A grinding positioning tool and v-groove grinding method for bending lower die

A technology for positioning tooling and positioning grooves, which is applied in the direction of grinding workpiece brackets, grinding machine parts, grinding/polishing equipment, etc., which can solve the problems of long processing time and cumbersome processing process, and achieve convenient processing and use. The method is simple and the relative position is accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

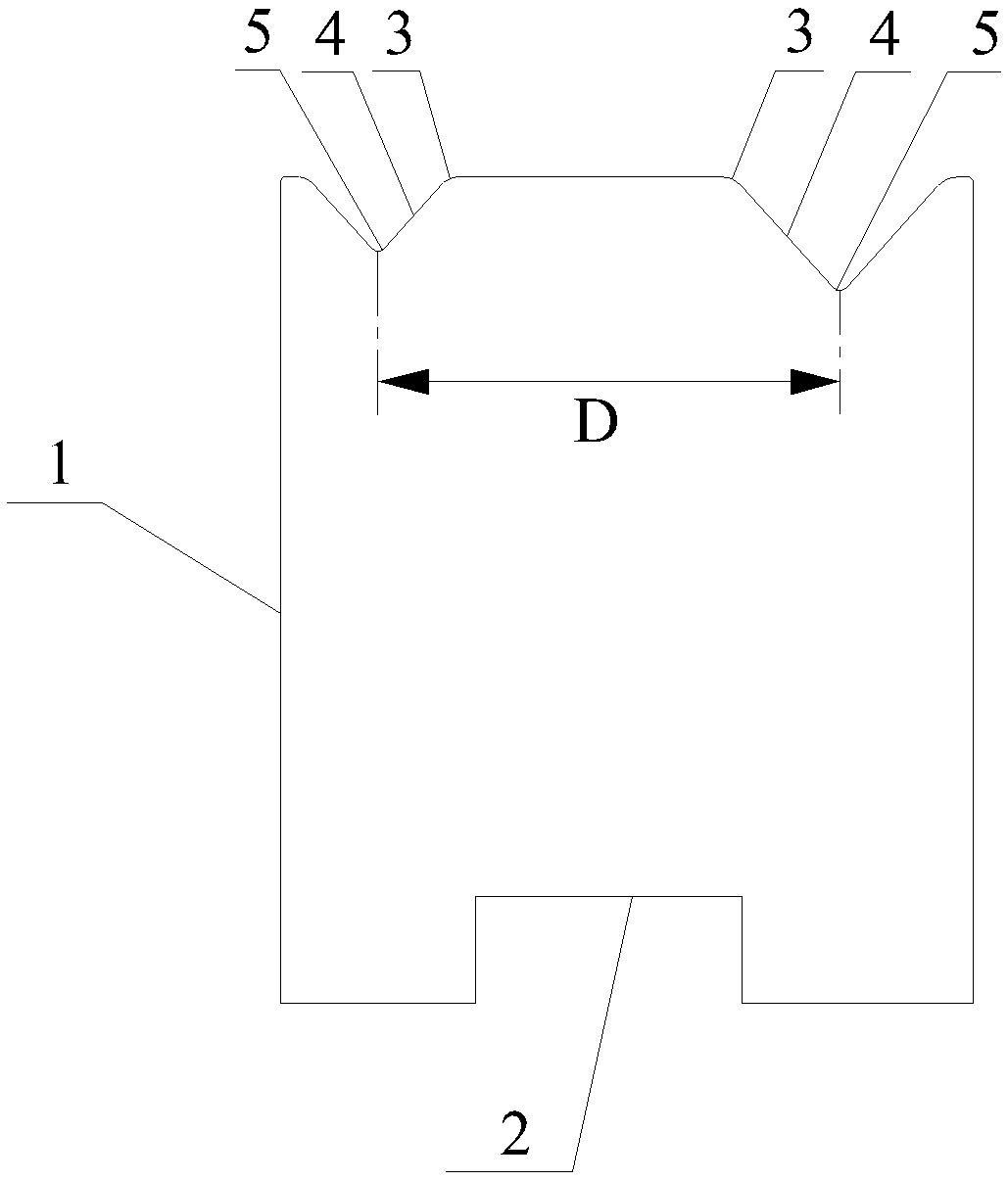

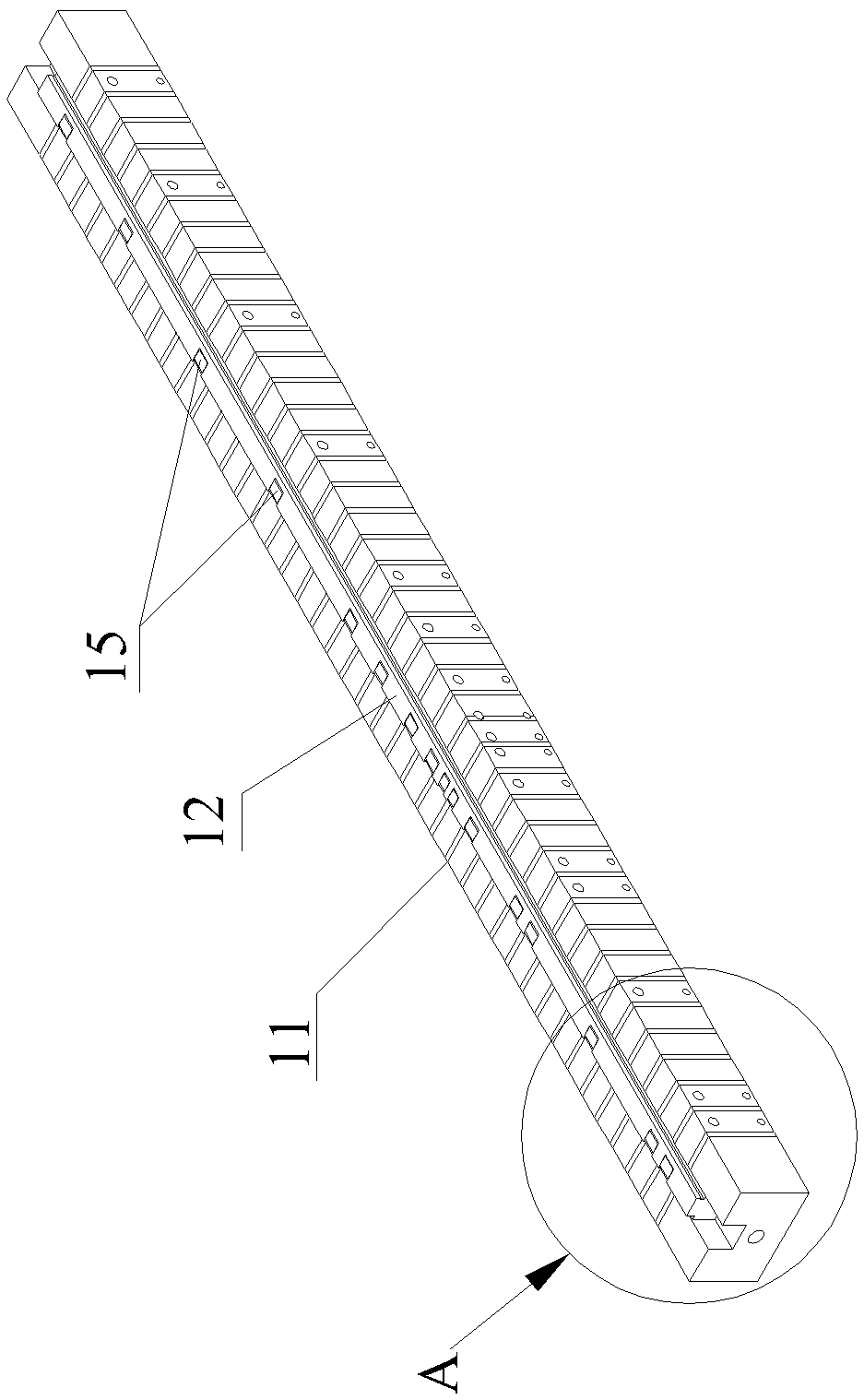

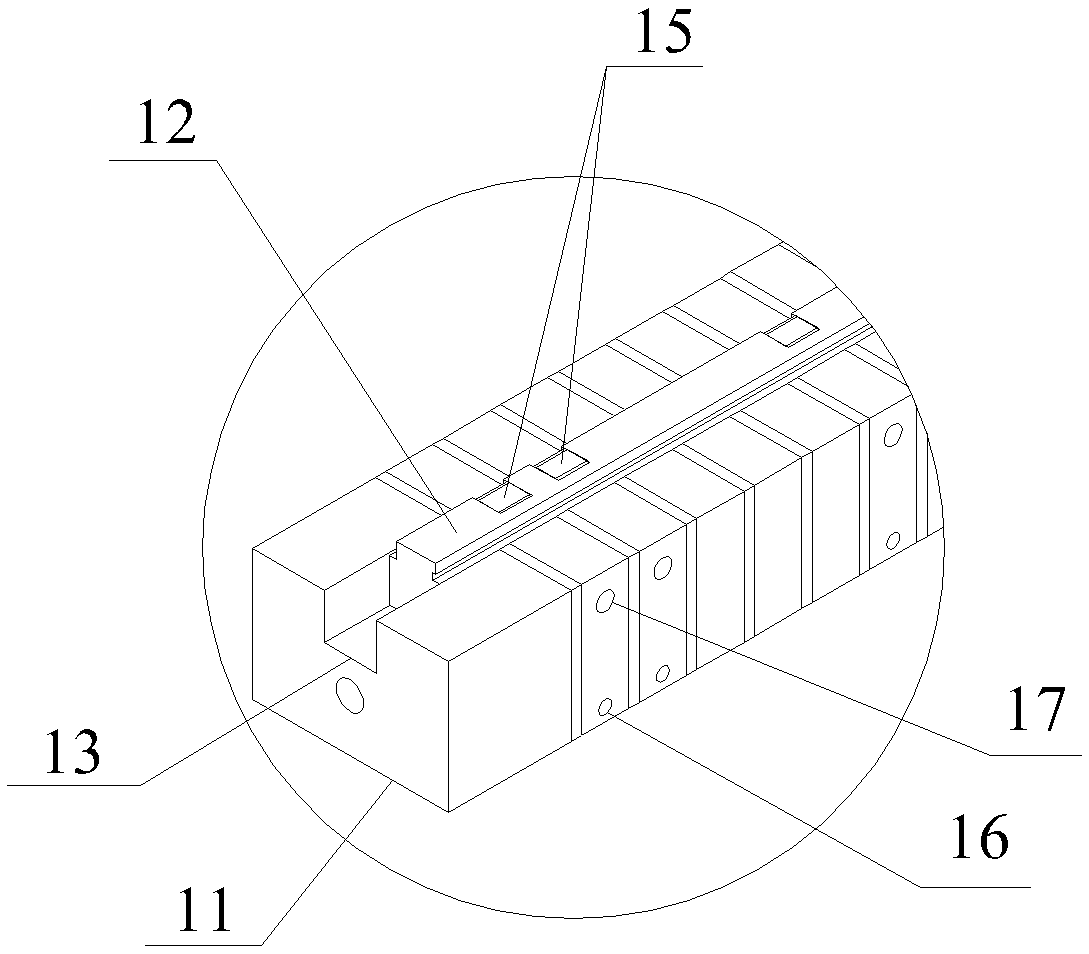

[0034] See Figure 2 to Figure 7 , a grinding and positioning tool for bending lower die of the present invention, which includes a magnetically conductive base 11 and a positioning block 12, the top surface of the magnetically conductive base is a horizontal positioning surface for supporting the bending lower die 1, and the magnetically conductive base A through groove 13 is opened on the top surface along the front and rear direction, and the positioning block 12 is fitted in the through groove 13 and its upper end protrudes from the through groove 13 and then inserted into the rectangular positioning groove 2 of the bending lower die 1. The upper end of the positioning block 12 is left The side is parallel to the left side of the rectangular positioning groove 2; the positioning block 12 and the magnetic base 11 are provided with mounting holes 14 that penetrate up and down, and the mounting holes 14 are provided with multiple mounting holes 14 along the magnetic base 11. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com