Zn-Al Alloy Having Excellent High-Speed Deformation Properties and Process For Producing the Same

a technology of al alloy and high-speed deformation, which is applied in the field of zn-al alloy, can solve the problems of reducing energy absorption capacity, deteriorating vibration-proof rubber, and unsuitable for use, and achieves excellent static deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Zn—Al Alloy

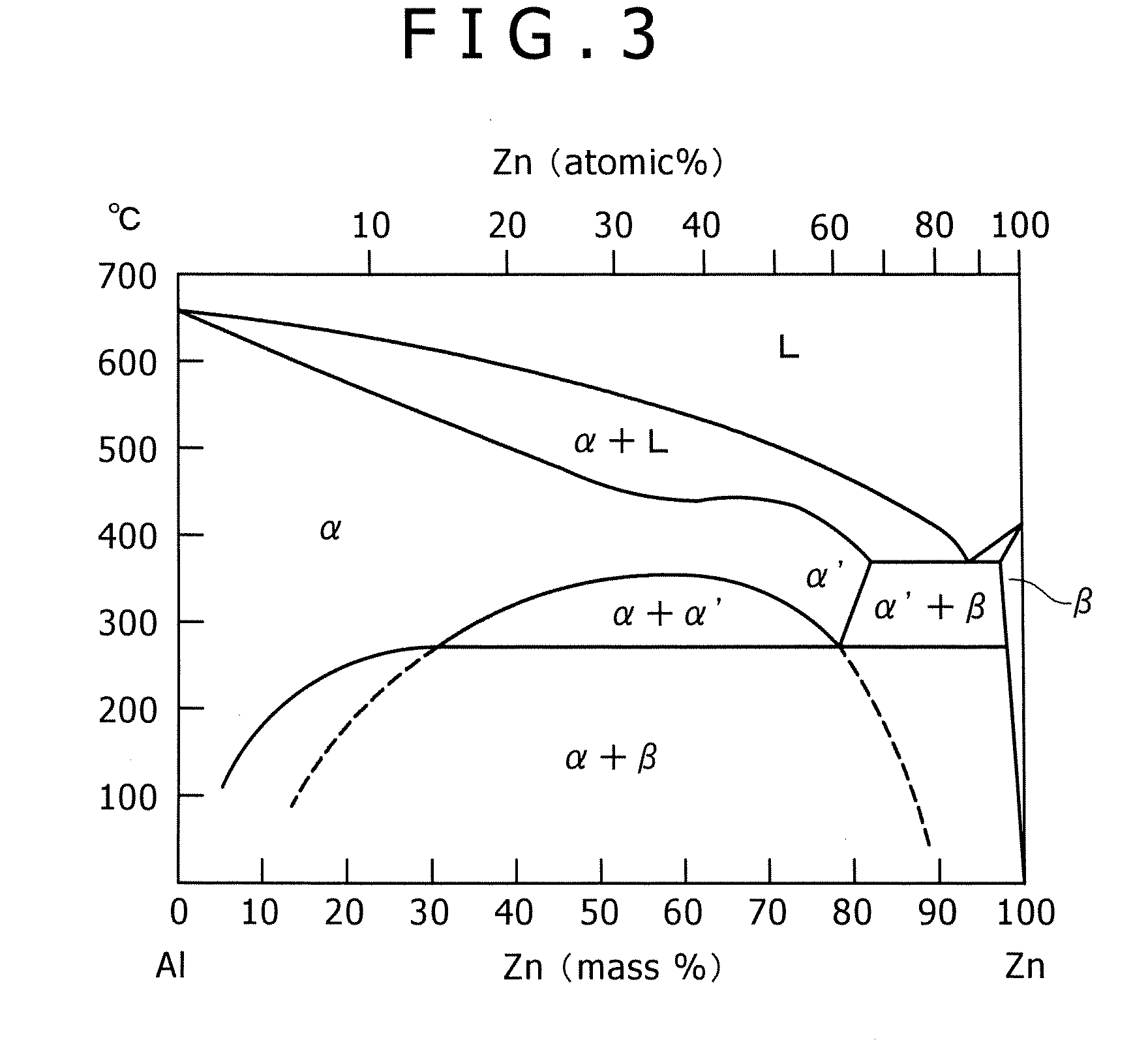

[0069]Various ingots (each weighing 180 kg) of Zn-22% Al alloy (with less than 0.5% impurities in total) liable to macrosegregation were prepared by casting into an air-cooled or water-cooled iron or copper mold measuring 200×350 mm in cross section, except that sample No. 12 (shown in Table 1) was prepared by continuous casting into a water-cooled copper mold measuring 200×200 mm in cross section.

[0070]The cooling behavior of each ingot was observed with a thermocouple placed in each ingot at the center of the cross section 300 mm above the bottom. FIG. 4 shows cooling curves representing the temperature change with time in the ingot. From the cooling curves were calculated the average cooling rate 1 in the solid-liquid dual phase region (425-375° C.) and the average cooling rate 2 at the temperature (275-250° C.) at which the β phase begins to precipitate. Incidentally, the melt was isolated from the ambient atmosphere during casting by keeping the mold i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com