A high-strength, high-toughness, corrosion-resistant, lead-free, arsenic-free brass alloy and preparation method thereof

A brass alloy, high-strength and high-toughness technology, applied in the field of non-ferrous metals, can solve the problems of lead damage to the brain center, shock, high price, etc., achieve good corrosion resistance, good forming effect, and increase the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention provides a method for preparing the lead-free and arsenic-free brass alloy described in the above scheme, comprising the following steps:

[0045] Melting the metal raw material composed of the lead-free and arsenic-free brass alloy corresponding to the above scheme to obtain an ingot;

[0046] The ingot is subjected to first heat treatment, rolling and second heat treatment in sequence to obtain a lead-free, arsenic-free brass alloy with high strength, high toughness and corrosion resistance;

[0047] The temperature of the first heat treatment is 850-950°C, and the time of heat treatment is 24-48 hours;

[0048] The temperature of the second heat treatment is 850° C., and the time is 10-60 minutes.

[0049] The present invention smelts the metal raw material composed of the lead-free and arsenic-free brass alloy corresponding to the above scheme to obtain an ingot. In the present invention, the metal raw material preferably includes elemental C...

Embodiment 1

[0059] High-strength, high-toughness, corrosion-resistant, lead-free, arsenic-free brass alloy material, its composition is: Cu 59%, Zn 33%, Al 5%, Fe 3%.

[0060] Cu and Zn used in smelting are pure metals, and Al and Fe are added in the form of Cu92Al5Fe3 alloy. The metal raw materials corresponding to the above components were smelted at 1200°C to obtain ingots (thickness: 14mm). The as-cast structure was mainly β phase and body-centered cubic FeAl phase; After the heat treatment, it is rolled into a sheet (1.5mm in thickness) at 850°C, and then subjected to a second heat treatment at 850°C for 30 minutes, and air-cooled to obtain a lead-free and arsenic-free brass alloy.

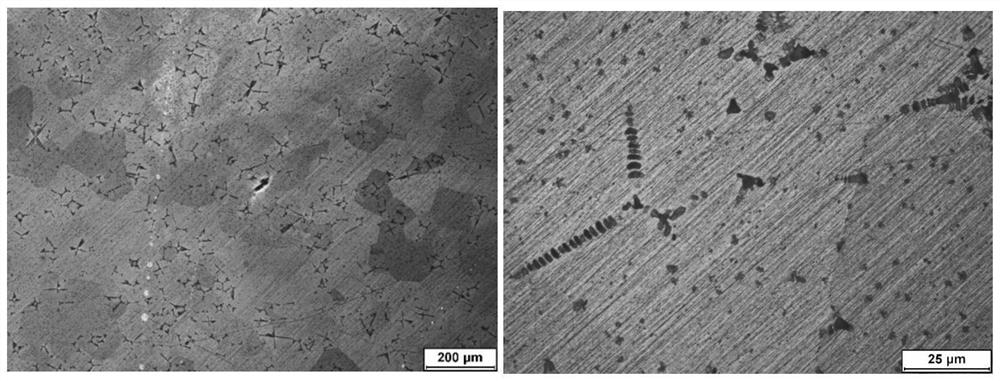

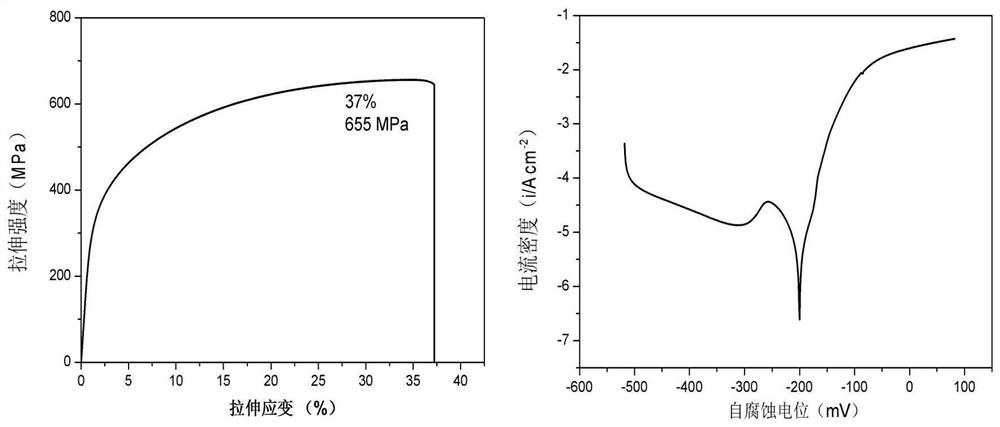

[0061] figure 1 It is the optical metallographic microstructure diagram of the ingot of embodiment 1; figure 2 It is the optical metallographic microstructure diagram of the lead-free and arsenic-free brass alloy prepared in Example 1. Depend on figure 1 and figure 2 It can be seen that both the a...

Embodiment 2

[0064] High-strength, high-toughness, corrosion-resistant, lead-free, arsenic-free brass alloy material, its composition is: Cu 60%, Zn 33%, Al 4%, Fe 3%.

[0065] Cu and Zn used in smelting are pure metals, and Al and Fe are added in the form of Cu93Al4Fe3 alloy. The metal raw materials corresponding to the above components were smelted at 1200°C to obtain ingots (thickness 14mm), the as-cast structure mainly consisted of β phase and body-centered cubic FeAl phase; After the heat treatment, it is rolled into a sheet (1.5 mm in thickness) at 800°C, and then heat-treated for 30 minutes at 850°C for a second time, and then lead-free and arsenic-free brass alloy is obtained after air cooling.

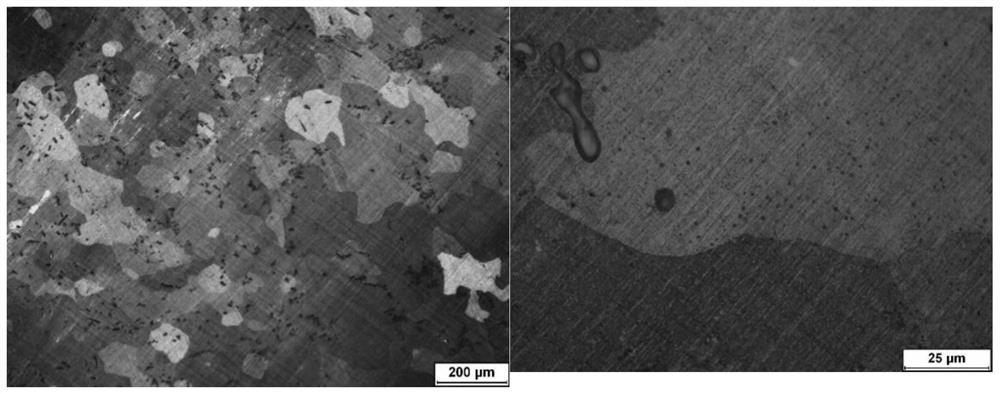

[0066] Figure 4 It is the optical metallographic microstructure diagram of the ingot of embodiment 2; Figure 5 It is the optical metallographic microstructure diagram of the lead-free and arsenic-free brass alloy prepared in Example 2. Depend on Figure 4 and Figure 5 It can be see...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com