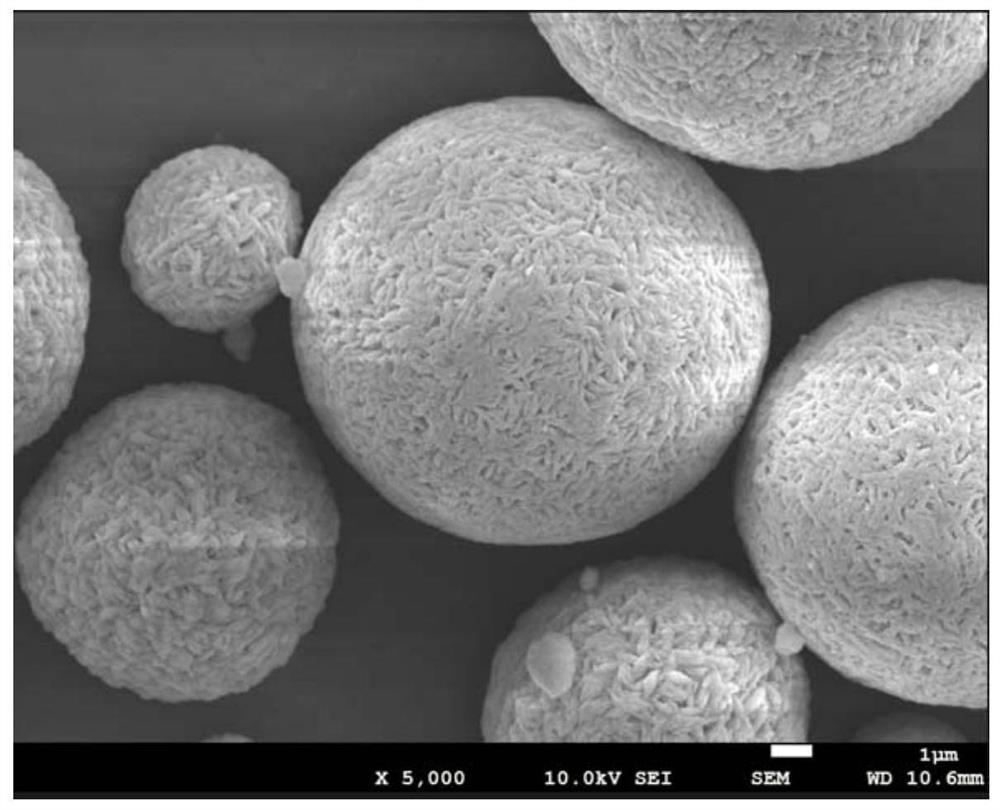

High-nickel quaternary precursor material as well as preparation method and preparation system thereof

A technology for preparing systems and precursors, applied in chemical instruments and methods, nickel compounds, electrical components, etc., can solve the problems affecting the specific capacity, cycleability, thermal stability, and low tap density of lithium batteries, and achieve particle crushing Or the possibility of hollowing is reduced, the heating rate is fast, and the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

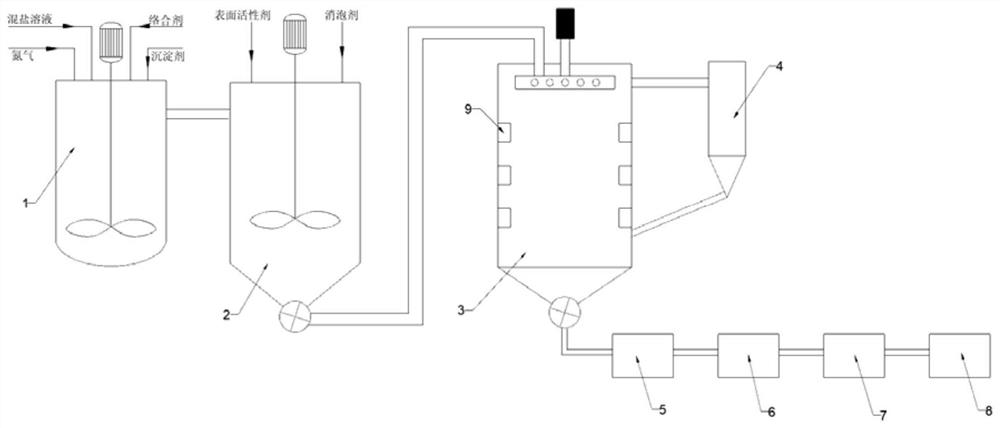

Method used

Image

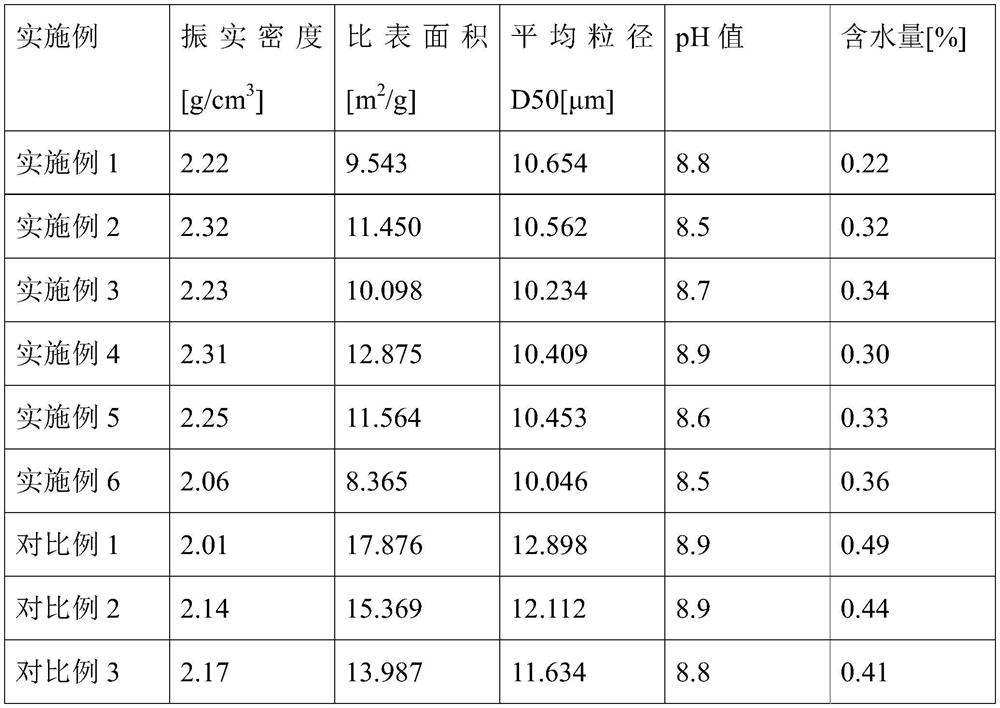

Examples

Embodiment 1

[0069] This embodiment provides a Ni 0.88 co 0.05 mn 0.05 Zr 0.02 (OH) 2 The preparation method of the quaternary precursor material, the preparation method is carried out in the preparation system provided in the above specific embodiment, and the preparation method specifically includes the following steps:

[0070] (1) Weigh nickel sulfate, cobalt sulfate, manganese sulfate and zirconium sulfate respectively according to the molar ratio of nickel, cobalt, manganese and zirconium in the ratio of 88:5:5:2, add water and mix them to prepare a concentration of 2mol / L mixed salt solution;

[0071] (2) Send mixed salt solution, ammonia solution (concentration is 10.4mol / L) and sodium hydroxide solution (concentration is 8mol / L) into reaction device 1 through peristaltic pump, fully stir reaction under nitrogen atmosphere to obtain mixed slurry , the stirring speed is 500r / min;

[0072] (3) The mixed slurry enters the aging device 2 by overflowing, mixes with sodium dodecylb...

Embodiment 2

[0077] This embodiment provides a Ni 0.89 co 0.05 mn 0.05 Zr 0.01 (OH) 2 The preparation method of the quaternary precursor material, the preparation method is carried out in the preparation system provided in the above specific embodiment, and the preparation method specifically includes the following steps:

[0078] (1) Weigh nickel chloride, cobalt chloride, manganese chloride and zirconium oxychloride respectively according to the molar ratio of nickel, cobalt, manganese and zirconium as 89:5:5:1, add water and mix to make the concentration 2mol / L mixed salt solution;

[0079] (2) Mixed salt solution, ammonium carbonate solution (concentration is 10.8mol / L) and potassium hydroxide solution (concentration is 9mol / L) are sent in the reaction device 1 by peristaltic pump, fully stir reaction under nitrogen atmosphere to obtain mixed Slurry, stirring speed is 600r / min;

[0080] (3) The mixed slurry enters the aging device 2 by overflowing, mixes with sodium dodecylbenze...

Embodiment 3

[0084] This embodiment provides a Ni 0.90 co 0.05 mn 0.04 Zr 0.01 (OH) 2 The preparation method of the quaternary precursor material, the preparation method is carried out in the preparation system provided in the above specific embodiment, and the preparation method specifically includes the following steps:

[0085] (1) Weigh nickel nitrate, cobalt nitrate, manganese nitrate and zirconium nitrate respectively according to the molar ratio of nickel, cobalt, manganese and zirconium as 90:5:4:1, add water and mix to prepare a mixed salt with a concentration of 2mol / L solution;

[0086] (2) Mixed salt solution, ammonium bicarbonate solution (concentration is 9.5mol / L) and lithium hydroxide solution (concentration is 7mol / L) are sent in the reaction device 1 by peristaltic pump, fully stirred reaction under nitrogen atmosphere to obtain Mix the slurry, the stirring speed is 650r / min;

[0087] (3) The mixed slurry enters the aging device 2 by overflowing, mixes with sodium d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com