Preparation method of high-hardness Cu-SiC nanometer compound plating layer and special device thereof

A nano-composite, special-purpose equipment technology, applied in the direction of electrolytic coatings, etc., can solve the problems of difficult composite plating process, full play, and lower overall performance, and achieve the effects of dense crystal structure, avoiding agglomeration, and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

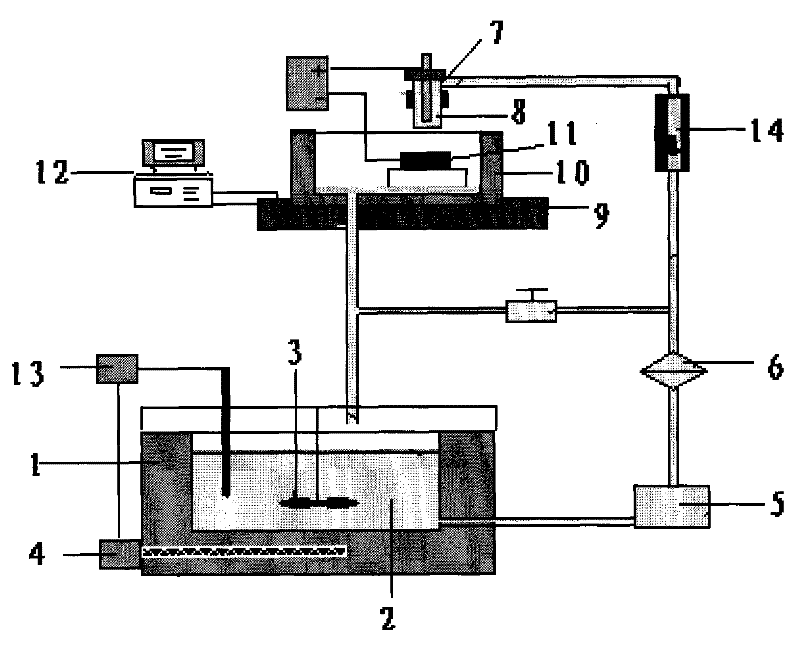

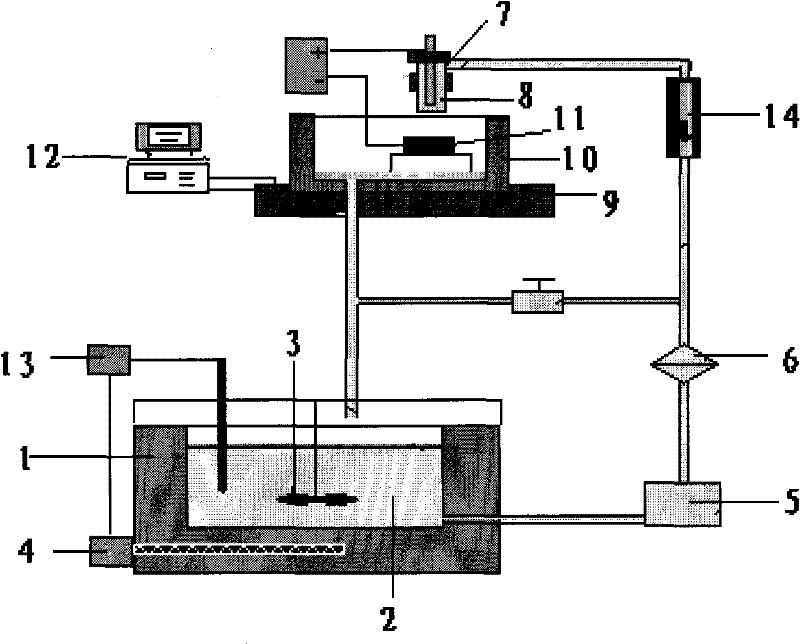

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing a high-hardness Cu-SiC nanocomposite coating, specifically comprising the following steps:

[0041] (1) Pretreatment of nano-SiC particles: soak the nano-SiC particles with 4mL / L polyacrylic acid solution for 10h before adding them to the electrolyte, and set aside;

[0042] (2) Preparation of electrolyte containing nano-SiC particles: the nano-SiC particles obtained in step (1) were added to the electrolyte prepared with deionized distilled water, and mechanically stirred at a stirring speed of 1000 rpm for 3 hours, and then The electrolyte containing nano-SiC particles was ultrasonically oscillated for 2 hours, so that the SiC particles were fully wetted and evenly dispersed in the electrolyte, and a 280g / LCuSO 4 ·5H 2 O, 80g / L98% concentrated sulfuric acid, 10g / L SiC, 4g / L saccharin and 0.2g / L C 12 h 25 SO 4 An electrolyte solution containing nano-SiC particles composed of Na, wherein the average diameter of the SiC particles is 30nm;

[0...

Embodiment 2

[0046] A method for preparing a high-hardness Cu-SiC nanocomposite coating, specifically comprising the following steps:

[0047] (1) Pretreatment of nano-SiC particles: soak the nano-SiC particles in 4 mL / L polyacrylic acid solution for 9 hours before adding them to the electrolyte, and set aside;

[0048] (2) Preparation of electrolyte containing nano-SiC particles: the nano-SiC particles obtained in step (1) were added to the electrolyte prepared with deionized distilled water, and mechanically stirred at a stirring speed of 1500 rpm for 3 hours, and then The electrolyte containing nano-SiC particles was ultrasonically oscillated for 1 hour, so that the SiC particles were fully wetted and evenly dispersed in the electrolyte, and a 300g / LCuSO 4 ·5H 2 O, 100g / L 98% concentrated sulfuric acid, 40g / L SiC, 4g / L saccharin and 0.4g / L C 12 h 25 SO 4 An electrolyte solution containing nano-SiC particles composed of Na, wherein the average diameter of the SiC particles is 45nm; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com