Improvement method for centrifugal casting silicon tube

A technology of centrifugal casting and silicone tubes, which is applied in applications, household utensils, tubular objects, etc. It can solve the problems of poor precision of extrusion molding process, easy to produce waste products, long development cycle, etc., achieve low cost, solve the problem of demoulding, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

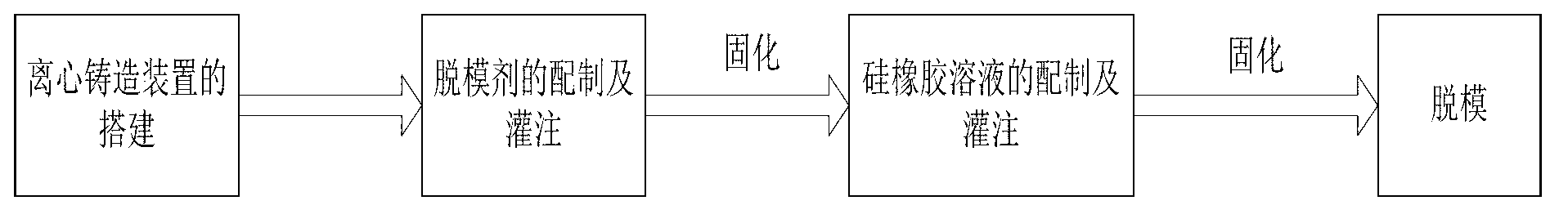

[0027] Such as figure 2 As shown, the main process steps of centrifugal casting of silica gel tube of the present invention are:

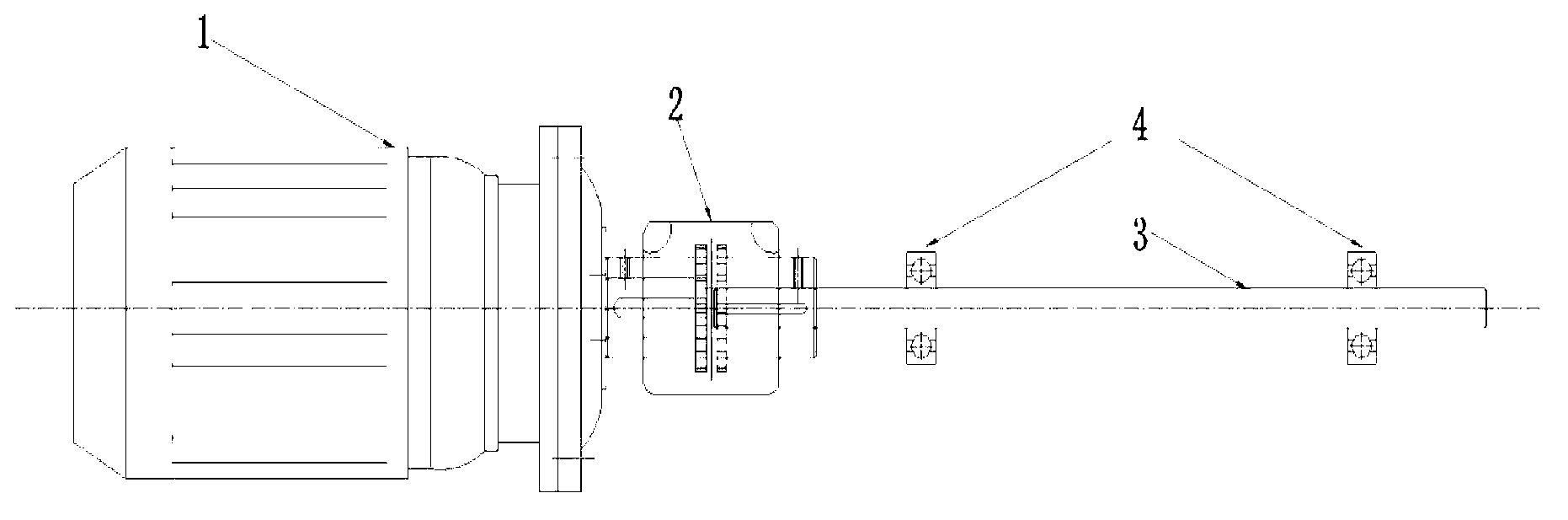

[0028] (1) Construction of the centrifugal casting device. The centrifugal casting device mainly includes motor 1, coupling 2, stainless steel precision tube 3 (for casting) and bearing 4, such as figure 1 As shown, the motor 1 drives the stainless steel precision tube 3 to rotate at high speed through the coupling 2. The outer diameter of the bearing 4 and the stainless steel precision tube 3 is interference fit, and its function is to reduce the frictional resistance between the stainless steel precision tube 3 and the shaft seat during high-speed rotation;

[0029] (2) Preparation of release agent. will be a certain amount (as long as the ratio of V 1 Soak gelatin in pure water for 5 hours (the mass ratio of gelatin to water is 1:7). After the gelatin fully absorbs the water and expands, place the container containing the gelatin in a water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com