Edible oil high-temperature swelling-resistant modified polypropylene material applied to household appliances and preparation method thereof

A polypropylene material and edible oil technology, which is applied in the field of polymer materials, can solve problems such as difficult cleaning and swelling of edible oil, and achieve the effects of low oil absorption rate, easy molding, and simple processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Prepare edible oil high temperature swelling resistant polypropylene material according to the raw materials in parts by weight shown in Table 1:

[0027] Table 1 The formula composition of high temperature swelling resistant edible oil polypropylene material

[0028] raw material Parts by weight (parts) Homo-PP 65 Anti-swelling modified masterbatch 18 heavy calcium 12 Compatibilizer 5 Antioxidant 1010 0.1 Antioxidant 168 0.2 sodium benzoate 0.2 Calcium stearate 0.2

Embodiment 2

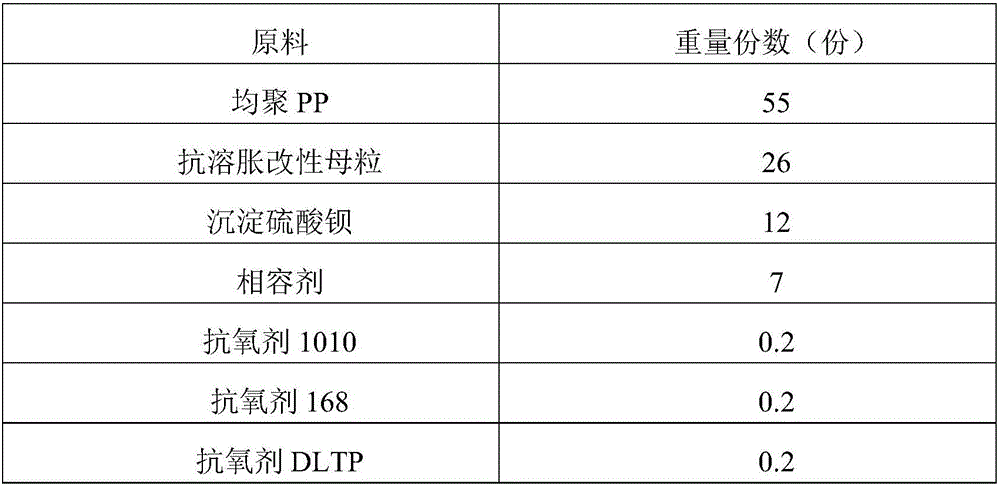

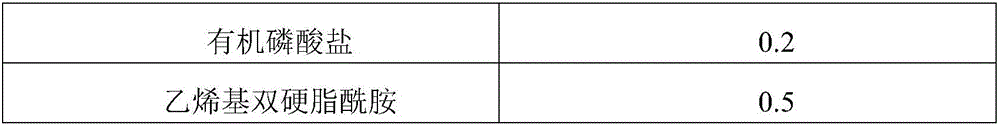

[0030] Prepare edible oil high-temperature swelling-resistant polypropylene material according to the raw materials in parts by weight shown in Table 2:

[0031] Table 2 The formula composition of high temperature swelling resistant edible oil polypropylene material

[0032]

[0033]

Embodiment 3

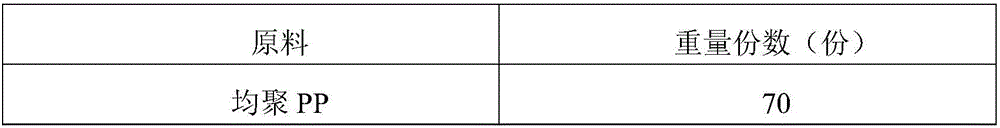

[0035] Prepare edible oil high-temperature swelling-resistant polypropylene material according to the raw materials in parts by weight shown in Table 3:

[0036] Table 3 The composition of the high temperature swelling resistant edible oil polypropylene material

[0037] raw material Parts by weight (parts) Copolymerized PP 65 Anti-swelling modified masterbatch 18 heavy calcium 12 Compatibilizer 5 Antioxidant 1010 0.1 Antioxidant 168 0.2 sodium benzoate 0.2 Calcium stearate 0.2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com