Corrugated board production method and apparatus thereof

A technology of corrugated cardboard and production method, which is applied in the field of corrugated cardboard production, can solve the problems of coal and electricity consumption, degumming, and low flatness of cardboard, and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

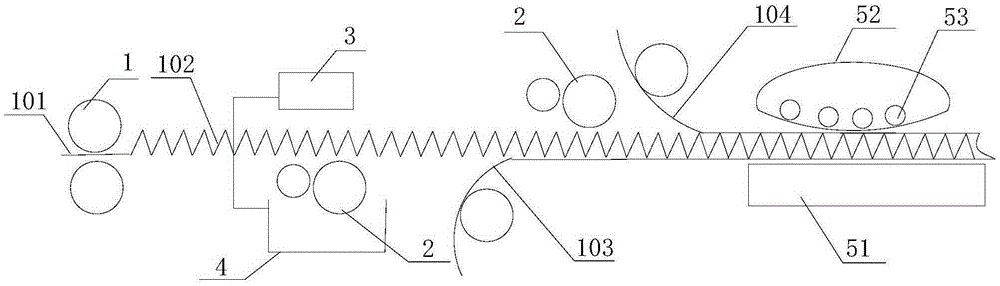

[0022] like figure 1 As shown, the device of this embodiment includes a corrugating roller 1, a rubberizing roller 2, a gluing mechanism 3, a glue storage mechanism 4, and a conveying mechanism 5; Glue roller 2 is coated with hot melt adhesive and bonded with cardboard 103 to form single-sided corrugated cardboard. Glue application mechanism 3 is connected to glue roller 2. Before the glue roller 2, the single-face corrugated cardboard is bonded with the upper paper 104 to obtain a single corrugation. The conveying mechanism 5 includes a conveying press belt and a conveying channel 51, and the produced single corrugated or multi-layer corrugated cardboard is clamped between the conveying pressing belt and the conveying channel 51, and the conveying pressing belt includes a conveying track 52 and a plurality of pressing rollers 53 , the conveying crawler belt 52 is wrapped on the plurality of pressing rollers 53 , the pressing roller 53 rotates to drive the conveying crawler b...

Embodiment 2

[0032] After the single-sided corrugated cardboard is prepared in this embodiment, a heated adhesive is coated on the two single-sided corrugated cardboards, and then the two single-sided corrugated cardboards are compounded to make a double-layer corrugated cardboard. Transported under pressure.

[0033] The other implementation modes of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com