Whitening ultraviolet-proof ethylene-propylene rubber insulation power cable for ships and manufacturing method thereof

An ethylene-propylene rubber insulation and anti-ultraviolet technology, which is applied in the direction of power cables, cable/conductor manufacturing, cables, etc., can solve the problem that the insulation color and printed digital logo cannot be clearly distinguished, the service life of the cable is short, and the service life of the ship design cannot be met. Cable anti-ultraviolet requirements and other issues, to achieve the effects of excellent ultraviolet light aging resistance, long service life, and excellent resistance to sunlight and weather aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

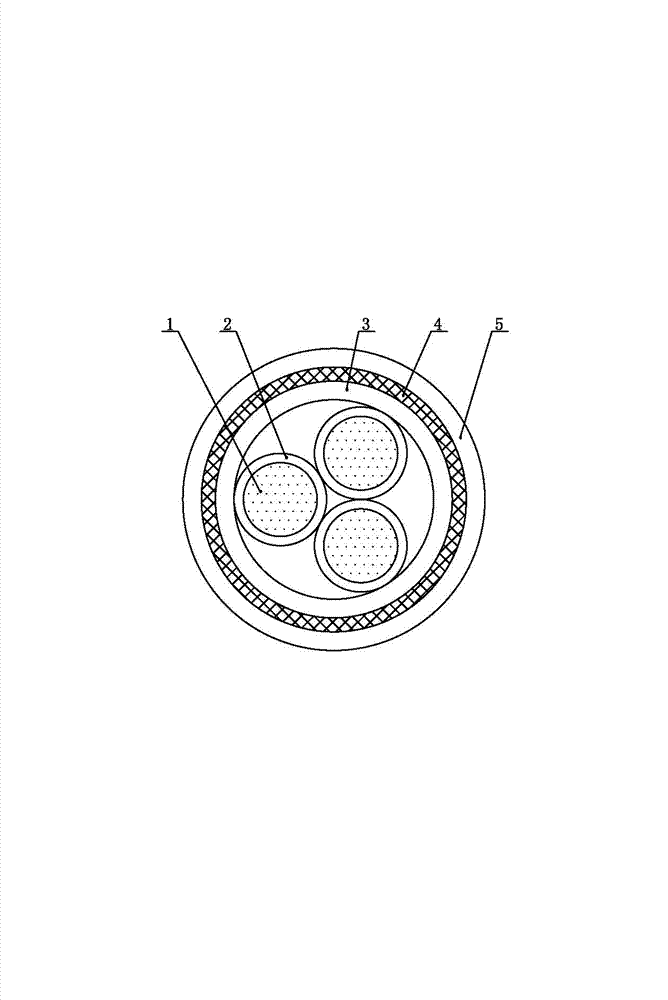

[0021] Such as figure 1 As shown, the whitening and anti-ultraviolet ethylene-propylene rubber insulated marine power cable of the present invention is manufactured according to the following steps: extruding the whitening and anti-ultraviolet ethylene-propylene rubber insulating layer 2 on the outer periphery of the tinned annealed stranded copper conductor 1 to form a power cable insulation Wire core, a plurality of insulated wire cores are twisted rightward with a stranded pitch ratio of 18 times to form a cable core, and then an inner liner 3 is extruded on the outer circumference of the cable core, and then the outer circumference of the inner liner 3 is wrapped Copper-clad alloy wire braided armor layer 4, and finally an outer sheath 5 is extruded around the outer periphery of the copper alloy wire braided armor layer 4.

[0022] Among them, the minimum thickness of the whitening and anti-ultraviolet ethylene-propylene rubber insulation layer 2 is not less than 90% of th...

Embodiment 2

[0026] The whitening and anti-ultraviolet ethylene-propylene rubber insulated marine power cable of the present invention is manufactured according to the following steps: extruding a whitening and anti-ultraviolet ethylene-propylene rubber insulating layer 2 on the outer periphery of a tinned annealed stranded copper conductor 1 to form an insulating wire core of a power cable, A plurality of insulated wire cores are twisted rightward at a twisting pitch ratio of 19 times to form a cable core, and then an inner liner 3 is extruded on the outer periphery of the cable core, and then the outer periphery of the inner liner 3 is coated with copper alloy The wire braided armor layer 4 is finally extruded with an outer sheath 5 around the outer periphery of the copper alloy wire braided armor layer 4 .

[0027] Among them, the minimum thickness of the whitening and anti-ultraviolet ethylene-propylene rubber insulation layer 2 is not less than 90% of the nominal value, and the maximum...

Embodiment 3

[0031] The whitening and anti-ultraviolet ethylene-propylene rubber insulated marine power cable of the present invention is manufactured according to the following steps: extruding a whitening and anti-ultraviolet ethylene-propylene rubber insulating layer 2 on the outer periphery of a tinned annealed stranded copper conductor 1 to form an insulating wire core of a power cable, A plurality of insulated wire cores are twisted rightward at a twisted pitch ratio of 20 times to form a cable core, and then an inner liner 3 is extruded on the outer periphery of the cable core, and then the outer periphery of the inner liner 3 is coated with copper alloy The wire braided armor layer 4 is finally extruded with an outer sheath 5 around the outer periphery of the copper alloy wire braided armor layer 4 .

[0032] Among them, the minimum thickness of the whitening and anti-ultraviolet ethylene-propylene rubber insulation layer 2 is not less than 90% of the nominal value, and the maximum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com