A tear-off whitening and whitening mask and its preparation method

A whitening mask and whitening technology, which are applied in the directions of pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc., can solve the problems of insufficient whitening and whitening effects, unclear effective ingredients for whitening and whitening, and unfavorable absorption of effective ingredients, etc. Achieve the effect of reducing the risk of minimally invasive skin damage, reducing the harm of skin aging and wrinkles, and good film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

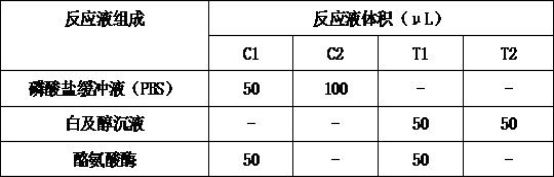

Method used

Image

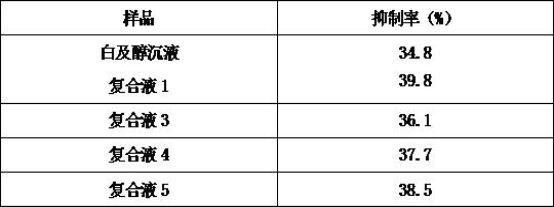

Examples

Embodiment 1

[0033] Baiji alcohol precipitation solution 3%, sodium zinc edetate 0.03%, vitamin C 0.2%, sodium hyaluronate 0.03%, sodium carboxymethyl cellulose 0.1%, allantoin 0.1%, polyvinyl alcohol 15% %, glycerin 10%, butylene glycol 5%, methylparaben 0.5%, disodium edetate 0.03%, chitosan 3%, ethanol 0.5%, and the balance is deionized water.

[0034] Preparation:

[0035] (1) Mix 0.1 parts by weight of allantoin, 0.03 parts by weight of disodium edetate, 0.03 parts by weight of sodium hyaluronate, 0.1 parts by weight of sodium carboxymethyl cellulose, 15 parts by weight of polyvinyl alcohol, 3 parts by weight of Add an appropriate amount of chitosan to deionized water, heat it in a water bath at 90°C to fully dissolve it, and obtain paste A;

[0036] (2) 10 parts by weight of glycerin, 5 parts by weight of butanediol, 0.5 parts by weight of methyl paraben, 0.5 parts by weight of ethanol, 3 parts by weight of white and alcohol precipitation solution, 0.03 parts by weight of sodium zin...

Embodiment 2

[0039] Baijiol solution 1%, sodium zinc edetate 0.05%, vitamin C 0.1%, sodium hyaluronate 0.05%, sodium carboxymethylcellulose 0.3%, allantoin 0.1%, polyvinyl alcohol 20% , Glycerin 10%, Butylene Glycol 15%, Methylparaben 0.1%, Disodium EDTA 0.05%, Chitosan 4%, and the balance is deionized water.

[0040] Preparation:

[0041] (1) Mix 0.1 parts by weight of allantoin, 0.05 parts by weight of sodium hyaluronate, 0.3 parts by weight of sodium carboxymethylcellulose, 20 parts by weight of polyvinyl alcohol, 0.05 parts by weight of disodium edetate, 4 parts by weight of Add an appropriate amount of chitosan to deionized water, heat it in a water bath at 90°C to fully dissolve it, and obtain paste A;

[0042] (2) 10 parts by weight of glycerin, 15 parts by weight of butanediol, 0.1 parts by weight of methylparaben, 1 part by weight of white and alcohol precipitation solution, 0.05 parts by weight of sodium zinc edetate, and 0.1 parts by weight of vitamin C Add an appropriate amou...

Embodiment 3

[0045] White and Alcohol Solution 3%, Vitamin C 0.1%, Sodium Hyaluronate 0.03%, Sodium Carboxymethyl Cellulose 0.1%, Allantoin 0.3%, Polyvinyl Alcohol 25%, Glycerin 15%, Butylene Glycol 10% , methylparaben 0.3%, and the balance is deionized water.

[0046] Preparation:

[0047] (1) Add 0.3 parts by weight of allantoin, 0.03 parts by weight of sodium hyaluronate, 0.1 parts by weight of sodium carboxymethylcellulose, and 25 parts by weight of polyvinyl alcohol into an appropriate amount of deionized water, and heat them in a water bath at 90°C to fully dissolve them , get paste A;

[0048] (2) Add 15 parts by weight of glycerin, 10 parts by weight of butanediol, 0.3 parts by weight of methyl paraben, 3 parts by weight of white and alcohol precipitation solution, and 0.1 parts by weight of vitamin C into an appropriate amount of deionized water, and stir evenly at 45 ° C , to get liquid B;

[0049] (3) Put paste A and liquid B in a vacuum mixer, add deionized water to make up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com