Prepreg, fiber-reinforced composite material, and method for producing fiber-reinforced composite material

A technology of prepregs and constituent elements, applied in the field of prepregs, can solve the problem that the dynamic mechanical strength cannot be fundamentally improved, and achieve the effect of excellent durability and sufficient heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

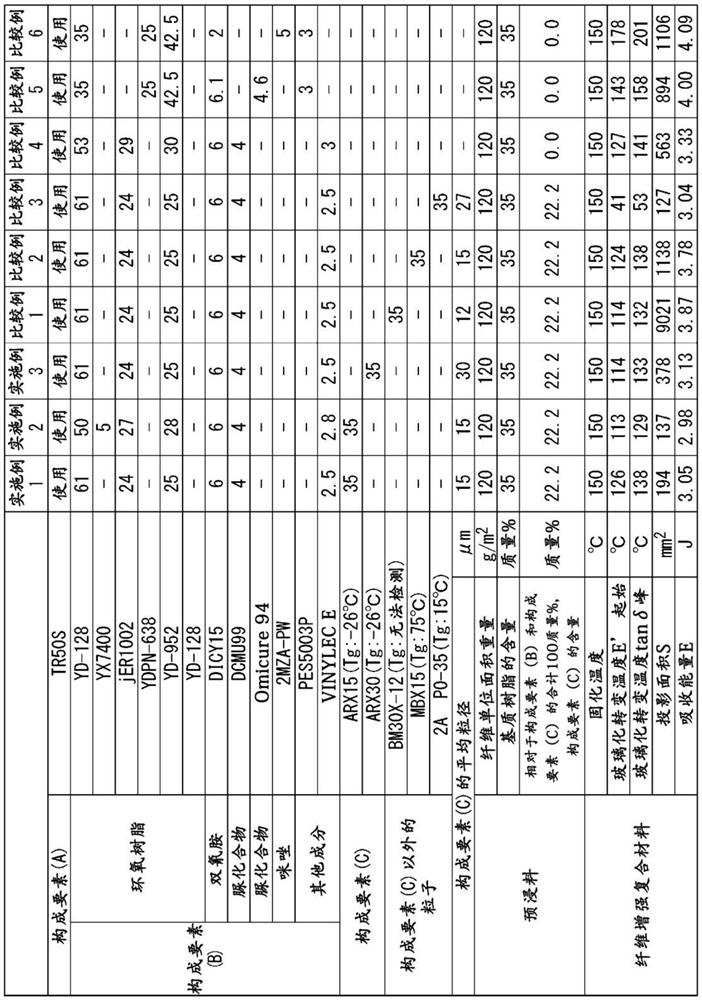

[0176] The present invention will be specifically described below by way of examples, but the present invention is not limited to these examples.

[0177]

[0178] The raw materials used in Examples 1 to 3 and Comparative Examples 1 to 6 are shown below.

[0179] (Component (A))

[0180] TR50S: carbon fiber bundle (Mitsubishi Chemical, PYROFIL (registered trademark) TR50S 15L, single-filament strength: 4900MPa, elastic modulus: 240GPa, fiber diameter of carbon fiber: 6.8 μm, number of carbon fibers: 15,000)

[0181] (Component (B))

[0182] [Epoxy resin]

[0183] ·YD-128: Bisphenol A liquid epoxy resin (Nippon Steel Chemical & Materials)

[0184] ·jER1002: bisphenol A solid epoxy resin (Mitsubishi Chemical)

[0185] YDPN-638: Phenol novolac type semi-solid epoxy resin (Nippon Steel Chemical & Materials)

[0186] ·YD-952: with Epoxy resin with oxazolidone ring skeleton (Nippon Steel Chemicals & Materials)

[0187] YX7400: Liquid 2-functional epoxy resin (Mitsubishi Ch...

Embodiment 2

[0218] (modulation of component (B))

[0219]As the raw material composition 2a of the component (B), 38 parts by mass of YD-128, 5 parts by mass of YX7400, 27 parts by mass of jER1002, 28 parts by mass of YD-952, and 2.8 parts by mass of VINYLEC E were put into a glass flask. Using an oil bath having a temperature of 140 to 160° C., the mixture is heated and mixed until the raw material composition 2a becomes uniform.

[0220] The raw material composition 2b of the component (B) was obtained by the same procedure and compounding as in 1b of Example 1. 100.8 parts by mass of the raw material composition 2a and 22 parts by mass of the above-mentioned raw material composition 2b in a glass flask that was allowed to cool to a temperature of about 60°C were placed in the container of the planetary mixer, the jacket temperature was set to 60 to 65°C, and the The mixture was mixed until each became uniform, and the component (B) used in Example 2 was obtained.

[0221] (Preparatio...

Embodiment 3

[0228] (modulation of component (B))

[0229] The component (B) used in Example 3 was obtained by the same procedure as in Example 1.

[0230] (Preparation of mixture (BC))

[0231] To 122.5 parts by mass of the prepared component (B), 35 parts by mass of ARX30 was added. Therefore, the content of ARX30 is 22.2 mass % with respect to the total of 100 mass % of the constituent element (B) and the constituent element (C). The jacket temperature of the planetary mixer was set to 60 to 70° C., and the mixture was mixed until uniform, thereby preparing a mixture (BC) of the component (B) and the component (C).

[0232] (production of prepreg)

[0233] The prepreg used in Example 3 was produced by the same method (α) as in Example 1 except that the mixture (BC) was changed. The composition and production method of the prepreg are shown in Table 1.

[0234] (Manufacture of fiber-reinforced composite materials)

[0235] By the same method as in Example 1, a molded plate for eval...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com