Method for increasing the circular degree of the metal thin-walled cylinder using pulse magnetic pressure

A technology for thin metal and cylindrical parts, applied in the field of manufacturing and processing, can solve the problems of small batches and diversified development trends of unsuitable cylindrical parts, easy wear on the surface of cylindrical parts, complex mechanisms and molds, etc., to reduce processing costs, The mechanism and mold are simple and the cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

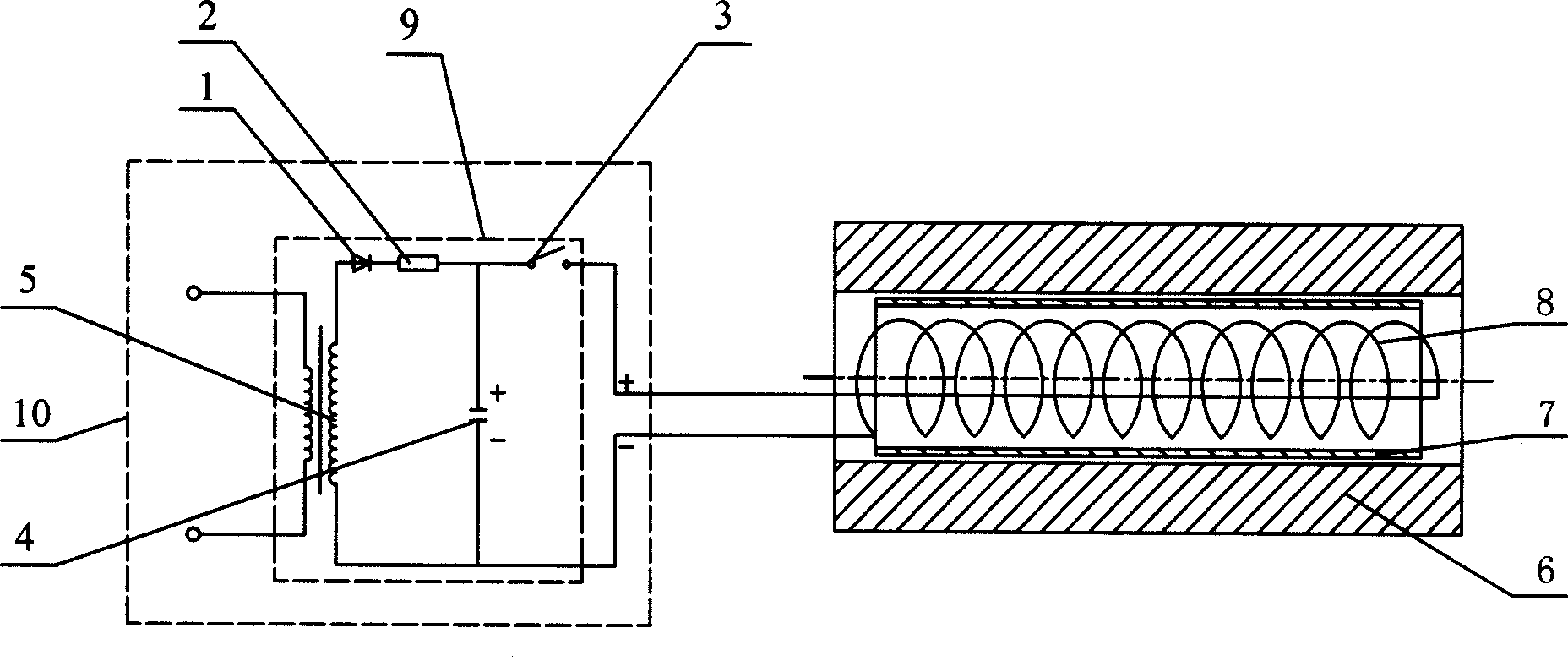

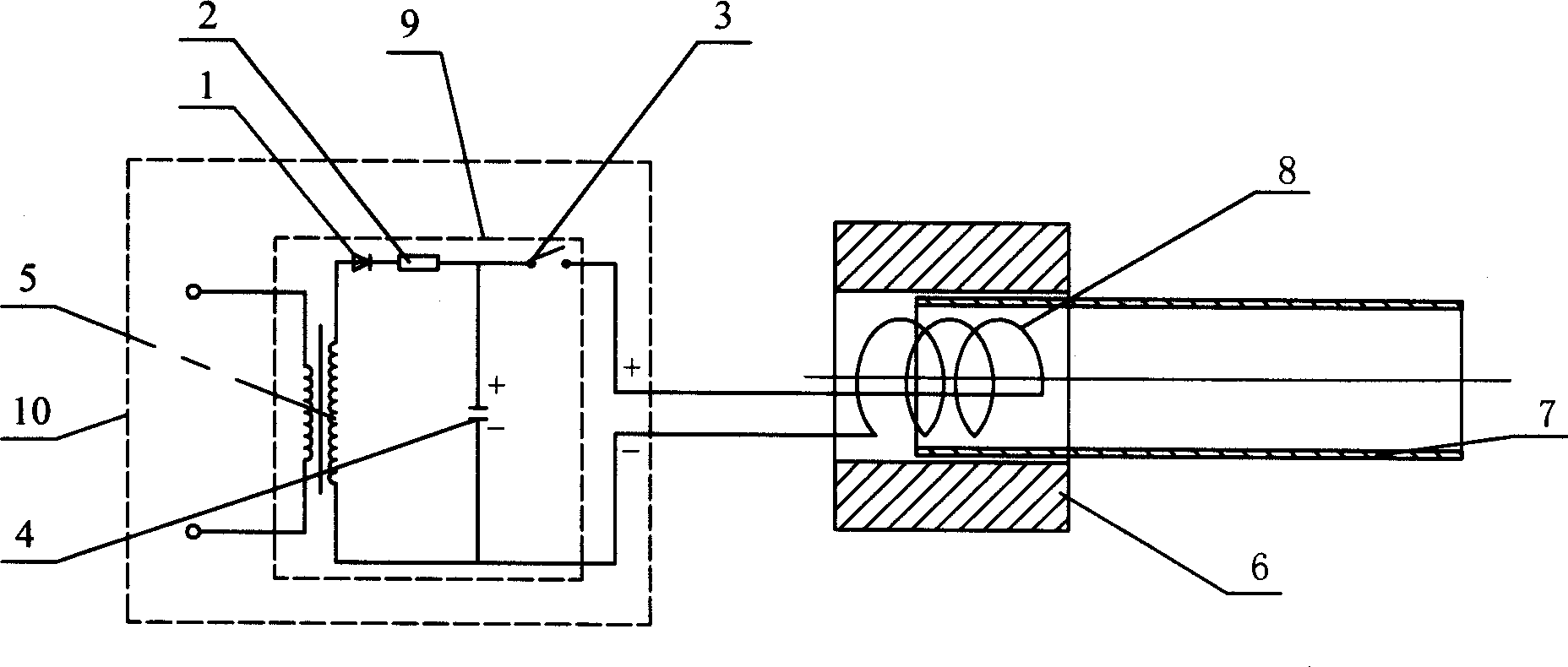

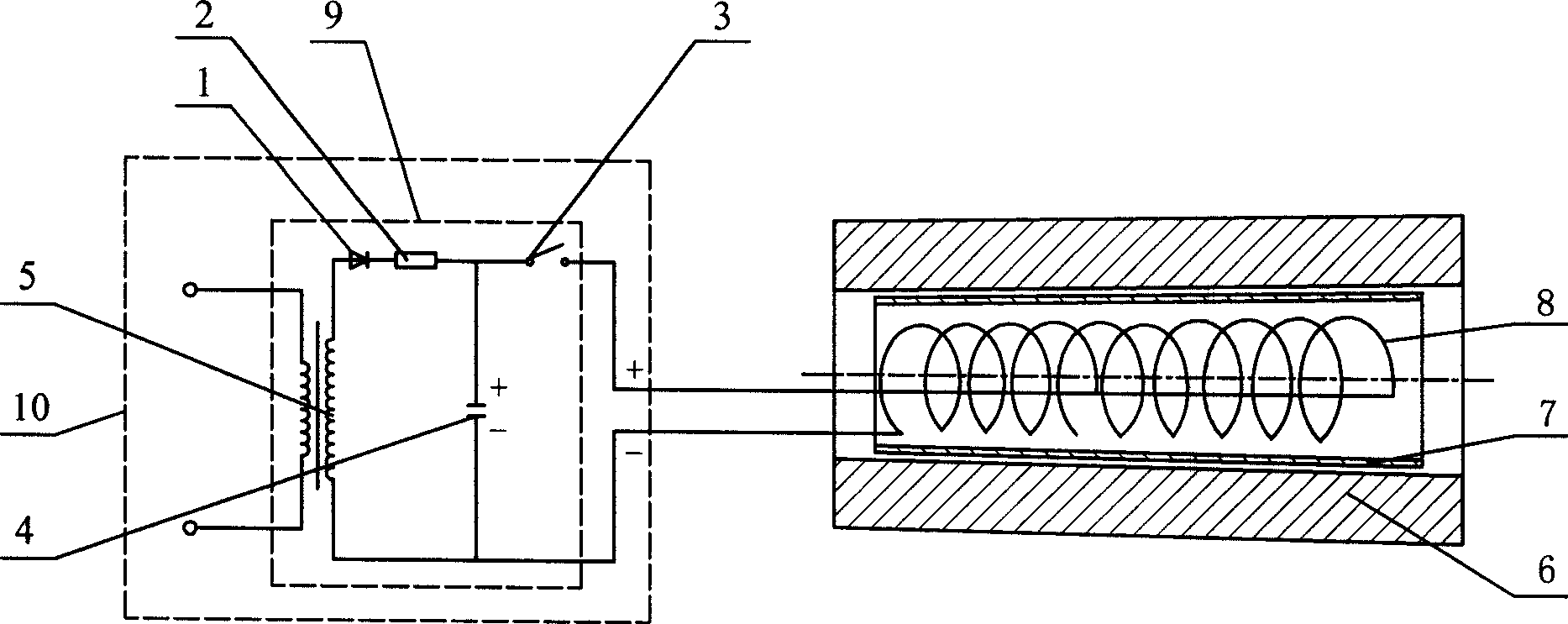

[0010] Specific implementation mode one: combine Figure 1-Figure 4 Describe this embodiment, the method step of this embodiment is:

[0011] Step 1: Place the metal thin-walled cylindrical part 7 or the port of the metal thin-walled cylindrical part 7 in the high-precision shaping mold 6, and place the magnetic pulse processing coil 8 in the metal thin-walled cylindrical part 7;

[0012] Step 2: use electromagnetic forming technology to correct the shape: connect the two terminals of the magnetic pulse processing coil 8 to the positive and negative poles of the magnetic pulse power supply 10, start the magnetic pulse power supply 10 at room temperature, and use the external power supply through a step-up transformer 5. The rectifier circuit 1 and the current-limiting resistor 2 charge the pulse capacitor bank 4. At this time, the air gap switch 3 is not turned on; when the pulse capacitor bank 4 stores enough electric energy and reaches the working voltage, close the air gap ...

specific Embodiment approach 2

[0013] Specific implementation mode two: combination figure 1 and figure 2 Describe this embodiment, the difference between this embodiment and specific embodiment 1 is: the magnetic pulse processing coil 8 described in step 1 of this embodiment is a cylindrical solenoid coil made of T3 copper wire with a rectangular cross section. , The coil turns are insulated with epoxy resin and glass cloth, and the coil skeleton is a glass cloth epoxy resin laminated rod. With such setting, the generated pulse magnetic pressure is greater and the machining accuracy is higher.

specific Embodiment approach 3

[0014] Specific implementation mode three: combination figure 1 and figure 2 Describe this embodiment, the difference between this embodiment and the specific embodiment one is: the metal thin-walled tubular part 7, the high-precision shape correction mold 6 and the magnetic pulse processing coil 8 described in the step one of the present embodiment are the same axis. With such an arrangement, the metal thin-walled cylindrical part 7 is more evenly stressed and has higher machining accuracy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com