength and high-toughness titanium alloy pipes and their preparation, can solve the problems of titanium alloy pipes that are difficult to meet in terms of strength and toughness, and achieve excellent mechanical properties, convenient preparation and processing, and excellent mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a high-strength and high-toughness titanium alloy drilling tool pipe composition design and preparation method used in oil and gas development of deep wells and ultra-deep wells. The oil pipes made of titanium alloy materials are used in meeting the severe oil and gas development conditions in China. In addition to corrosion resistance, it also has high strength, high toughness and good fatigue performance.

[0030] The high-strength and high-toughness titanium alloy material of the present invention is composed of the following components by mass percentage, Al: 3.8-5.0%, V: 2.4-3.3%, Fe: 1.3-1.8%, Nb: 0.4-0.8%, Ni: 0.3-1.0 %, O ≤ 0.2%, C ≤ 0.04%, N ≤ 0.04%, H ≤ 0.0135%, the balance is Ti; on this basis, one of Cr: 0.15-0.35%, Mo: 0.05-1.0% can also be added One or two alloying elements.

[0031] In the alloy composition of the present invention, a small amount of Fe element is used to replace part of V element with higher price. Fe element is ...

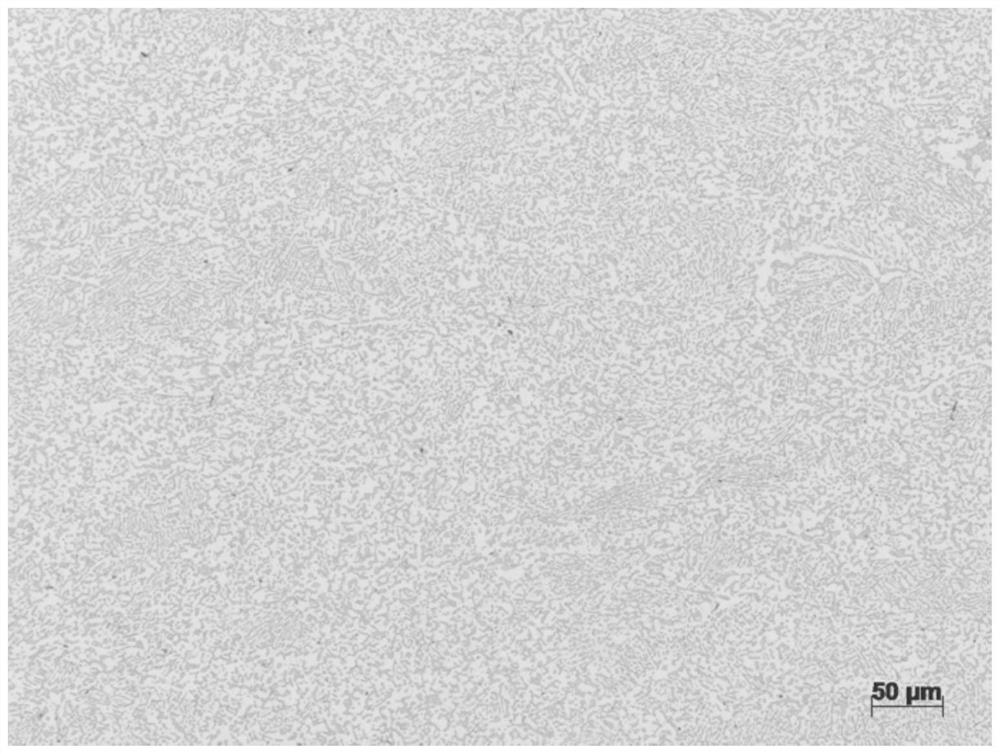

Embodiment 1

[0042] The composition of the high-strength and high-toughness titanium alloy material used in the oil and gas development of deep wells and ultra-deep wells of the present invention is composed of Al: 4.53%; V: 3.11%; Fe: 1.69%; Ni: 0.33%; Nb: 0.77%; O: 0.12%; C: 0.035%; N: 0.007%; H: 0.0131%; Mo: 0.09%, and the balance is Ti.

[0043] The preparation processing method of above titanium alloy tube comprises the following steps:

[0044] 1) The titanium alloy composition with the above ratio is dispersed and batched and then pressed into an electrode. It is melted in a vacuum consumable furnace for three times and vacuum smelted to form an ingot. The outer diameter of the ingot is 400 mm, and there is no obvious iron element segregation. ;

[0045] After peeling the ingot, cutting the riser, removing the bottom pad, and sampling and analyzing the chemical composition, the ingot is heated to a temperature of 1000-1050 °C, and the temperature is lowered for more than two times ...

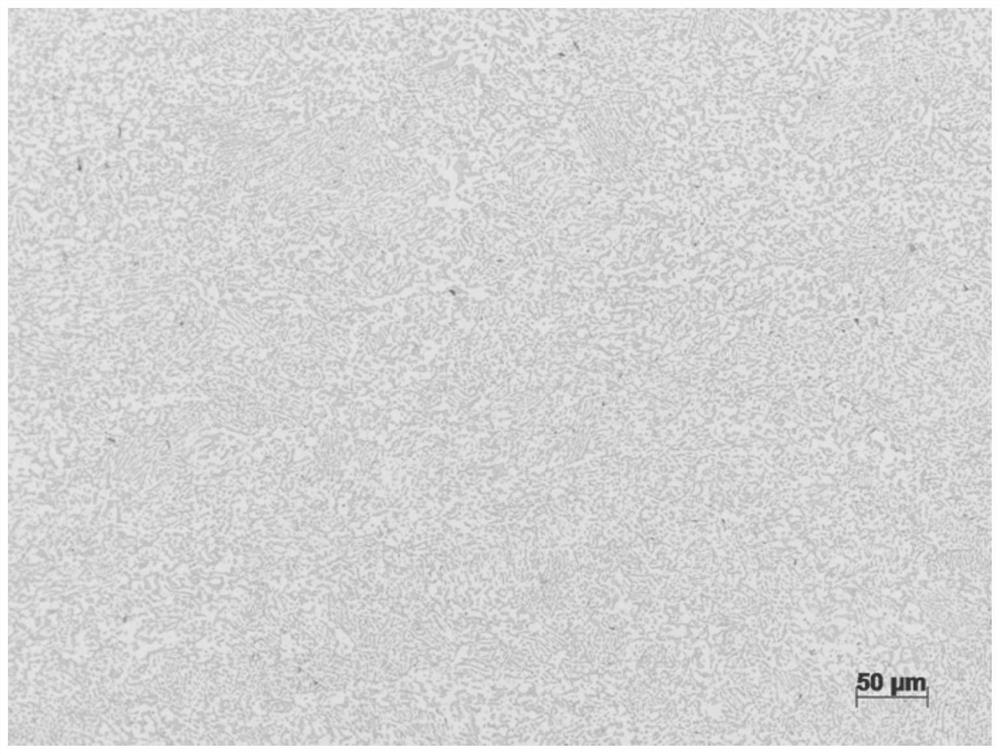

Embodiment 2

[0051] The composition of the high-strength and high-toughness titanium alloy material used in the oil and gas development of deep wells and ultra-deep wells of the present invention is composed of Al: 4.92%; V: 2.56%; Fe: 1.41%; Ni: 0.89%; Nb: 0.51%; O: 0.13%; C: 0.028%; N: 0.016%; H: 0.0134%; Mo: 0.88%, Cr: 0.19%; the balance is Ti;

[0052] The preparation and processing method of the above-mentioned titanium alloy tube comprises the following steps:

[0053] 1) The titanium alloy composition with the above ratio is dispersed and batched, then pressed into an electrode, melted in a vacuum consumable furnace for three times and vacuum smelted to form an ingot. The outer diameter of the ingot is 600 mm, and there is no obvious iron element segregation ;

[0054] After peeling the ingot, cutting the riser, removing the bottom pad, and sampling and analyzing the chemical composition, the ingot is heated to a temperature of 1000-1050 °C, and the temperature is lowered for more ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com