Negative rake angle grinding clamp for slotting cutter

A gear shaper, negative rake angle technology, used in grinding workpiece supports and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

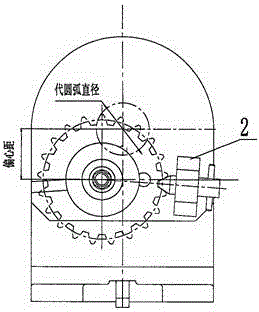

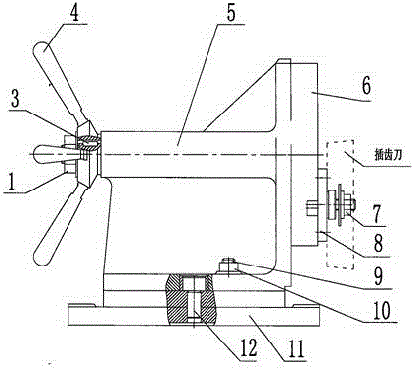

[0022] A grade AA cemented carbide gear shaper cutter, the material is YT758, the modulus is 6, the number of teeth is 21, the pressure angle is 20°, the negative rake angle is 7°, the ligament width of the negative rake angle is 1mm, and the smoothness is 0.8, in the vertical machining center When processing the negative rake angle of the teeth of the cemented carbide gear-shaping cutter, the grinding wheel will fall off seriously, resulting in uneven ligaments, and the grinding wheel foam will damage the guide rail of the CNC machine tool. Utilize the fixture of the present invention to grind the negative rake angle of the gear shaper cutter on the universal tool grinder, and the operation is simple; and the diamond disc-shaped grinding wheel is used to avoid the shedding of the grinding wheel, and meet the negative rake angle of the gear shaper cutter with a ligament width of 1 mm, a smoothness of 0.8, and a negative angle. 7° requirement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com