Ultraviolet-resistant sealing gasket for outdoor transformers and preparation method thereof

An anti-ultraviolet and transformer technology, which is applied in the field of sealing materials, can solve the problems of power system and user economic losses, transformer oil leakage, cracks, etc., and achieve excellent ultraviolet light aging resistance, long service life and good mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

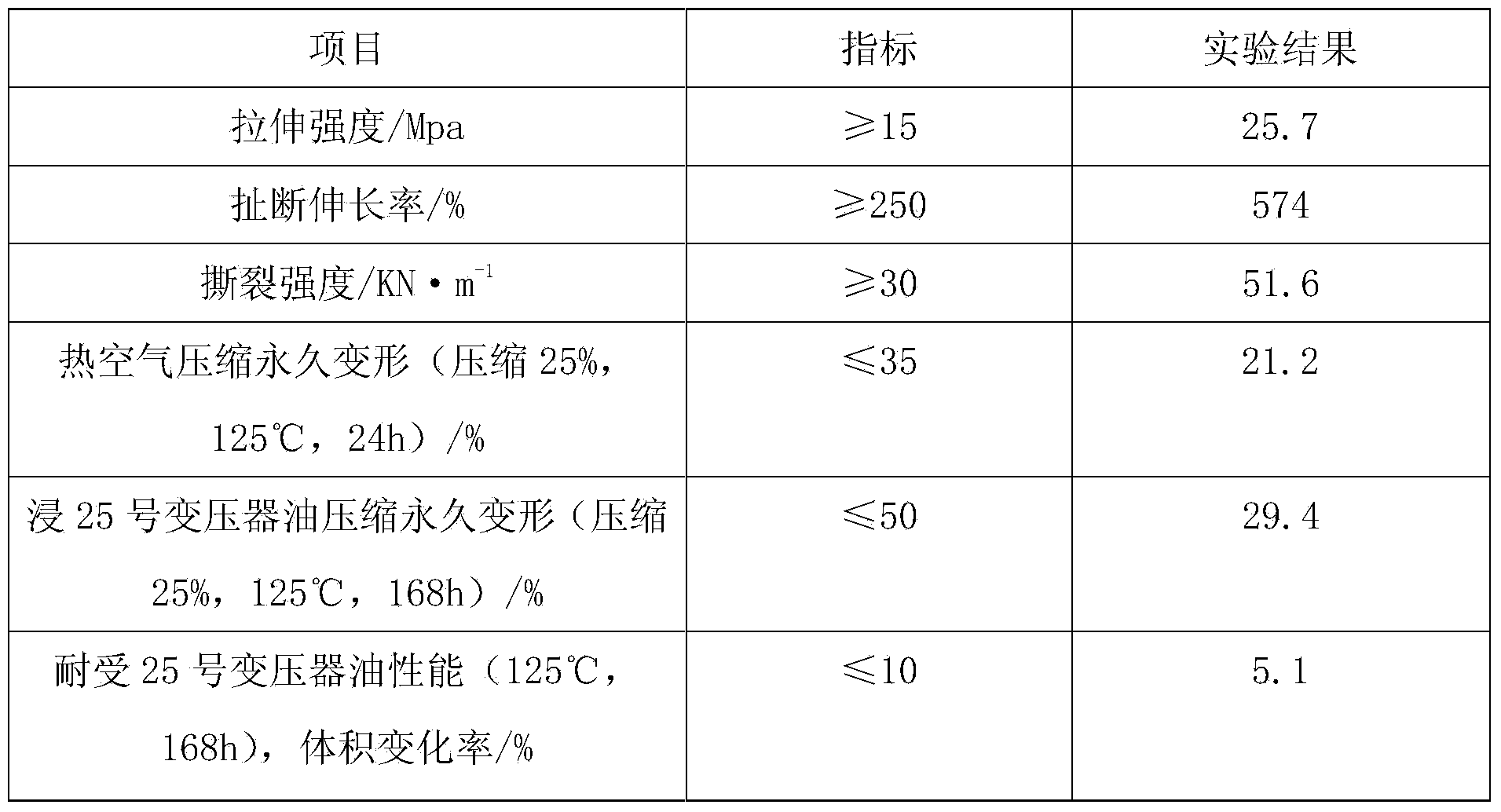

Examples

Embodiment Construction

[0012] An anti-ultraviolet gasket for outdoor transformers, made of the following raw materials by weight (kg): neoprene (CR121) 70, styrene-butadiene rubber (SBR1712) 30, SEBS8, dioctyl phthalate 12, triphosphate Benzyl ester 10, No. 30 motor oil 15, zinc oxide 4, magnesium oxide 3, stearic acid 1, carbon black N22025, insoluble sulfur 2, diethylene glycol dimethacrylate 3, nano aluminum nitride 8, talc powder 10 , nano barite 6, composite filler 4, anti-aging agent 2642, anti-aging agent MBZ0.5, accelerator DZ1.5, ultraviolet absorber UV-91;

[0013] The preparation method of the composite filler is as follows: a. Weigh wollastonite, pyrophyllite, and attapulgite in a weight ratio of 4:3:1 and mix them evenly, calcinate at 515°C for 4 hours, and put in hydrochloric acid with a concentration of 16% after cooling to normal temperature Soak in the solution for 3 hours, filter, wash the above-mentioned ore mixture with distilled water until neutral, dry, pulverize, and pass thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com