Junction structure

一种接合结构体、接合层的技术,应用在焊接介质、焊接设备、电固体器件等方向,能够解决欠缺延展性、导热率等问题,达到防止裂缝的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

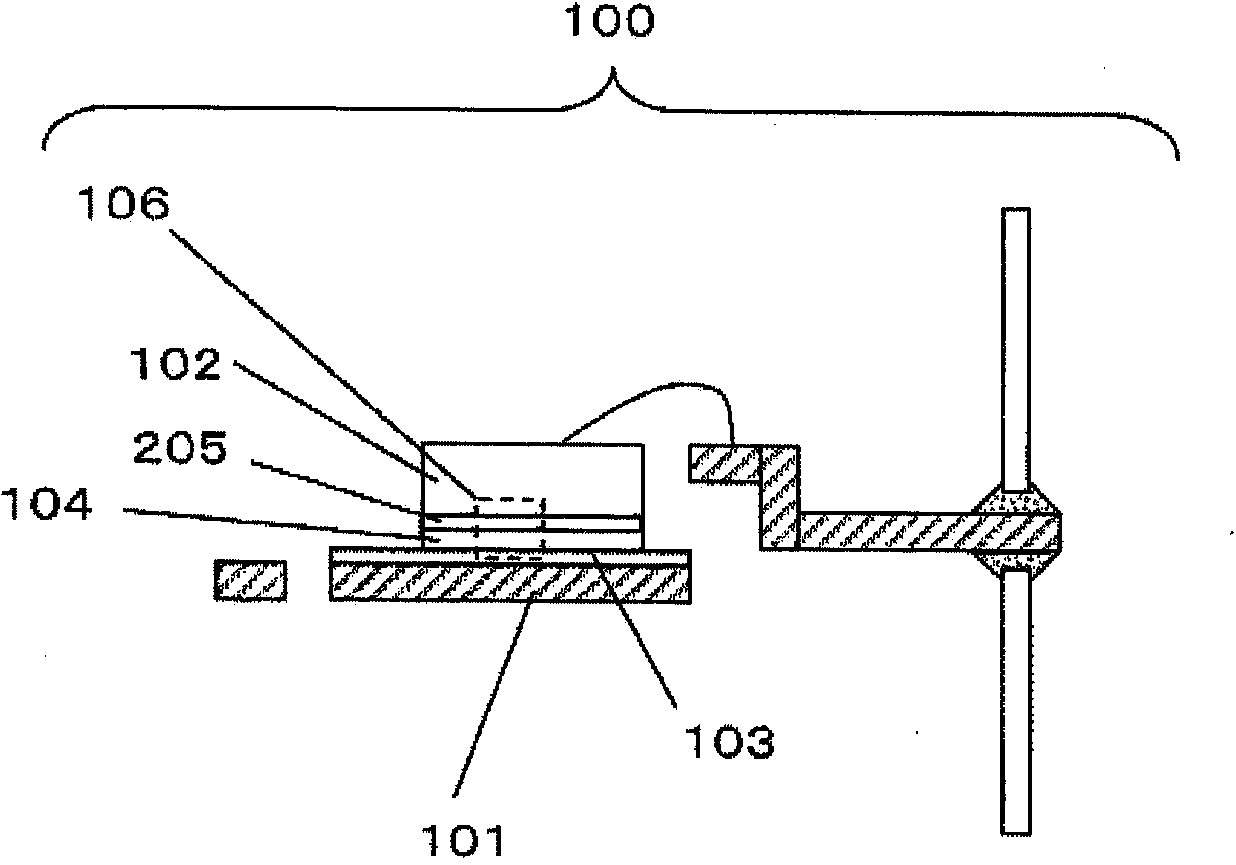

[0073] figure 1 It is a sectional view of the power semiconductor module 100 bonded by the bonding layer 104 according to the first embodiment. This power semiconductor module 100 includes: a substrate 101 ; and a semiconductor element 102 bonded to an electrode 103 on the substrate 101 via a bonding layer 104 . In addition, the junction structure 106 is constituted by the electrode 205 of the semiconductor element 102 , the junction layer 104 , and the electrode 103 .

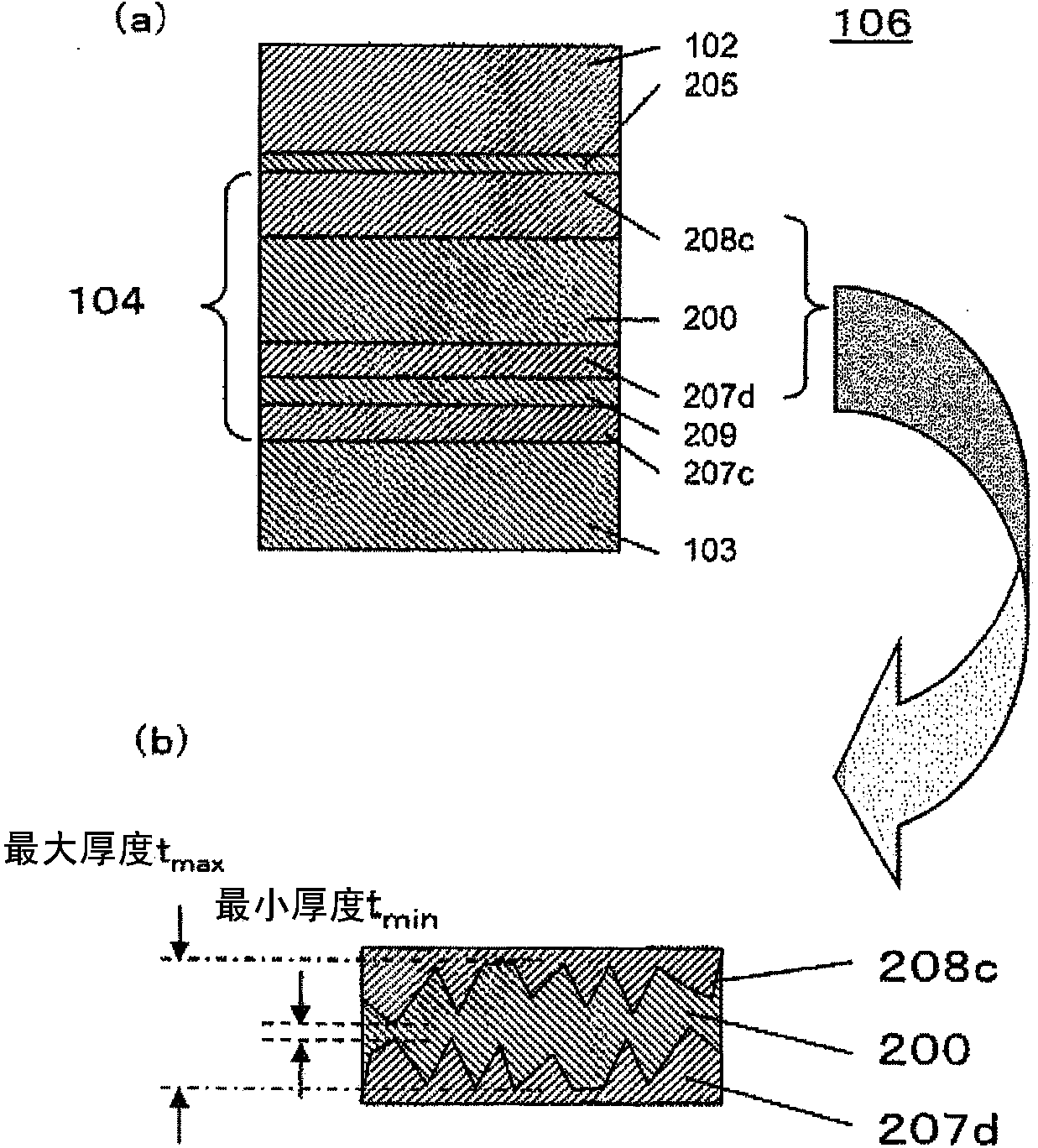

[0074] Next, use figure 2 (a) and (b) describe the formed joint structure 106 in detail. figure 2 (a) is a cross-sectional view showing a detailed cross-sectional structure of the bonded structure 106 . This junction structure 106 includes: an electrode 103 ; an electrode 205 of the semiconductor element 102 ; and a junction layer 104 that joins the electrode 103 and the electrode 205 . The bonding layer 104 is sequentially arranged from the electrode 103 side toward the electrode 205 side of the semico...

Embodiment approach 2

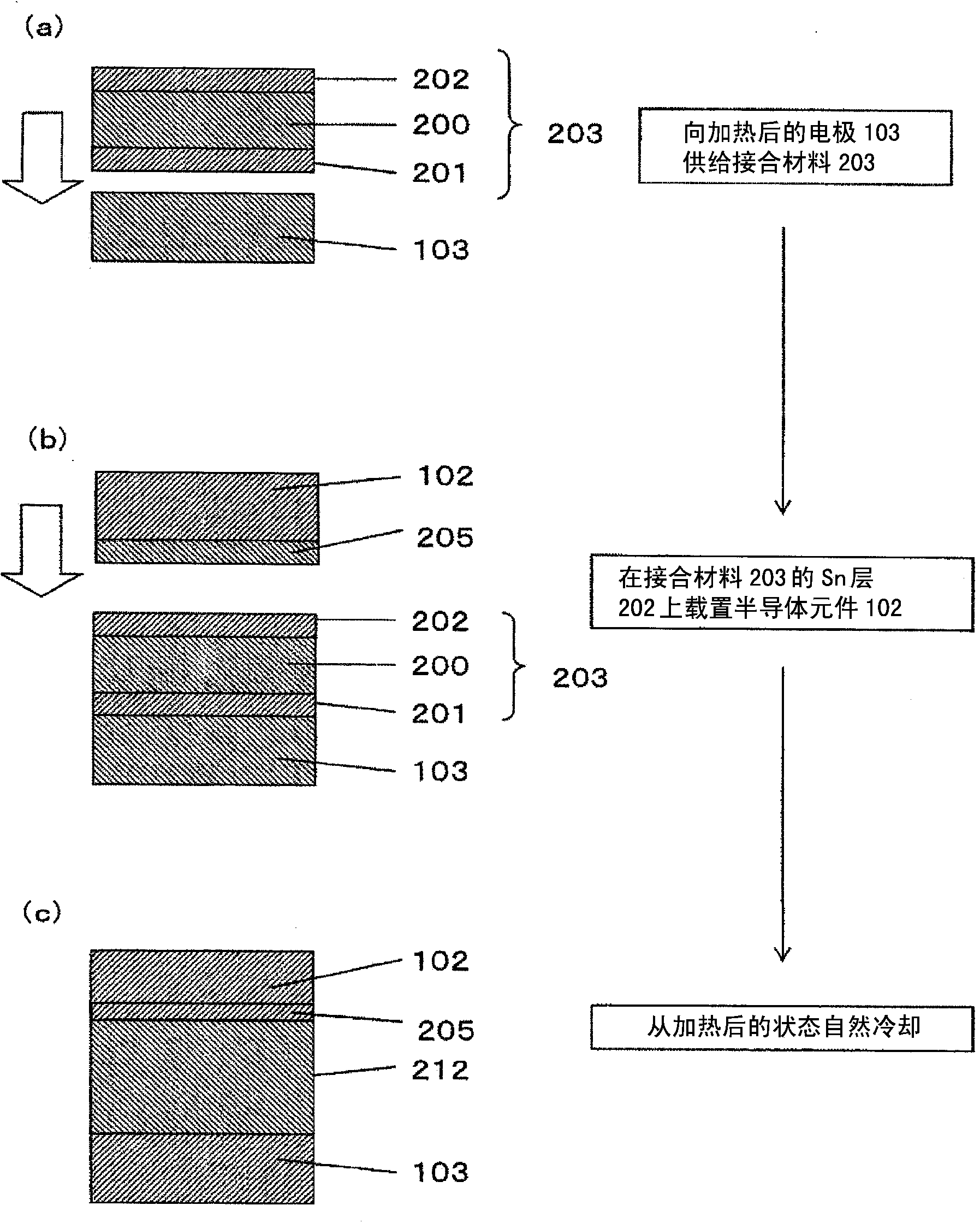

[0110] Figure 5 (a) is a cross-sectional view showing a detailed cross-sectional structure of the bonded structure 106 according to the second embodiment. Figure 5 (b) is Figure 5 (a) An enlarged cross-sectional view of the Cu layer 200. Figure 6 (a) to (c) are flowcharts of manufacturing steps of the bonded structure according to the second embodiment.

[0111] Such as Figure 5 As shown in (a), the junction structure 106 according to the second embodiment includes: the electrode 103 ; the electrode 205 of the semiconductor element 102 ; and the junction layer 104 between them. Such as Figure 6 As shown in the sectional view of (a), compared with the bonding material according to Embodiment 1, the bonding material 213 used in Embodiment 2 differs in that the electrode 103 side and the electrode 205 of the semiconductor element 102 are different. Meanwhile, the arrangement of the Sn—Bi layer 204 and the Sn layer 206 relative to the Cu layer 200 is an upside-down arra...

Embodiment approach 3

[0117] Figure 7 (a) is a cross-sectional view showing a detailed cross-sectional structure of the bonded structure 106 according to the third embodiment. This junction structure 106 includes: an electrode 103 ; an electrode 205 of the semiconductor element 102 ; and a junction layer 104 that joins the electrode 103 and the electrode 205 . The bonding layer 104 is sequentially arranged from the electrode 103 side toward the electrode 205 side of the semiconductor element 102: a first intermetallic compound layer 227 containing a CuSn-based intermetallic compound; a Bi layer 229; a second layer 227 containing a CuSn-based intermetallic compound. Cu layer 200; third intermetallic compound layer 228c containing a CuSn-based intermetallic compound; Bi layer 230; and fourth intermetallic compound layer 228d containing a CuSn-based intermetallic compound. and then, Figure 7 (b) is Figure 7 (a) Enlarged cross-sectional view of the three layers. as it should Figure 7 As shown ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com