Homogenization heat treatment method of as-cast zinc-aluminum alloy material

A homogeneous heat treatment, zinc-aluminum alloy technology, applied in the field of heat treatment of metal materials, can solve problems such as the inability to completely eliminate alloy dendrite segregation and non-equilibrium eutectic phase, the as-cast ZA27 alloy has not been seen, and reduce the dimensional stability of the alloy, etc. , to achieve the effects of improving plasticity and dimensional stability, reducing and non-equilibrium eutectic phase, and improving composition uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

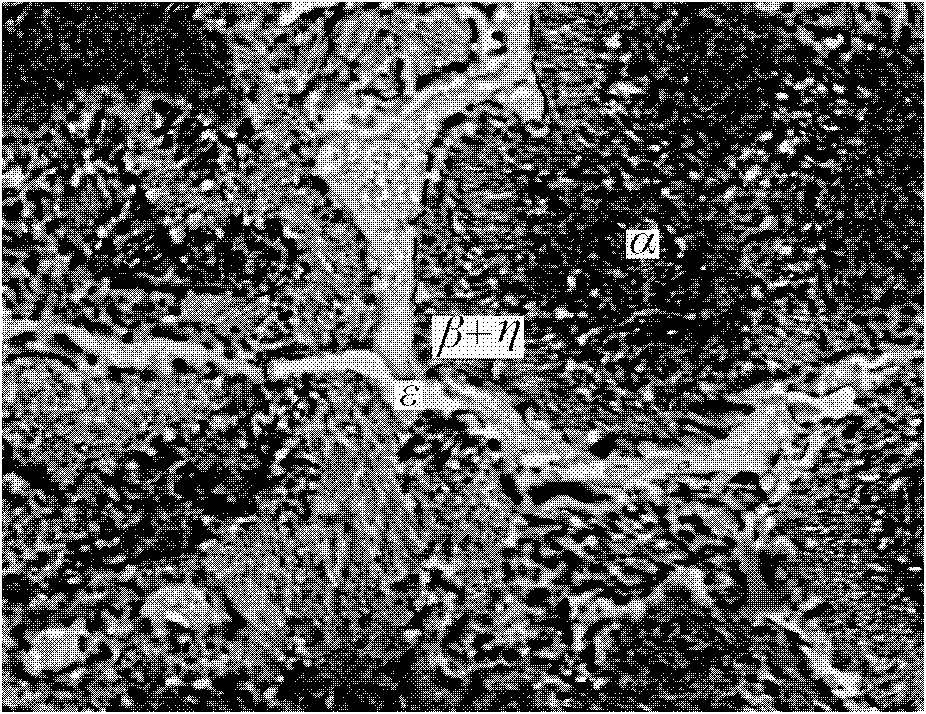

[0025] The ZA27 alloy whose composition is Al 26.0wt%, Cu 2.3wt%, Mg 0.018wt%, Fe figure 2 , compared with the comparative example, in the as-cast ZA27 alloy microstructure after the homogenization treatment in this example, the non-equilibrium eutectic β phase has basically disappeared, the Cu-rich ε phase at the grain boundary has been basically eliminated, and the dendrite segregation has been greatly reduced. See Table 1 for the mechanical property indexes of the as-cast ZA27 alloy after the homogenization treatment in this embodiment.

Embodiment 2

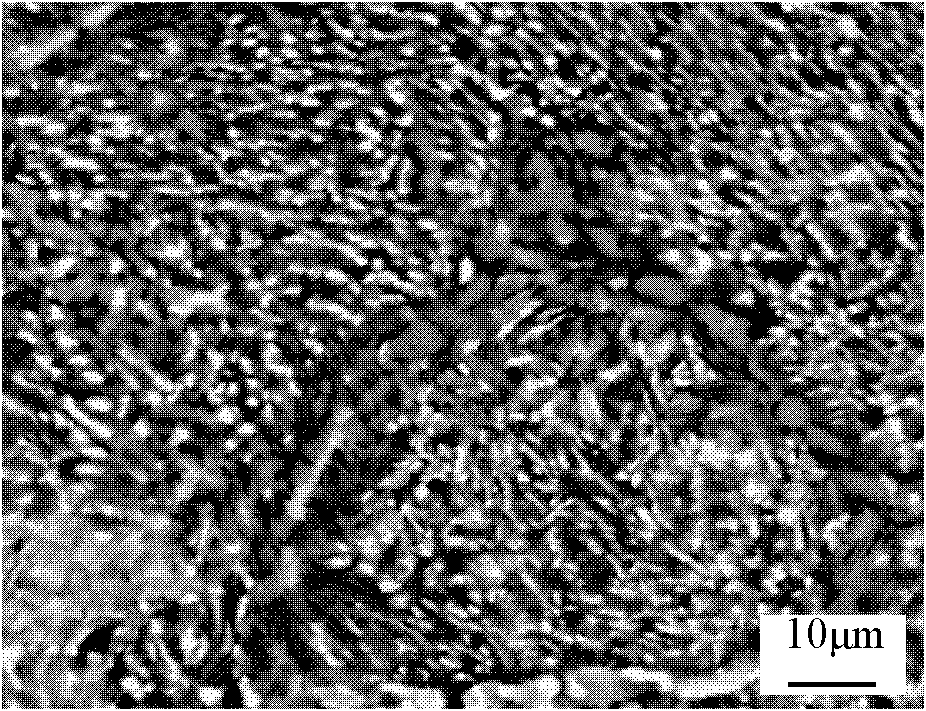

[0027] The ZA27 alloy whose composition is Al 26.0wt%, Cu 2.3wt%, Mg 0.018wt%, Fe image 3 , compared with the comparative example, in the as-cast ZA27 alloy structure after homogenization treatment in this example, the non-equilibrium eutectic β phase basically disappeared, and obvious lamellar morphology and discontinuous precipitates appeared, indicating that the β phase The eutectoid reaction has occurred and transformed into α+η. In addition, the morphology of the primary α phase has changed. Through amplitude modulation decomposition, the primary α phase has transformed into a fine α+η lamellar structure. At the same time, the ε phase at the grain boundary has a certain Reduced, the shape changed from elongated to oval, but still relatively thick. See Table 1 for the mechanical property indexes of the as-cast ZA27 alloy after the homogenization treatment in this embodiment.

Embodiment 3

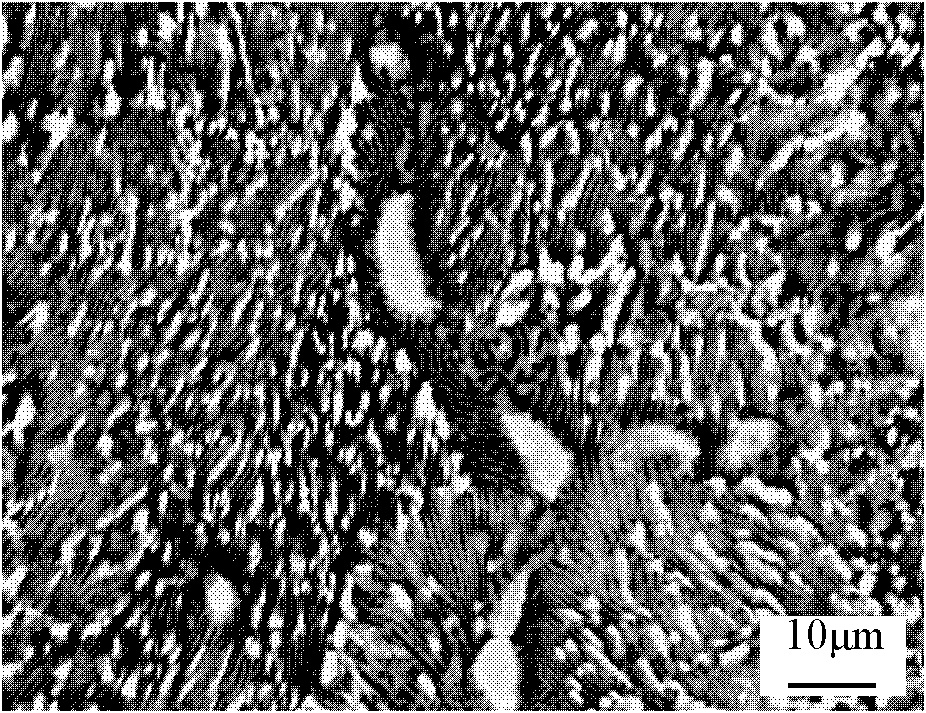

[0029] The ZA27 alloy whose composition is Al 26.0wt%, Cu 2.3wt%, Mg 0.018wt%, Fe Figure 4 , compared with the comparative example, in the as-cast ZA27 alloy structure after the homogenization treatment in this embodiment, the primary α phase begins to transform into a fine lamellar structure, and at the same time, the amount of Cu-rich ε phase at the grain boundary is greatly reduced, And the distribution is more diffuse and fine. See Table 1 for the mechanical property indexes of the as-cast ZA27 alloy after the homogenization treatment in this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com