High-temperature-resistant light-cured resin and preparation method thereof

A light-curing resin and high-temperature-resistant technology, which is applied in the direction of additive processing, can solve the problems of light-curing 3D printing technology standing still, unable to be used in large-scale production, slow light-curing reaction rate, etc., and achieve high dimensional stability, Improved bond strength and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

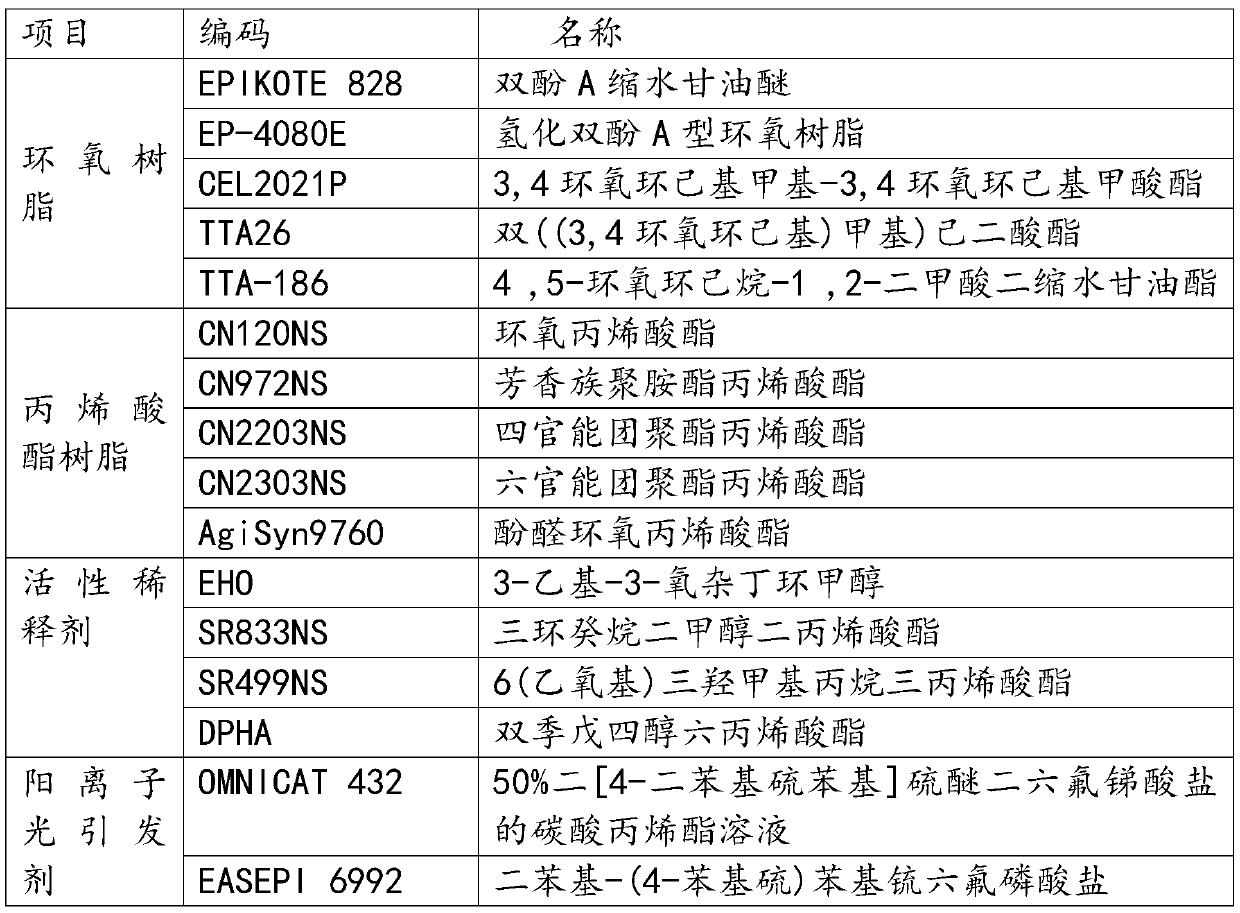

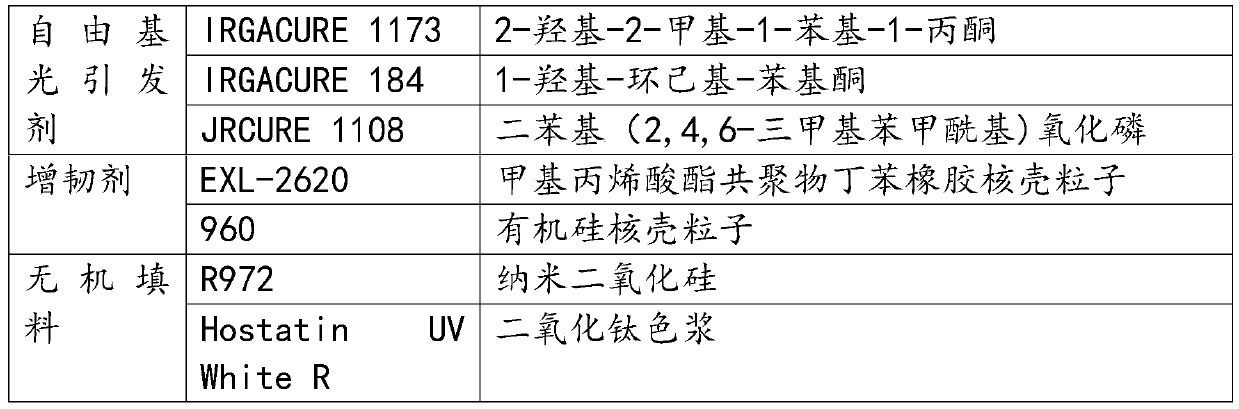

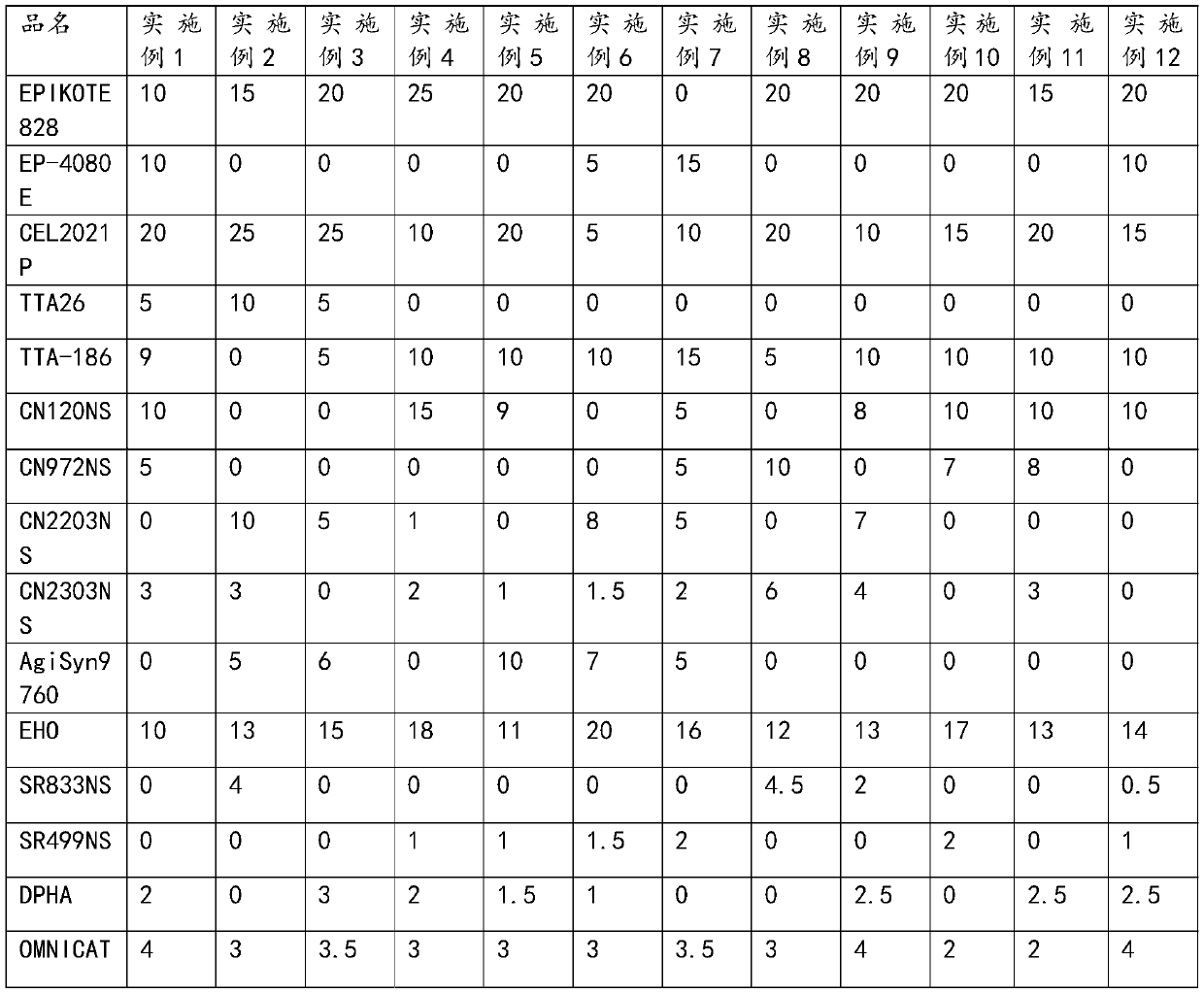

[0038] The component composition of each embodiment 1-12 is shown in Table 2.

[0039] The content (mass percentage %) of various compositions in the embodiment 1-12 of table 2

[0040]

[0041]

[0042] The preparation method of the high temperature resistant photocurable resin mainly includes the following steps:

[0043] (1) Purchasing raw materials, storing and producing them at a temperature of 25°C, humidity below 40%, and dark conditions;

[0044] (2) Check whether the dispersing and emulsifying machine is clean, and whether the pipes and valves are in place;

[0045] (3) Heat each raw material in an oven at 60°C for 30 minutes to reduce the viscosity for later use;

[0046] (4) Add epoxy resin, acrylic resin and cardanol into the dispersing emulsifier in proportion, set the temperature at 60°C, 50 rpm, and stir for 2 hours;

[0047] (5) Add reactive diluent, cationic photoinitiator, free radical photoinitiator and inorganic filler in proportion to the dispersi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com