A composite construction method for the main girder of a cable-stayed bridge and its counterweight structure system

A construction method and technology of cable-stayed bridges, which are applied in the direction of cable-stayed bridges, bridges, bridge construction, etc., can solve the problems that the construction technology cannot be realized, and the clearance cannot meet the requirements of hanging basket hanging pouring, etc., so as to protect property safety and life safety , the application of counterweight is flexible, and the effect of reducing construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

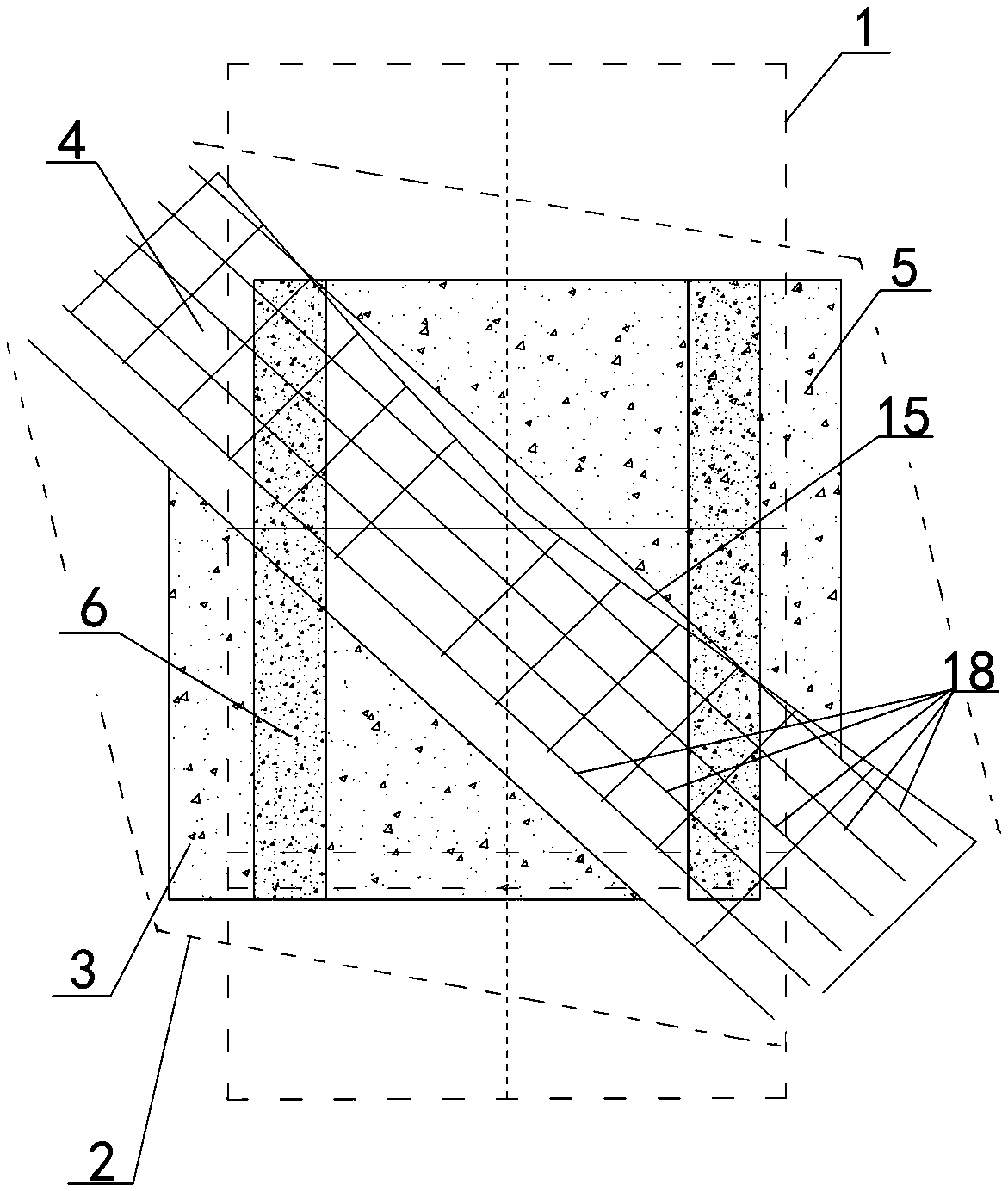

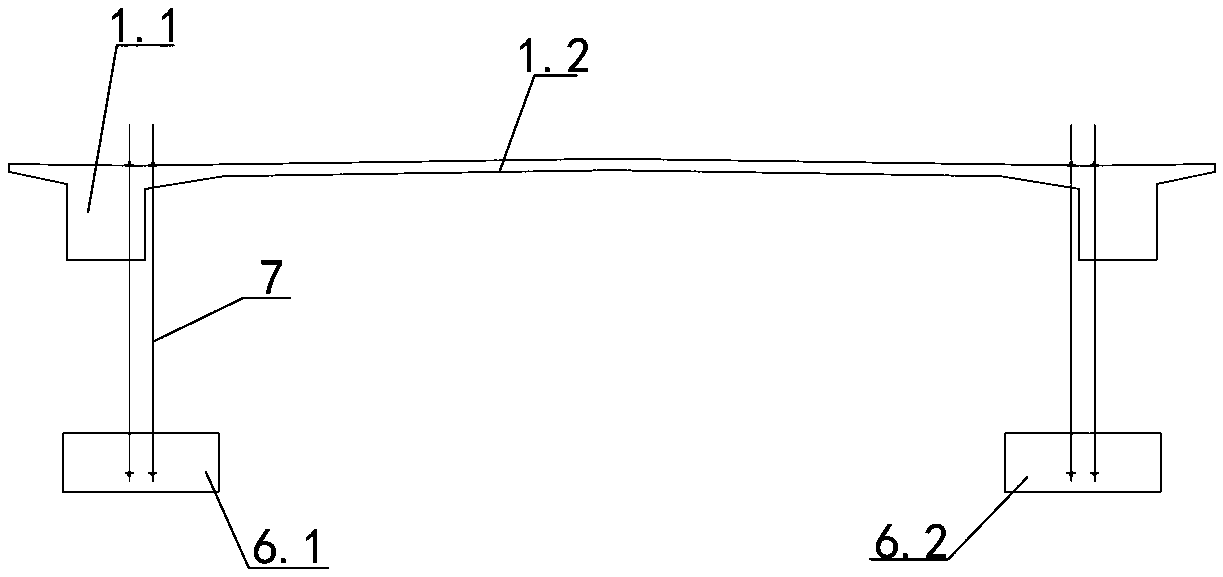

[0053] Examples see Figure 1-9 As shown, a cable-stayed bridge main girder combination construction method, the nth block 12 to the n+mth block 12 of the side span 1 of the cable-stayed bridge main girder intersects obliquely with the dam area 2, where n> 2, m≥1, in this embodiment n=8, m=4 construction steps are as follows:

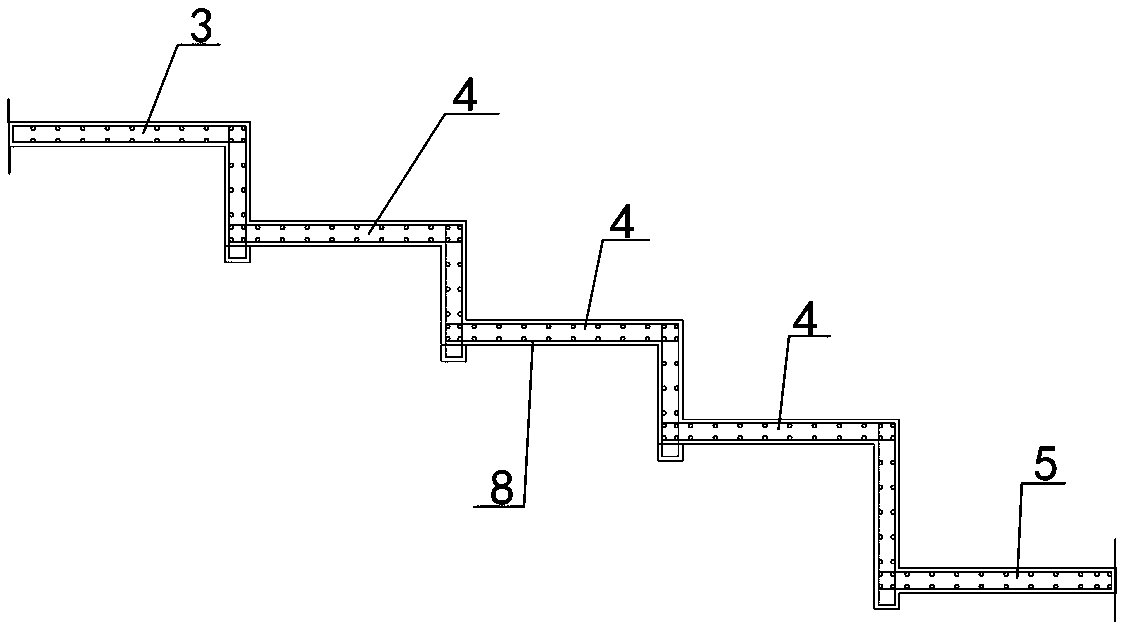

[0054] Step 1, design scaffolding foundation: the width of scaffolding foundation is greater than the width of cable-stayed bridge girder, and the length of scaffolding foundation is greater than the length of No. 8 block to No. 12 block of side span to be constructed; Dam area is divided into dam area, For the side slope area and the sub-dam area, the scaffolding foundation includes the over-dam foundation 3 poured along the site above the dam, the side slope foundation 4 poured along the surface of the steps after excavating along the dam in the step-like direction of the side slope area, and the site along the sub-dam area. Poured sub-dam foundation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com