Grinding method of offset gear

A grinding method and technology of gears, applied in the direction of elements with teeth, belts/chains/gears, gear teeth, etc., can solve the problems of dependence on imports, failure to meet high requirements, and limited mold accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

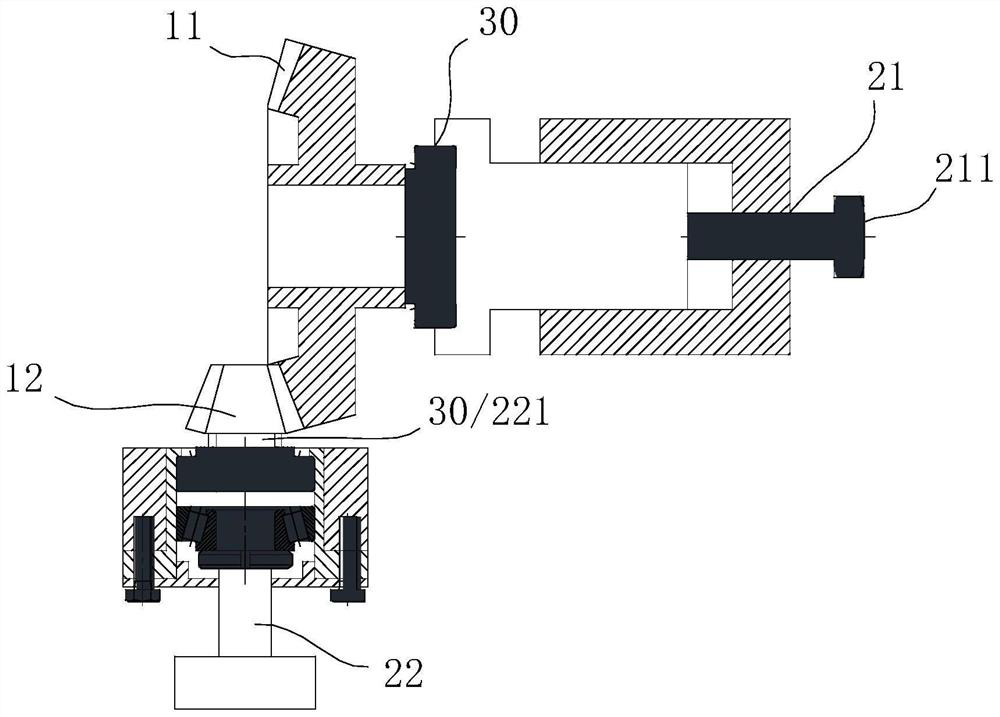

[0032] A grinding method of an offset gear, the offset gear includes a main gear 11 and an auxiliary gear 12, the steps are as follows:

[0033] S1. Apply abrasive paste between the tooth surfaces of the main gear 11 and the auxiliary gear 12. The particle size of the abrasive paste is 800-900 mesh, and mesh and fix the main gear 11 and the auxiliary gear 12.

[0034] S2. The pinion gear 12 rotates on its own and maintains a relatively fixed position in the space where it is located. The pinion gear 12 drives the main gear 11 to rotate.

[0035] S3. Apply a force of a set size to the contact surface between the main gear 11 and the pinion gear 12, the force of the set size is parallel to the axis of rotation of the main gear 11 and applied to the shaft of the main gear 11; and the The form of force application is: when starting grinding, the force starts from 0 N, after 10-15 times of force application, it reaches 200 N at the end of grinding; adjust the speed of pinion 12 to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com