Automatic board grinding system for circuit board resistance welding and board grinding method

A circuit board and grinding board technology, which is applied in the direction of automatic grinding control devices, machine tools suitable for grinding workpiece planes, and machine tools suitable for grinding workpiece edges, etc., which can solve the problems of low automation, waste of resources, and low grinding efficiency and other problems, to achieve the effect of high degree of automation, easy operation, and simple grinding method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

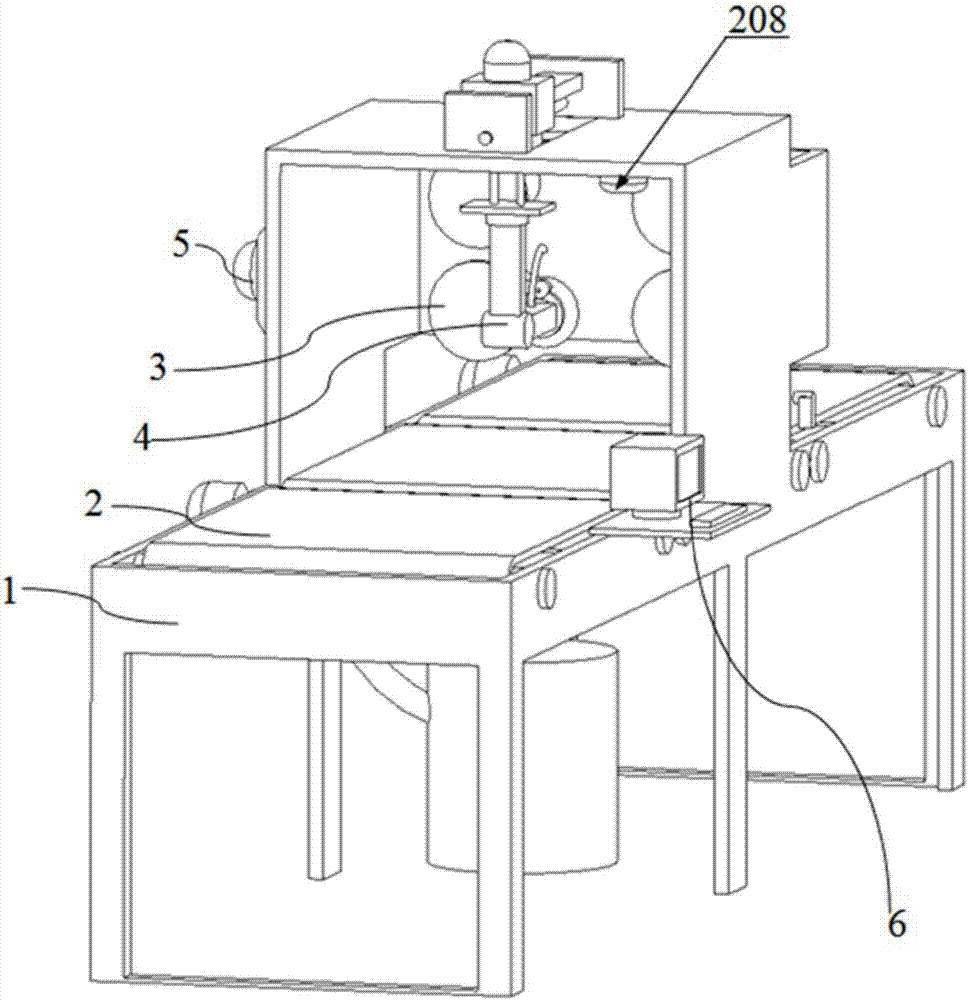

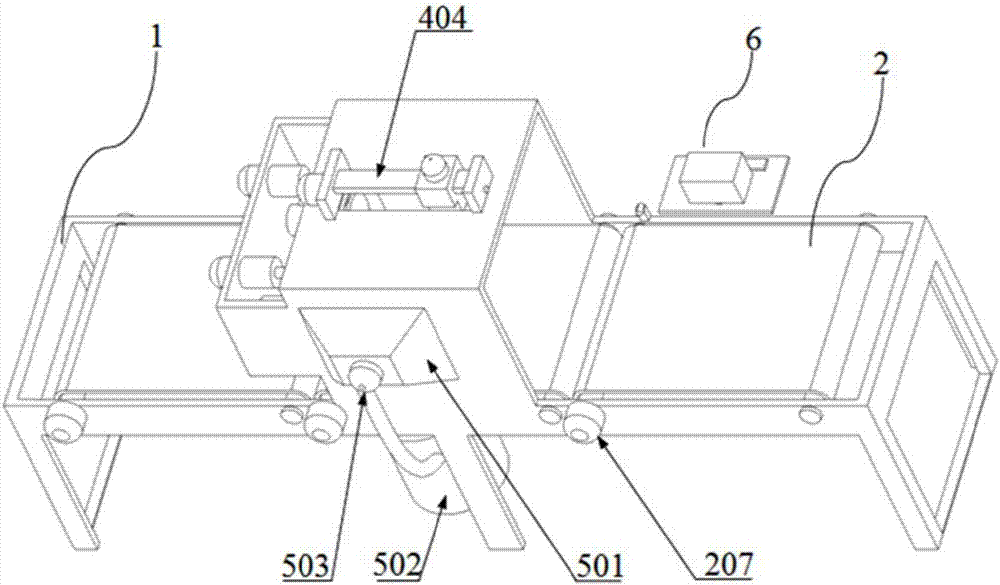

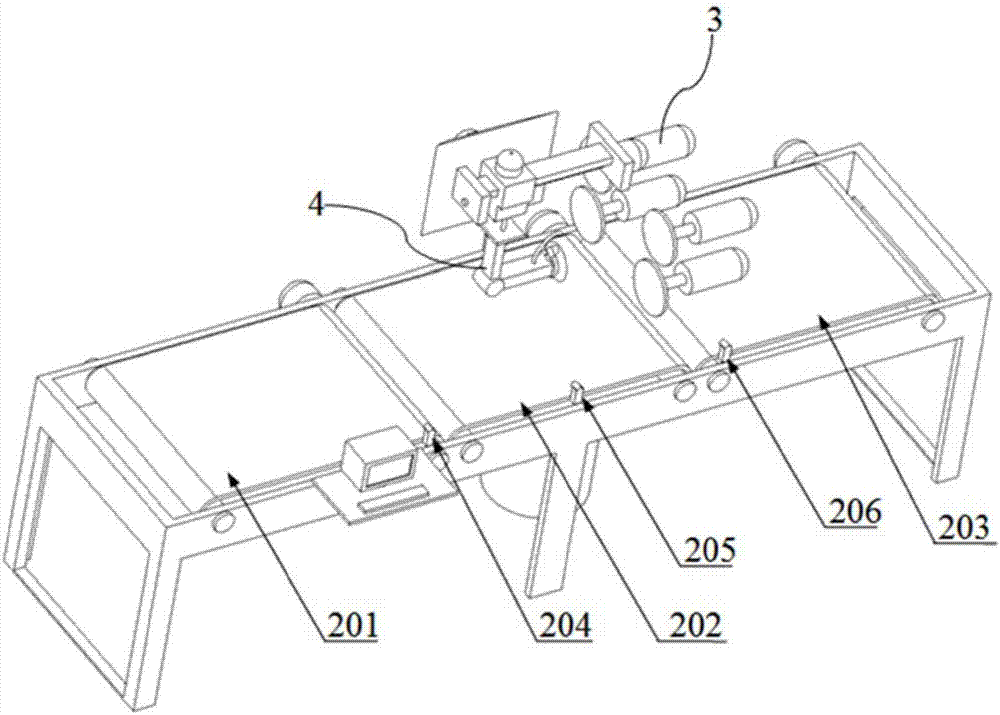

[0040] Reference Figure 1 to Figure 3 , An automatic plate grinding system for circuit board solder resist, comprising a conveying frame 1, a conveying mechanism set on the top of the conveying frame 1, a grinding mechanism 3, a grasping mechanism 4, a recycling mechanism 5 and a control mechanism for controlling the operation of the system 6. The conveying mechanism 2 includes a first conveying component 201, a second conveying component 202, and a third conveying component 203. A waiting sensor 204 is installed at the exit of the first conveying component 201, and in the middle of the second conveying component 202 A grasping positioning sensor 205 is installed at the position, and a board ejection sensor 206 is installed at the entrance of the third conveying assembly 203;

[0041] A fixed bracket is arranged on the conveying frame 1 at the position of the second conveying assembly 202, the polishing mechanism 3 and the recovery mechanism 5 are arranged on the side wall of the...

Embodiment 2

[0043] Refer to Figure 1 to Figure 5 , An automatic plate grinding system for circuit board solder resist, comprising a conveying frame 1, a conveying mechanism set on the top of the conveying frame 1, a grinding mechanism 3, a grasping mechanism 4, a recycling mechanism 5 and a control mechanism for controlling the operation of the system 6. The conveying mechanism 2 includes a first conveying component 201, a second conveying component 202, and a third conveying component 203. A waiting sensor 204 is installed at the exit of the first conveying component 201, and in the middle of the second conveying component 202 A grasping positioning sensor 205 is installed at the position, and a board ejection sensor 206 is installed at the entrance of the third conveying assembly 203;

[0044] A fixed bracket is arranged on the conveying frame 1 at the position of the second conveying assembly 202, the polishing mechanism 3 and the recovery mechanism 5 are arranged on the side wall of the...

Embodiment 3

[0058] This embodiment adds a fill light and a light sensor on the basis of the second embodiment.

[0059] The supplementary light is arranged on the inner wall of the fixed bracket, and the supplementary light and the light sensor are both connected with the main control single-chip circuit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com