Antibacterial plastic master batch and preparation method thereof

An antibacterial plastic and masterbatch technology, applied in the field of plastic production, can solve problems such as harmful microbial pollution and health threats of plastics, and achieve long-term antibacterial properties, good compatibility, and excellent photoaging properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

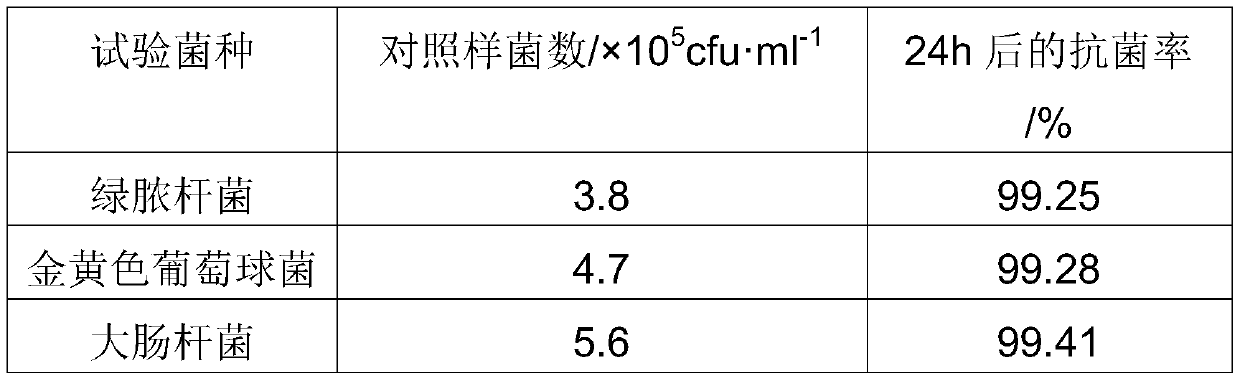

Examples

Embodiment 1

[0025] A kind of antibacterial plastic master batch of the present embodiment, according to the parts by weight, comprises:

[0026] Polypropylene raw material: 150 parts

[0027] Nano-zirconium phosphate silver-loaded antibacterial agent: 50 parts

[0028] Surface treatment agent: 0.8 parts

[0029] Auxiliary: 1.6 servings

[0030] The surface treatment agent is a mixture of hyperdispersant, titanate coupling agent and aluminate coupling agent, and the weight ratio of hyperdispersant, titanate coupling agent and aluminate coupling agent in the surface treatment agent is 1.0 :1.5:1.5.

[0031] The auxiliary agent is polyethylene wax and light stabilizer, and the weight ratio of dispersant and light stabilizer in the auxiliary agent is 3:1.

[0032] The particle size of the nano-zirconium phosphate-loaded silver antibacterial agent is 80 meshes, and the silver content is 3.5%.

[0033] A preparation method of antibacterial plastic masterbatch, comprising the steps:

[003...

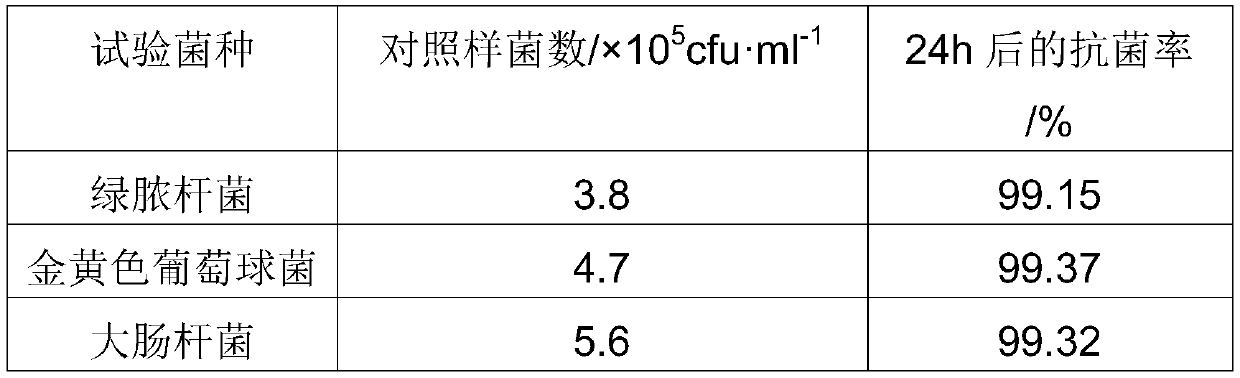

Embodiment 2

[0043] A kind of antibacterial plastic master batch of the present embodiment, according to the parts by weight, comprises:

[0044] Polyethylene raw material: 180 parts

[0045] Nano-zirconium phosphate silver-loaded antibacterial agent: 60 parts

[0046] Surface treatment agent: 1.2 parts

[0047] Auxiliary: 2.0 servings

[0048] The surface treatment agent is a mixture of hyperdispersant, titanate coupling agent and aluminate coupling agent, and the weight ratio of hyperdispersant, titanate coupling agent and aluminate coupling agent in the surface treatment agent is 1.0 :2.0:2.0.

[0049] The auxiliary agent is polyethylene wax and light stabilizer, and the weight ratio of dispersant and light stabilizer in the auxiliary agent is 3:2.

[0050] The particle size of the nano-zirconium phosphate-loaded silver antibacterial agent is 50 meshes, and the silver content is 4.0%.

[0051] A preparation method of antibacterial plastic masterbatch, comprising the steps:

[0052...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com