Method for raising metal and alloy strength

A technology of alloy strength and metal, which is applied in the field of dynamic plastic deformation technology to improve the strength of metal and alloy, can solve the problems of changing the physical and chemical properties of materials, achieve the effect of simple preparation method, optimization of process parameters, and improvement of material strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Using high-speed deformation technology to prepare high-strength, high-conductivity bulk high-density nano-twinned pure copper materials;

[0023] Equipment: Pneumatic high-speed deformation equipment;

[0024] Deformation strain rate: 1×10 2 the s -1 ;

[0025] Deformation strain: deformation 2.3 (5 deformations, each deformation of the first four deformations is 0.5, and the fifth deformation is 0.3);

[0026] Deformation temperature: -196°C;

[0027] Pure copper material: purity 99.95%, annealed at 700°C for 3 hours, grain size 150-200 microns.

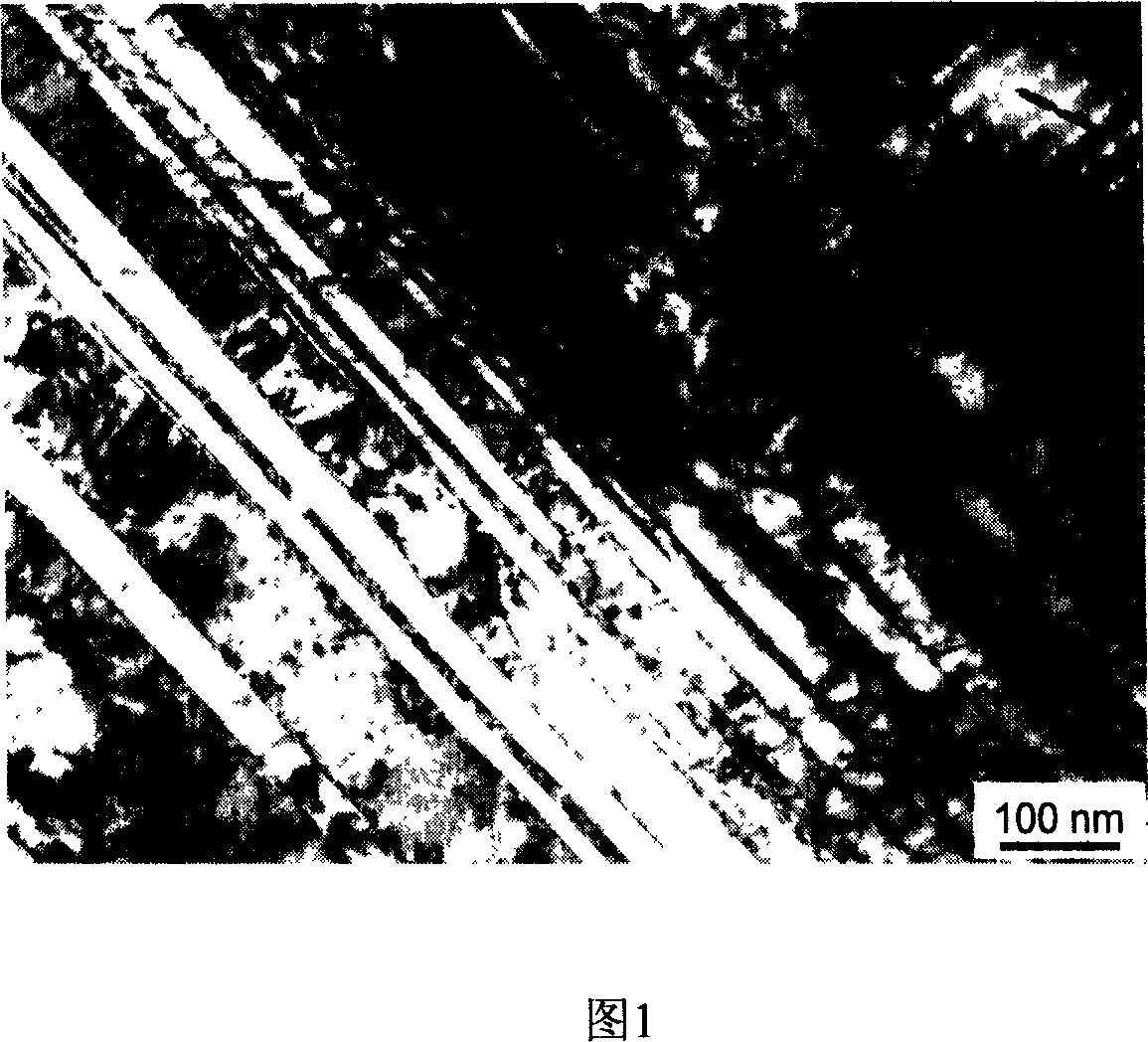

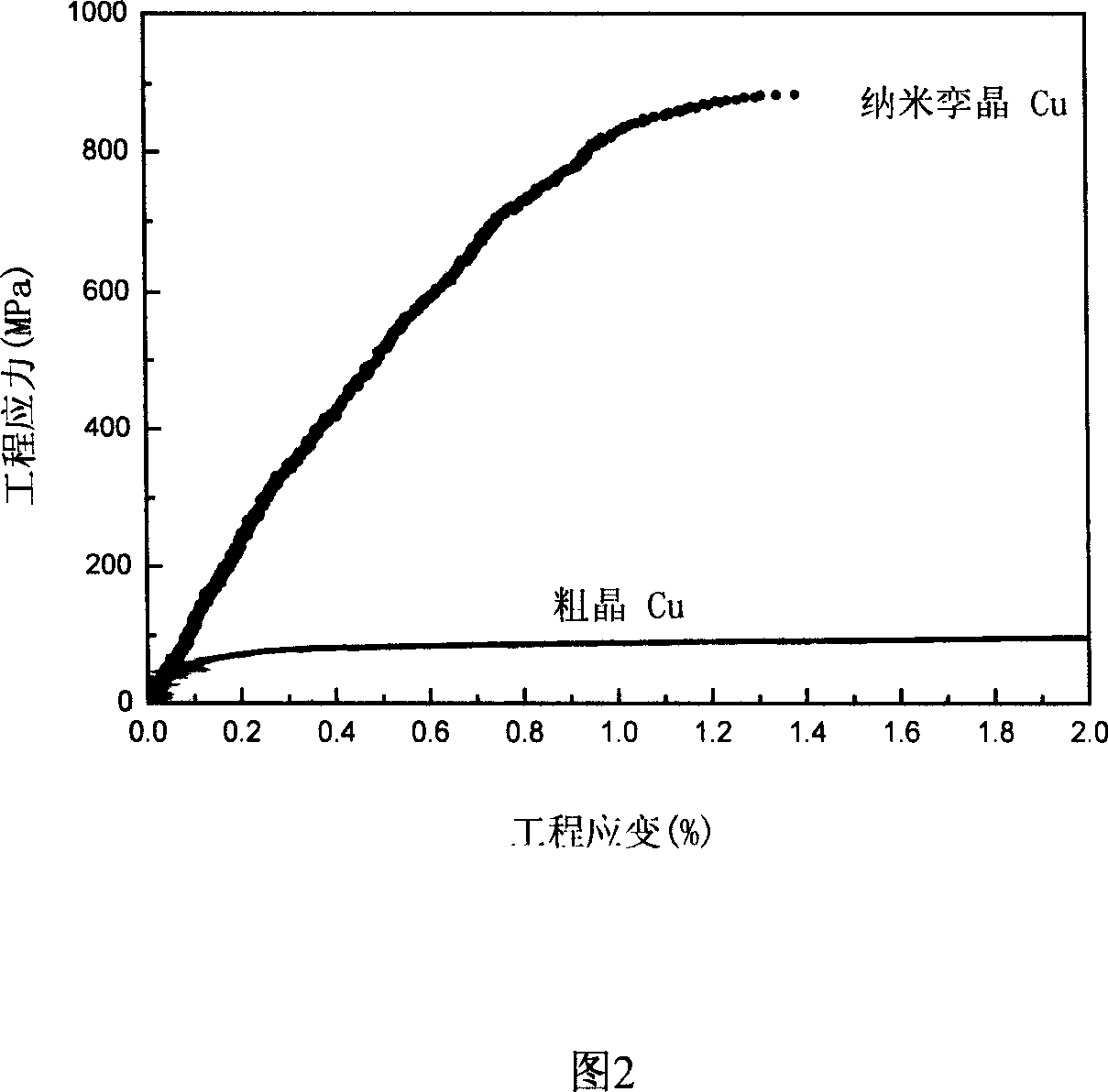

[0028] A bulk high-density nano-sized twinned pure copper material is prepared, as shown in Figure 1. The main feature of its microstructure is bundle-shaped high-density nano-mechanical twins, with an average twin layer thickness of 30-50 nanometers and a length of 200-800 nanometers. The twin density is about 3×10 7 m 2 / m 3 . There are high-density dislocations in both the matrix and the twins, and the dislocatio...

Embodiment 2

[0030] Using high-speed deformation technology to prepare high-strength pure iron materials;

[0031] Equipment: Pneumatic high-speed deformation equipment;

[0032] Deformation strain rate: 1×10 3 the s -1 ;

[0033] Deformation strain: deformation 2 (4 deformations, each deformation 0.5);

[0034] Deformation temperature: -196°C;

[0035] Pure iron metal material: purity 99.95%, annealed at 950°C for 2 hours, grain size 100-150 microns.

[0036] The bulk pure iron material prepared by the deformation technology of the present invention uses a strain rate of 6×10 -3 the s -1 A tensile test at room temperature was carried out, and the yield strength was 680MPa (0.2% strain), and the breaking strength was 730MPa.

Embodiment 3

[0038] Using the deformation technology of the present invention to prepare high-strength nano-twinned copper-aluminum alloys;

[0039] Equipment: Pneumatic high-speed deformation equipment;

[0040] Deformation strain rate: 1×10 3 the s -1 ;

[0041] Deformation strain: deformation 2 (5 deformations, each deformation 0.4);

[0042] Deformation temperature: -196°C;

[0043] Copper-aluminum alloy: the aluminum content is 4.5wt%, annealed at 700°C for 3 hours, and the grain size is 150-200 microns.

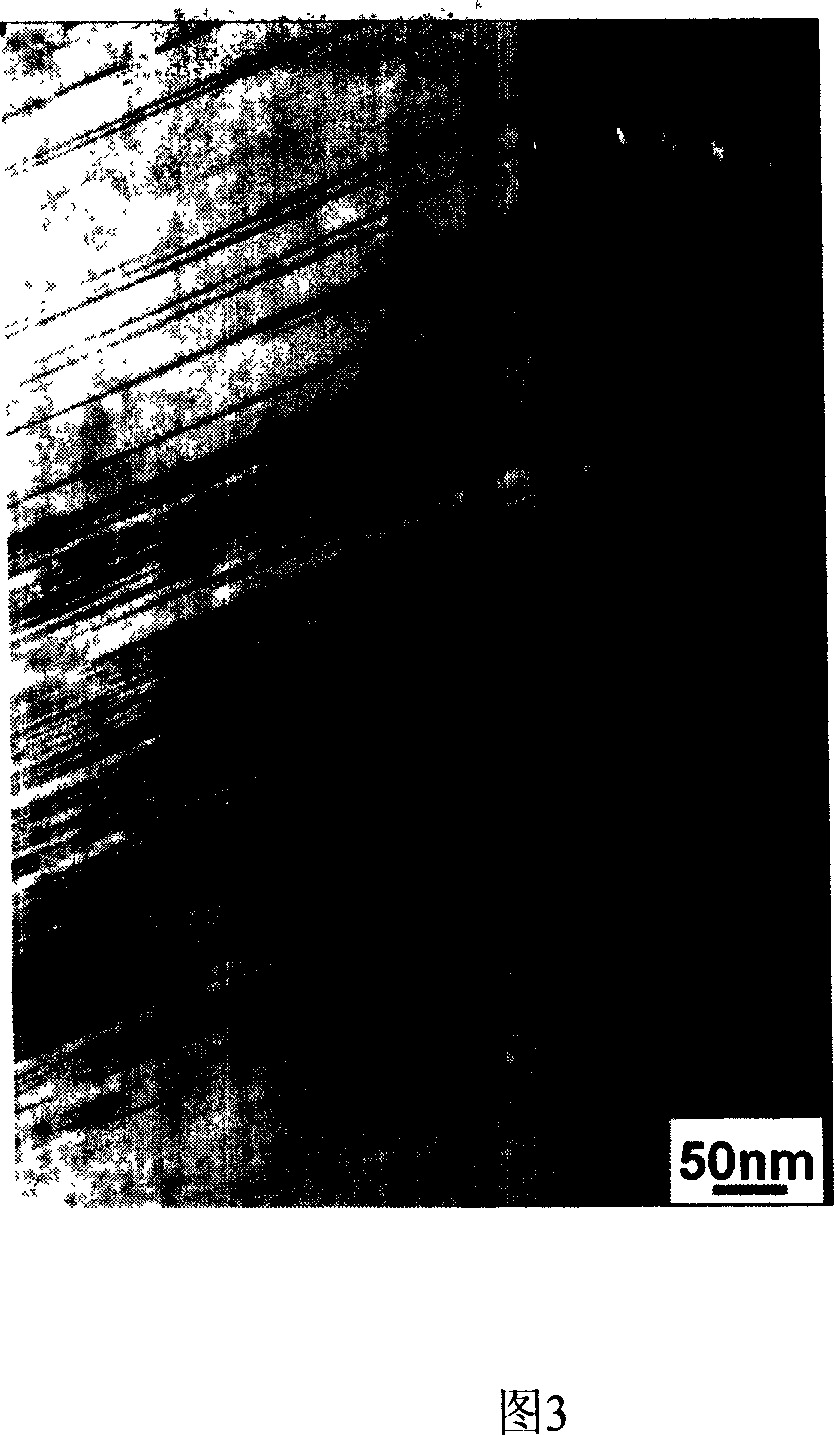

[0044] The microstructure of the high-strength copper-aluminum alloy prepared by the deformation technology of the present invention is shown in Figure 3, and its microstructure is mainly characterized by beam-shaped high-density nanomechanical twins, with an average twin layer thickness of 15-50 nanometers and a length of 100-600 nanometers , the twin density is about 3.5×10 7 m 2 / m 3 . Using a strain rate of 6 x 10 -3 the s -1 Tensile test at room temperature was carri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| deformation temperature | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| deformation temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com