Al2O3 or Cr2O3 film thermal growth type M-Cr-Al nano composite coating, and preparation and application thereof

A nano-composite and thermal growth technology, applied in the field of electrophoretic deposition technology and electrodeposition, can solve the problems affecting the industrial promotion of nano-composite coatings, low particle usage rate, insignificant effect, etc., and achieves good corrosion resistance, low cost and suitable for use. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

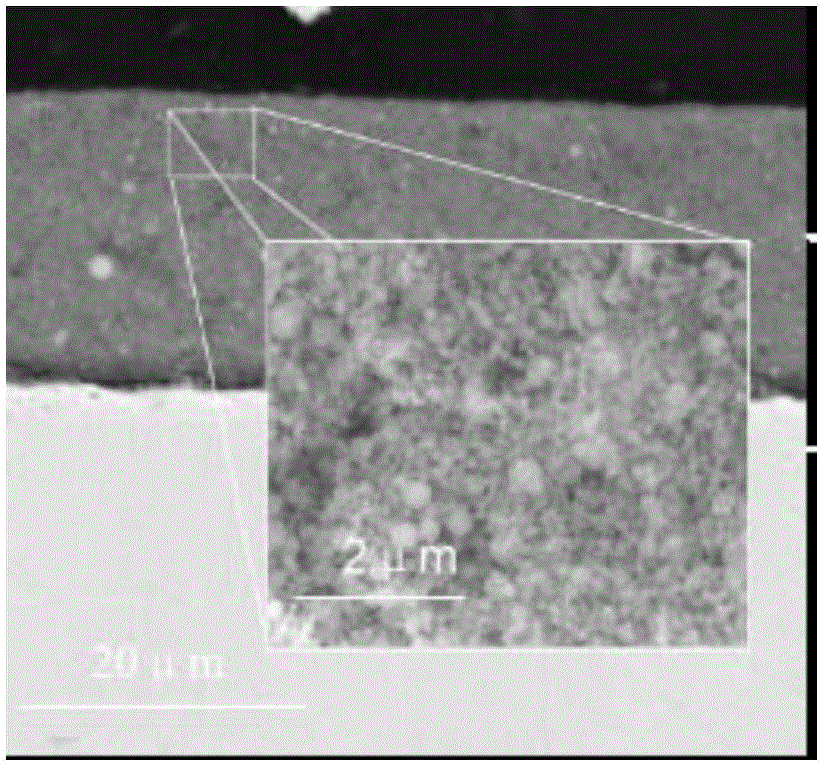

[0041] The preparation method of the nanocomposite coating is carried out in two steps: (1) taking metal Ni, Fe, Co, carbon steel or low alloy steel as the base material, pre-electrophoretic deposition of nano metal Cr, Al particles and / or CrAl alloy on the base material (2) put the substrate of the electrophoretic deposition CrAl layer into the electroplating solution of Ni, Fe or Co for electrodeposition, so that the corresponding metal is deposited in the pores of the nanoparticles Internal nucleation and growth to prepare M-Cr-Al type nanocomposite coatings, namely Ni-Cr-Al, Fe-Cr-Al or Co-Cr-Al nanocomposite coatings.

[0042] Step (1) electrophoresis solution is: acetylacetone solution or acetone solution that has dissolved iodine simple substance, or dissolved AlCl 3 ·6H 2 O or MgCl 2 ·6H 2 O ethanol solution; the concentration of iodine element is 0.2 ~ 3.0g / L, AlCl 3 ·6H 2 O or MgCl 2 ·6H 2 The concentration of O is 0.2-3.0 g / L. During electrophoretic depositi...

Embodiment 1

[0046] This example provides the preparation and performance of the electrophoresis-electrodeposition two-step method for preparing nano-composite coatings when the electrophoresis solution is an acetylacetone solution. First, it introduces the preparation method for preparing a nano-coating by electrophoresis-electroplating when the electrophoresis solution is an acetylacetone solution. The specific steps are as follows :

[0047] 1) Take Ni as the base material, process it into a sample with a size of 15×10×2mm, grind it to 800# with water-grinding paper, clean it ultrasonically in acetone, and blow dry it for later use;

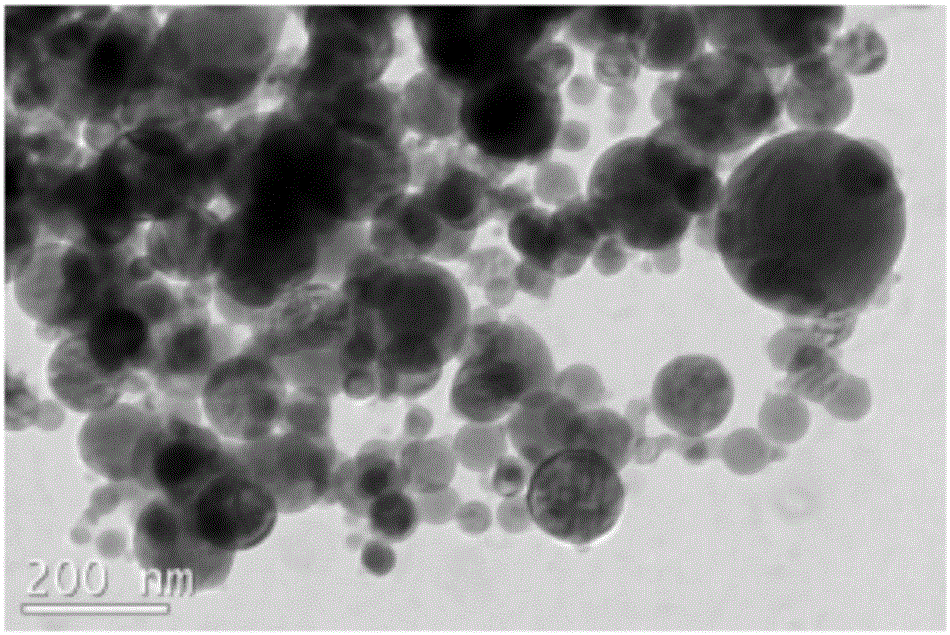

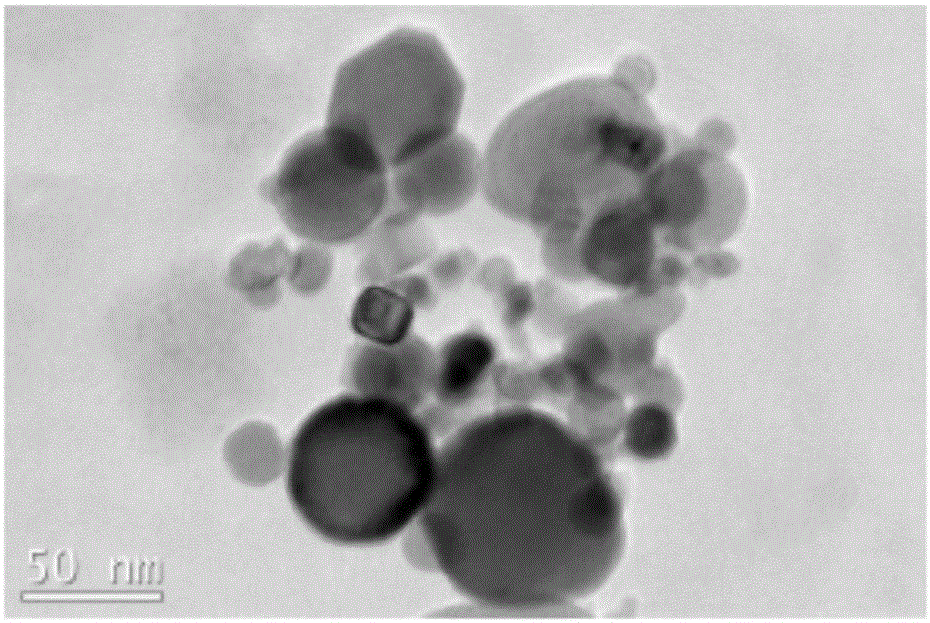

[0048] 2) 0.3g of Cr particles with an average particle diameter of 39nm ( Figure 1-2 ), 0.1g of CrAl alloy particles with an average particle size of 58nm ( Picture 1-1 ) soaked in the electrophoresis solution composed of 100ml acetylacetone and 0.03g iodine simple substance, so that the particles are dispersed and evenly suspended in the dispersant.

...

Embodiment 2

[0054] This embodiment provides a method for preparing a nanocomposite coating by electrophoresis-deposition two-step method when the electrophoresis solution is an ethanol solution, and the specific steps are as follows:

[0055] 1) Take Ni as the base material, process it into a sample with a size of 15×10×2mm, grind it to 800# with water-grinding paper, clean it ultrasonically in acetone, and blow dry it for later use;

[0056] 2) 0.4g average particle diameter is 39nm Cr particle, 0.1g average particle diameter is that 58nmCrAl alloy particle is soaked in by 100ml ethanol and 0.4g MgCl 2 ·6H 2 O in the electrophoretic solution, so that the particles are dispersed and evenly suspended in the dispersant.

[0057] 3) Electrophoretic deposition of a CrAl coating composed of Cr and CrAl particles on the surface of the Ni substrate. Before each electrophoresis, the nano-Cr and CrAl alloy particles are fully suspended in the electrophoresis solution by ultrasonic vibration. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com