Patents

Literature

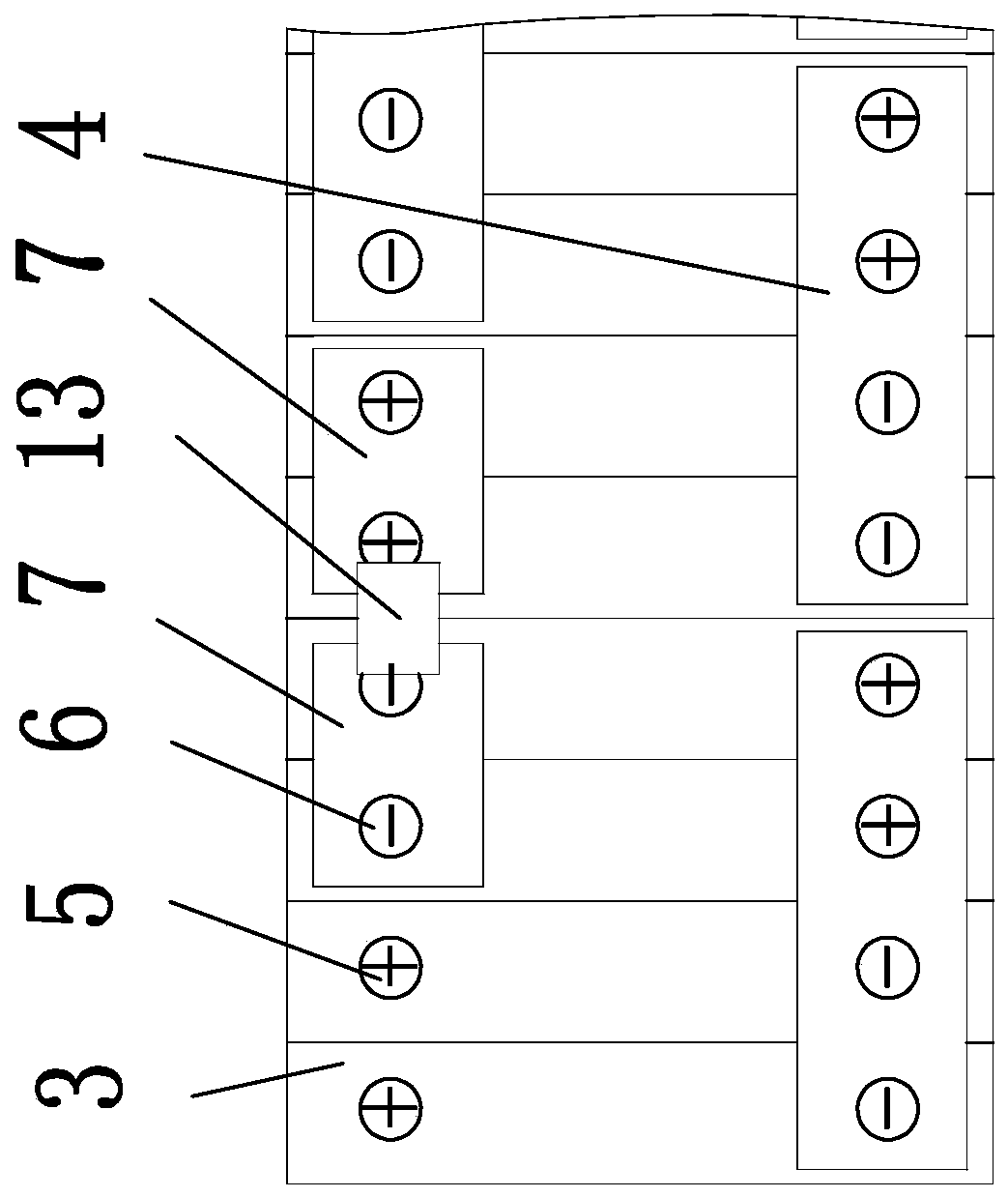

57results about How to "Easy to fuse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

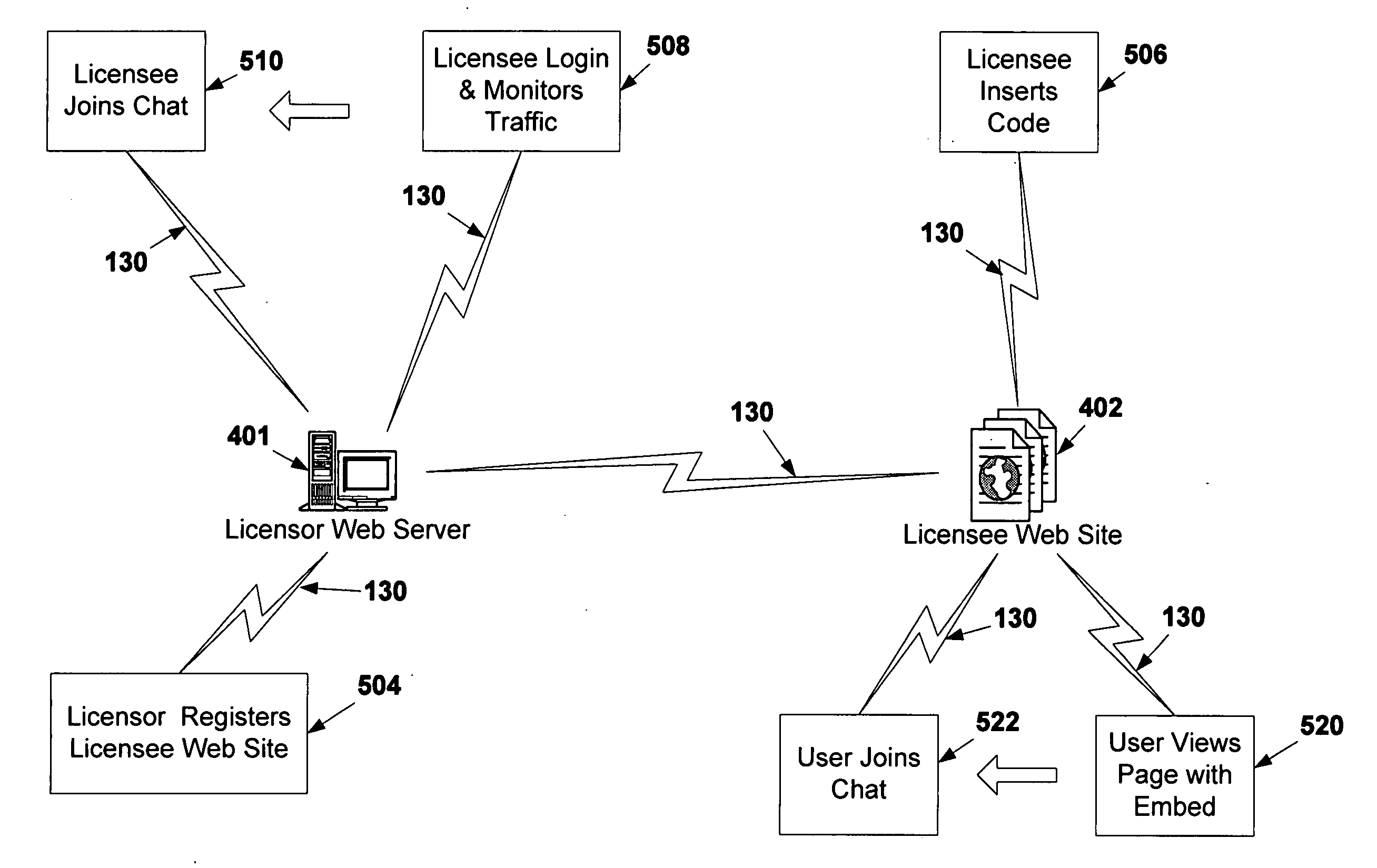

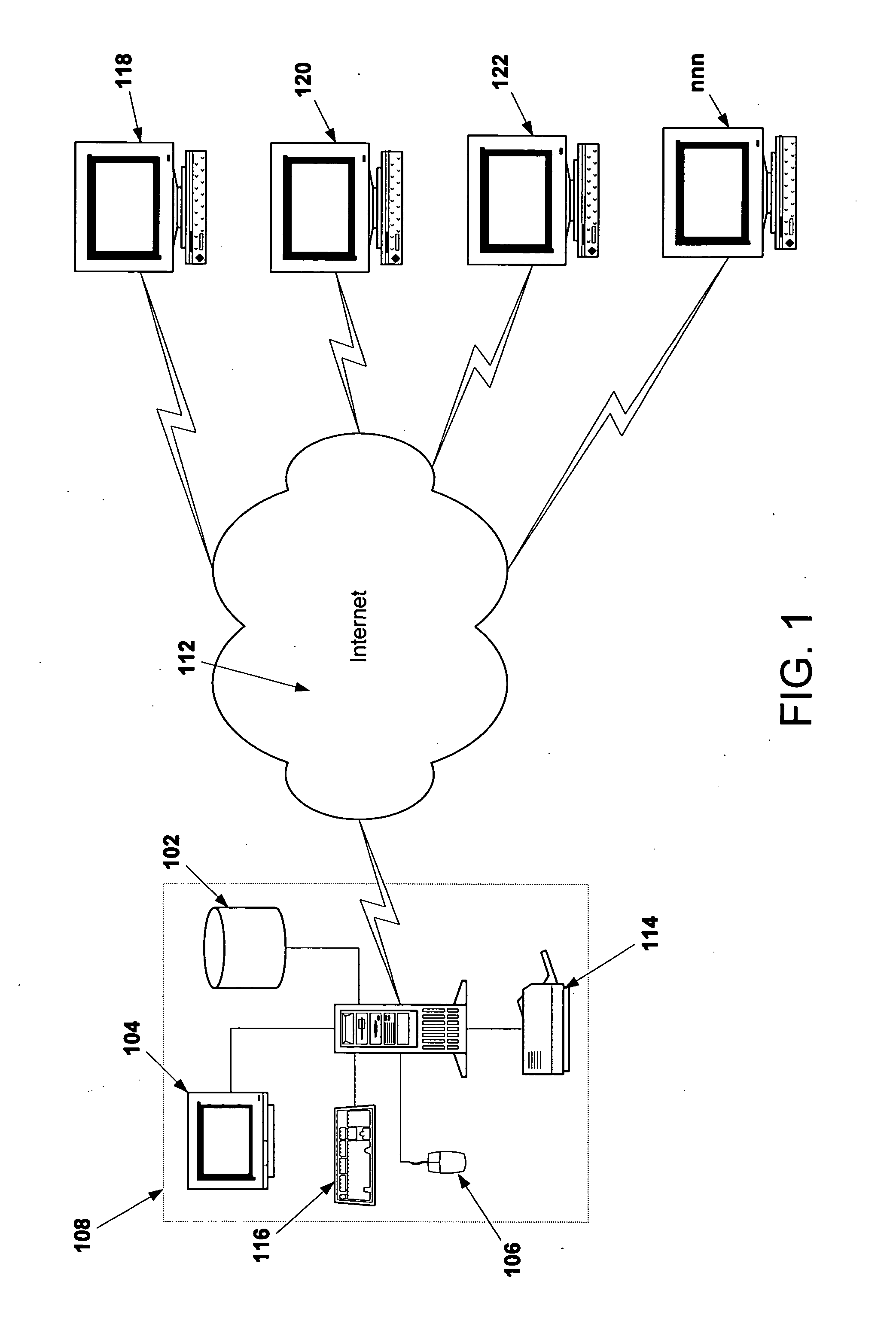

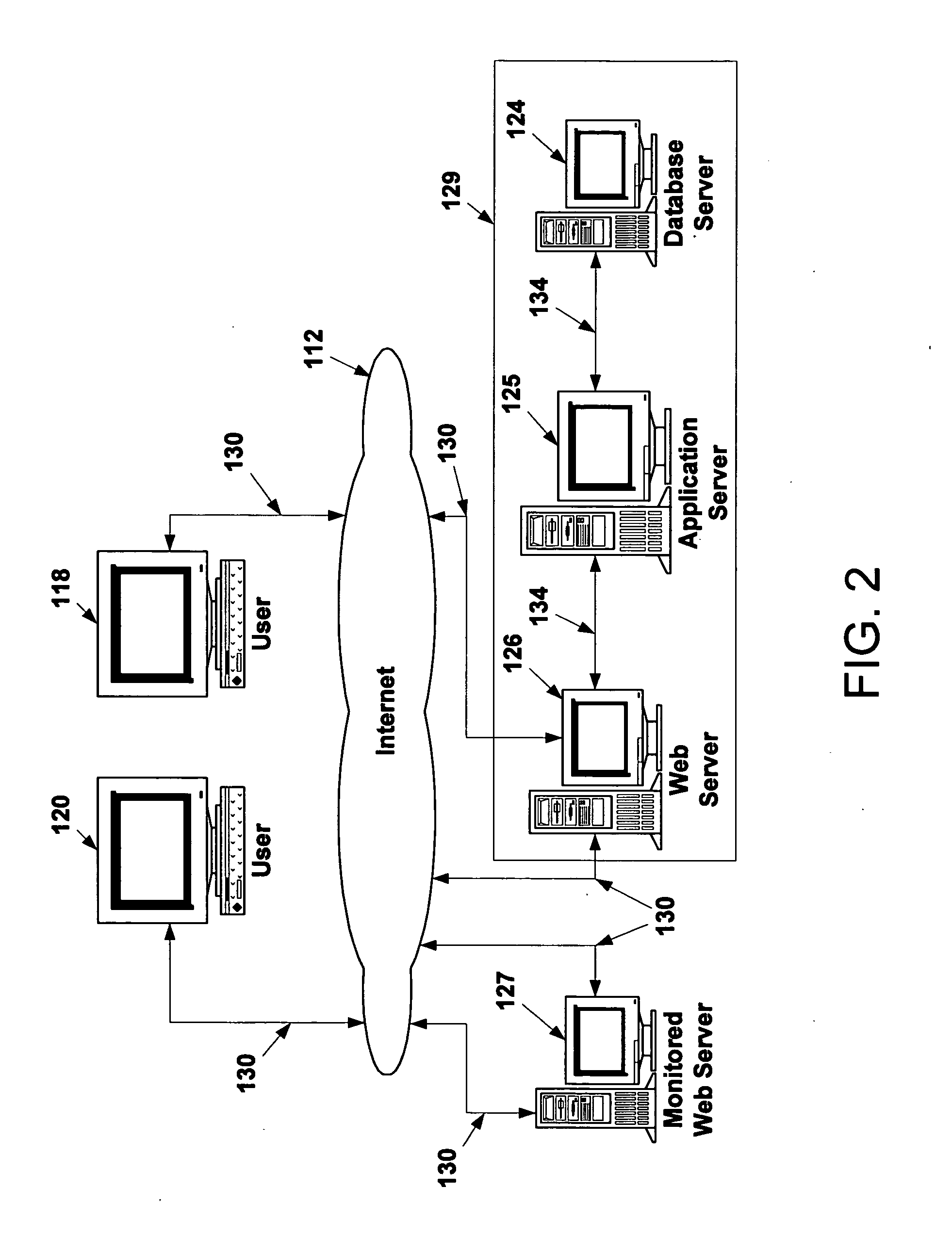

Web page monitoring and collaboration system

InactiveUS20050102358A1Facilitate conductionEasy to participateDigital data information retrievalMultiple digital computer combinationsInternet communicationWeb site

This invention relates to providing a system for improved methods of promoting, forming and managing Internet-based communities on the Internet through and within standard web pages without requiring the installation of additional software on a user's computer or on web sites where the system is implemented by using the latest software tools, presentation techniques and Internet communication methods. Additionally, this invention provides real time monitoring of user counts to all visitors and web page owners when a page with the embedded URL is accessed. In particular, this invention permits web page visitors to initiate and participate in anonymous ad hoc chat sessions initiated from a selected web page. Additionally, this invention provides a web-based location which permits Internet users to join and participate in Internet-based communities and the related activities such as messaging other members, participating in member chat sessions and web resource sharing without the need to install software.

Owner:GOLD STUART A +1

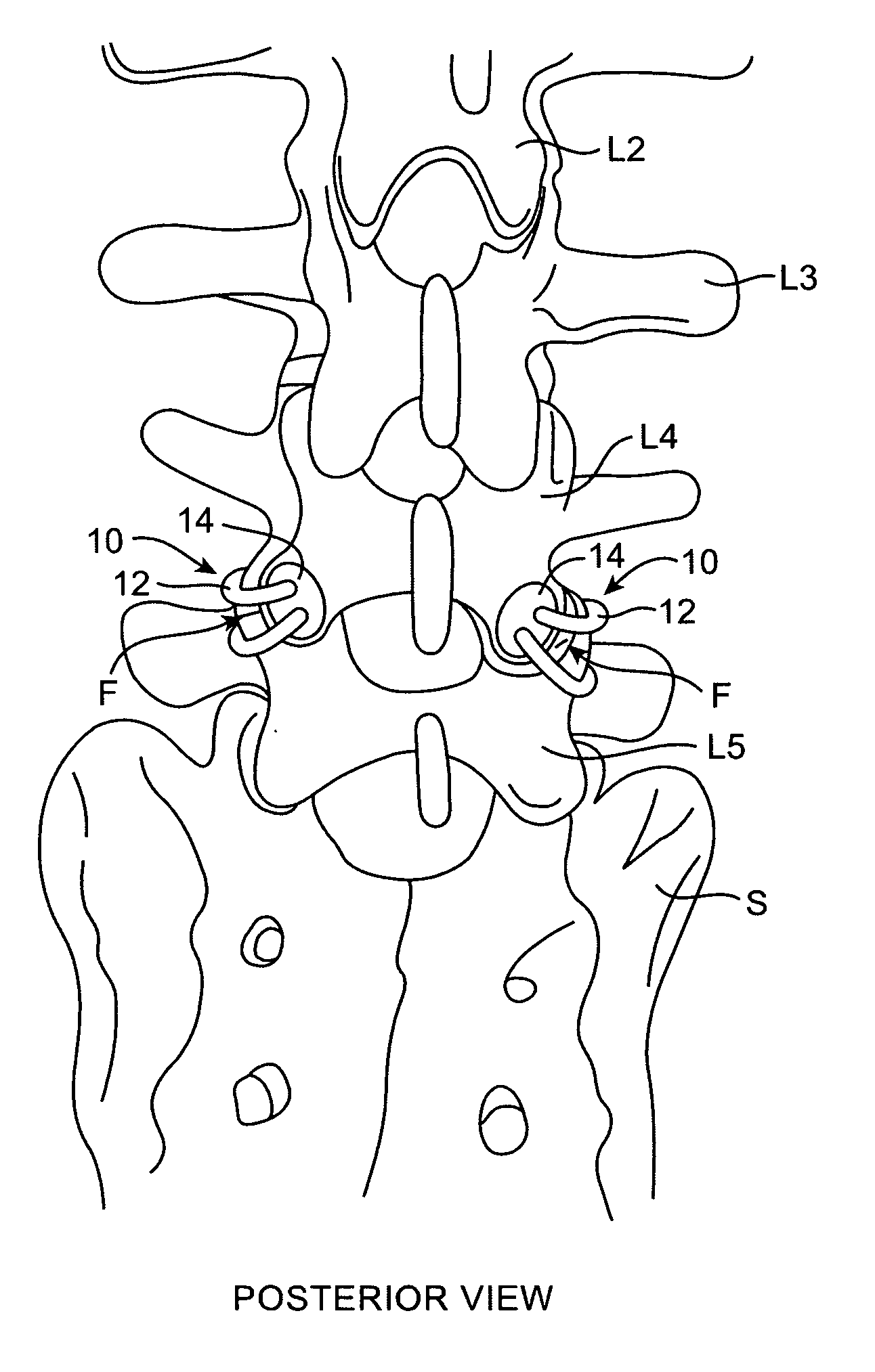

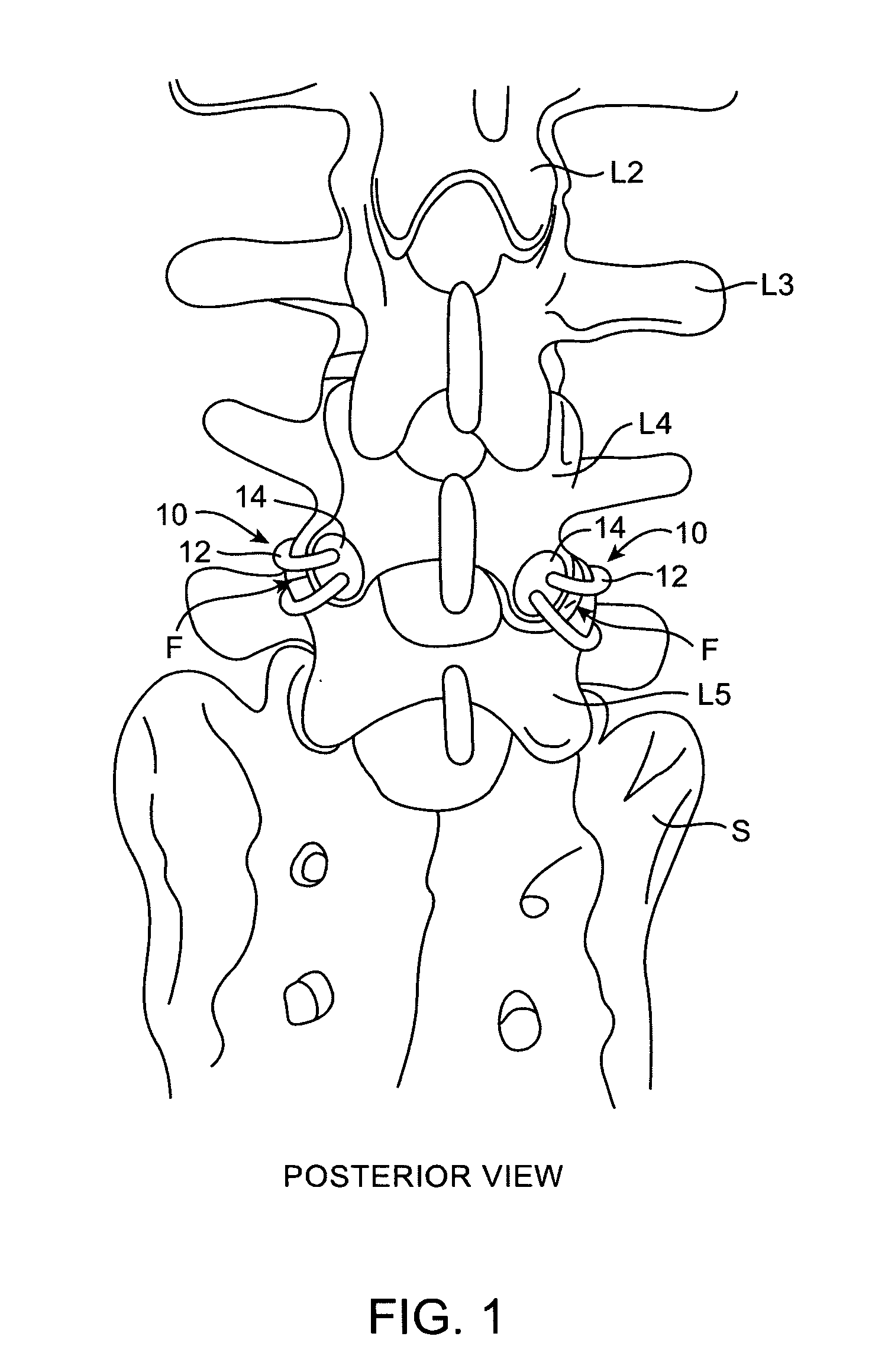

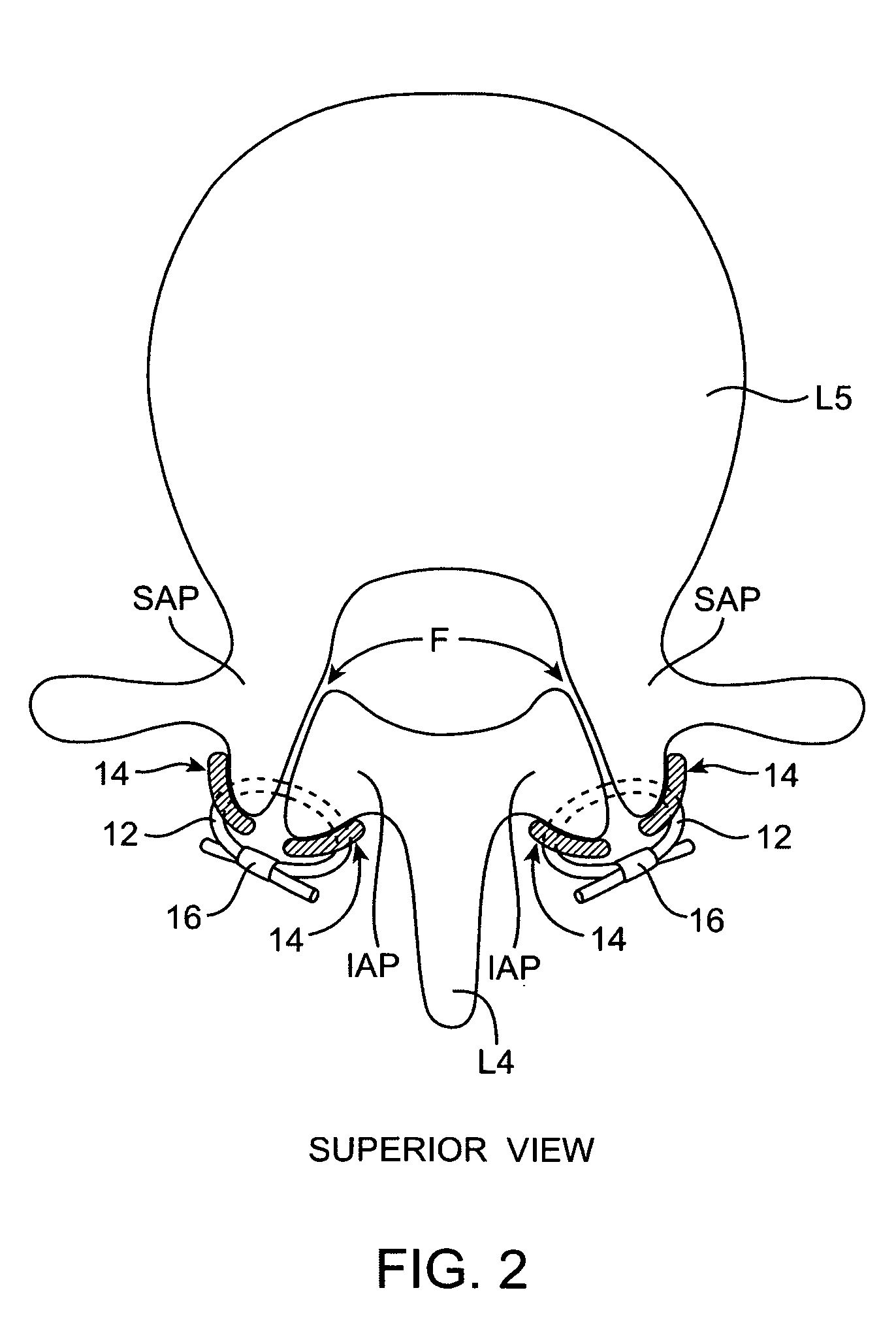

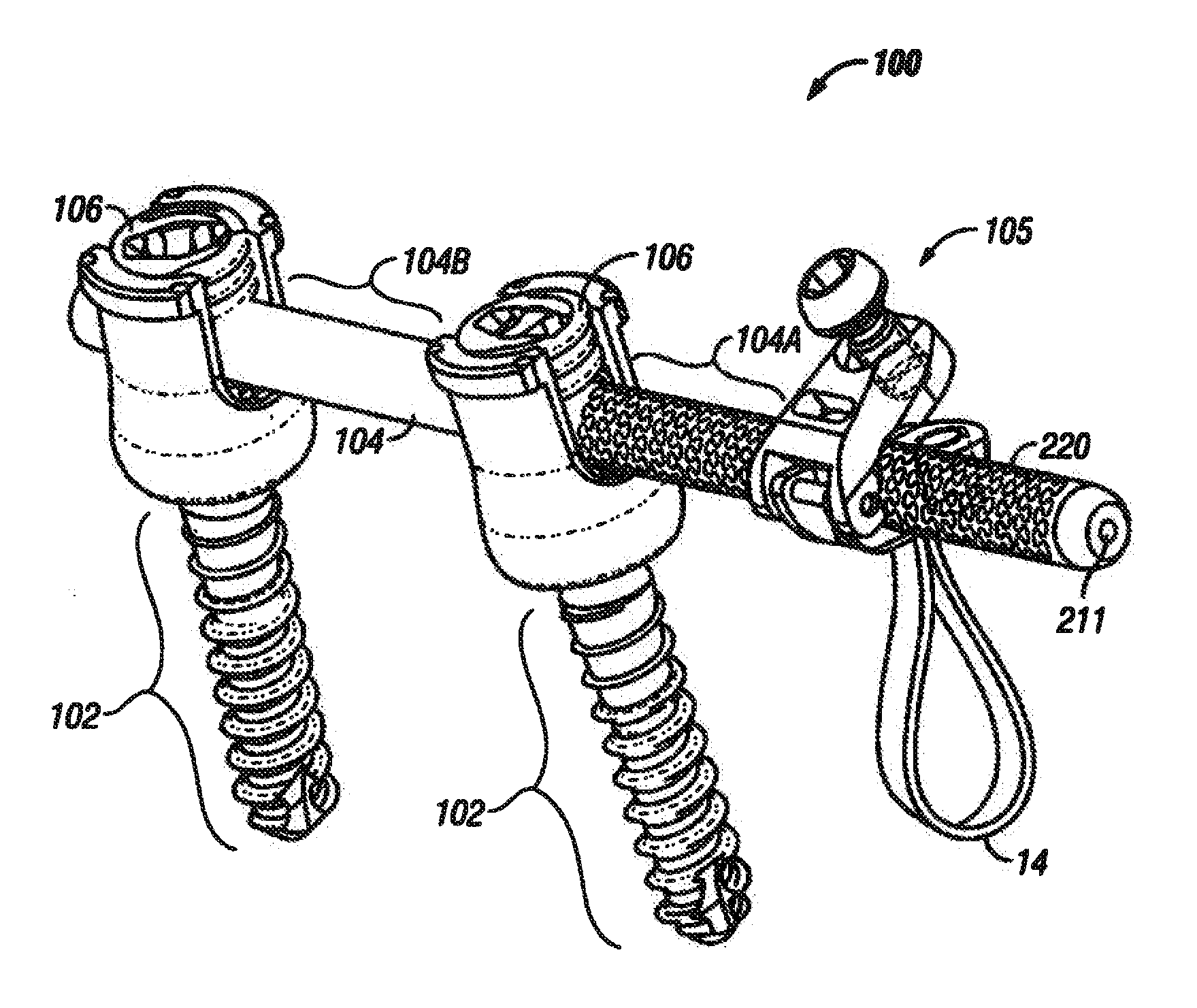

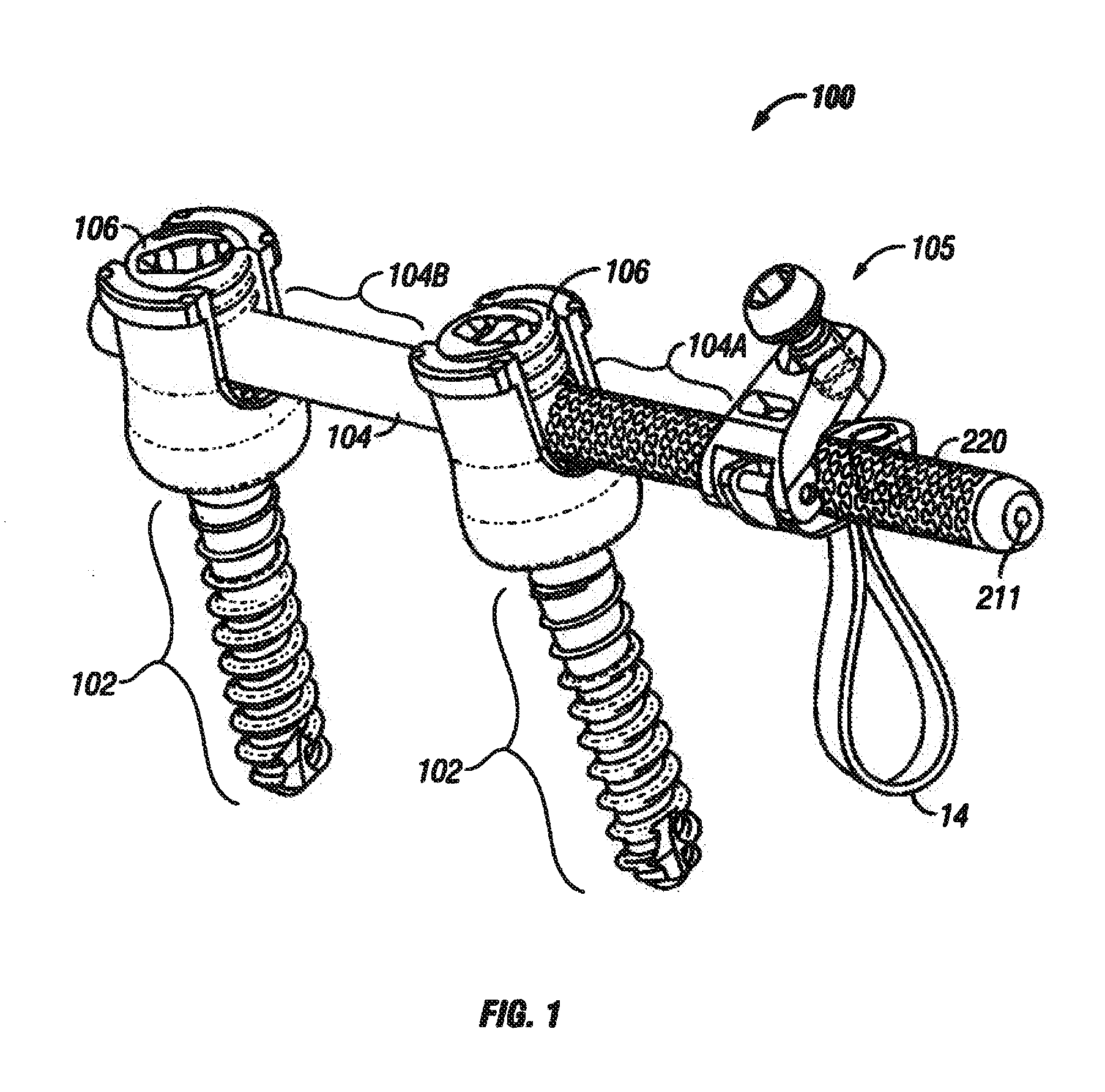

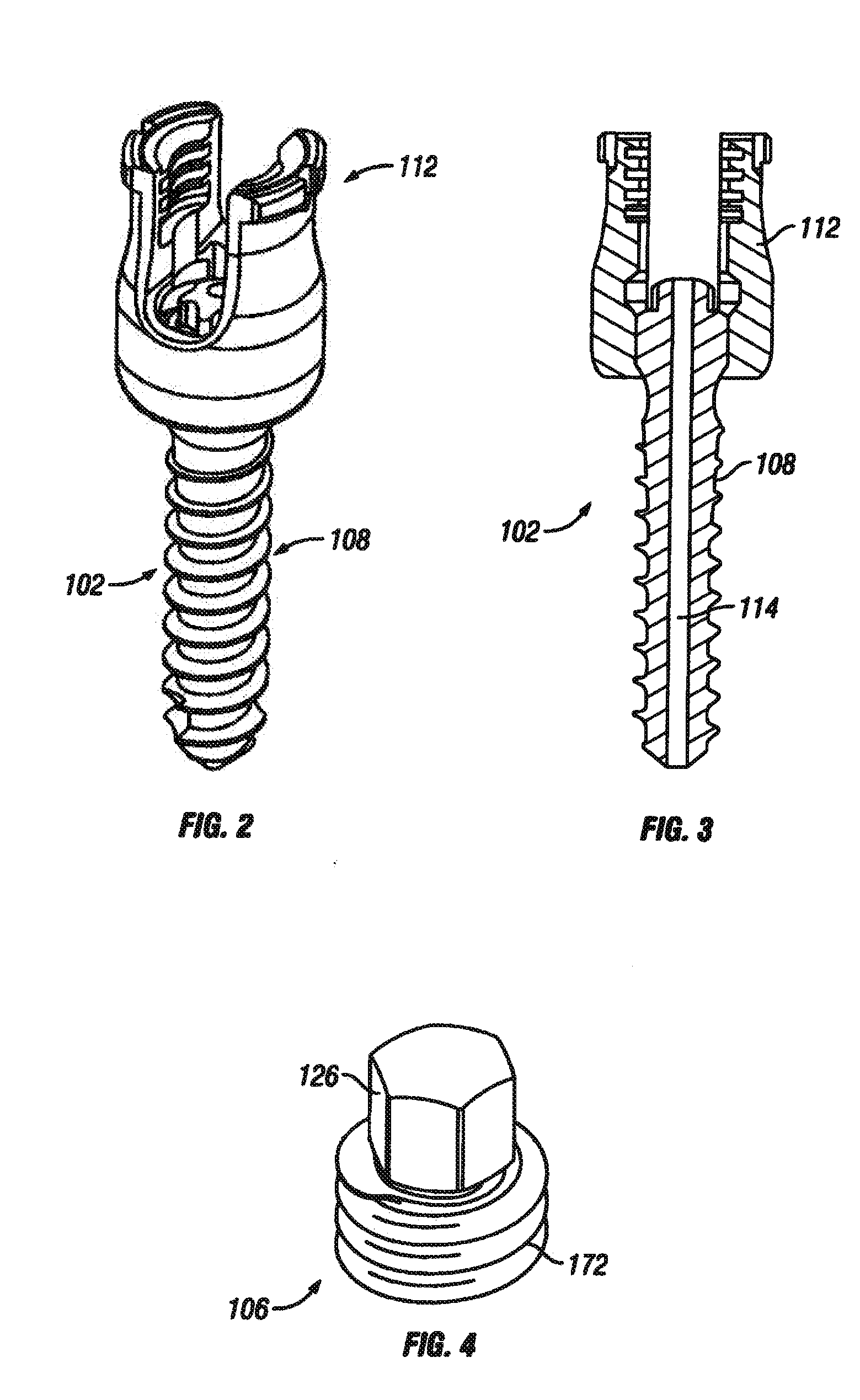

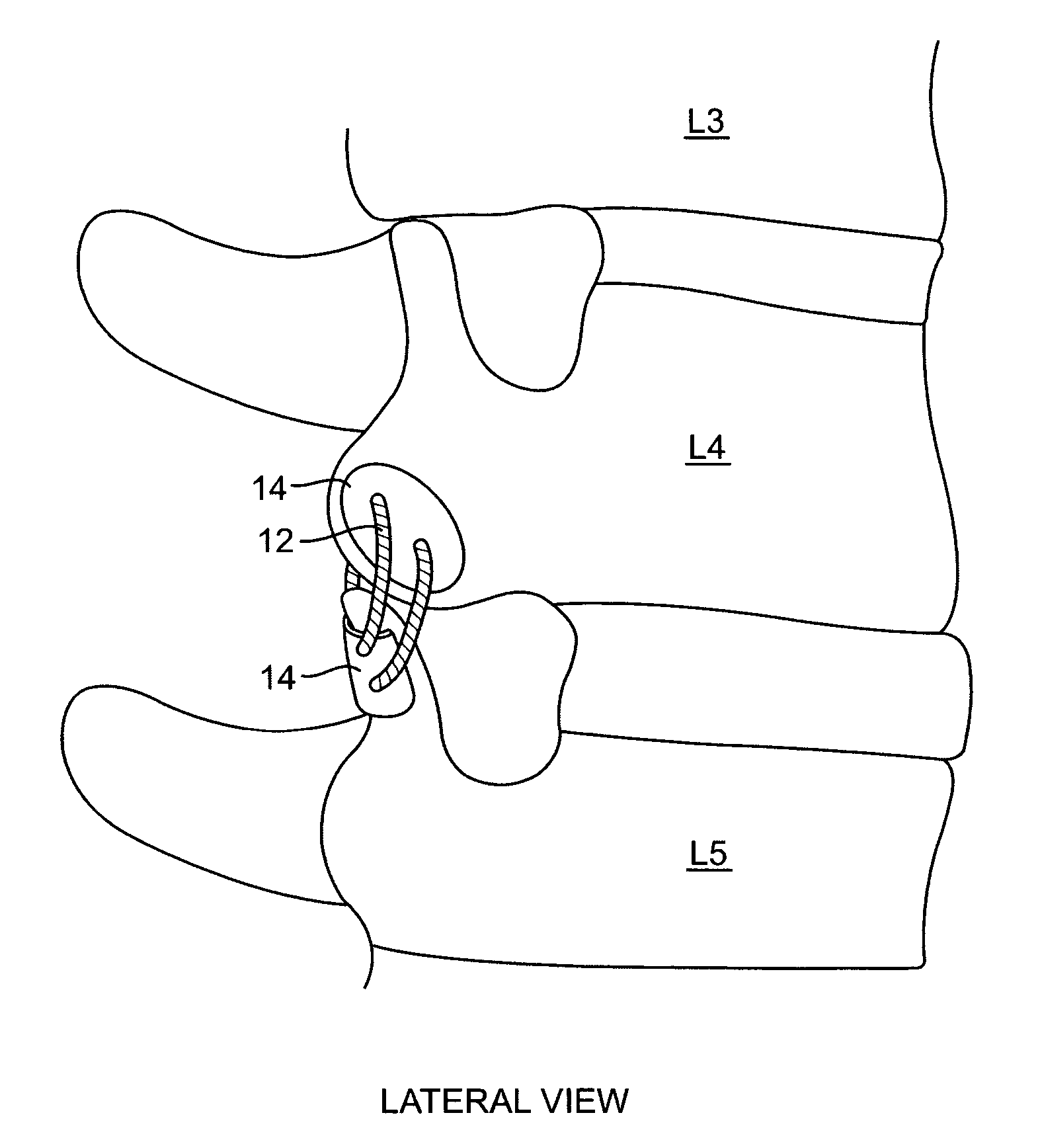

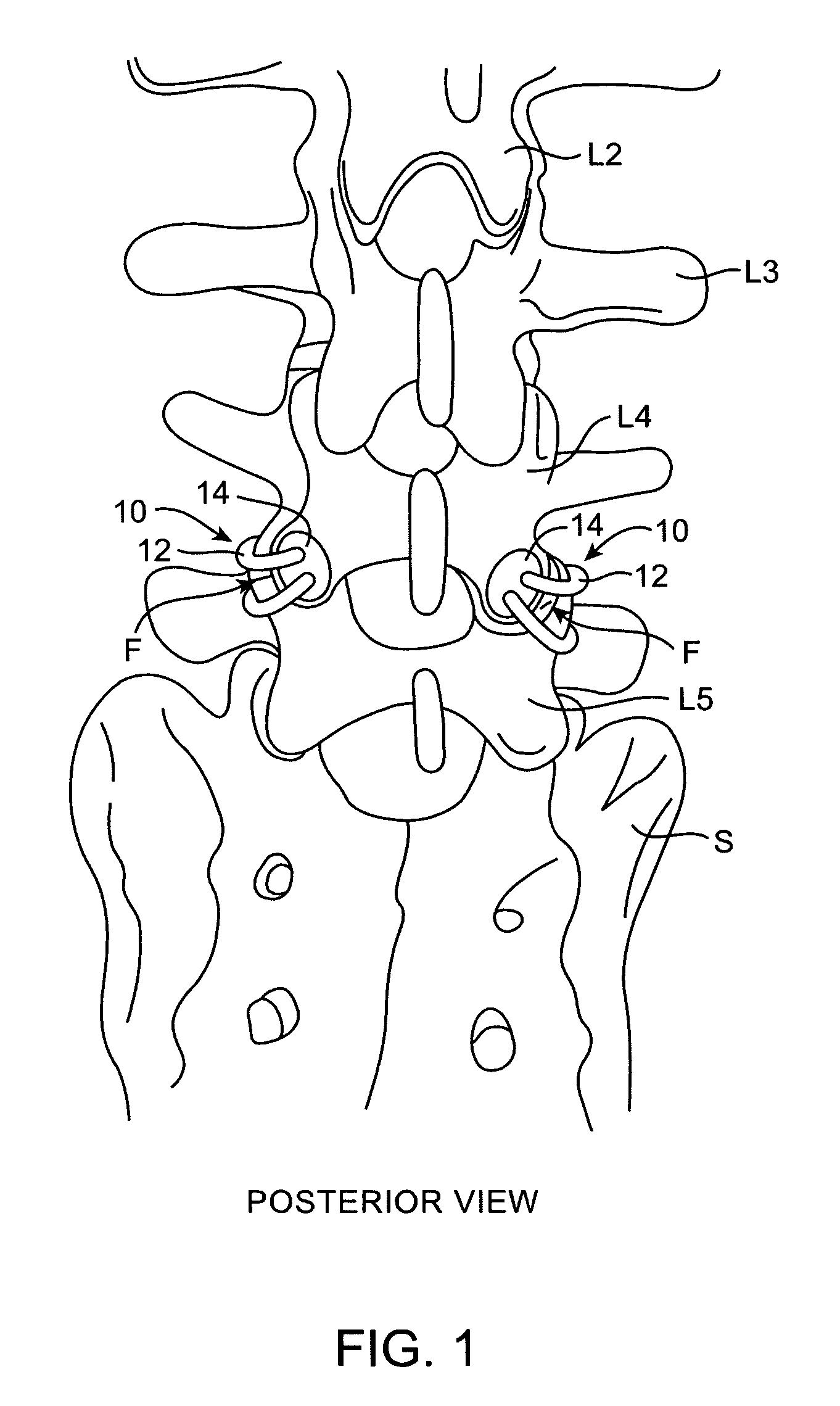

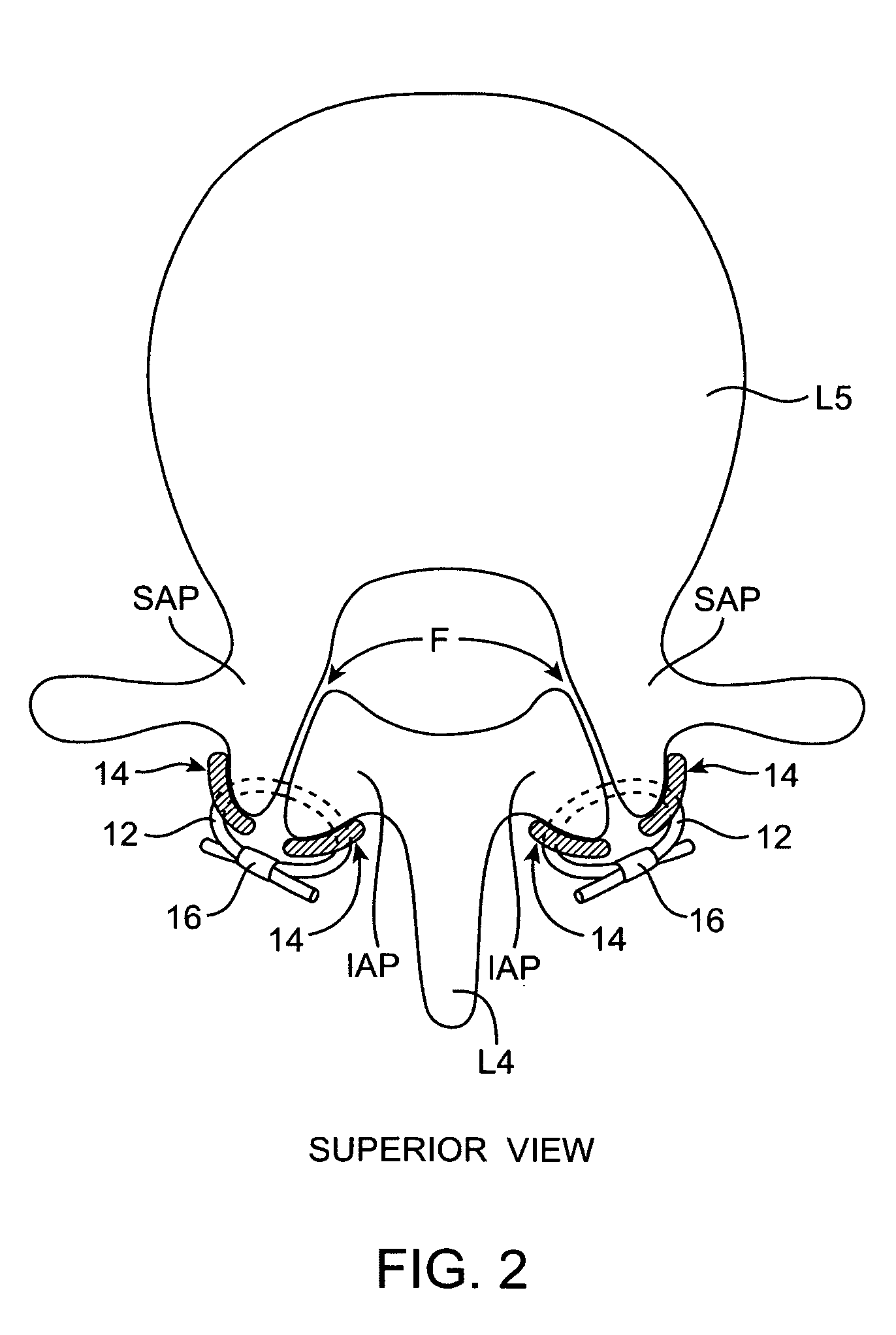

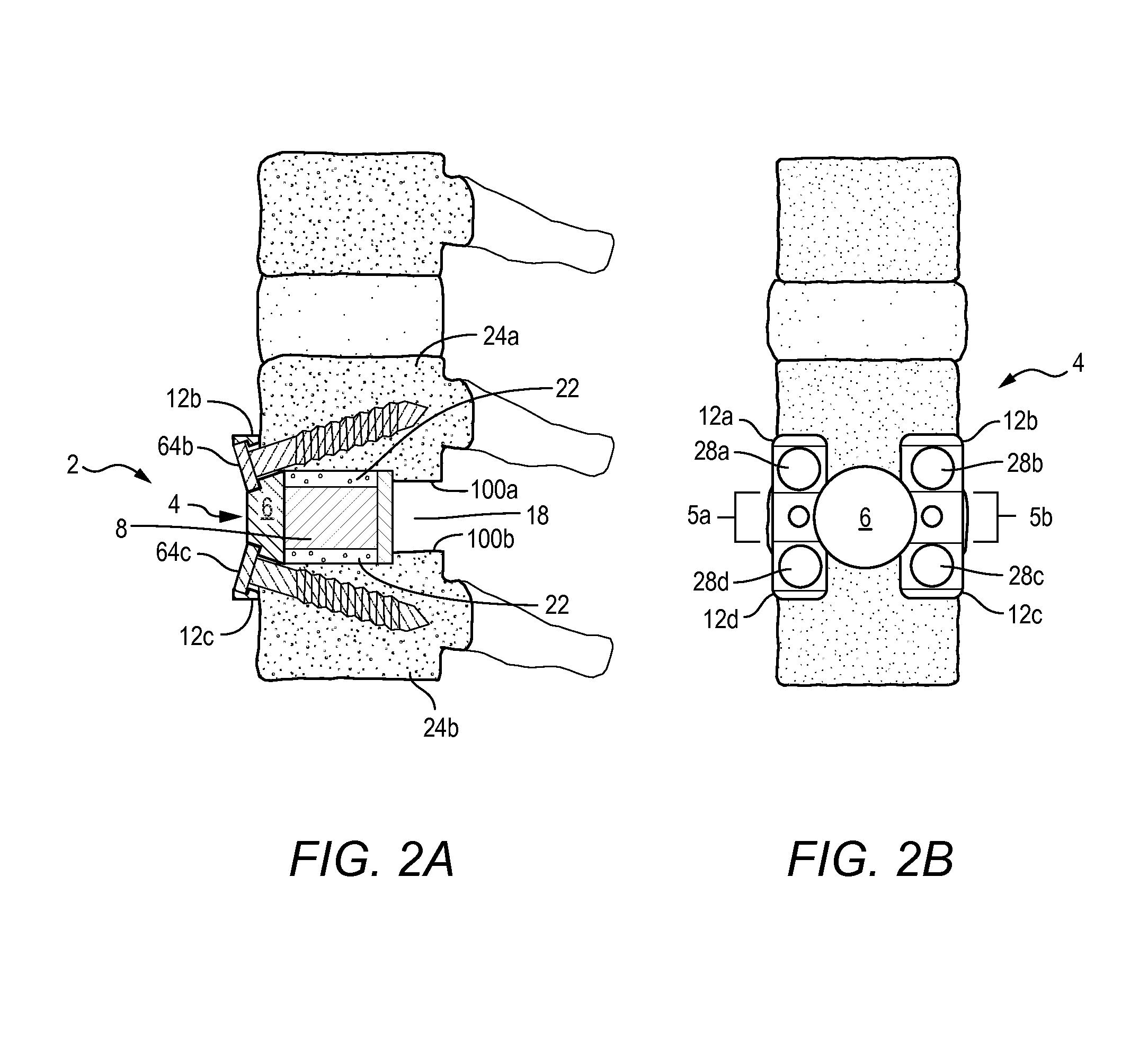

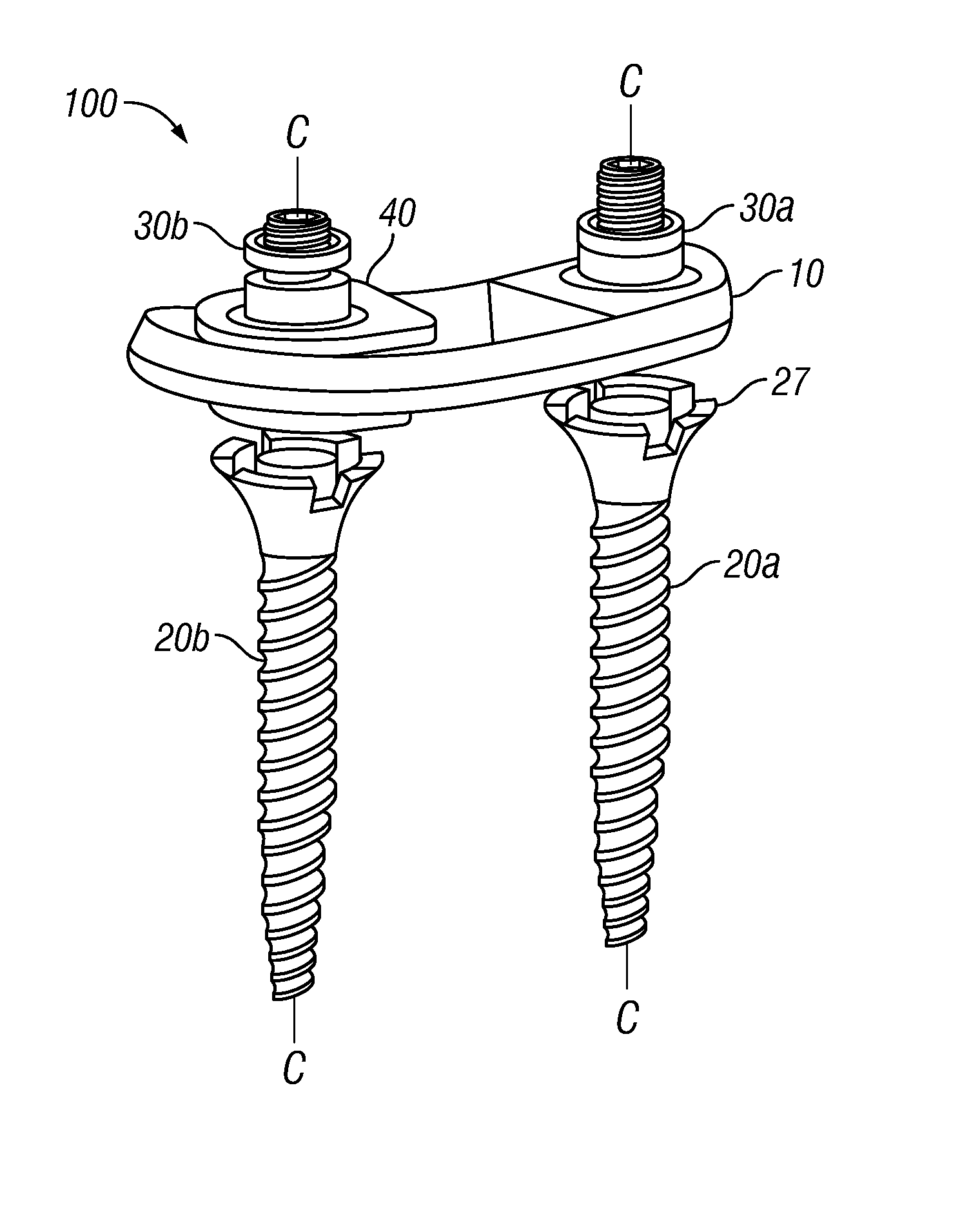

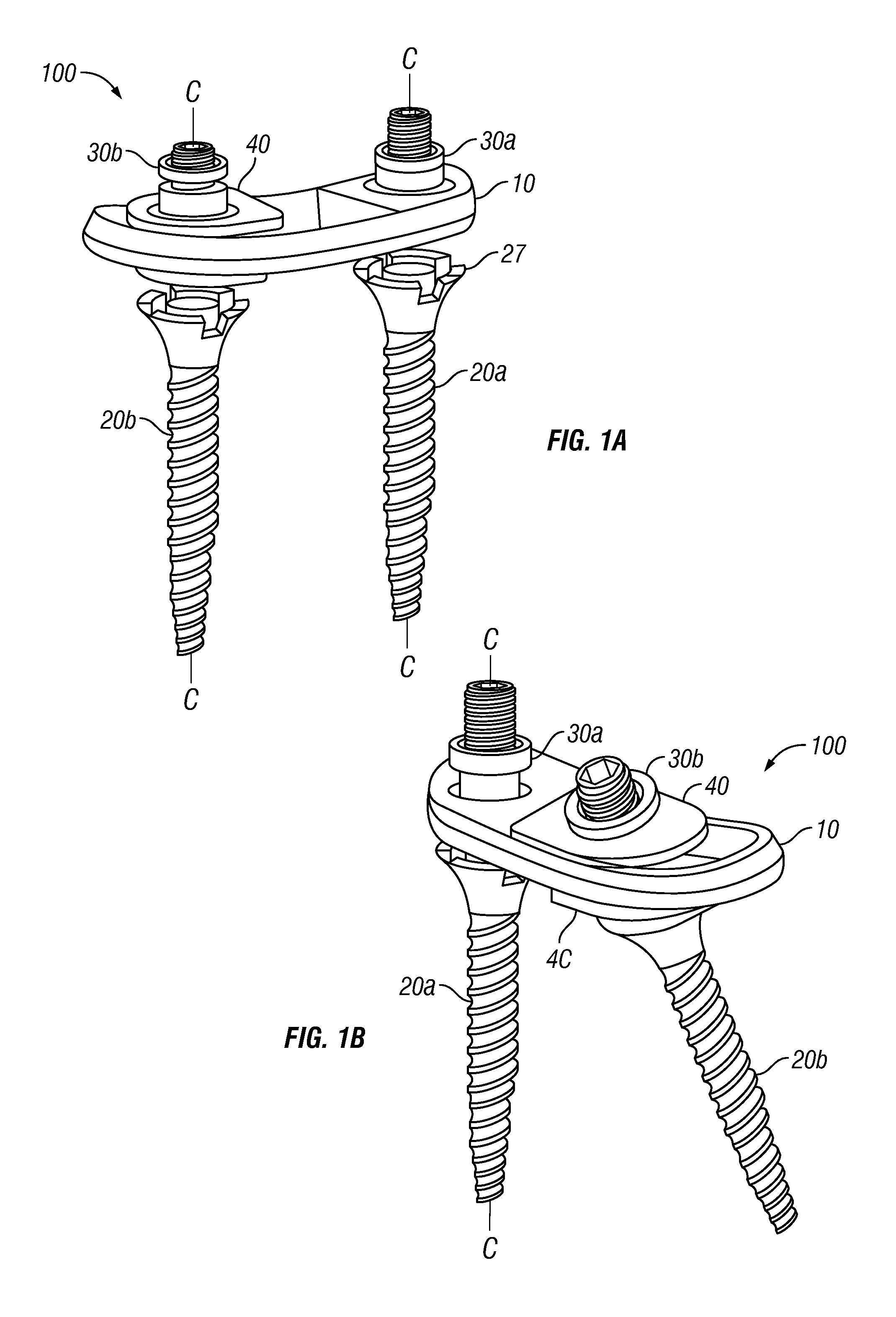

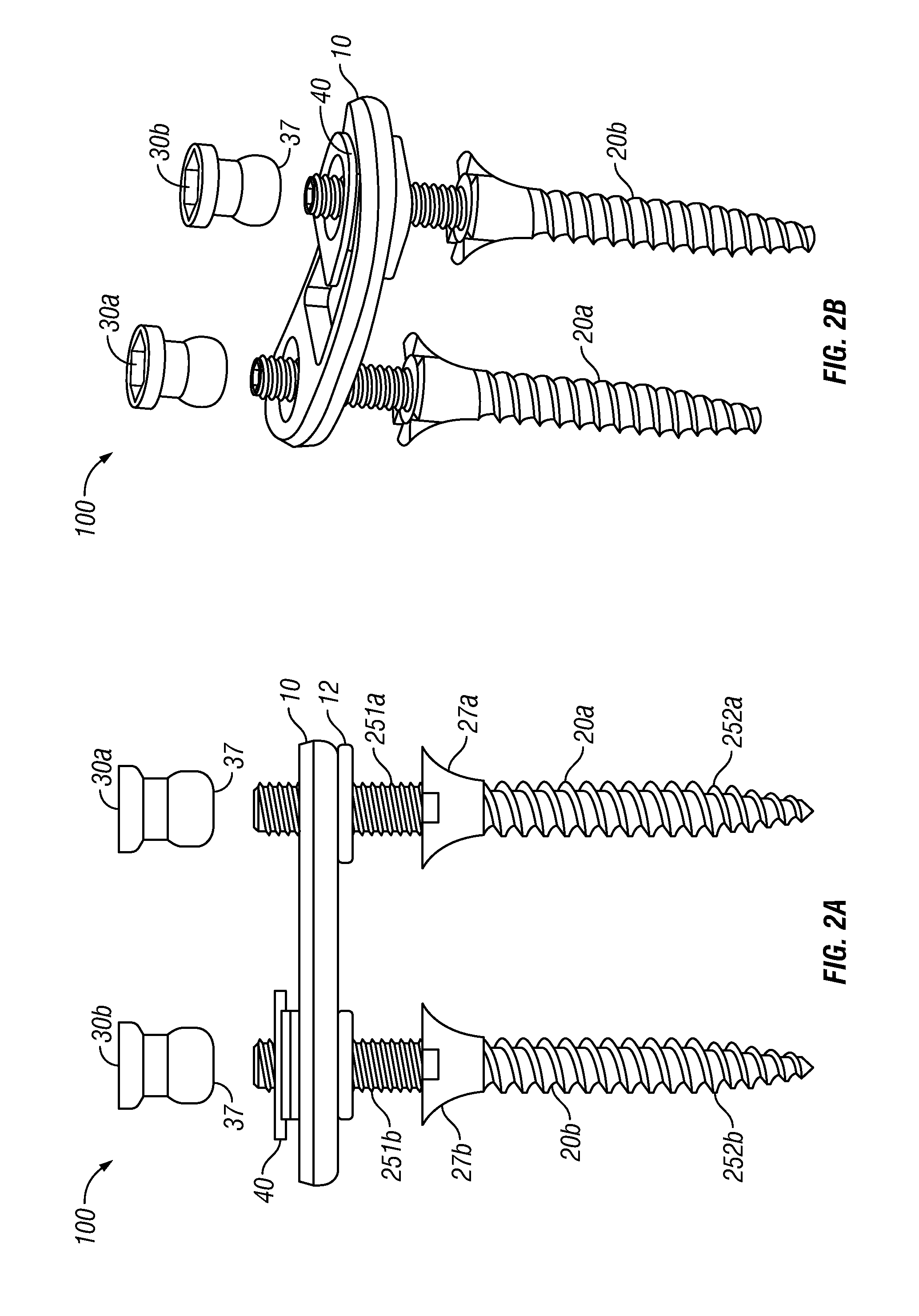

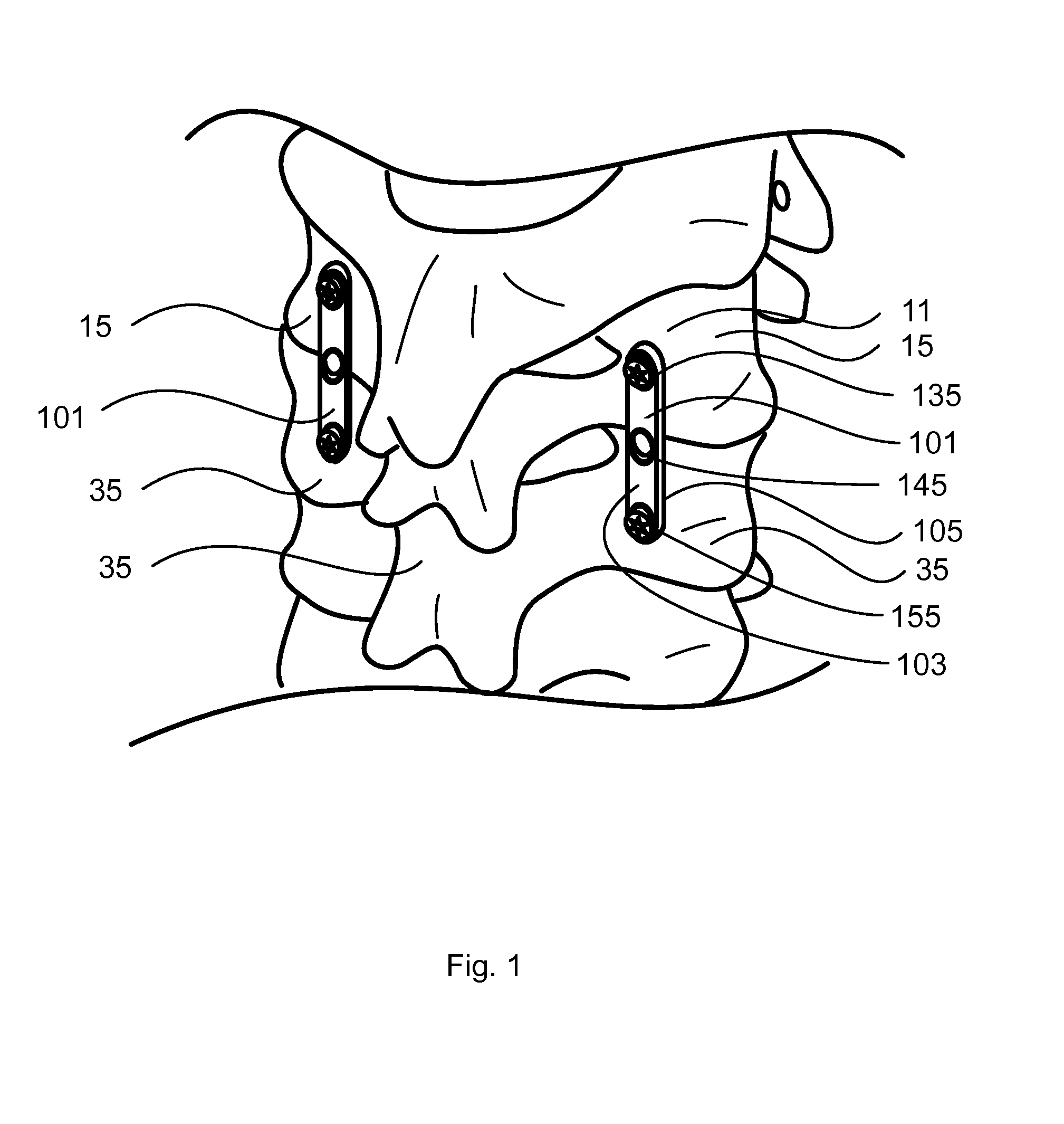

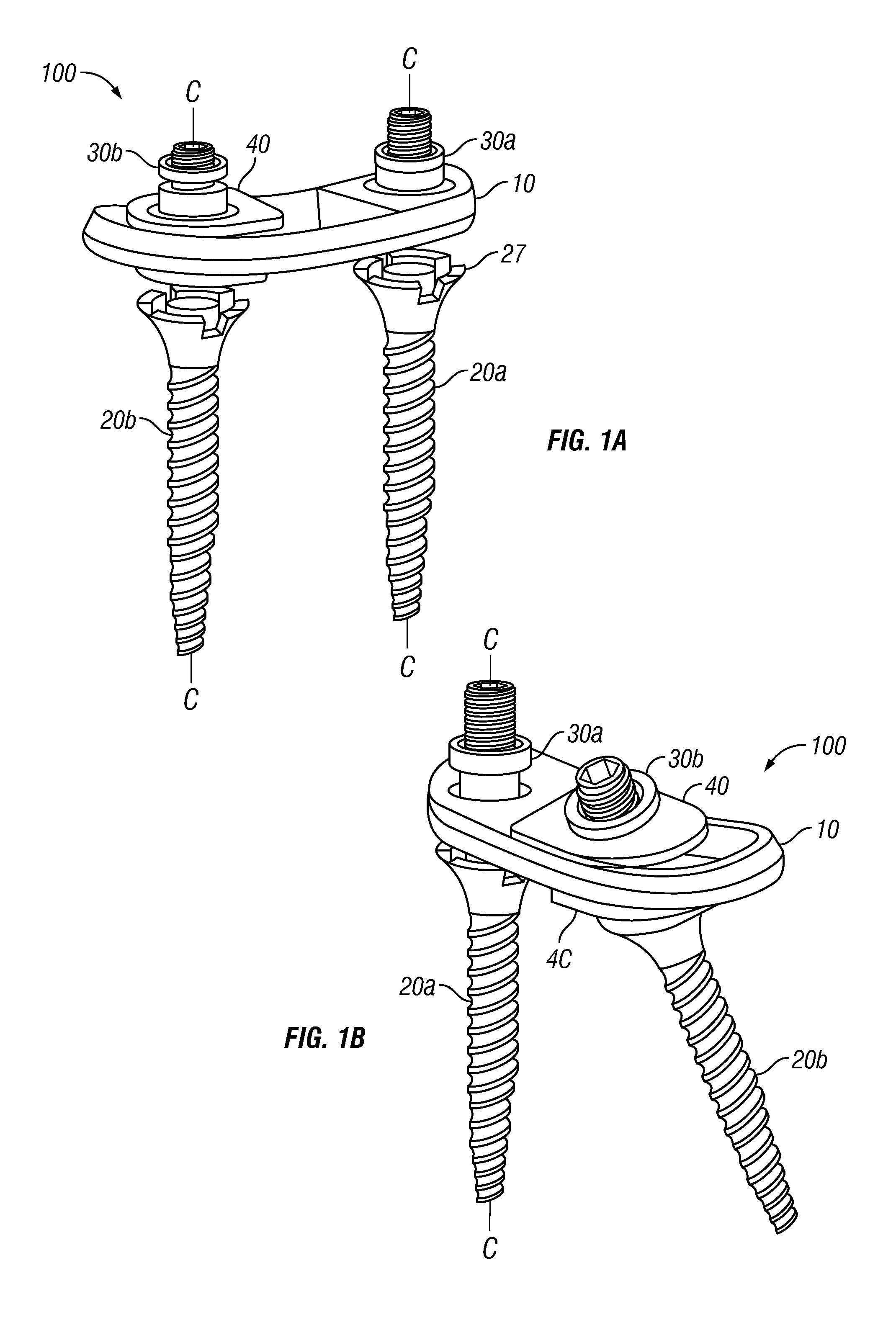

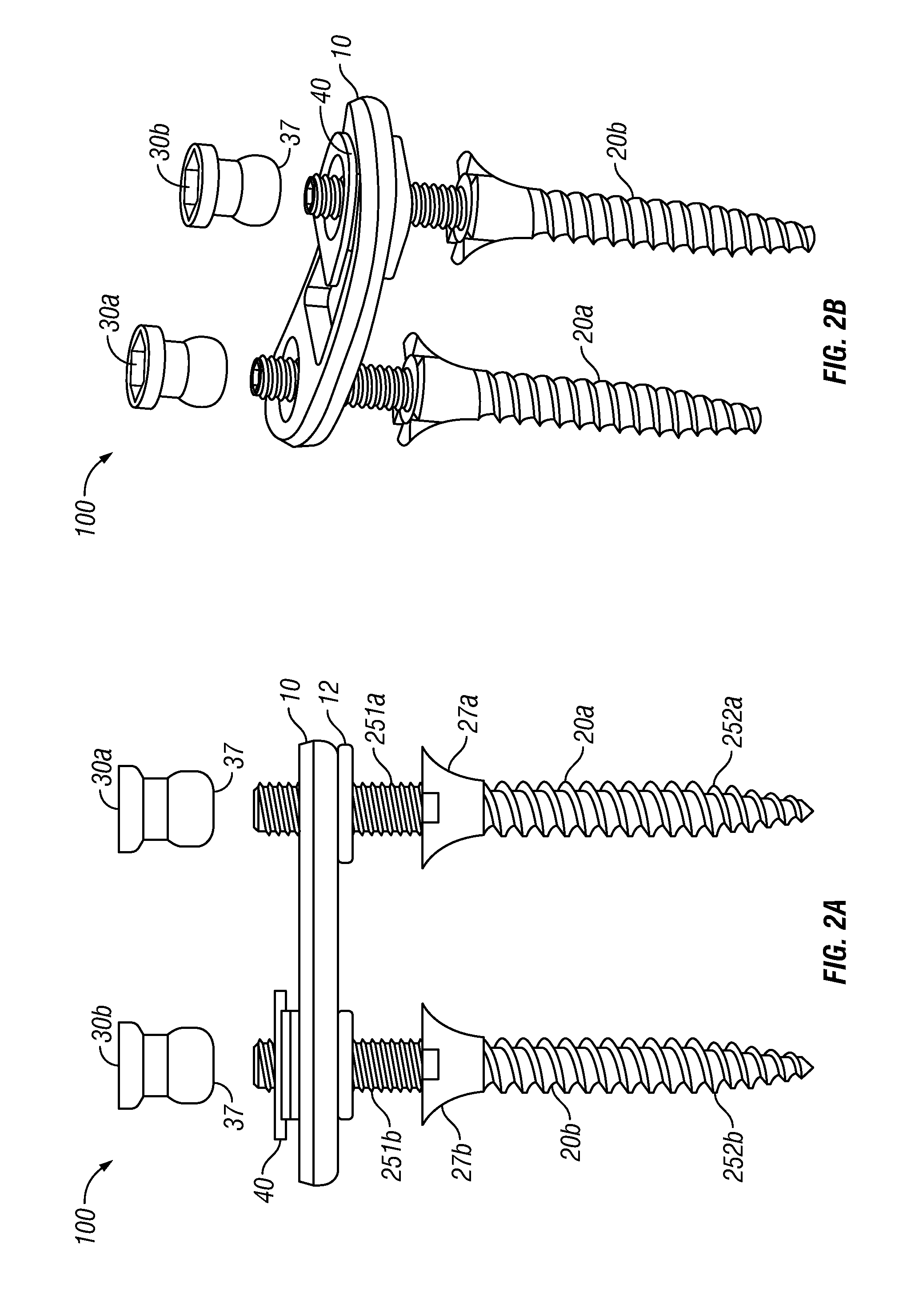

Facet joint fusion devices and methods

ActiveUS20060004367A1Improve abilitiesMinimally invasiveInternal osteosythesisJoint implantsTethered CordVertebra

A method for promoting fusion of and / or stabilizing a facet joint between two adjacent vertebrae comprises clamping the two adjacent vertebrae across the facet joint to apply a compressive force across the joint. Apparatus for promoting fusion of and / or stabilizing a facet joint comprises at least one cinchable tether and at least one locking member coupled with the tether for locking the cinched tether to maintain compressive force across the facet joint. The tether is adapted to extend through at least one hole through each of two adjacent vertebrae, across the facet joint.

Owner:ALAMIN TODD F +1

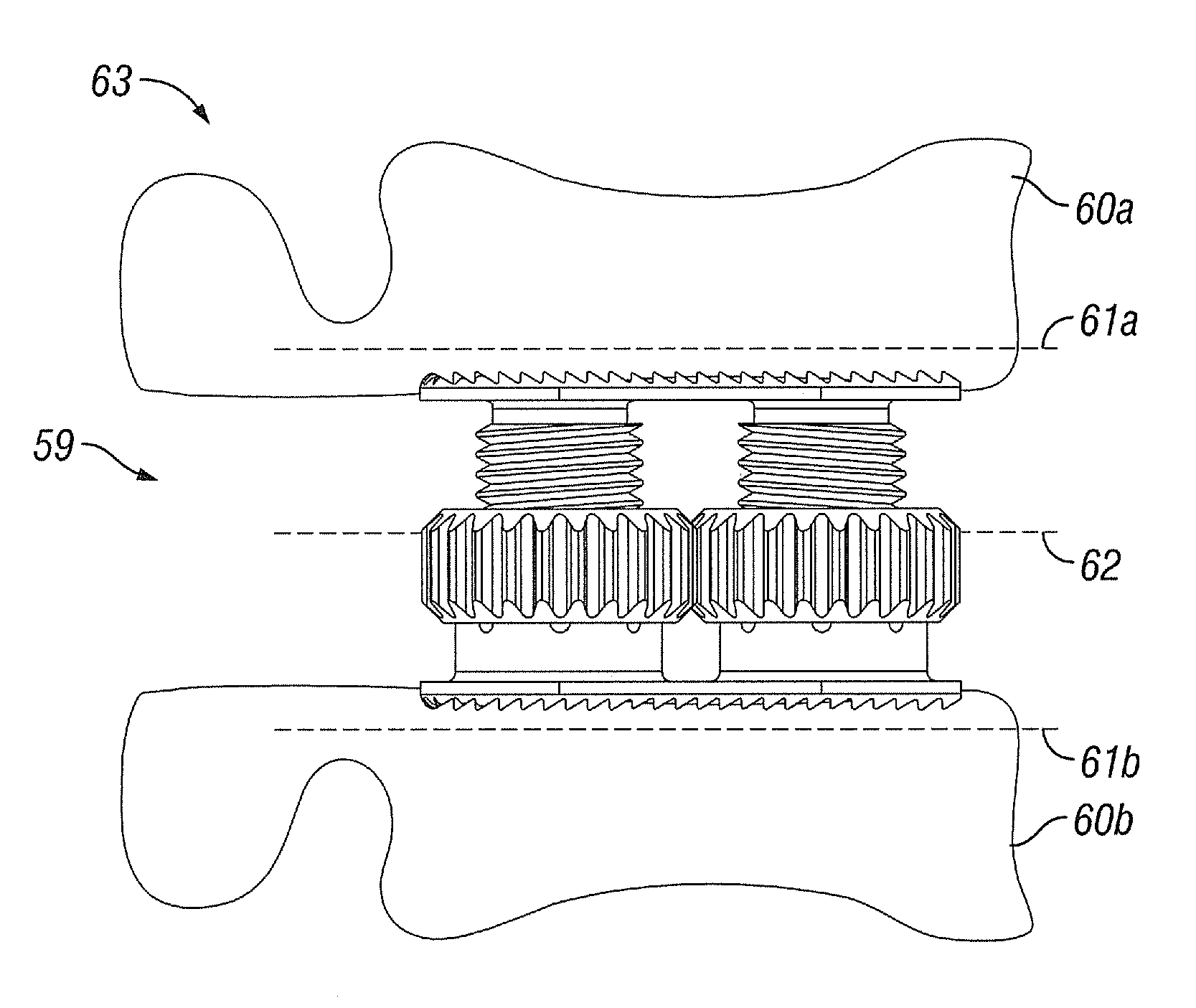

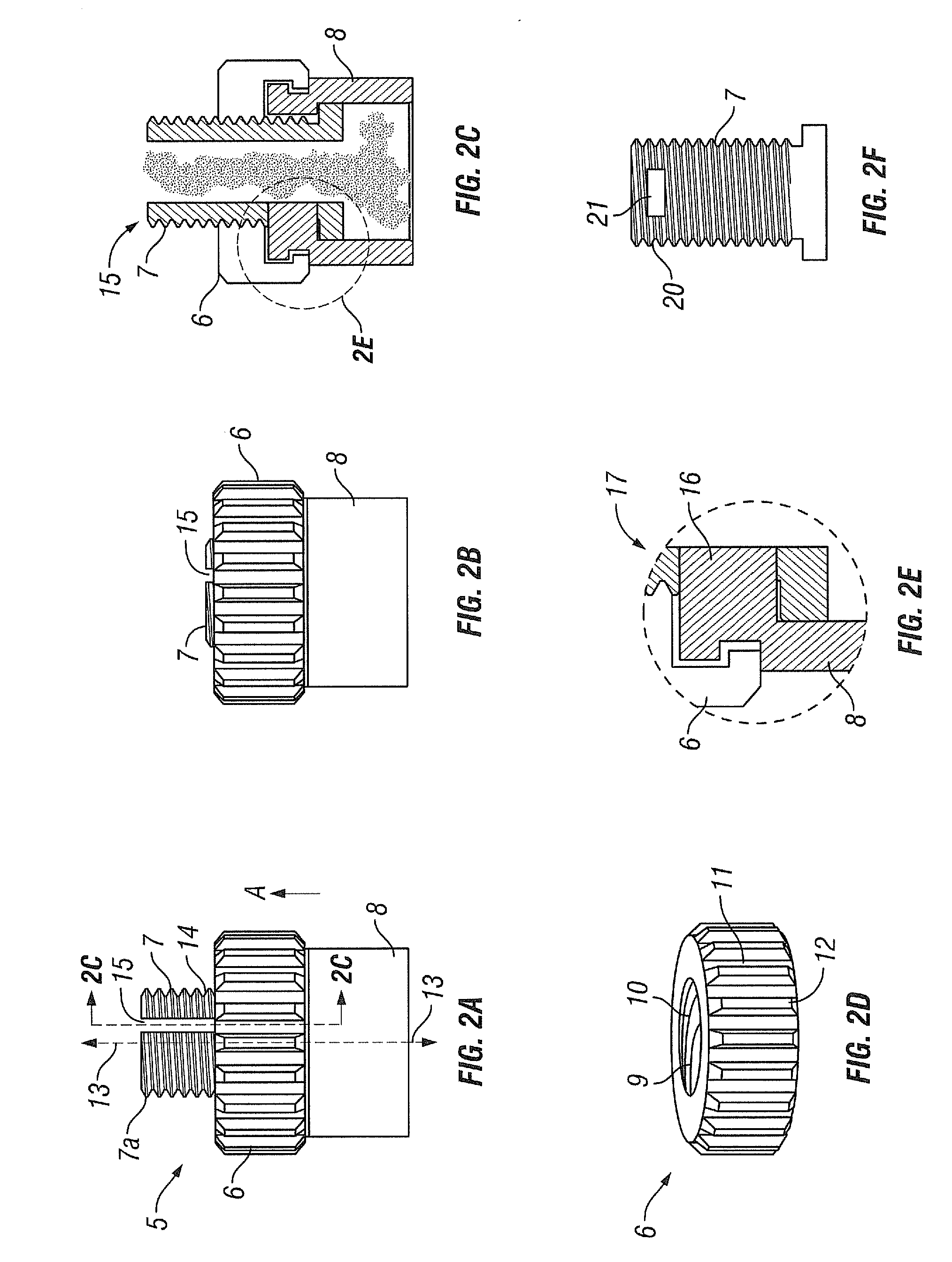

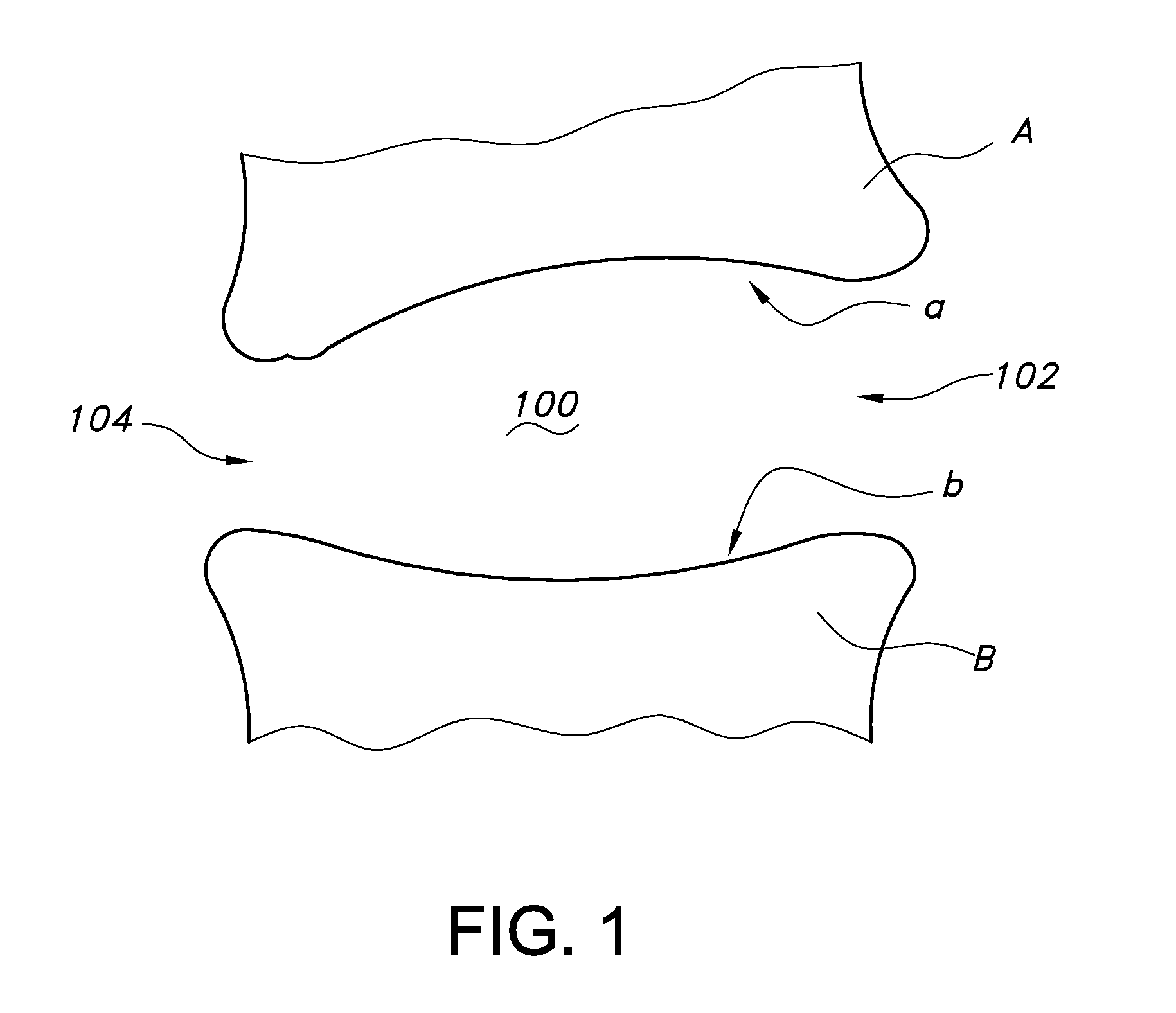

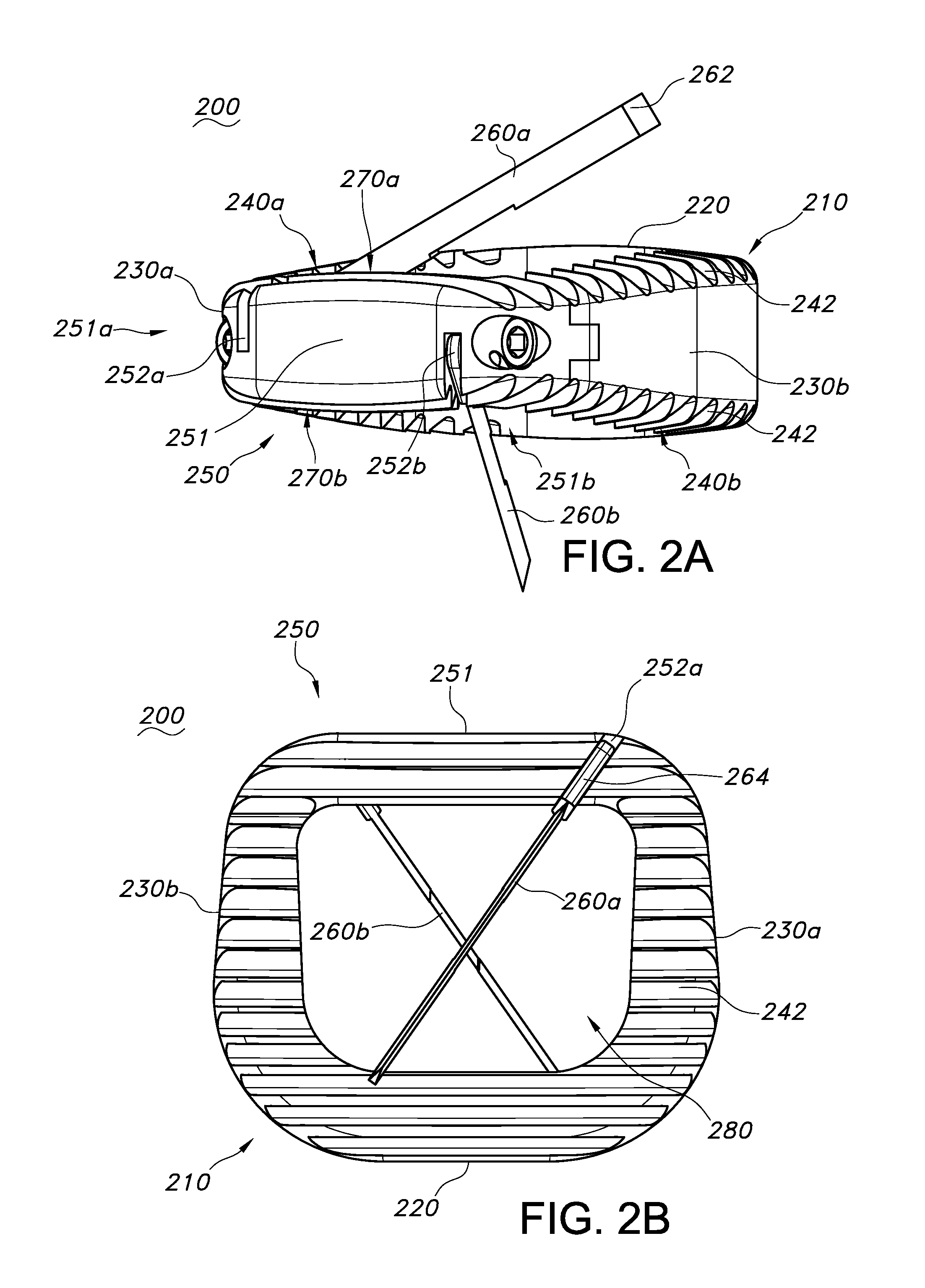

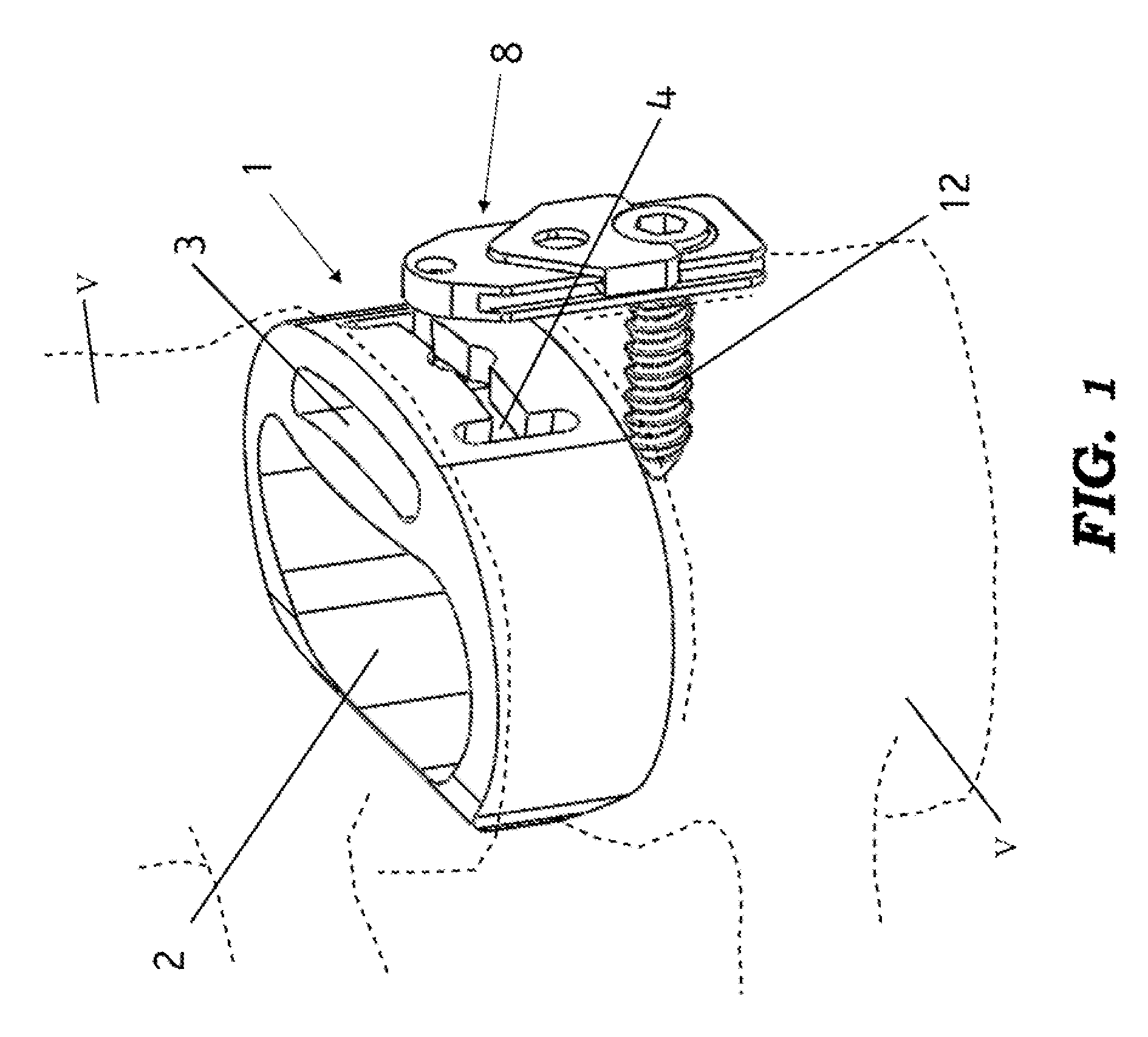

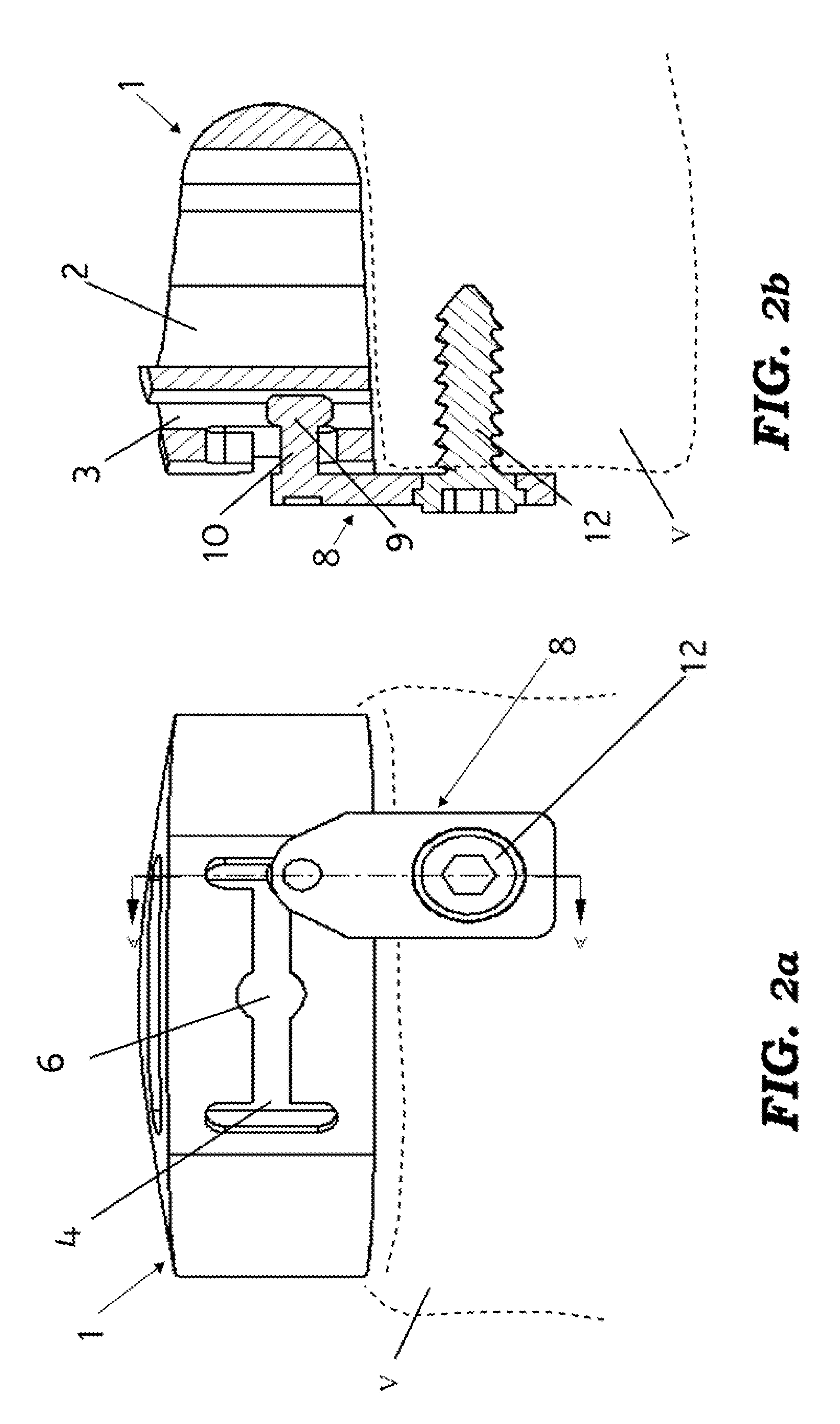

Expandable Spacer and Method For Use Thereof

ActiveUS20110172716A1Facilitates arthrodesisEasy to fuseBone implantJoint implantsArticular surfacesJoint arthrodesis

An expandable implant is disclosed having an adjustable height for insertion between two adjacent bony structures or joint surfaces, for example between two adjacent spinal vertebrae. The implant includes at least one gear associated with at least one threaded shaft. Rotation of the gear engages the threaded shaft to expand the implant. The implant can be inserted in a collapsed configuration and expanded in situ. The invention also provides methods for using the implant to facilitate arthrodesis or fusion of adjacent joint surfaces or spinal vertebrae.

Owner:GLOBUS MEDICAL INC

Hybrid dynamic stabilization

InactiveUS20090248077A1Preventing and slowing down effectAvoid relative motionSuture equipmentsInternal osteosythesisDiseaseVertebral level

A spine stabilization for the prophylactic treatment of adjacent level disease. A first vertebral level may be fused by advancing a pedicle screw in the first and second vertebrae and coupling the bone screws to a rigid portion of a rod. A conformable ligature may be passed around a non-pedicle portion of a third vertebra and coupled to a dynamic portion of the rod using a blocking body. The dynamic properties of the dynamic portion of the rod allow movement of the third vertebra relative to the first and second vertebrae to slow down or prevent Adjacent Level Disease in the third vertebra.

Owner:ZIMMER SPINE INC +1

Facet joint fusion devices and methods

InactiveUS7935136B2Easy to integrateEasy to fuseInternal osteosythesisJoint implantsSacroiliac jointBiomedical engineering

A method for promoting fusion of and / or stabilizing a facet joint between two adjacent vertebrae comprises clamping the two adjacent vertebrae across the facet joint to apply a compressive force across the joint. Apparatus for promoting fusion of and / or stabilizing a facet joint comprises at least one cinchable tether and at least one locking member coupled with the tether for locking the cinched tether to maintain compressive force across the facet joint. The tether is adapted to extend through at least one hole through each of two adjacent vertebrae, across the facet joint.

Owner:ALAMIN TODD F +1

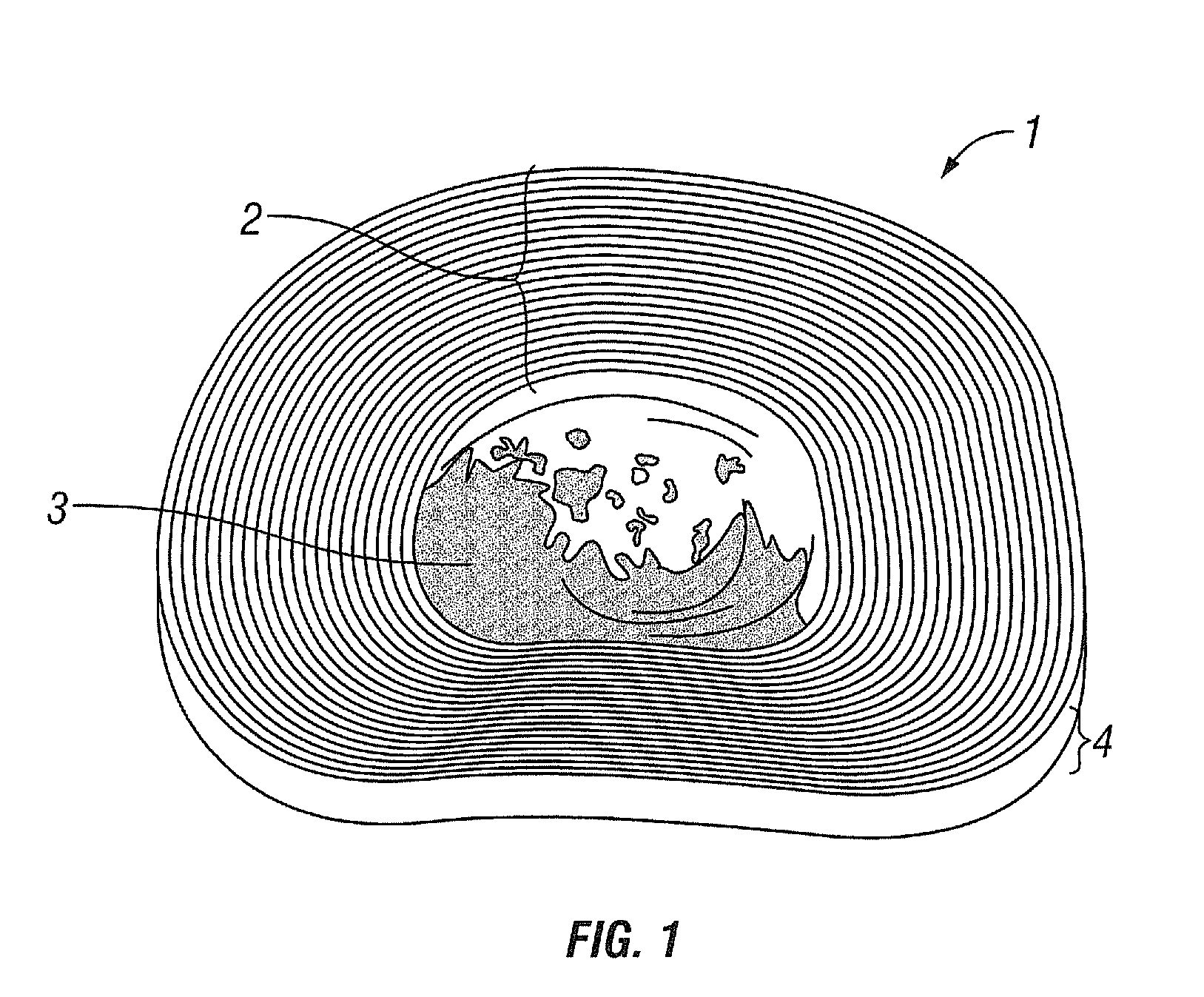

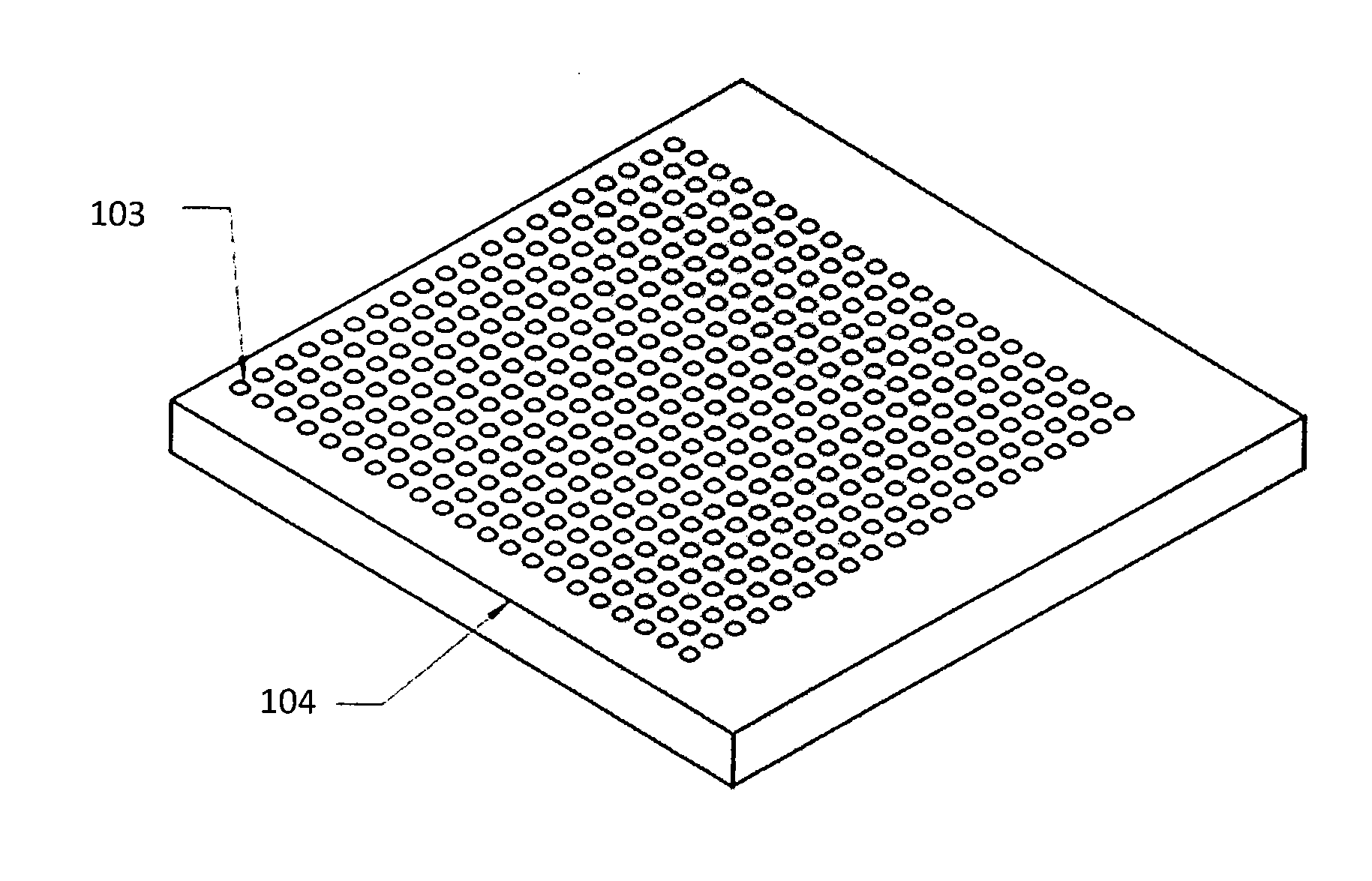

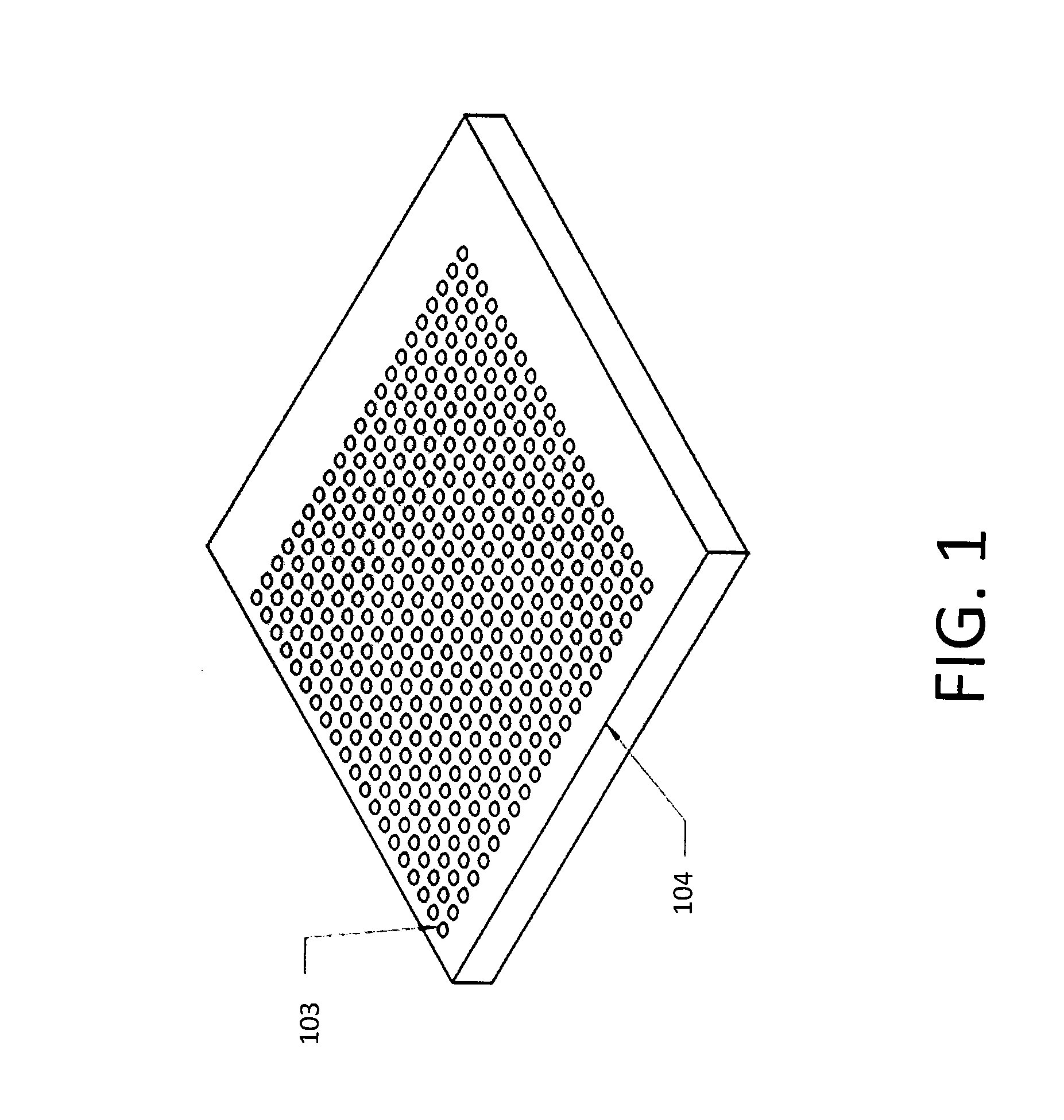

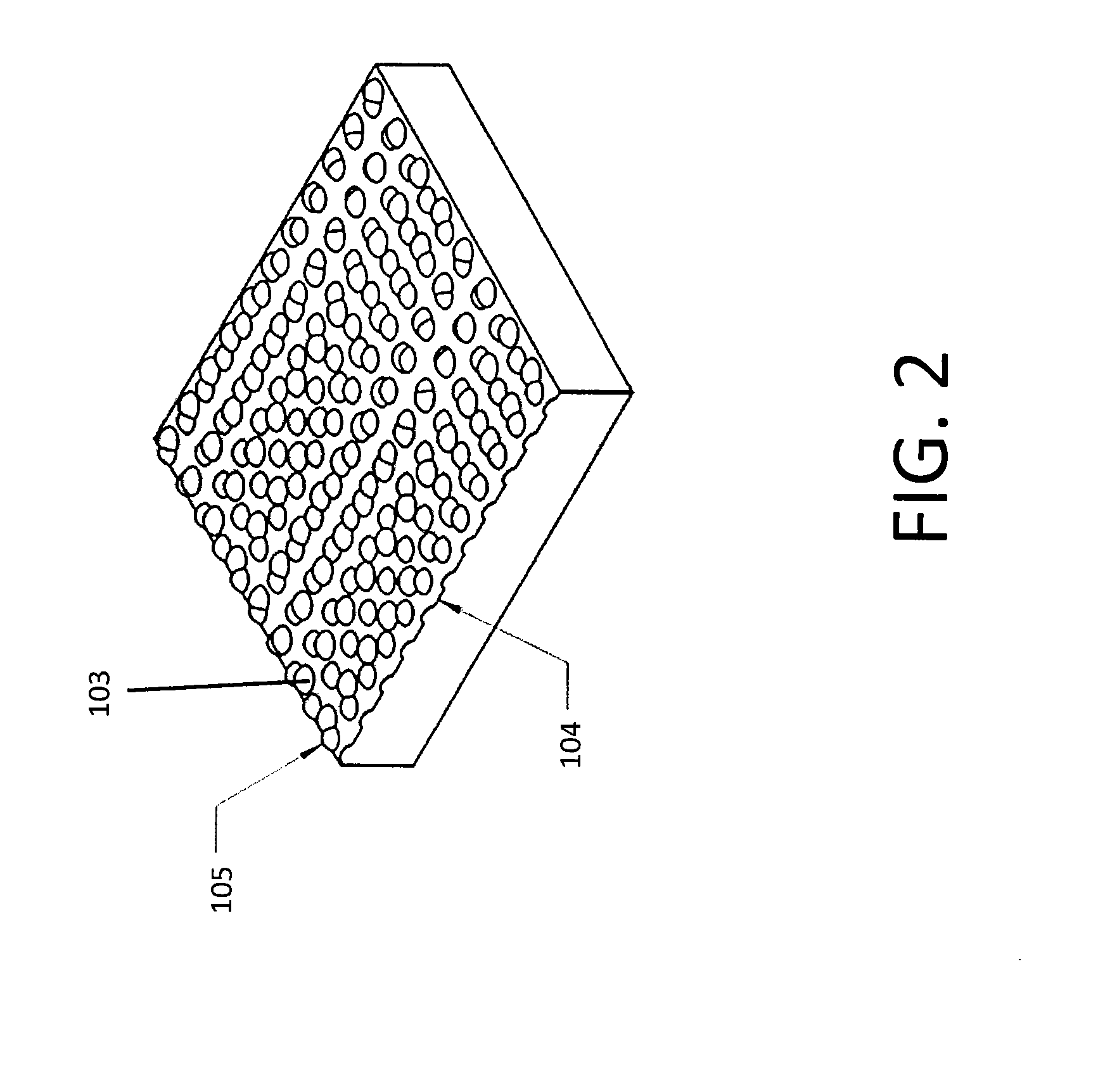

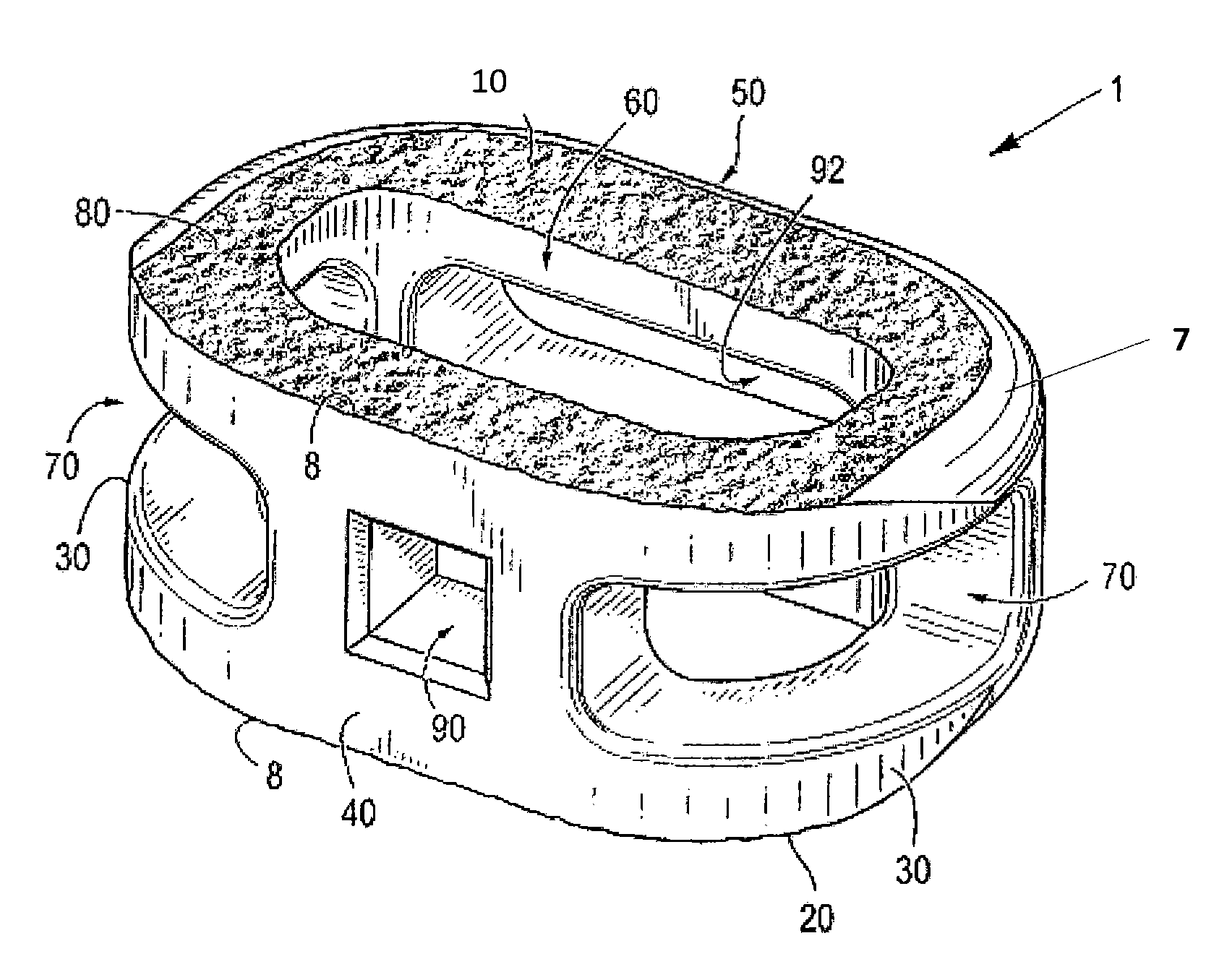

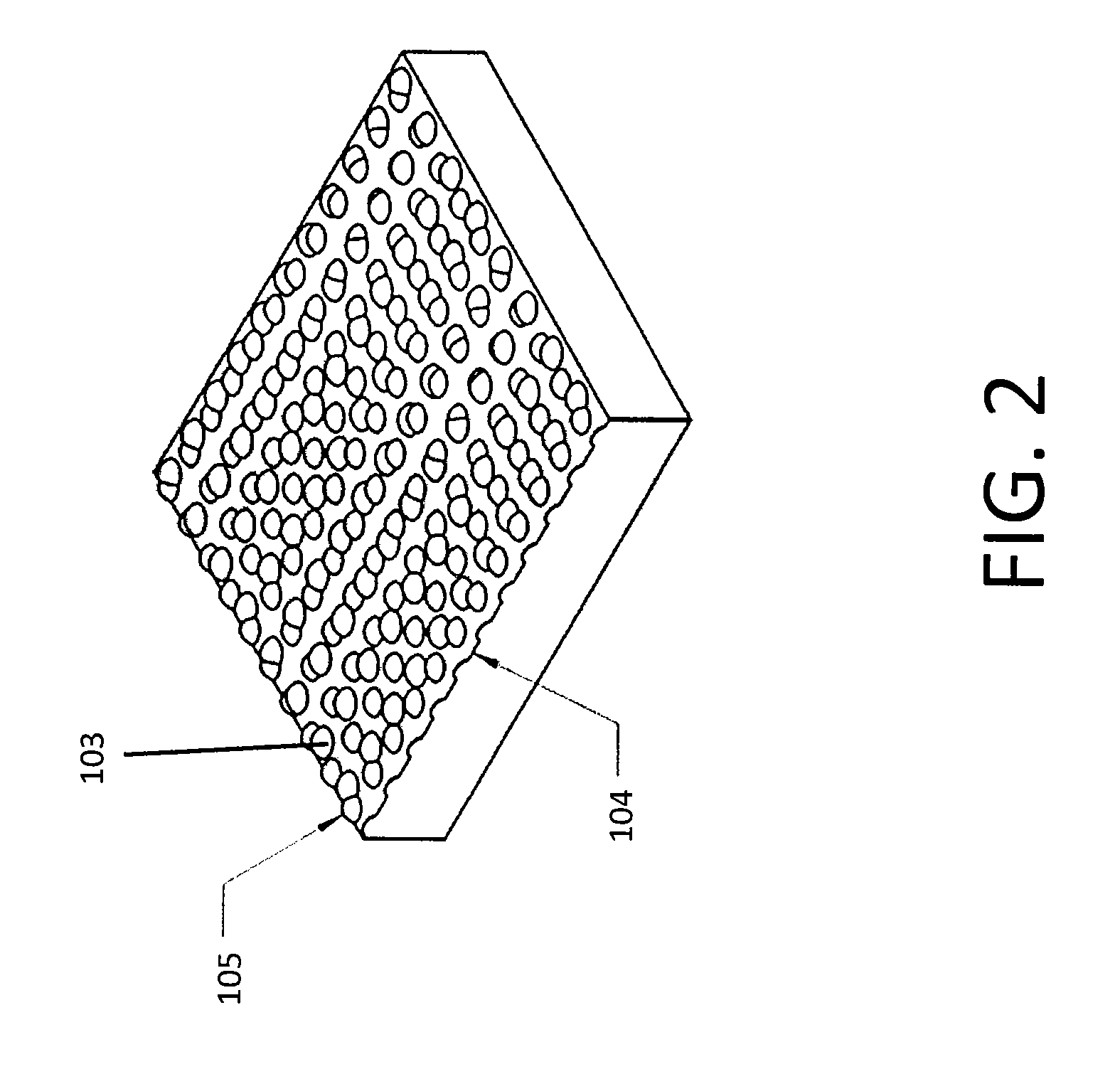

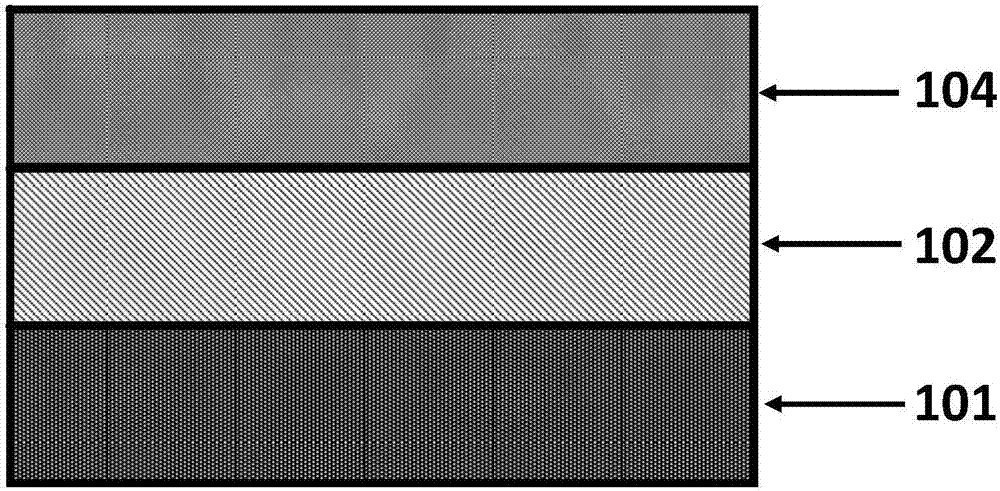

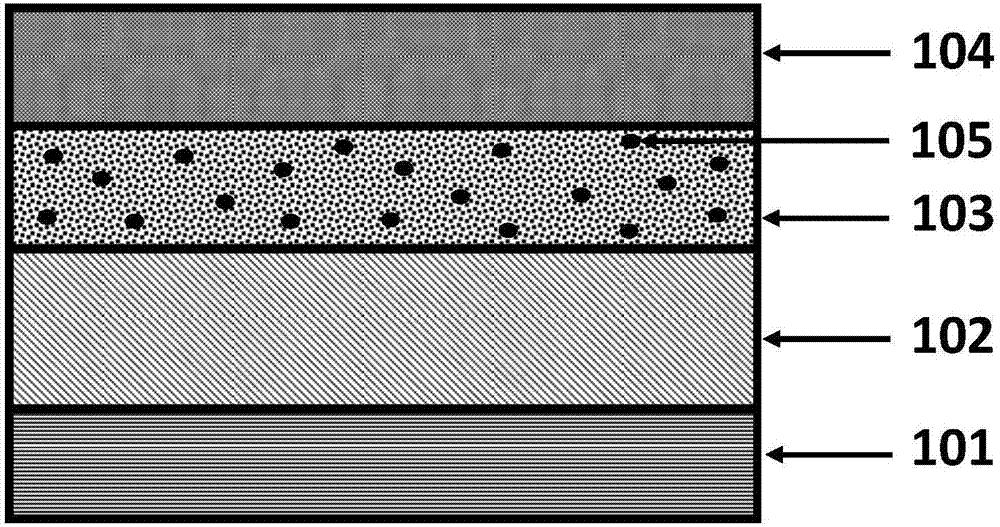

Processes for producing regular repeating patterns on surfaces of interbody devices

ActiveUS20120312778A1Sufficient bioactivityHigh positioning accuracyDecorative surface effectsVacuum evaporation coatingRough surfaceMedicine

Processes for producing interbody spinal implants having a body with a top surface, a bottom surface, opposing lateral sides, opposing anterior and posterior portions, a substantially hollow center, and a single vertical aperture; and optionally, one or two integration plates affixed to the body. The processes include applying an additive process, a subtractive process, or both processes to at least one surface of the interbody spinal implant to form a roughened surface topography having a regular repeating pattern. The roughened surface topography is specifically designed to provide certain frictional characteristics, load dispersion, and to influence the biological responses that occur during bone healing and fusion.

Owner:TITAN SPINE

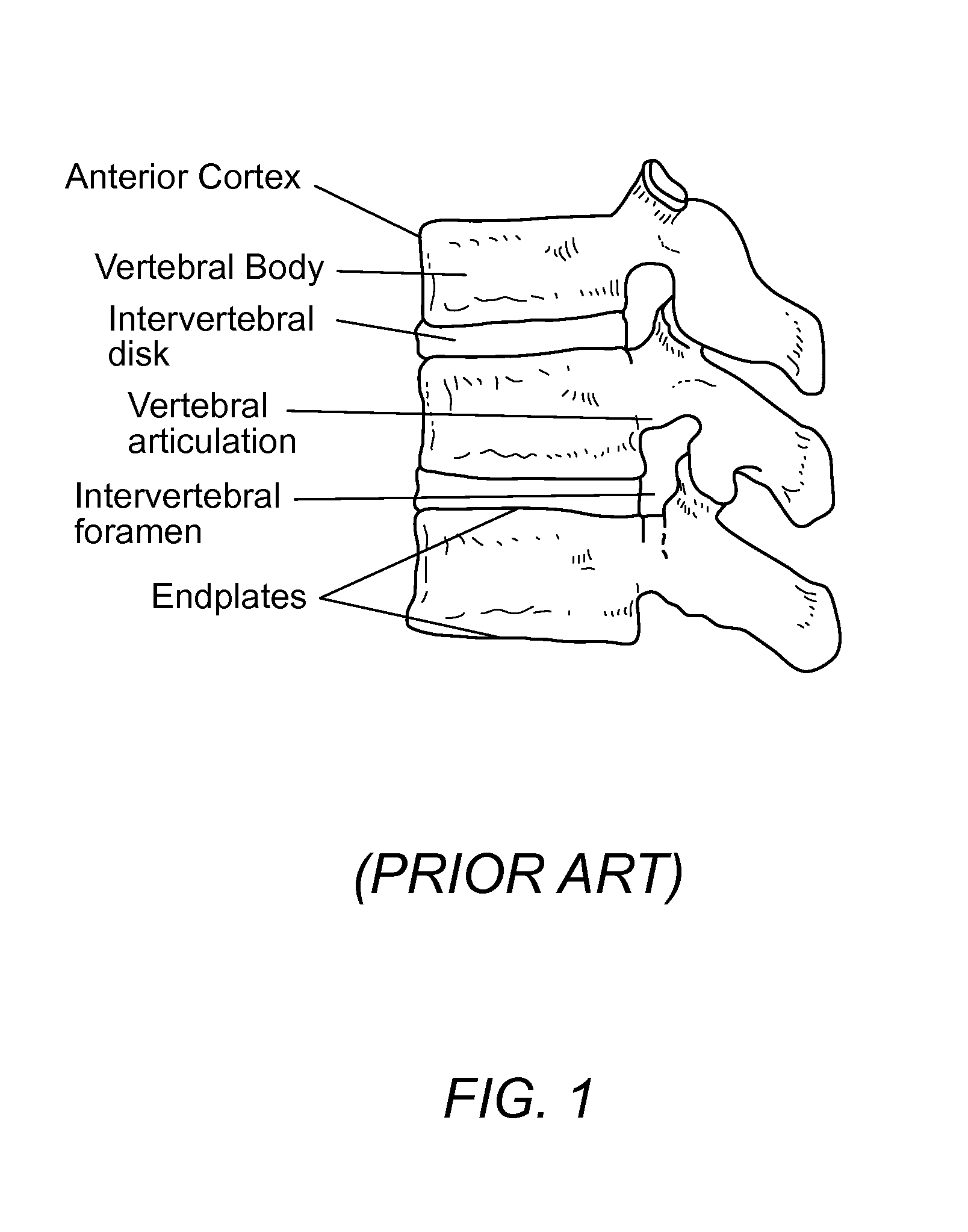

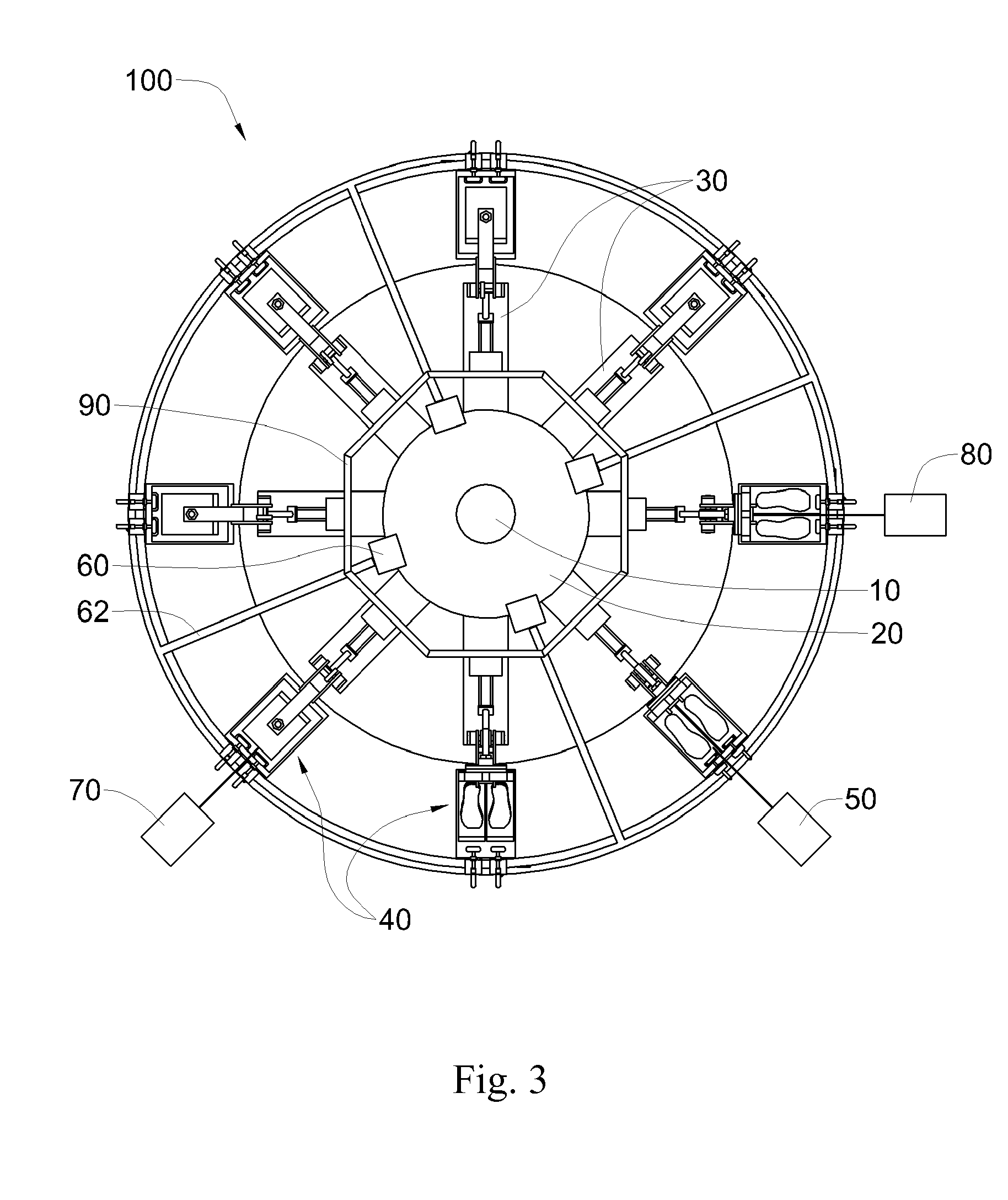

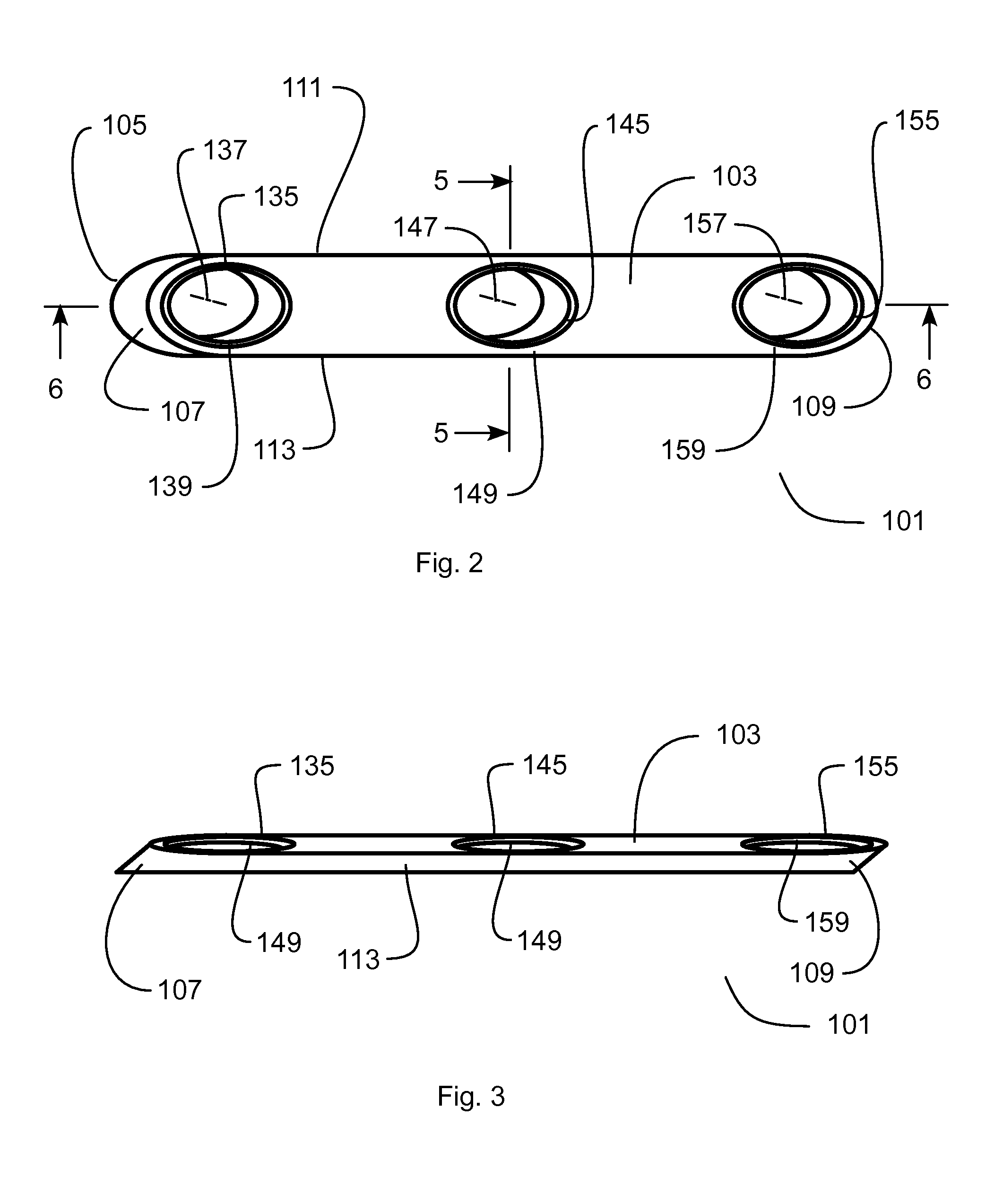

Anterior intervertebral spacer and integrated plate assembly and methods of use

InactiveUS8932358B1Easy to fuseImprove stabilityBone implantSpinal implantsAnterior cortexIntervertebral spaces

A precisely size matched intervertebral plate and spacer assembly for ensuring a tight fit within a disc space to promote spinal fusion, comprising: a “U-shaped” spacer configured to fit within the intervertebral space; and, a matching countersunk low profile “H-shaped” anterior plate joined perpendicularly to the spacer. The plate further comprises: a plurality of anchor members configured to attach to the junctions of the anterior cortex faces and the endplates; and, channels individually traversing through the anchor members for inserting screws into the vertebral bodies' cortical bone. The spacer comprises a hollow three-sided U-shaped member, comprising two opposing parallel side walls, and a perpendicular posterior wall, while lacking a superior, inferior, and anterior wall. The exterior walls of the plate and spacer are planar, while the interior walls of the spacer are curved to house a precisely fitting cylindrical graft, or other insert such as DBM, bone dust, bone paste, bone dowel with direct contact to the endplates to promote fusion.

Owner:NEHLS DANIEL

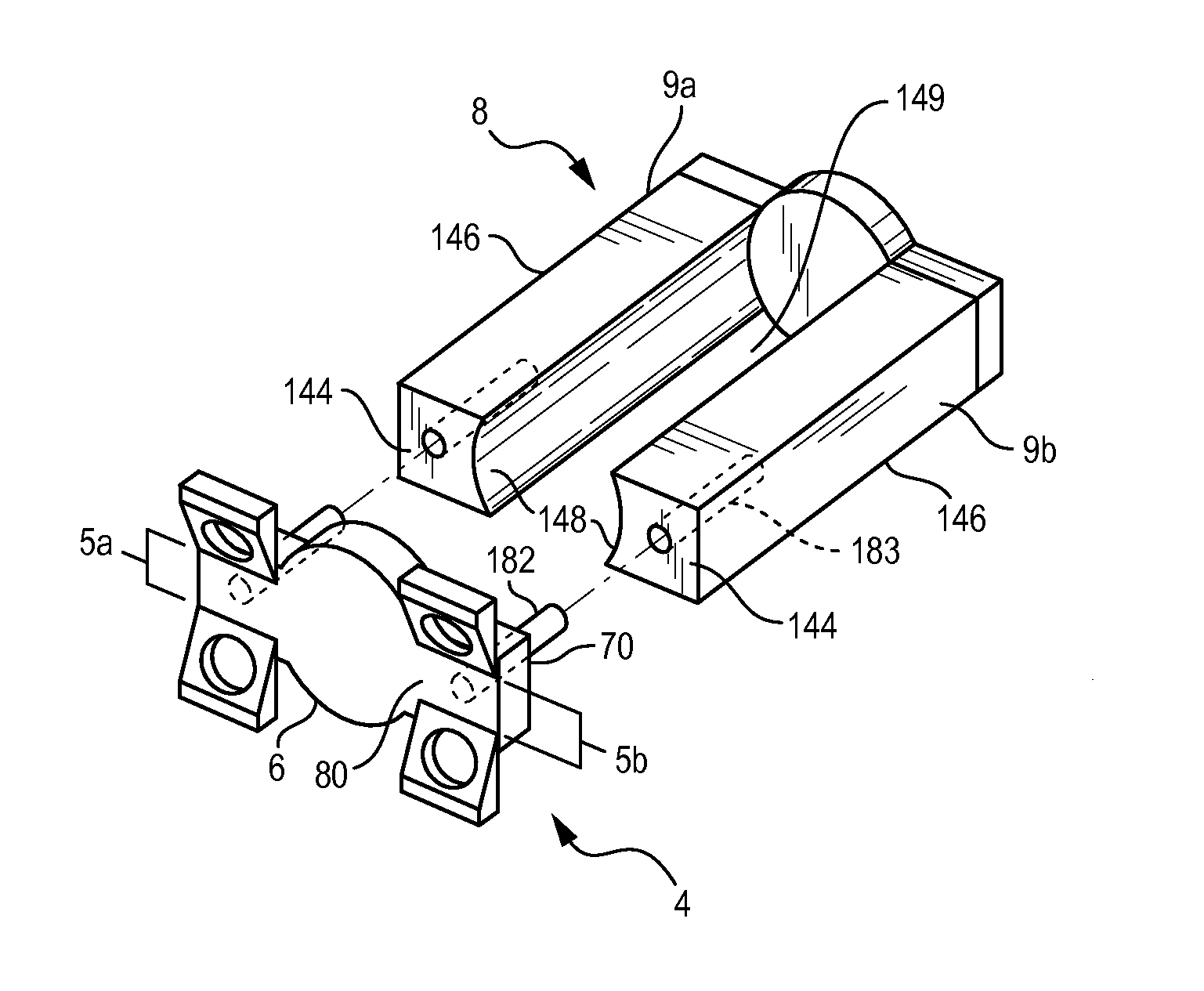

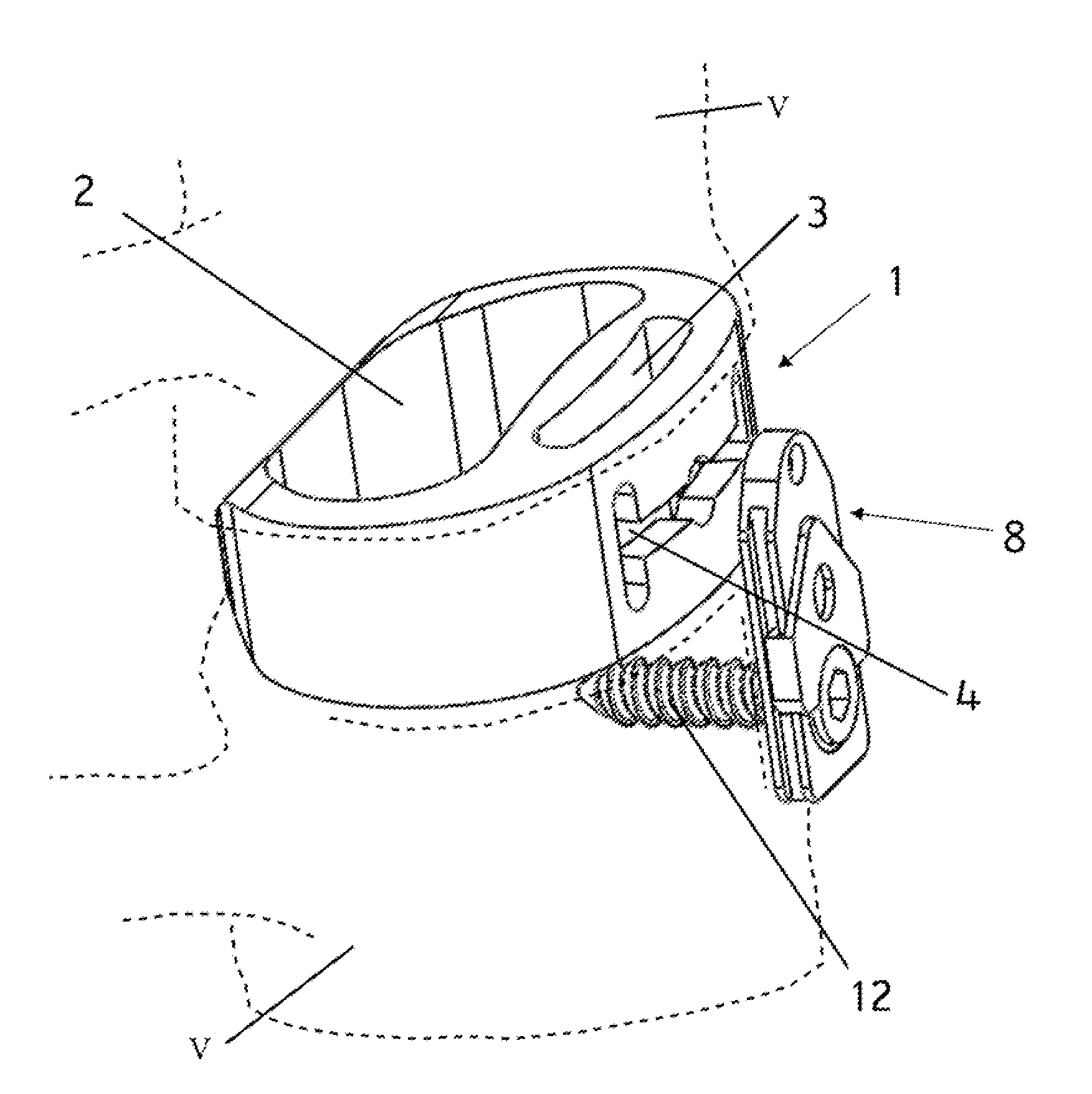

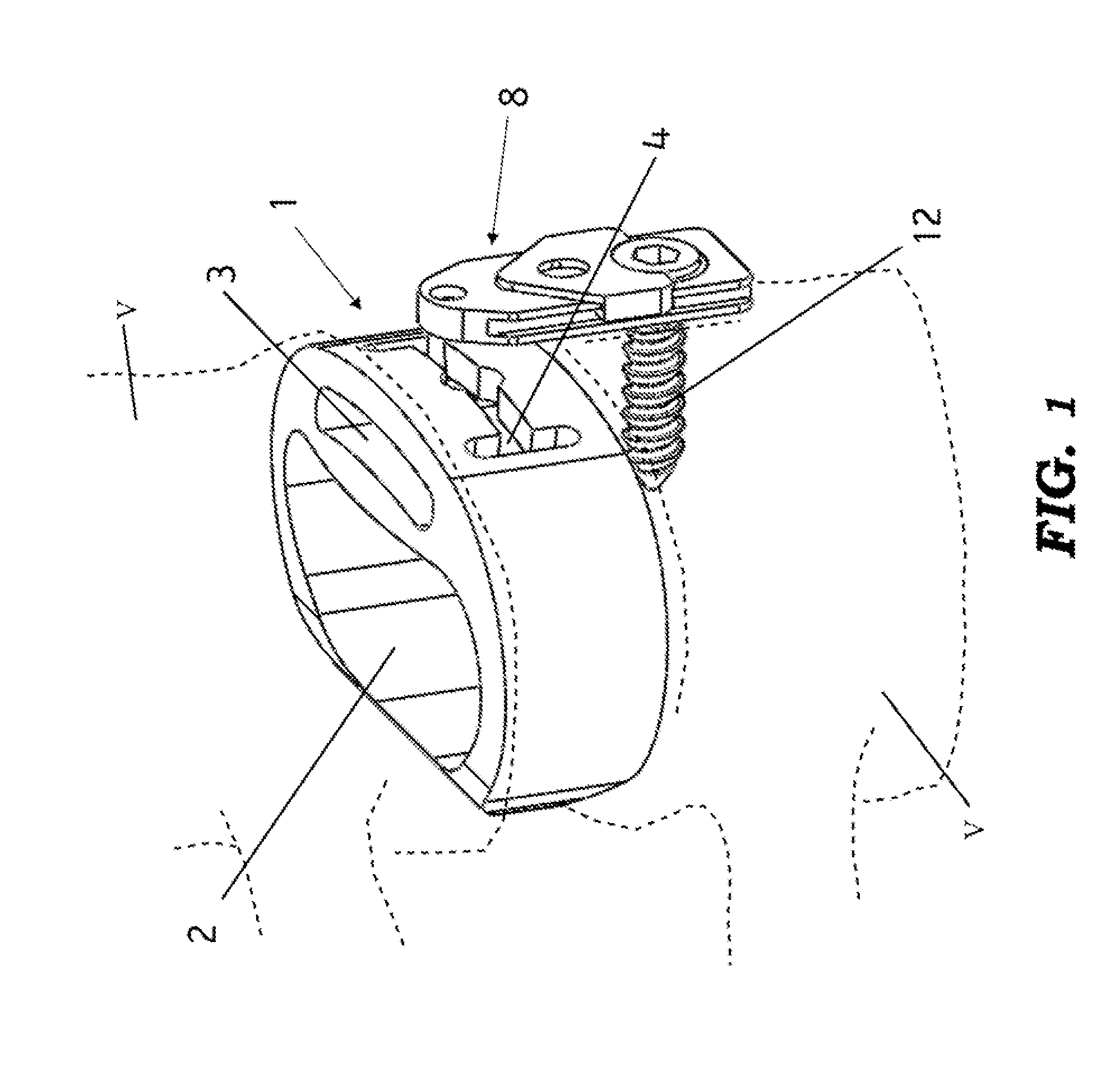

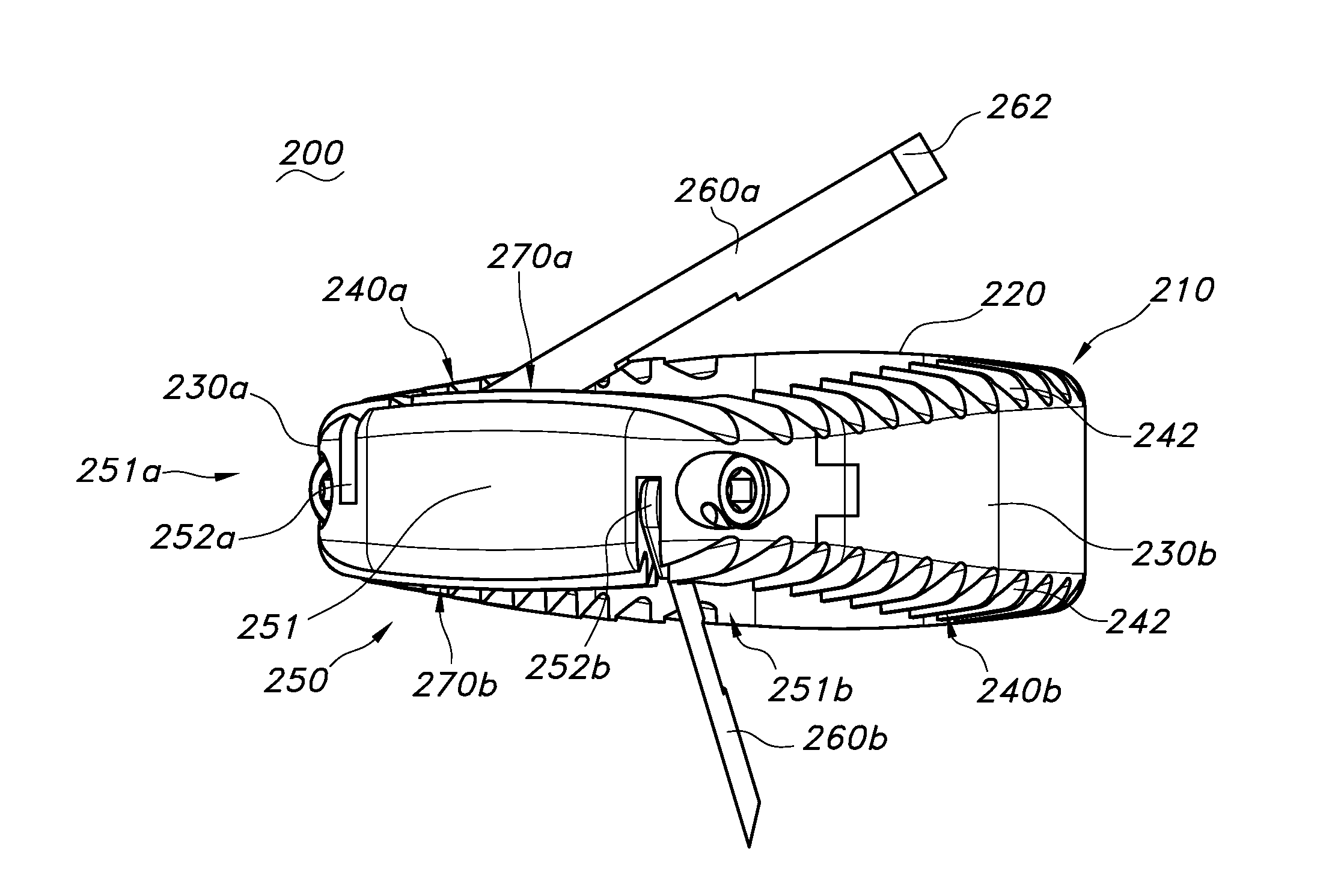

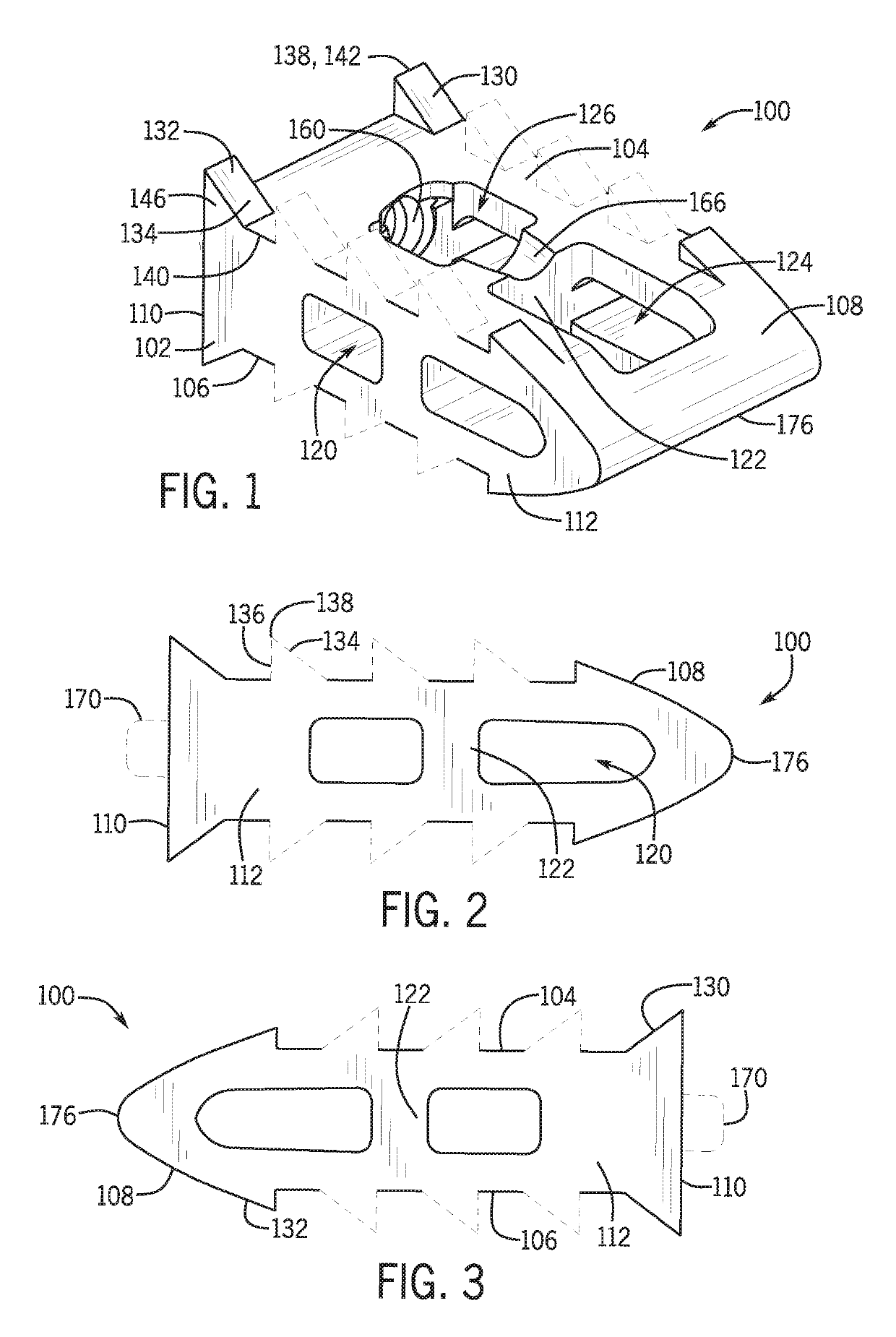

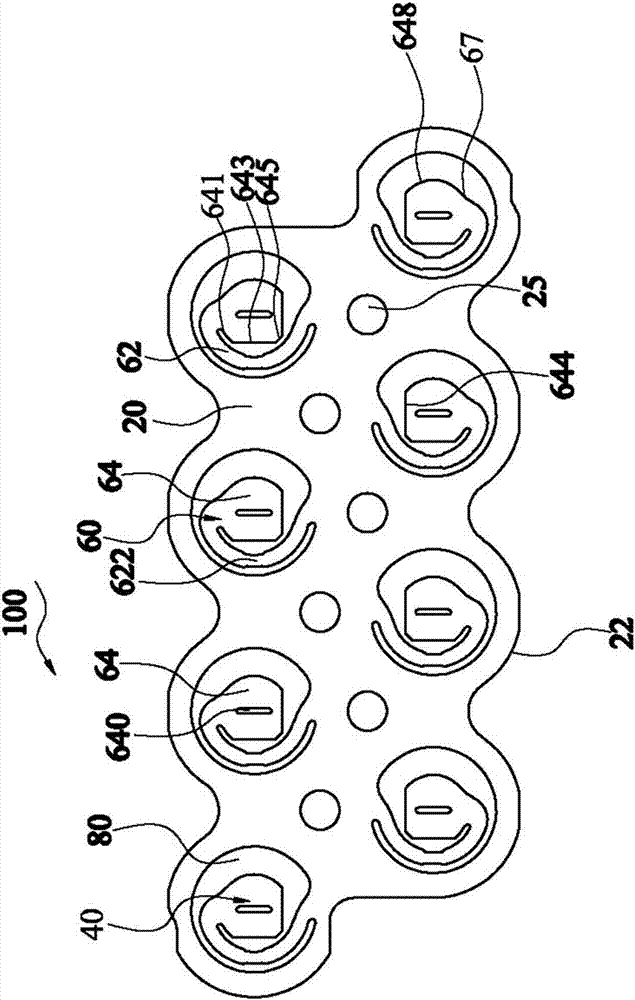

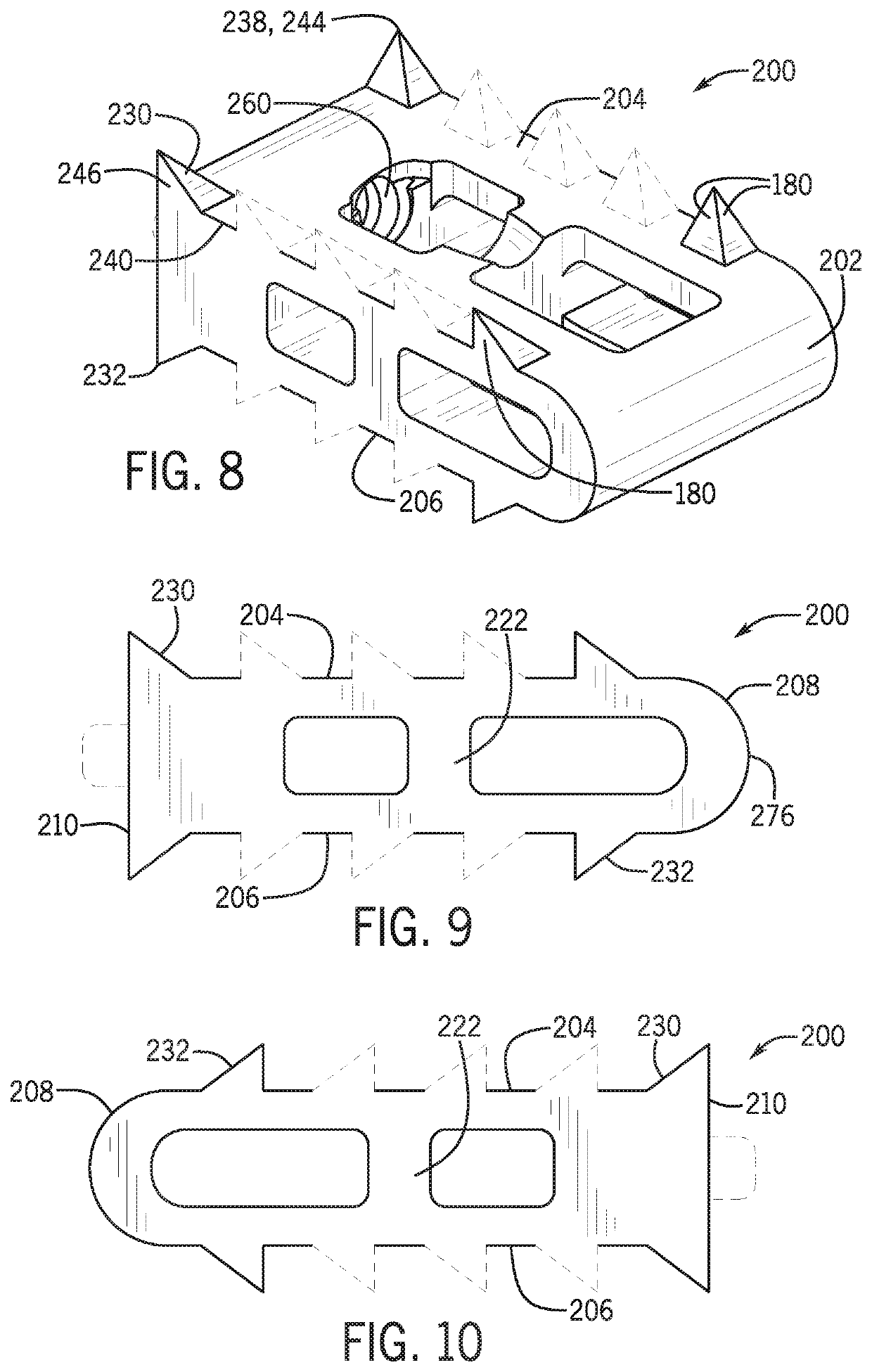

Dynamic interbody cage anchor system

ActiveUS20120143336A1Promote bone growthEasy to fuseBone implantSpinal implantsAnterior surfaceIntervertebral space

A system and method of securing an intervertebral fusion cage within the intervertebral space between adjacent vertebra in which one or more slots are provided in an anterior surface of the cage each extending from an oversized aperture. A retention plate having a post and enlarged head is advanced into each slot via the oversized aperture and captured therein. The post is advanced to the terminal end of the plate and secured to vertebral body at its distal end by a bone screw. A locking clip is slideably positioned on the retention plate to prevent withdrawal of the bone screw. The slots preferably extend to margins of the anterior surface of the cage in, for example, the pattern of an “X” or an “H”. Sliding of the posts in the slots prevents the system from carrying the vertebral load (load shielding) and permits reduction in the intervertebral space to promote bone growth and fusion by graft material retained in the spacer.

Owner:AFLATOON KAMRAN

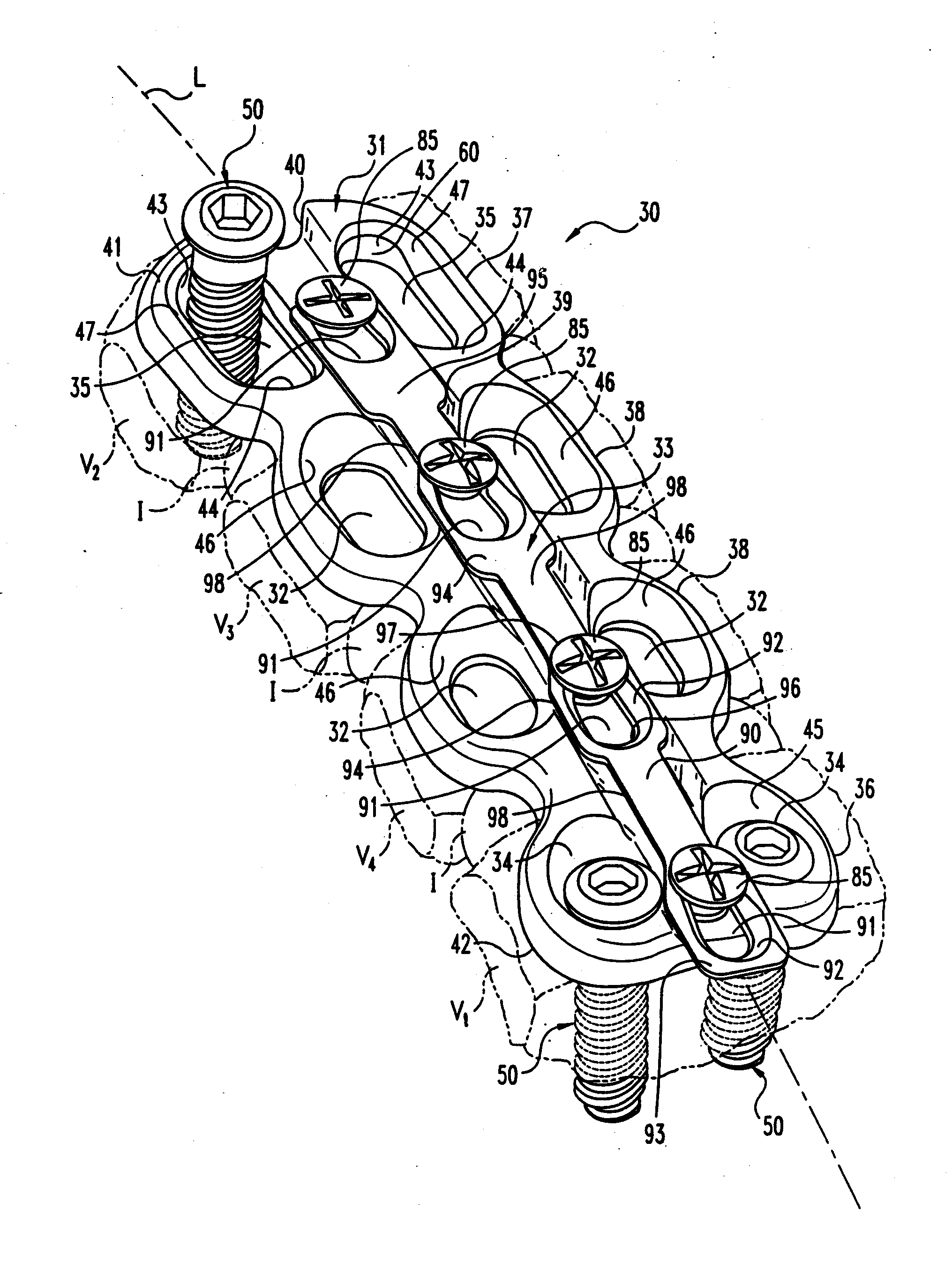

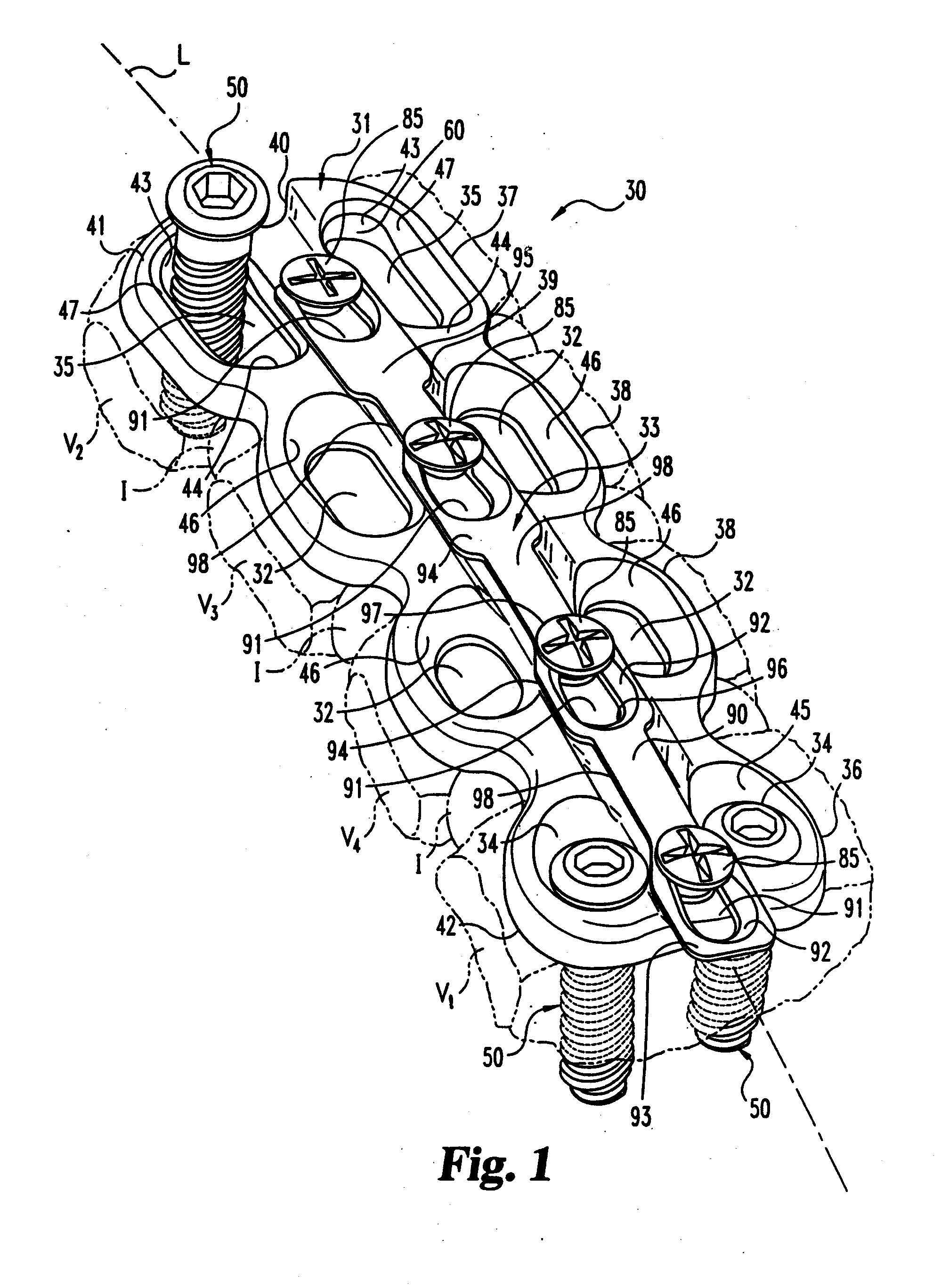

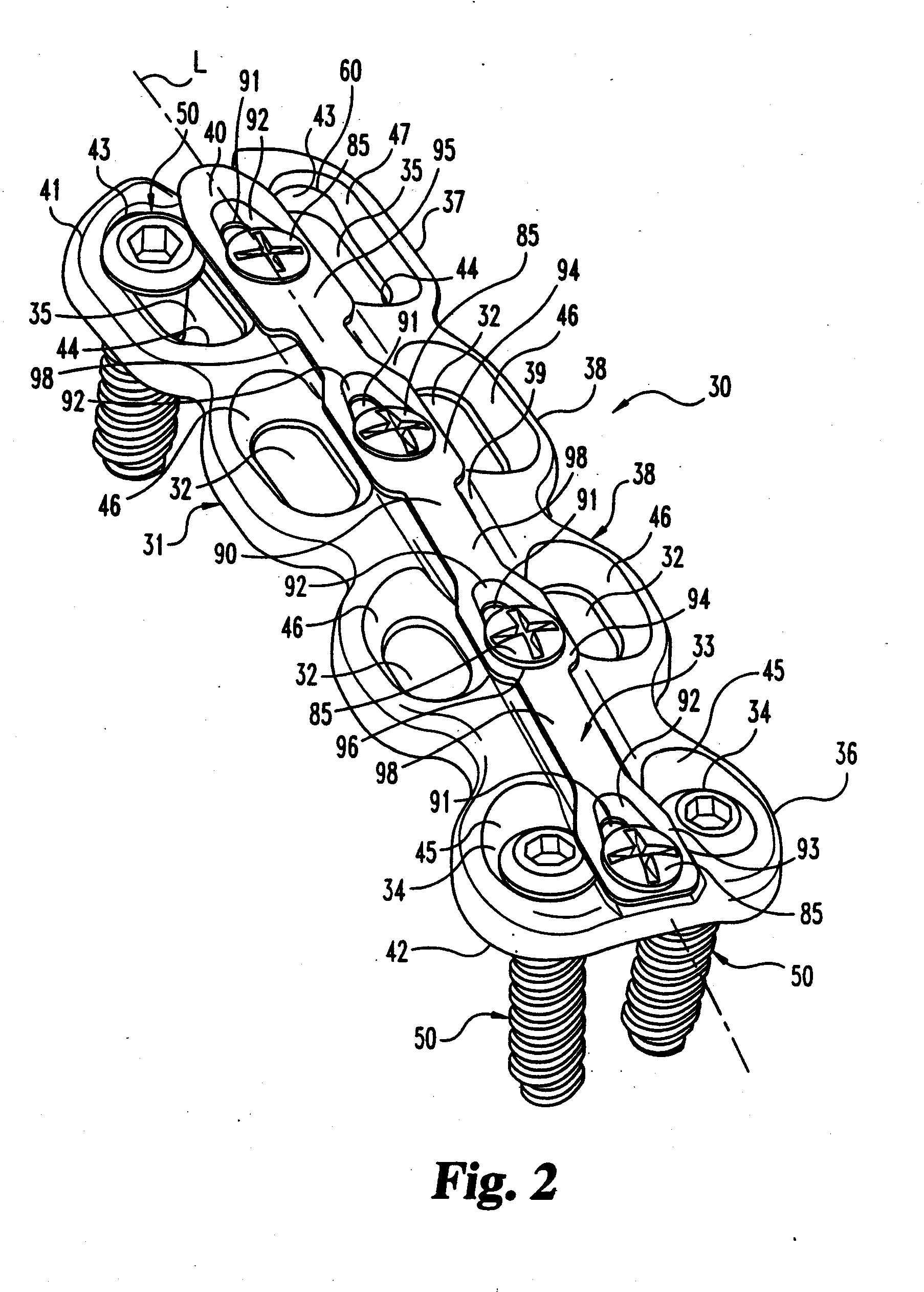

Anterior cervical plating system and method

InactiveUS20070203492A1Easy to fuseEasy to incorporateInternal osteosythesisBone platesSpinal columnAnterior approach

The present invention is directed to a system for anterior fixation of the spine that utilizes an elongated fixation plate. The plating system stabilizes the spine and promotes fusion and incorporation of a graft or implant in a portion of the spinal column. In one aspect of the invention, the fixation plate has a first end with a pair of holes. Bone screws extend through the holes to rigidly secure the plate to a first vertebra. The second end of the plate is provided with a pair of slots through which bone screws extend for engagement with a second vertebra. The screws extending through the slots are translatable in the slot to maintain compression of the spinal column portion. The plating system includes a retainer assembly that prevents screw back out. Methods and instruments relating to the plating system are also described.

Owner:WARSAW ORTHOPEDIC INC

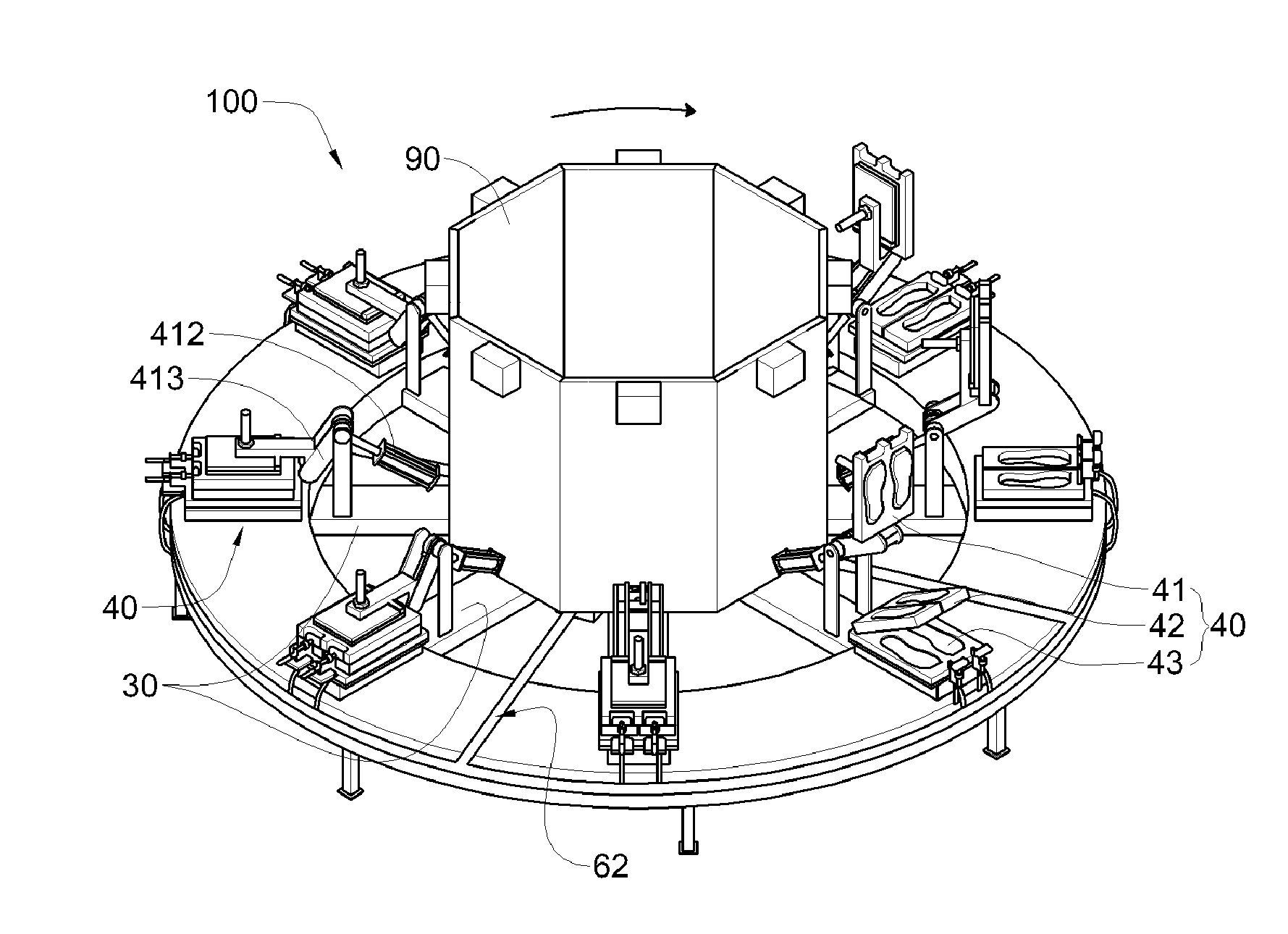

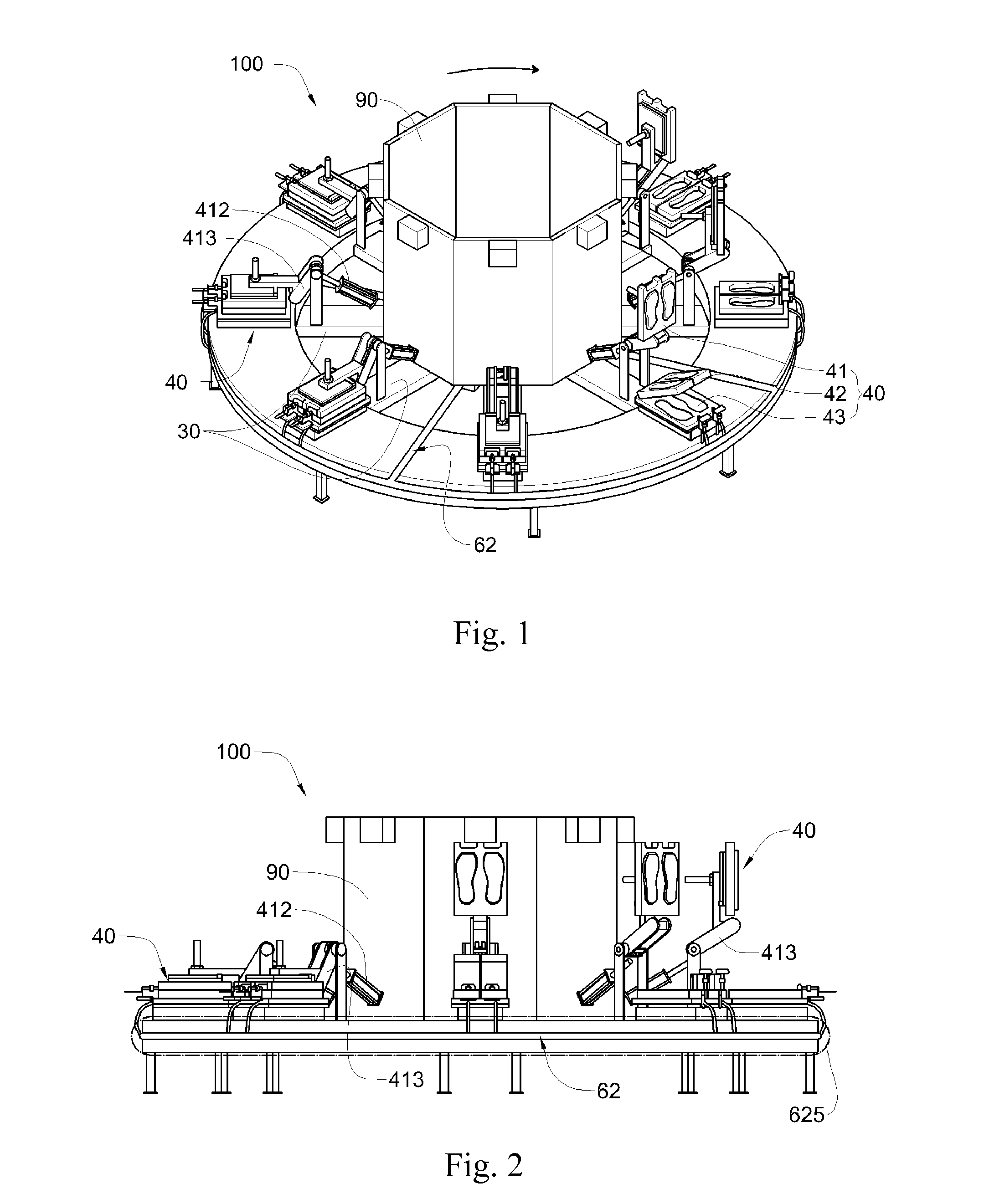

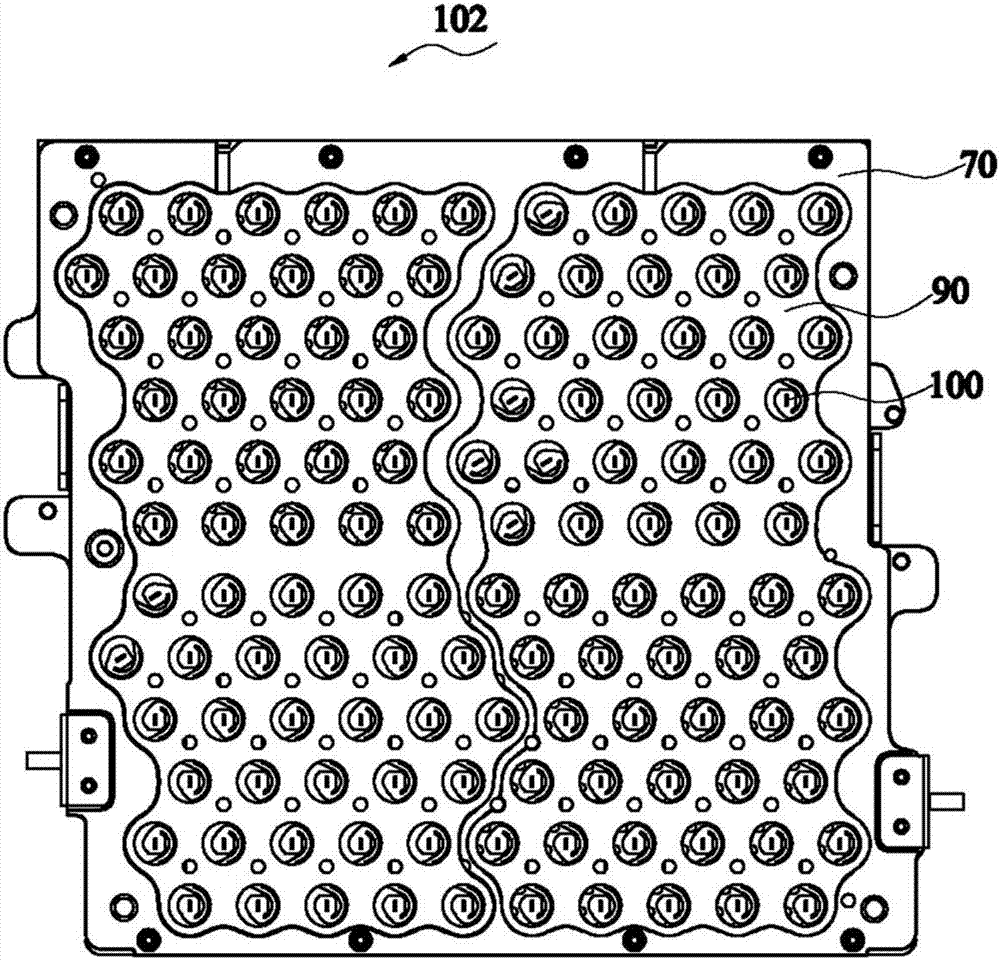

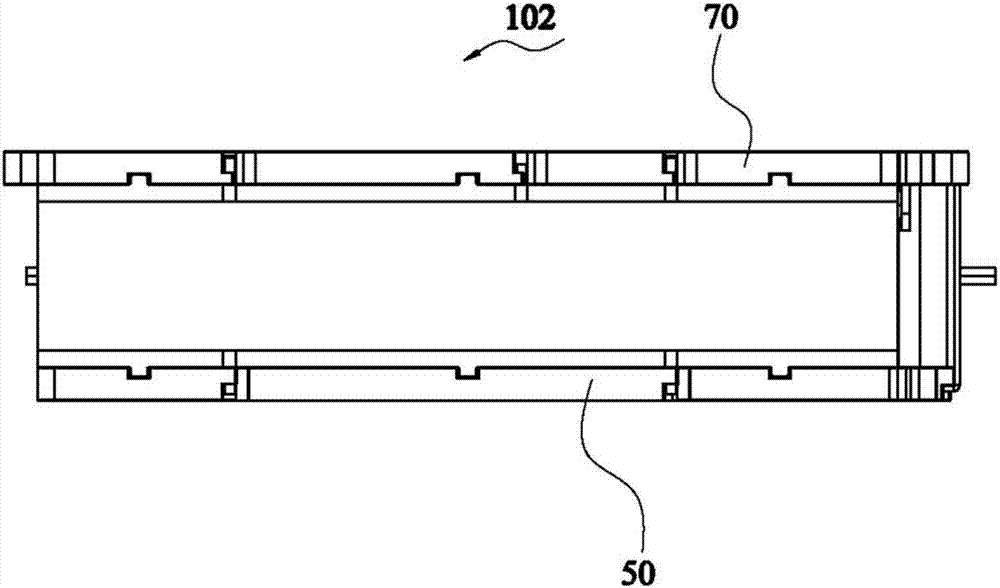

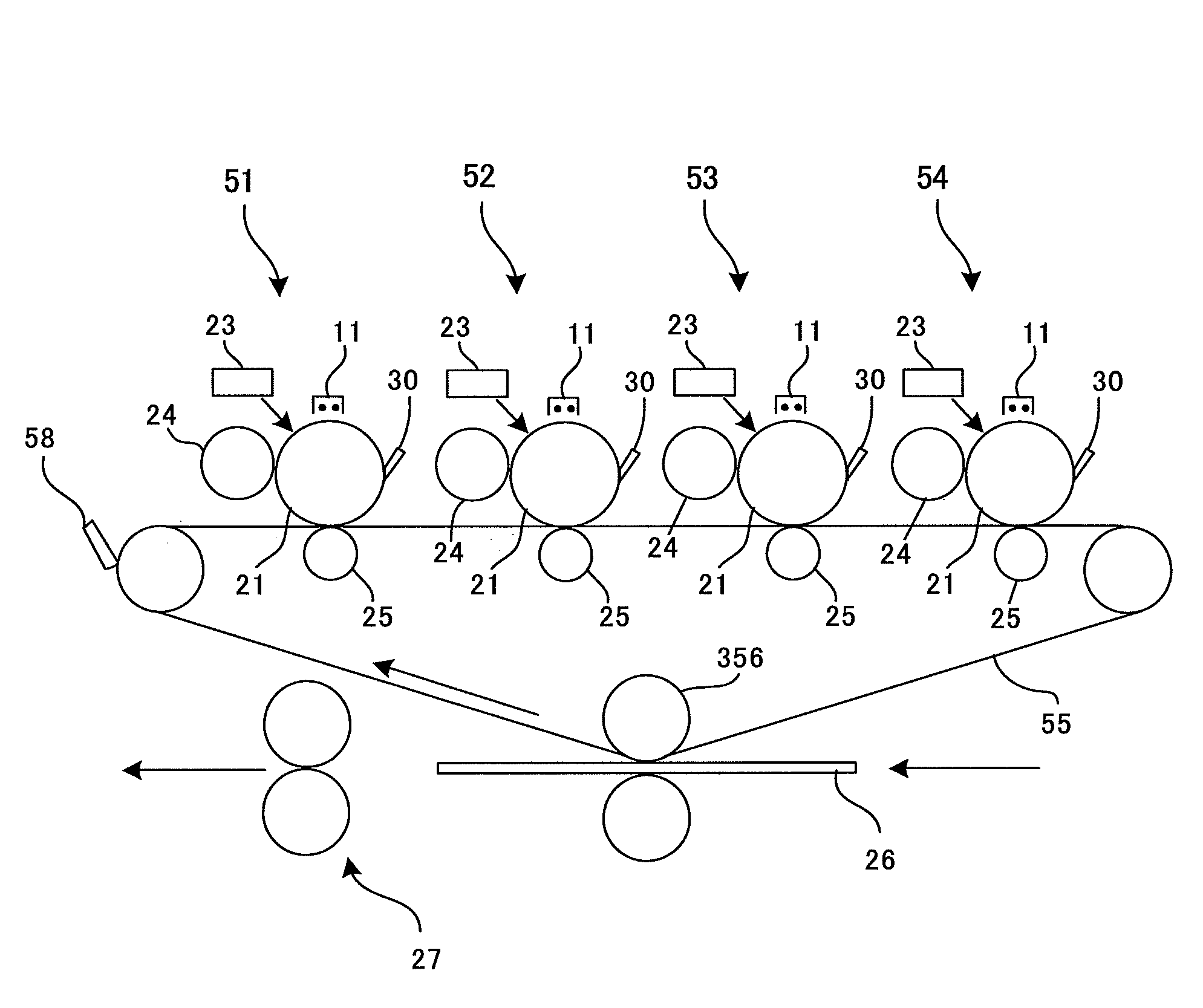

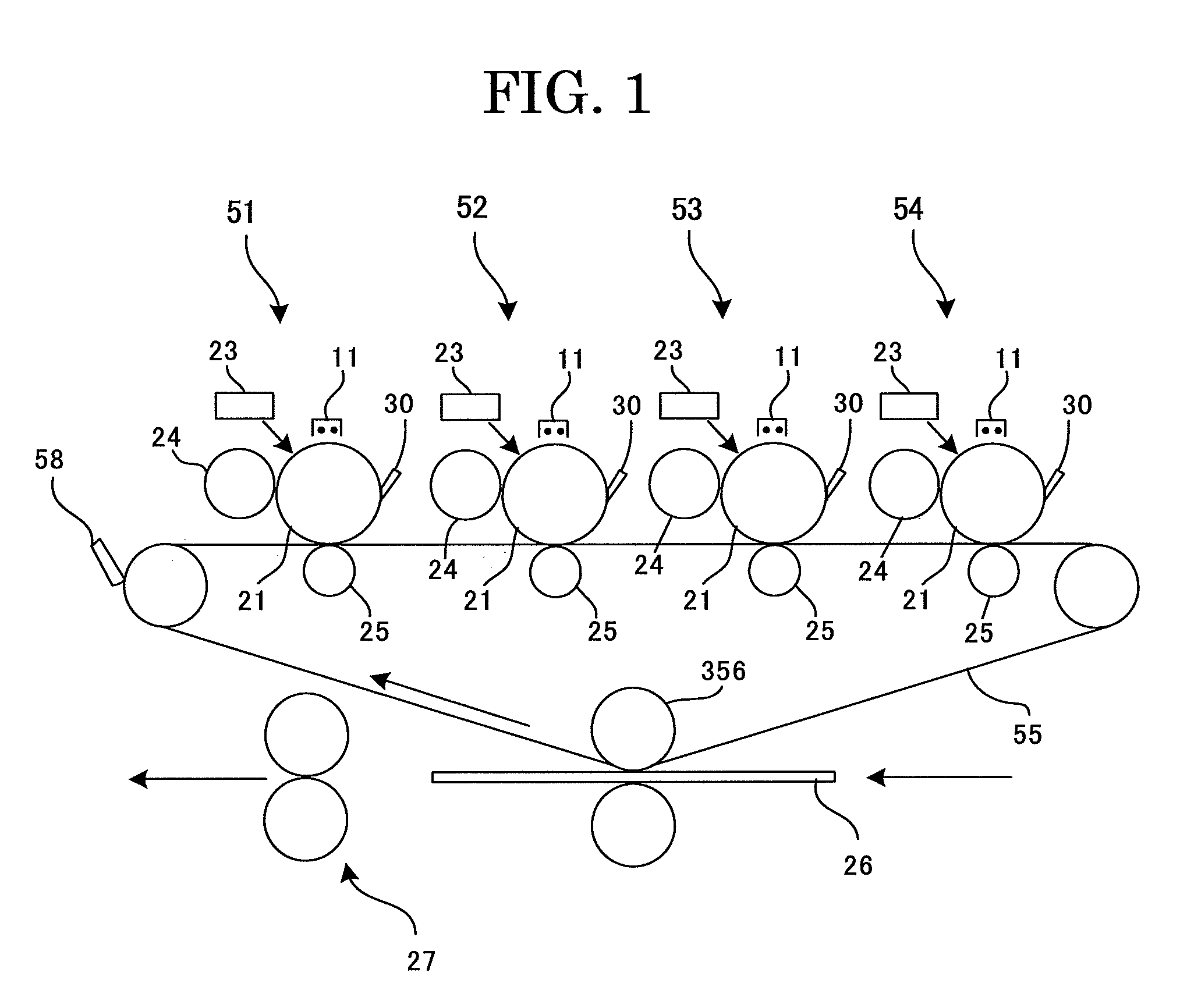

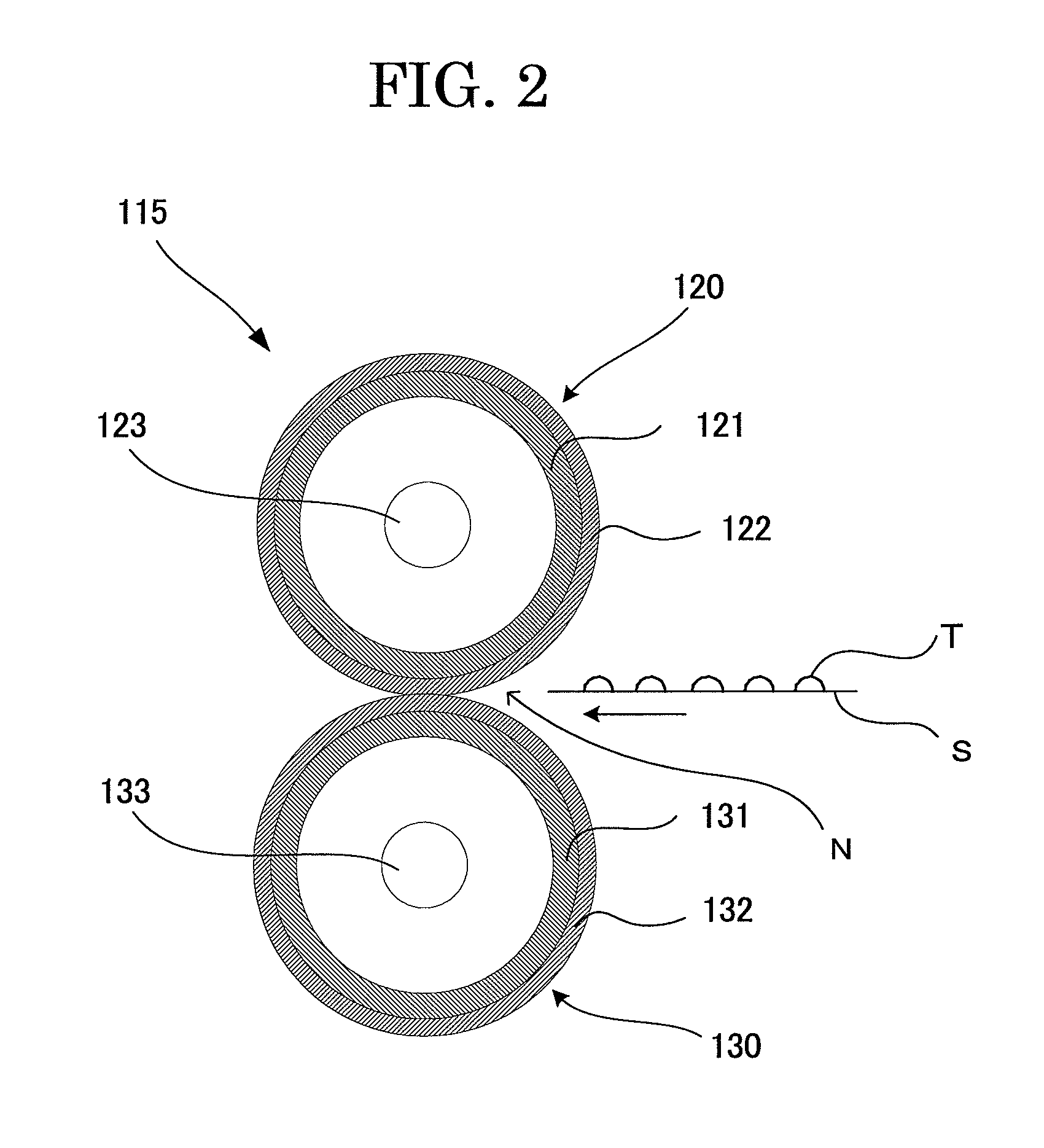

Polyurethane-coated spandex fabric-fused midsole and apparatus and method for manufacturing the same

ActiveUS20120056345A1Easily and conveniently manufacturedReduce laborTailstocks/centresConfectioneryEngineeringMechanical engineering

The present invention relates to a polyurethane-coated (PU-coated) spandex fabric-fused midsole, and an apparatus and method for manufacturing the same, which allow a shoe midsole to be easily and conveniently manufactured through a single automatic process, and allows a PU-coated spandex fabric to be easily fused to a surface of the midsole in the process of manufacturing the midsole. For this purpose, there is provided a polyurethane-coated (PU-coated) spandex fabric-fused midsole manufacturing apparatus including: a central axis rotated by a driving force of a motor; a rotary disc fitted on the central axis to be rotated together with the central axis; a plurality of midsole forming mold units, which are mounted on the outer ends of support members radially extending from the outer circumference of the rotary disc, respectively; a PU-coated spandex fabric supply apparatus installed above the trace of rotation of the midsole forming mold units to provide a PU-coated spandex fabric to each of the midsole forming mold units; vacuum means installed between the rotary disc and the midsole forming mold units to vacuum the inside of a midsole forming mold unit supplied with a PU-coated spandex fabric to such an extent that the PU-coated spandex fabric comes into close contact with the inner surface of the midsole forming mold unit; a resin introducing apparatus installed outside of the trace of rotation of the midsole forming mold units to introduce polyurethane (PU) resin into the midsole forming mold unit having the PU-coated spandex fabric film in contact with inner surface thereof; and a foam-molded product removal apparatus installed outside of the trace of rotation of the midsole forming mold units to remove a foam-molded product formed by foaming the polyurethane resin introduced into the midsole forming unit by leaving the polyurethane resin in the midsole forming mold unit at a predetermined temperature for a predetermined length of time.

Owner:LEE DONG GUN

Processes for producing regular repeating patterns on surfaces of interbody devices

ActiveUS9125756B2High positioning accuracyRapid productionDecorative surface effectsVacuum evaporation coatingSpinal columnRough surface

Processes for producing interbody spinal implants having a body with a top surface, a bottom surface, opposing lateral sides, opposing anterior and posterior portions, a substantially hollow center, and a single vertical aperture; and optionally, one or two integration plates affixed to the body. The processes include applying an additive process, a subtractive process, or both processes to at least one surface of the interbody spinal implant to form a roughened surface topography having a regular repeating pattern. The roughened surface topography is specifically designed to provide certain frictional characteristics, load dispersion, and to influence the biological responses that occur during bone healing and fusion.

Owner:TITAN SPINE

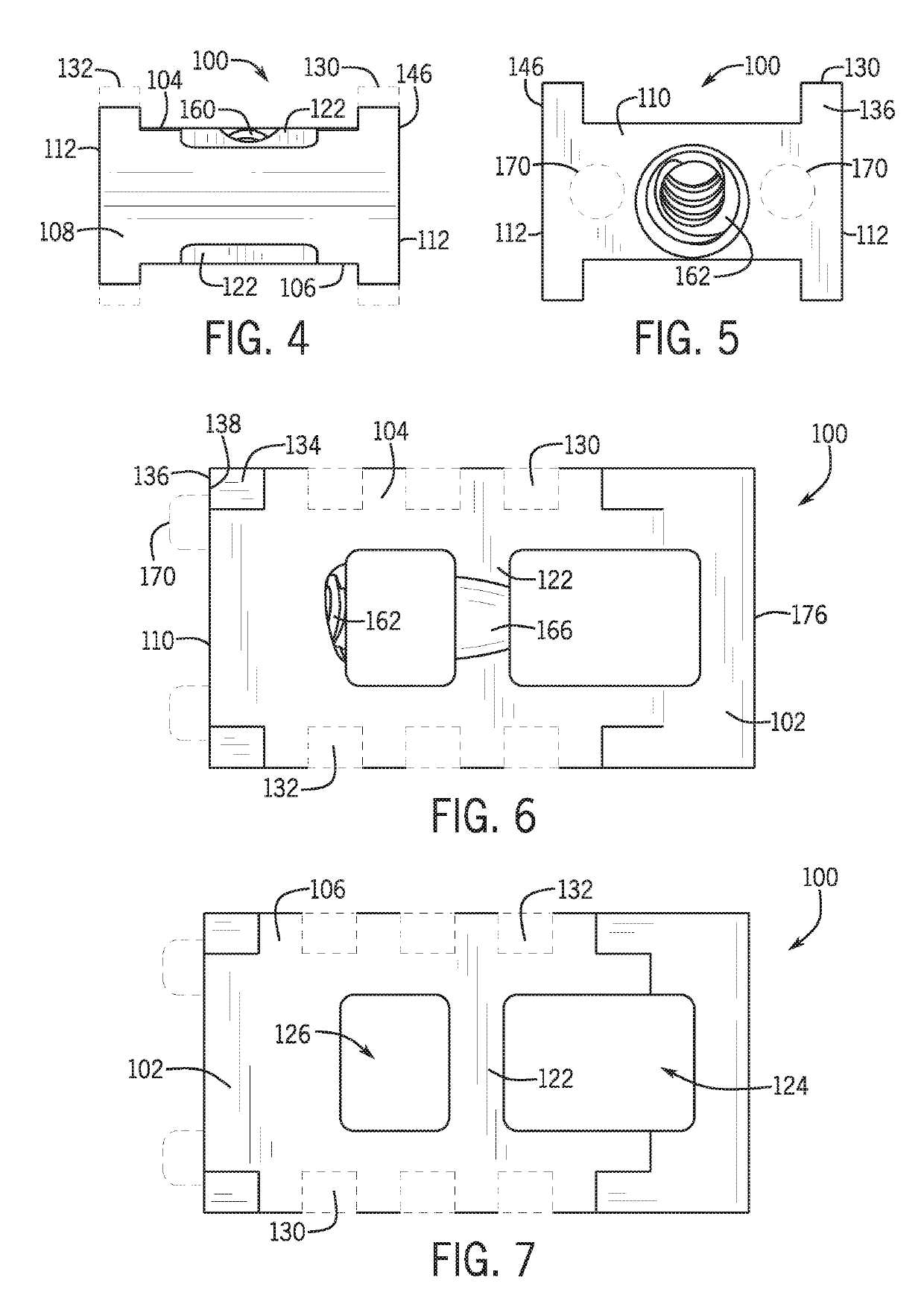

Reverse cage intervertebral fusion implants

InactiveUS20140379085A1Easy to fusePromote growthSpinal implantsFastenersMedicineIntervertebral space

Low-profile reverse cage intervertebral implants are provided having an endplate positioned on the posterior side of the cage. Having the endplate positioned posteriorly provides several advantages including placement of fastening means away from blood vessels anterior to the intervertebral region as well as placement of bone screws to prevent backing out. The endplates are overall smaller than corresponding endplates for traditional (anterior) positioning. Implants are provided having various means for securing the implant in the intervertebral space, including one or more blades and / or one or more bone screws.

Owner:INST FOR MUSCULOSKELETAL SCI & EDUCATION

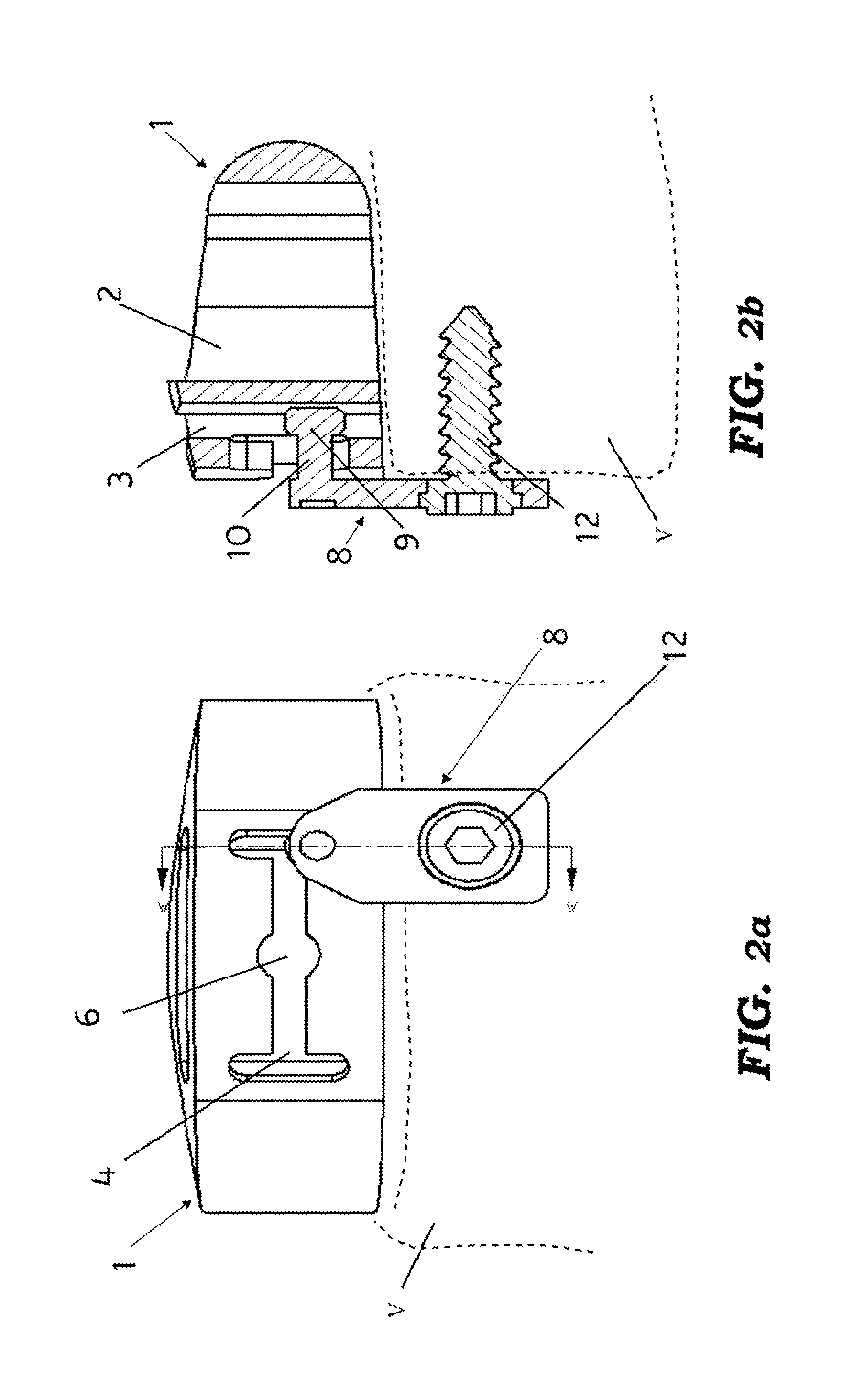

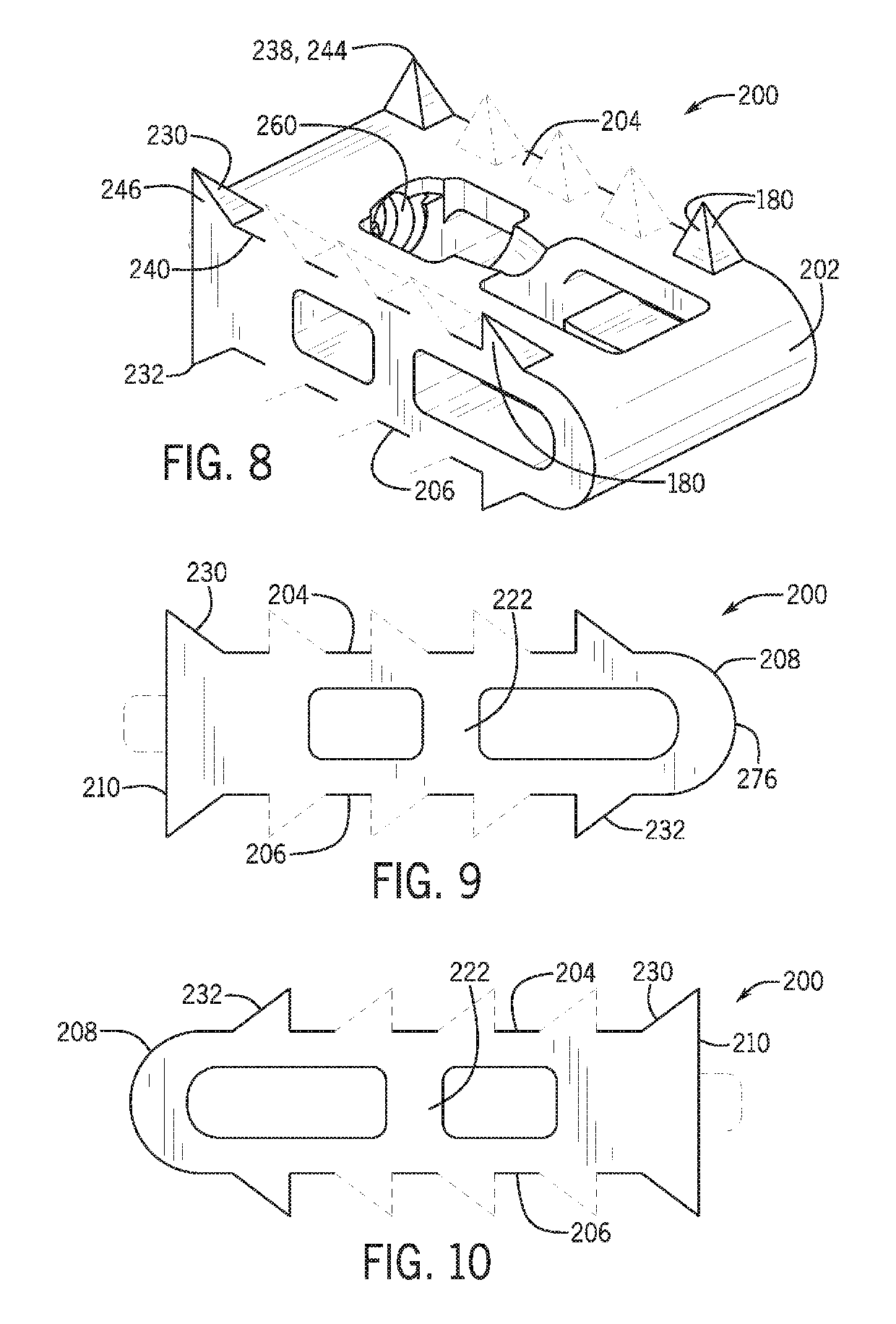

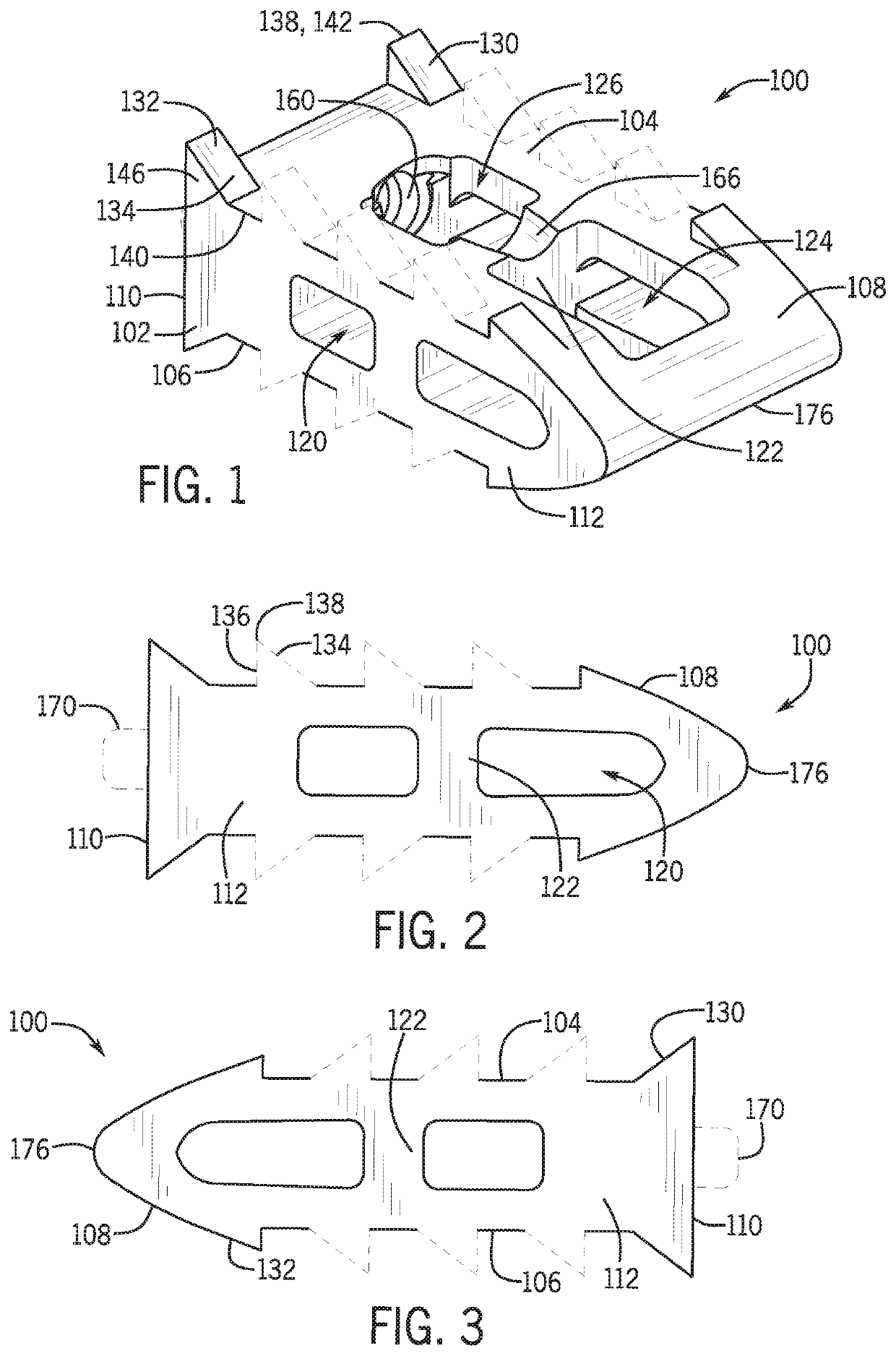

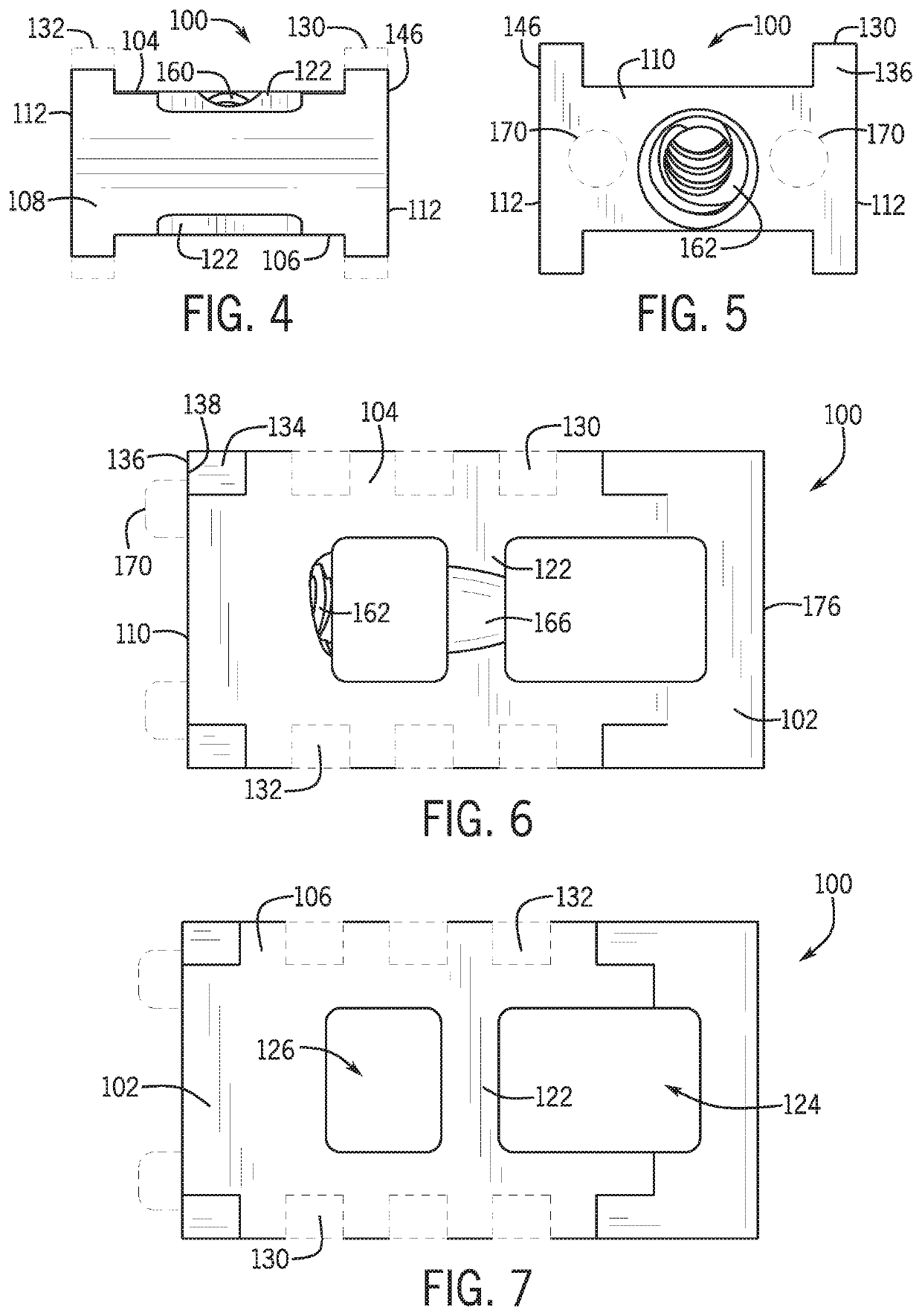

Spinal implant and methods of using the same

ActiveUS20190239932A1Preventing implant motionEasy to integrateInternal osteosythesisBone implantSacroiliac jointSpinal implant

A spinal implant for implantation within a spinal facet joint is provided. The spinal implant may include a main body including opposing top and bottom surfaces, opposing front or distal and rear or proximal surfaces, and opposing side surfaces. At least one retaining feature may be associated with at least one surface of the main body to frictionally engage the implant within the spinal facet joint. At least one securement feature may be associated with at least one surface of the main body to selectively secure the implant within the spinal facet joint.

Owner:PROVIDENCE MEDICAL TECH

Dynamic interbody cage anchor system

A system and method of securing an intervertebral fusion cage within the intervertebral space between adjacent vertebra in which one or more slots are provided in an anterior surface of the cage each extending from an oversized aperture. A retention plate having a post and enlarged head is advanced into each slot via the oversized aperture and captured therein. The post is advanced to the terminal end of the plate and secured to vertebral body at its distal end by a bone screw. A locking clip is slideably positioned on the retention plate to prevent withdrawal of the bone screw. The slots preferably extend to margins of the anterior surface of the cage in, for example, the pattern of an “X” or an “H”. Sliding of the posts in the slots prevents the system from carrying the vertebral load (load shielding) and permits reduction in the intervertebral space to promote bone growth and fusion by graft material retained in the spacer.

Owner:AFLATOON KAMRAN

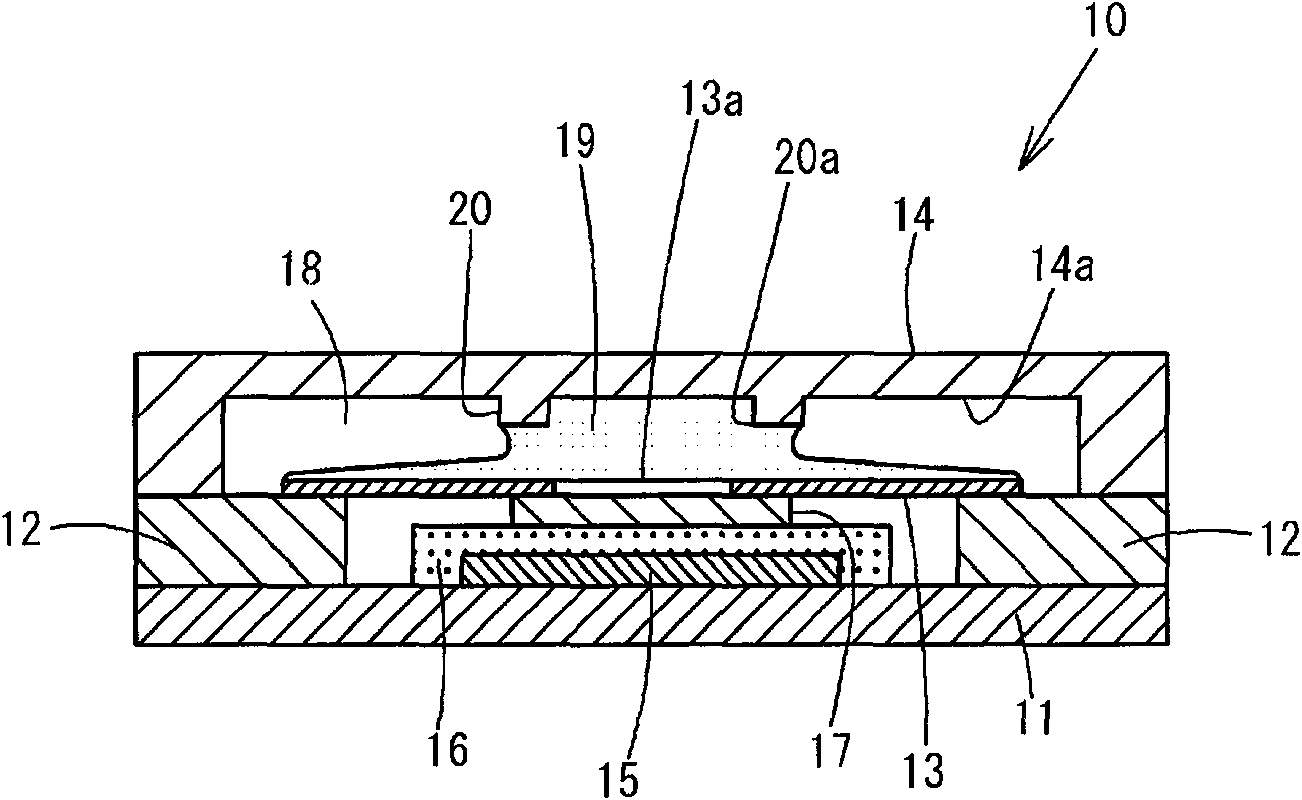

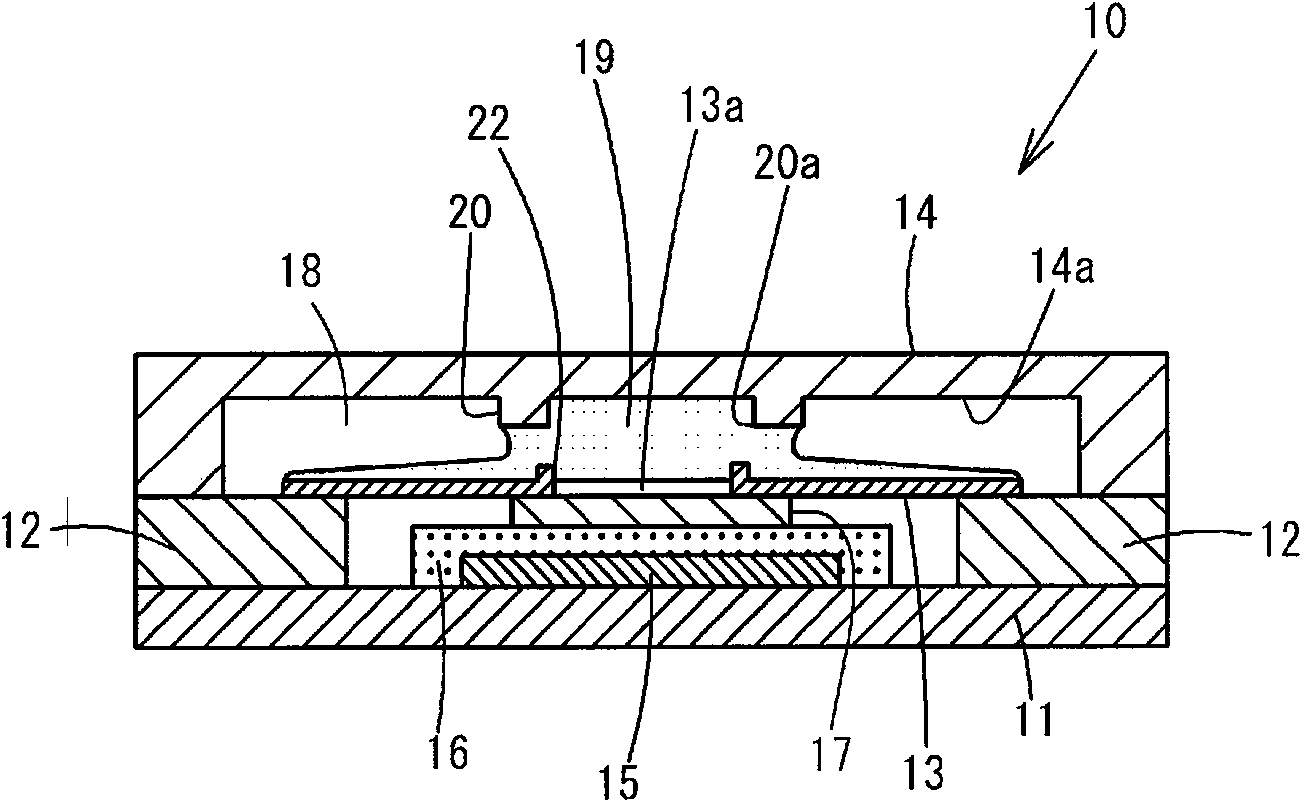

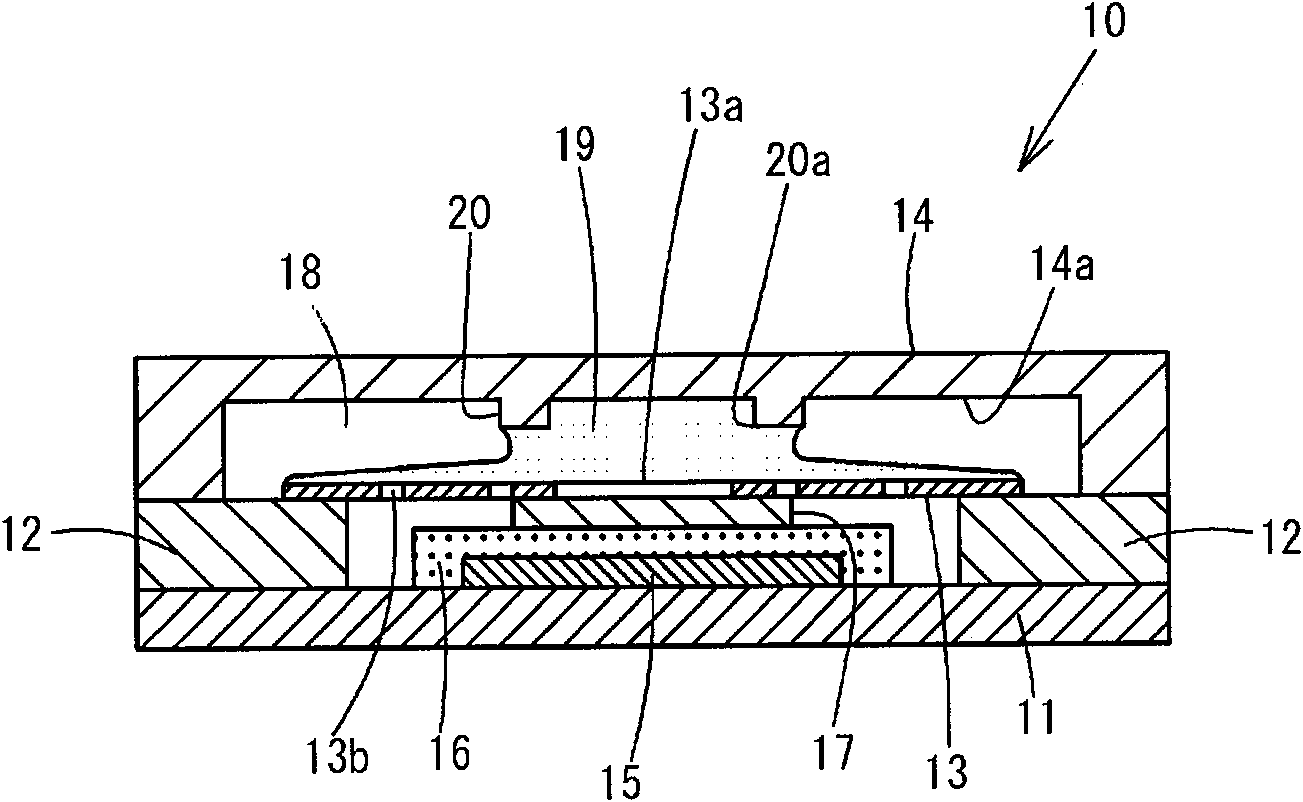

Protection element

ActiveCN102239535APrevent uneven activityReduce environmental burdenHeating/cooling contact switchesContactsElectrical conductorElectric power

Provided is a protection element wherein a flux on a soluble conductor can be stably held at a predetermined position and the soluble conductor can speedily and accurately fuse when abnormality occurs. The protection element has: a soluble conductor (13), which is arranged on an insulating base substrate (11), is connected to the power supply line of an apparatus to be protected and fuses with a predetermined abnormal power; a flux (19) applied on the surface of the soluble conductor (13); and an insulating cover (14) which covers the soluble conductor (13) and is attached to the base substrate (11). The protection element is provided with a protruding strip section (20), which is formed on the inner surface of the insulating cover (14) by facing the soluble conductor (13) and has a step section (20a) which is in contact with the flux (19) and holds the flux (19) at the predetermined position. The soluble conductor (13) is provided with a hole section (13a) which holds the flux (19) therein.

Owner:DEXERIALS CORP

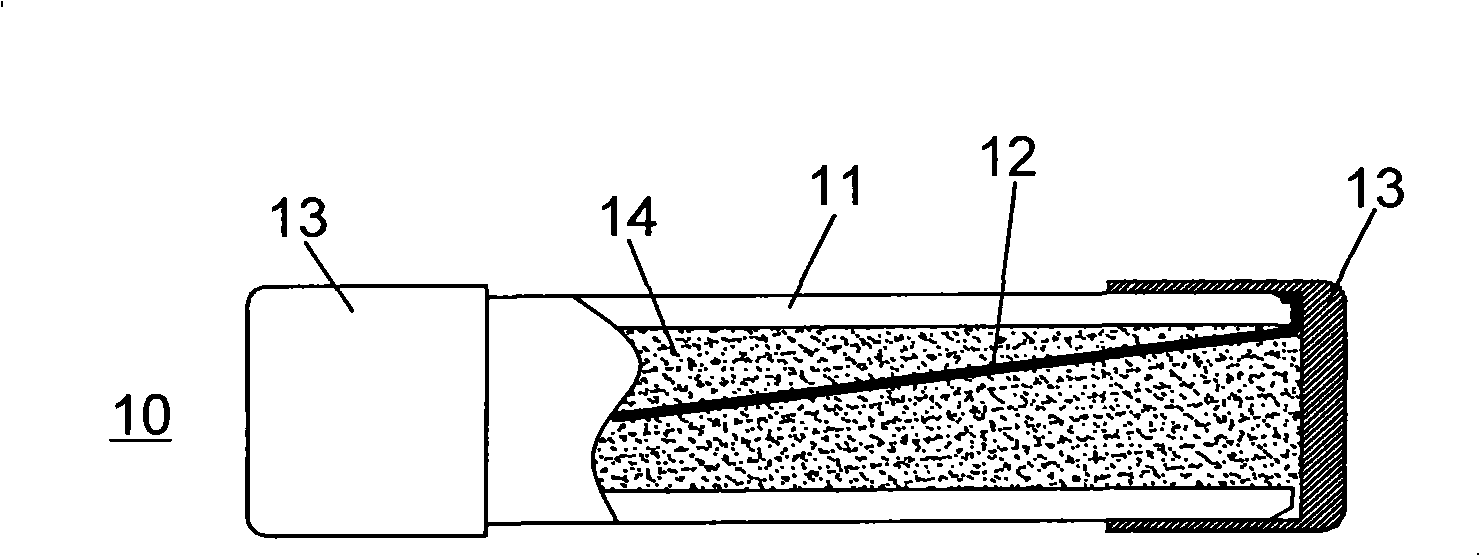

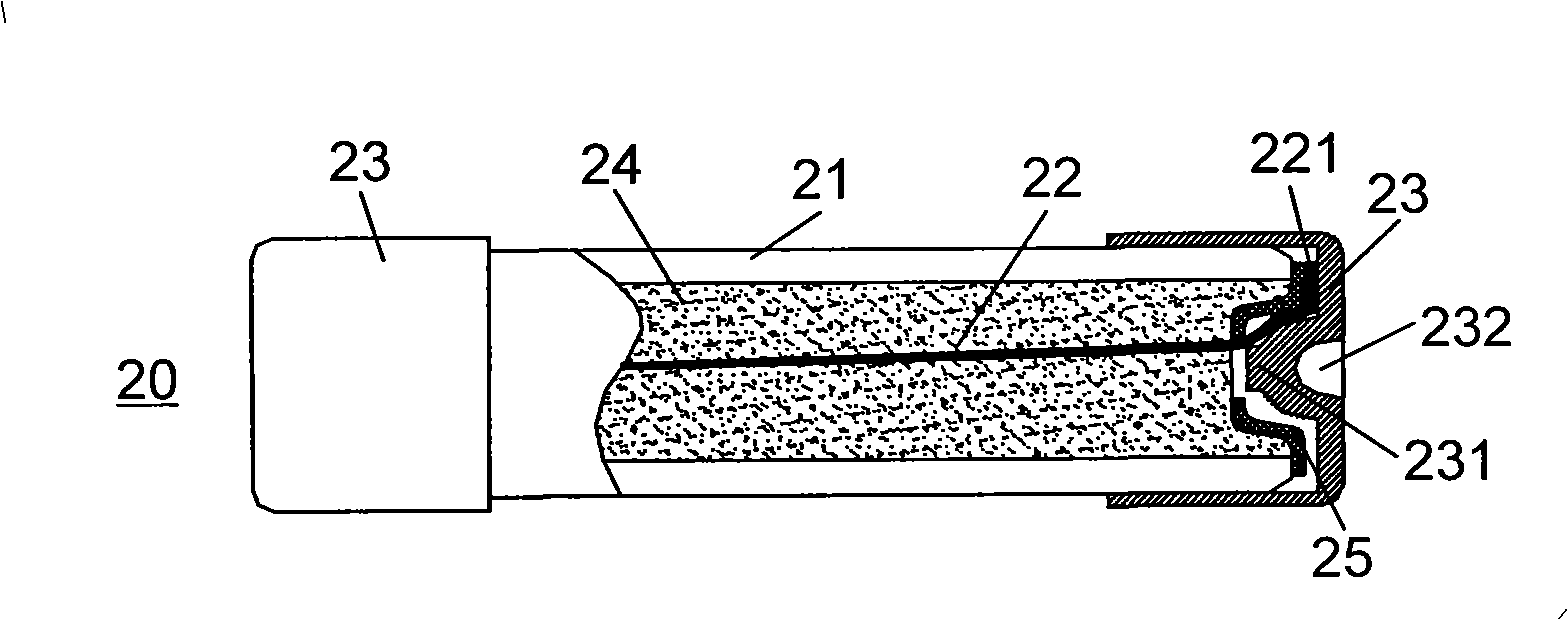

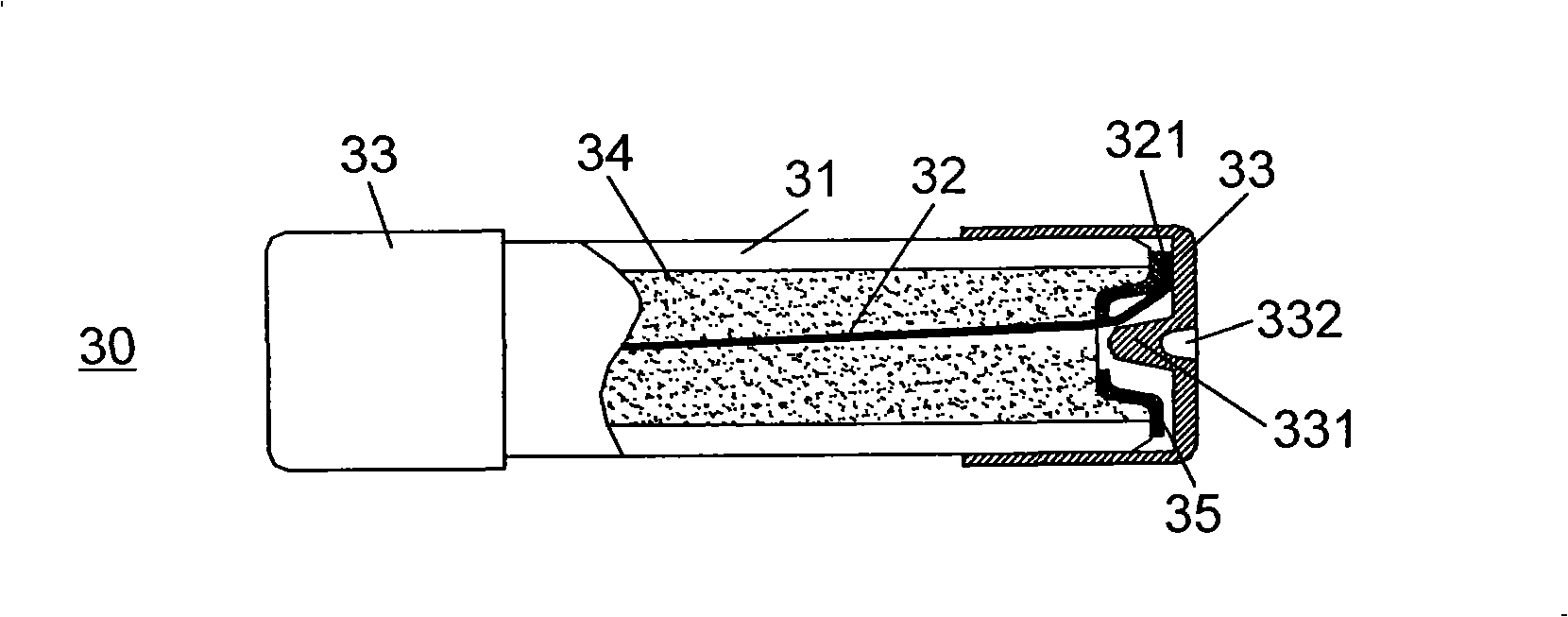

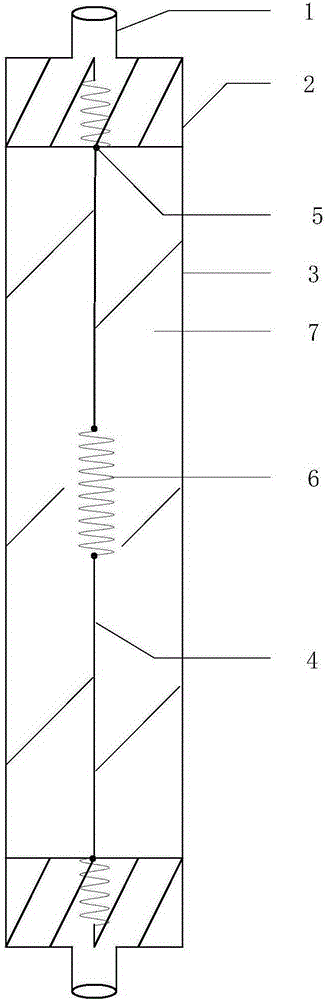

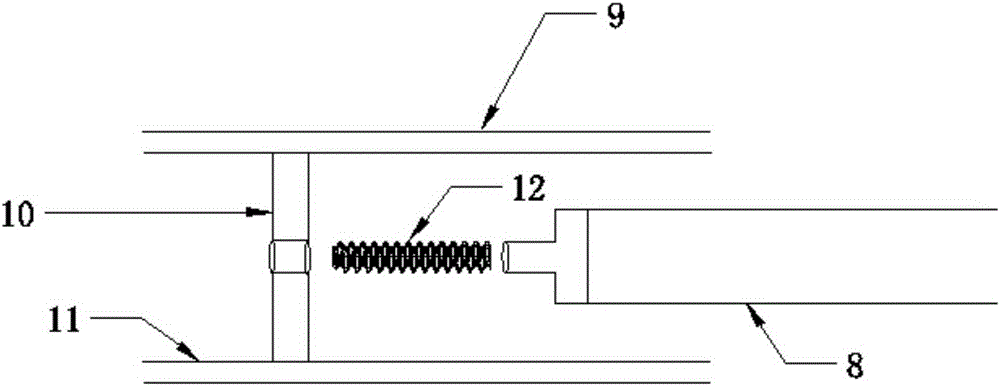

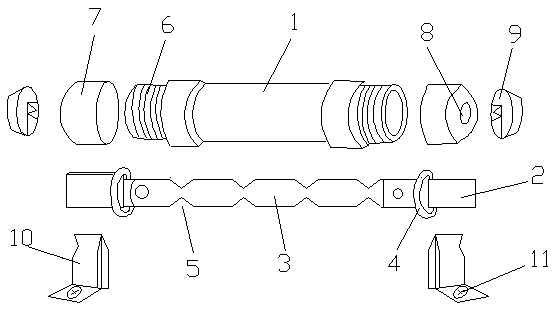

Fuse and assembly method thereof

ActiveCN101308744APrevent overflowAvoid solder overflow and fuse solder joints and prevent overflowEmergency protective devicesSafety wireEconomic benefits

The invention discloses a fuse which comprises a main body, a safety wire and a fixed sealing assembly. The main body is a tubular structure with two open ends and is provided with a quartz sand layer inside. The safety wire stretches into the main body, with both ends extending out of the main body and then bending at the outside. The fixed sealing assembly is composed of a fixed gasket and a sealing cap; the fixed gasket is arranged at two ends of the main body and rests against the two ends of the main body, and the sealing cap is fixedly hitched at two ends of the main body, respectively resting against the fixed gasket and the safety wire. The invention further discloses a fuse installation method. The fuse and the installation method are simple and convenient; the fuse is reliable in performance and resurfacing welding is not required during the installation, thus avoiding overflow of the solder and fault soldered joint and preventing the safety fuse from being broken by compression; therefore good contact between the safety wire and the sealing cap and the integrity of the product can be ensured, thus improving qualification rate and economic benefits.

Owner:COOPER ELECTRONICS TECH SHANGHAI

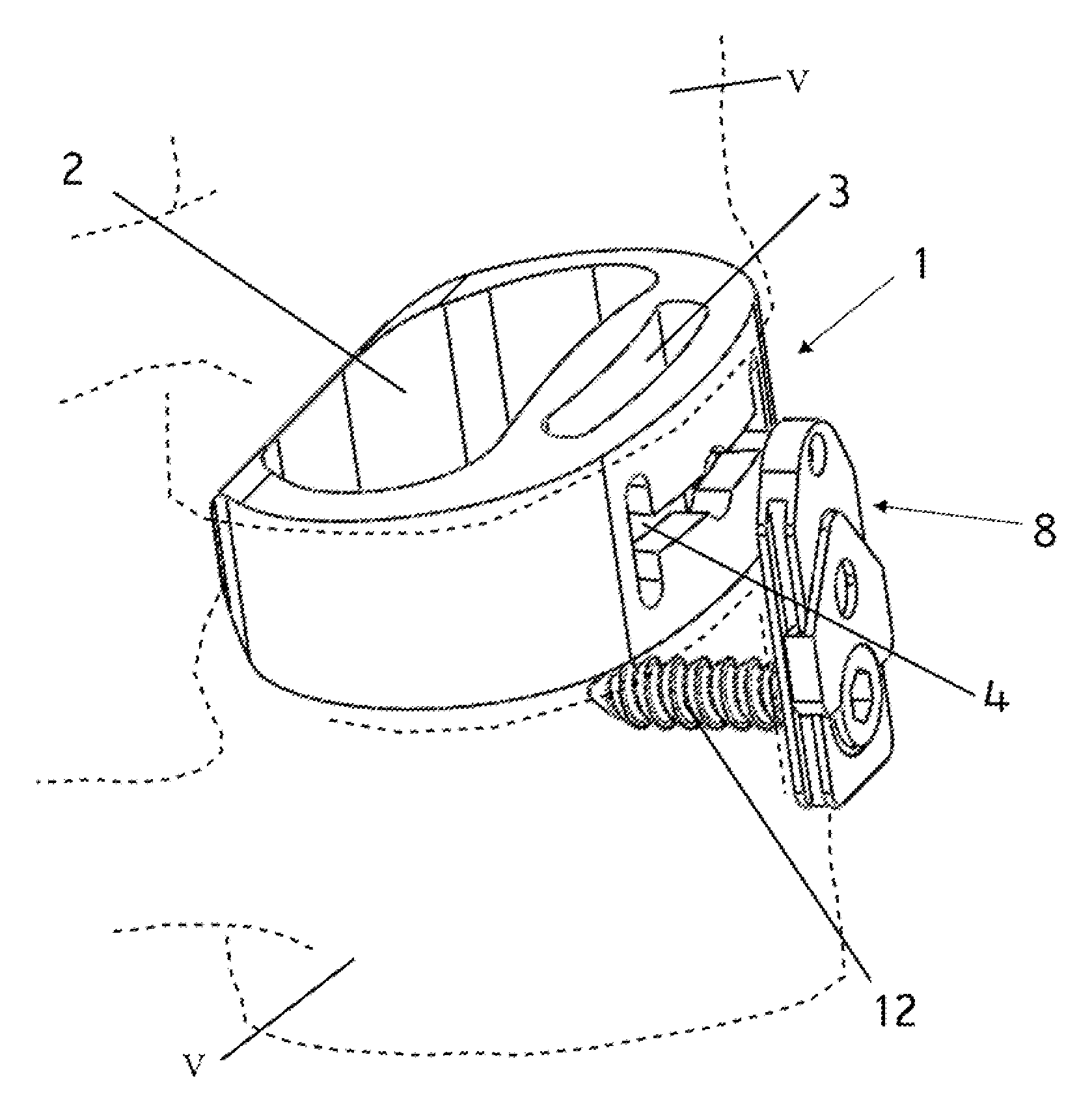

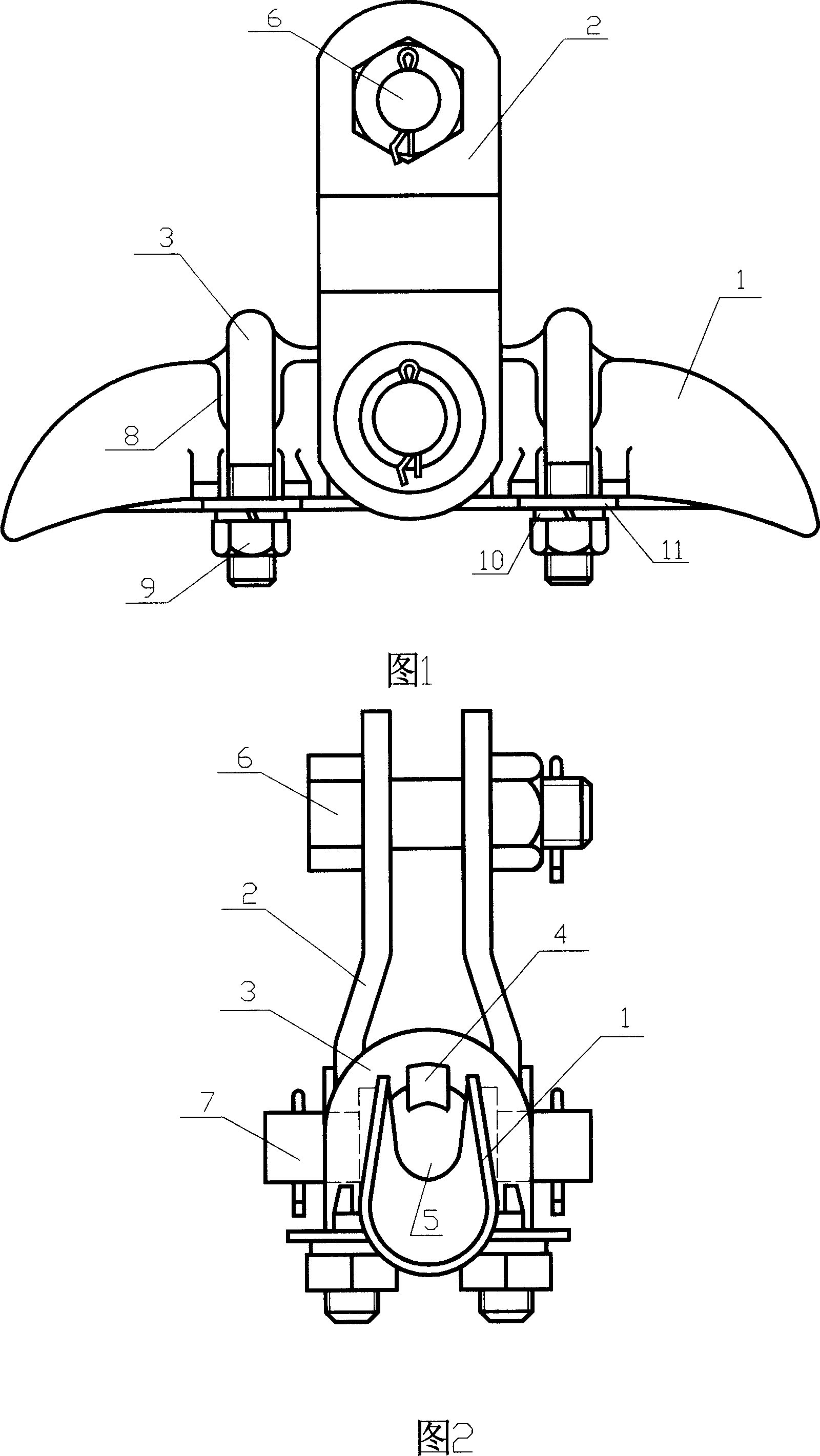

An energy-saving suspending wire clamp

InactiveCN1996689AEliminate or reduce lossLow costSuspension arrangements for electric cablesEngineeringMechanical engineering

This invention relates to one electrical wares and to one energy saving hanging clamper, which comprises clamper body, U shape screw wire, press bar and hanging board, wherein, the said hanging board is set on both side of clamper body through opens; the hanging board top is set with screw bolt with holes; the said pressure bar is fixed onto clamper body wire tank top through U shape screw made of clamper body, U shape screw, pressure bar and hanging board.

Owner:PHOENIX TECH GROUP

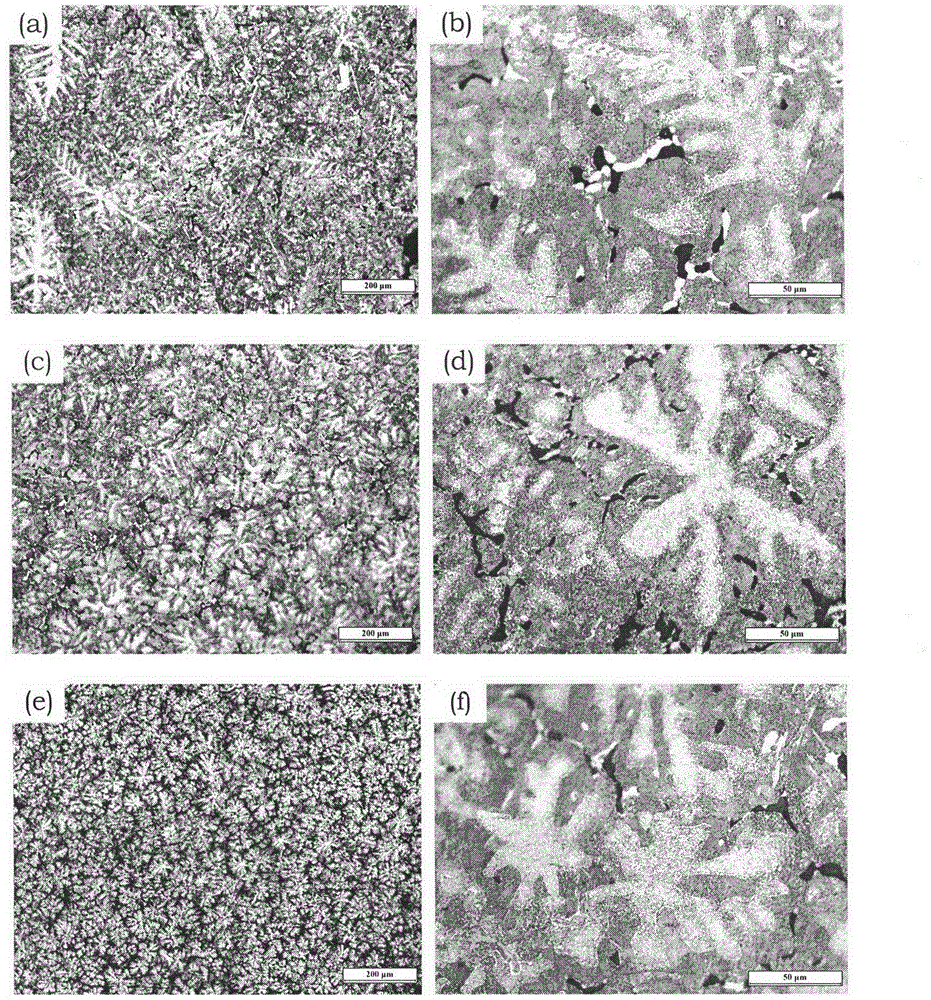

Process method capable of improving comprehensive mechanical property of multielement zinc-aluminum alloy

The invention relates to a multielement zinc-aluminum alloy capable of improving comprehensive mechanical property, belonging to the technical field of zinc-aluminum alloy preparation. The multielement zinc-aluminum alloy is characterized in that the multielement zinc-aluminum alloy is prepared from the following raw materials: industrial aluminum ingot NO.A00, zinc ingot NO.0, electrolytic copper, composite modifier and pure magnesium, wherein the composite modifier contains 20-30% of Ni, 15-25% of Ti, 5-15% of Mn, 5-15% of Cr, 5-10% of Si, 5-10% of Ce, 5-10% of La, 1-6% of Y, 1-6% of Nb, 1-6% of V and the balance of aluminum; the multielement zinc-aluminum alloy is smelted in a medium-frequency induction melting furnace after weighing 27-29% of Al, 2-2.5% of Cu (added in the form of aluminum-copper intermediamidstfrequencye alloy containing 50% of copper ), 0-1.2% of composite modifier, 0.01-0.02% of Mg and the balance of Zn based on percentage by weight. A round-rod-shaped blank iscasted by a common metal type and metal type vibrational casting method, and then processed to a national standard test rod to be subjected to mechanical property testing.

Owner:ZHENJIANG YINUOWEI SHAPE MEMORY ALLOYS

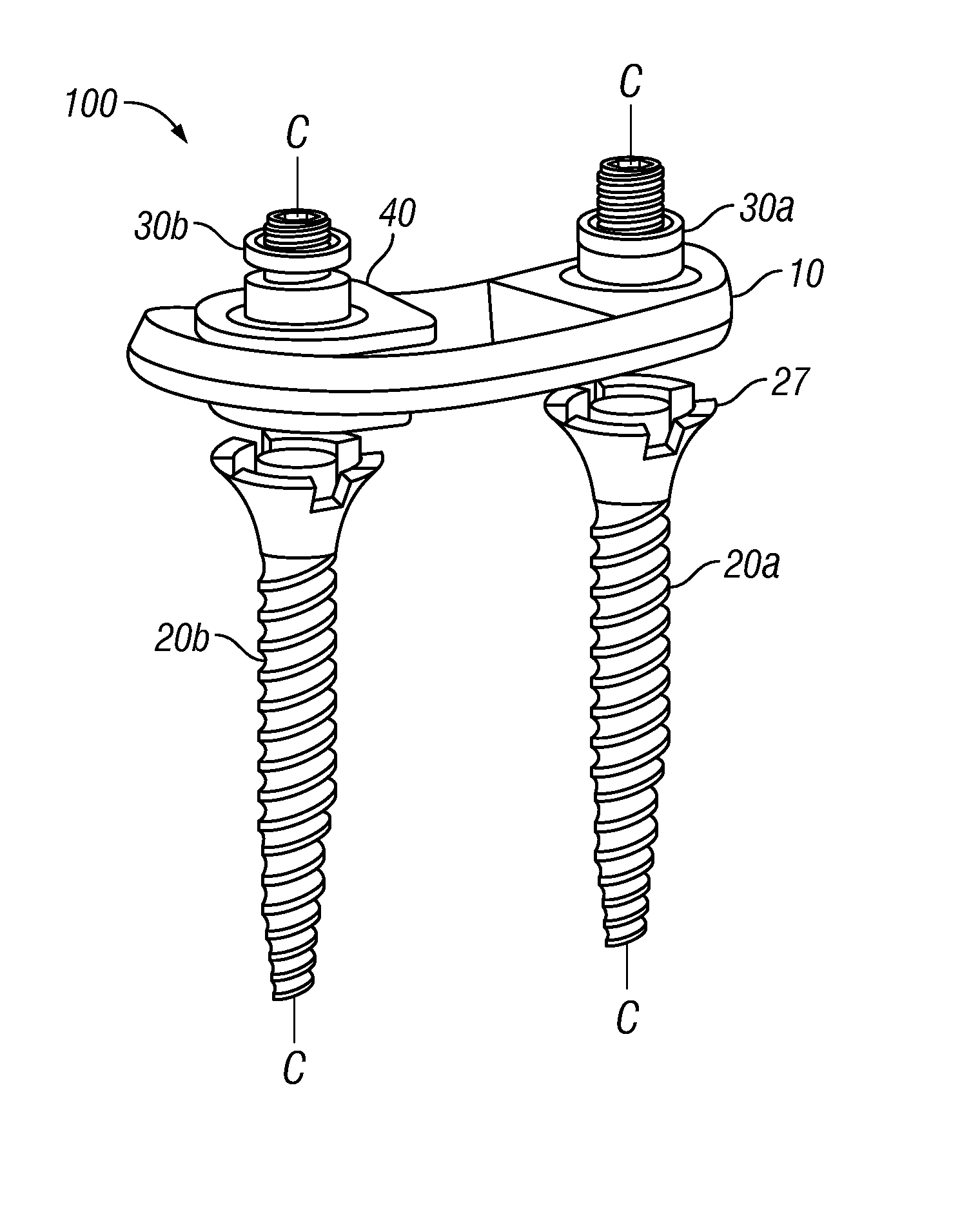

Posterior Lumbar Plate

InactiveUS20140188178A1Facilitate bony fusionImprove stabilityInternal osteosythesisFastenersDiseaseStable fixation

The present invention relates to stable fixation of spine segments, allowing for fusion in, e.g., skeletally mature patients. More particularly, the invention relates to a bone fixation device that can be affixed to vertebrae of a spine to provide reduction (or enlargement) capabilities and allow for fixation in the treatment of various conditions, including, e.g., spondyloslisthesis, degenerative disc disease, fracture, dislocation, spinal tumor, failed previous fusion, and the like, in the spine. The invention also relates to a method for delivering and implanting the bone fixation device.

Owner:GLOBUS MEDICAL INC

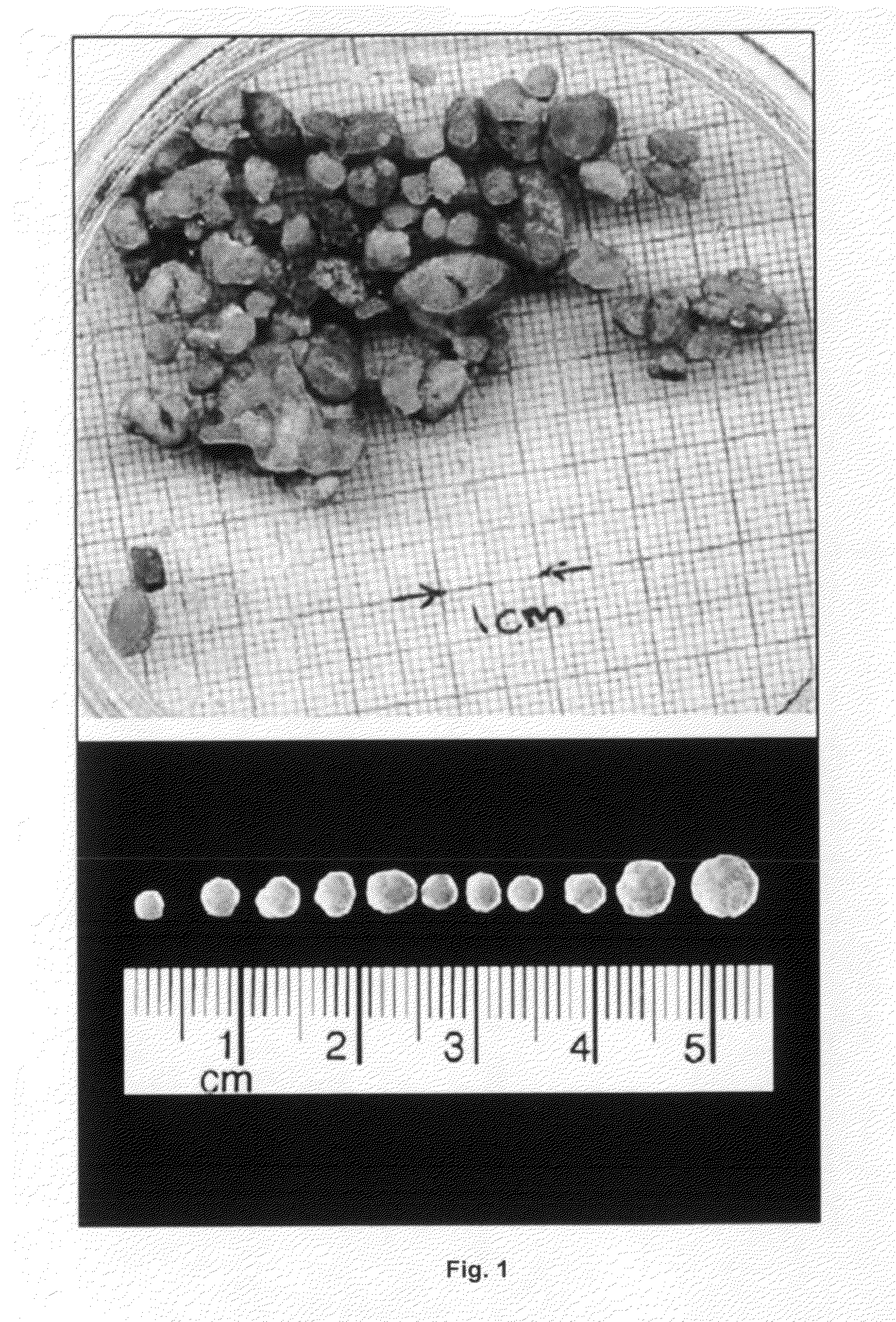

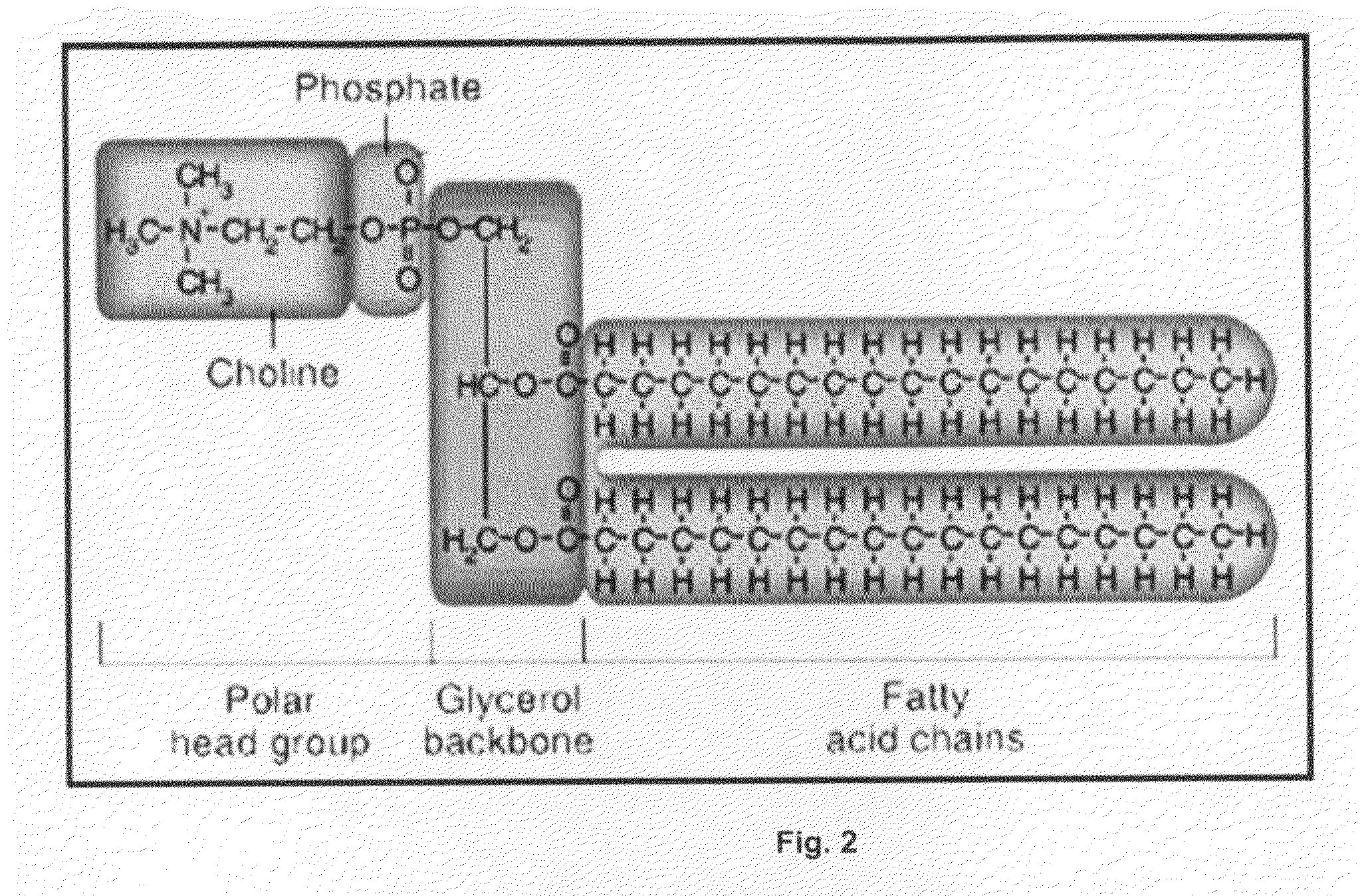

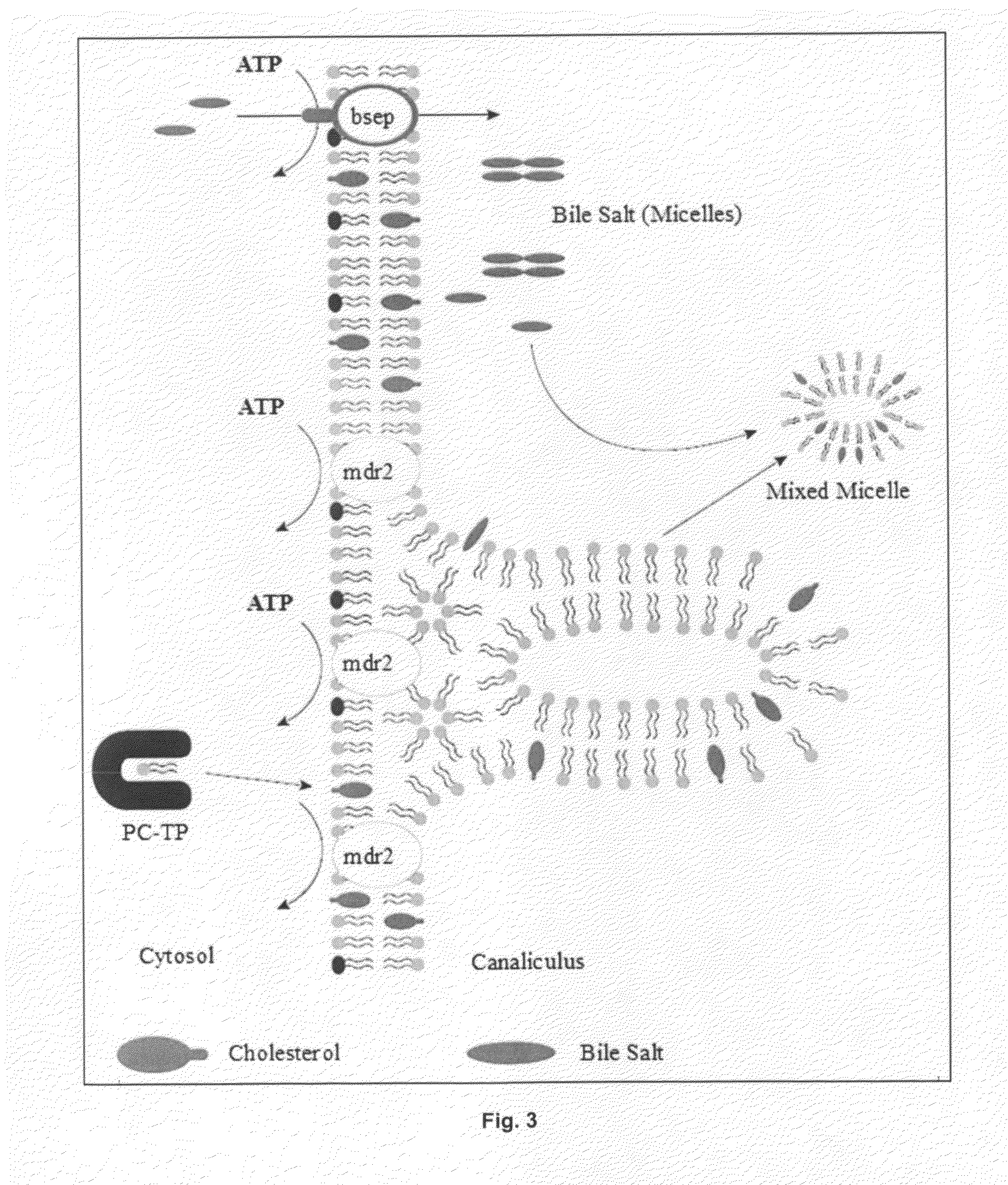

Nanoveson™: treatment, biomarkers and diagnostic tests for liver diseases and comorbid diseases

ActiveUS20090181109A1Prevent choline deficiencySufficient quantityBiocideNervous disorderCholecystokininTG - Triglyceride

A method of treatment of liver diseases and comorbid diseases is disclosed wherein an oral dose of lipids in an amount effective to trigger the release of cholecystokinin (CCK) into the duodenum to generate a major release of bile phospholipids from remodeled stores of triglycerides (TAG) in the liver, is administered to a patient in need thereof, thereby causing the formation of sequestered and aggregated mixed micelles and vesicles (SAMMVs) in the intestines of the patient which are then eliminated via the bowels of the patient.

Owner:NANOVESON

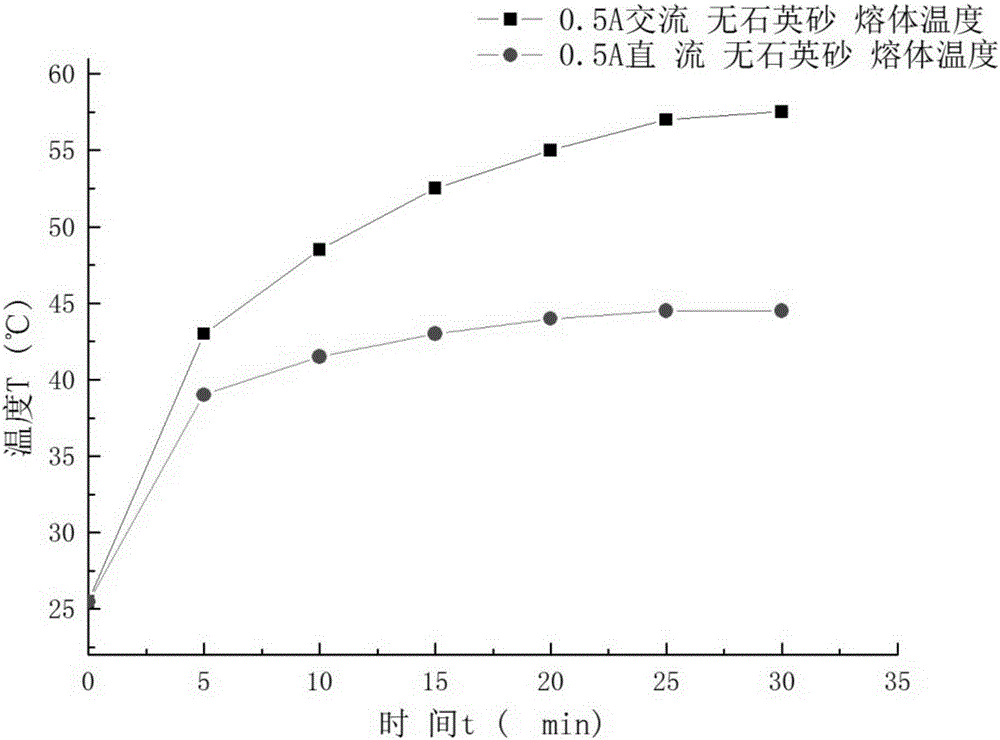

Current-limiting fuse used for protecting ozone high-frequency discharge unit

InactiveCN105280451ASimple structureImprove breaking capacityOzone preparationEmergency protective devicesCurrent limitingHigh frequency

The invention provides a current-limiting fuse used for protecting an ozone high-frequency discharge unit. The current-limiting fuse comprises a shell body provided with copper caps on both ends, a fuse body unit communicated with the two copper caps is arranged inside the shell body, the shell body is filled with quartz sand, the fuse body unit comprises a fuse body, and metal or alloy with a fusing point lower than that of the fuse body is arranged on the fuse body. The current-limiting fuse is simple, reasonable and compact in structure, enhances the connecting / disconnecting capacity by adopting a design of combining metallurgical effects with multiple fractures, enhances arc extinguishing capacity of the fuse by adopting the quartz sand for filling and connecting springs in tensional state at both ends of the fuse body, and achieves the current-limiting protective function of cutting off a circuit at the fracture under a high current fault and directly cutting off the circuit by the fuse body under a short circuit fault. The current-limiting fuse has high connecting / disconnecting capacity and good arc extinguishing capacity, and can effectively avoid the risk of damaging an ozone generator due to faults such as overcurrent and short circuit by arranging the current-limiting fuse on one side of the discharge unit of the ozone generator.

Owner:DALIAN UNIV OF TECH

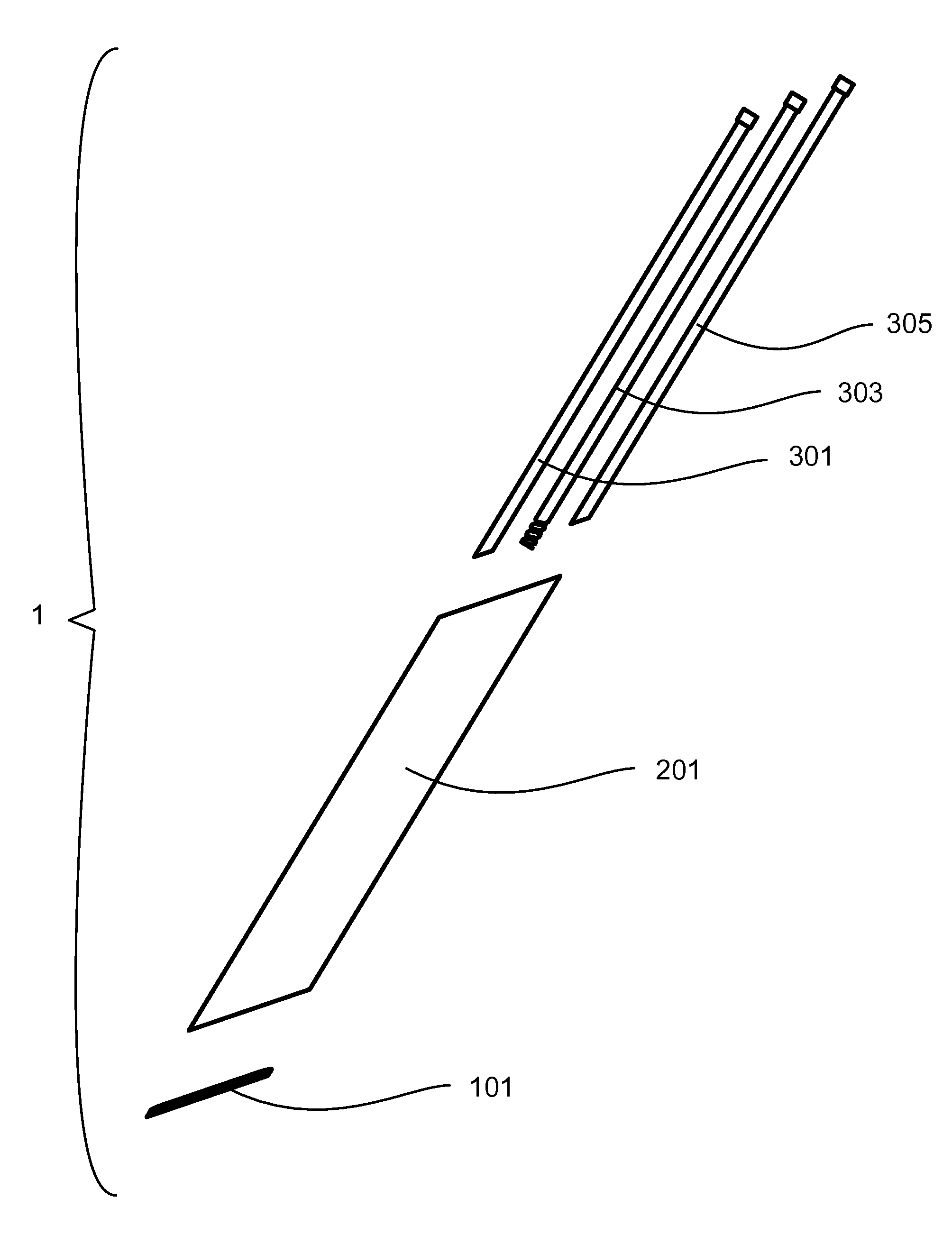

Spine Fixation Device and Method

InactiveUS20140276807A1Easy to fuseImprove stabilityInternal osteosythesisDiagnosticsSpinal columnDisease

A novel device and method for surgical inducement of cervical vertebra fusion as a treatment for cervical spinal disease using a guide wire, slide knife, and a minimally invasive portal access device and an inter-vertebra linking member.

Owner:LOVELL LAVERNE

Electrostatic image developing toner

ActiveUS20160370721A1Low-temperature glossinessLow-temperature propertyDevelopersElectrographic process apparatusPolyester resinPolymer chemistry

Provided is an electrostatic image developing toner comprising a toner base particle containing a binder resin and a releasing agent, wherein the binder resin comprises an amorphous vinyl resin and a crystalline polyester resin; a weight-average molecular weight of the electrostatic image developing toner is in the range of 50000 to 90000, when calculated from a chromatogram which represents a molecular weight distribution and is measured by gel permeation chromatography; a ratio of content of a resin component having a molecular weight of 100000 or more is in the range of 10 to 20% by area, in the chromatogram which represents the molecular weight distribution; the crystalline polyester resin has a melting point in the range of 65 to 85° C.; and, a ratio of content of the crystalline polyester resin in the binder resin is in the range of 5 to 20% by mass.

Owner:KONICA MINOLTA INC

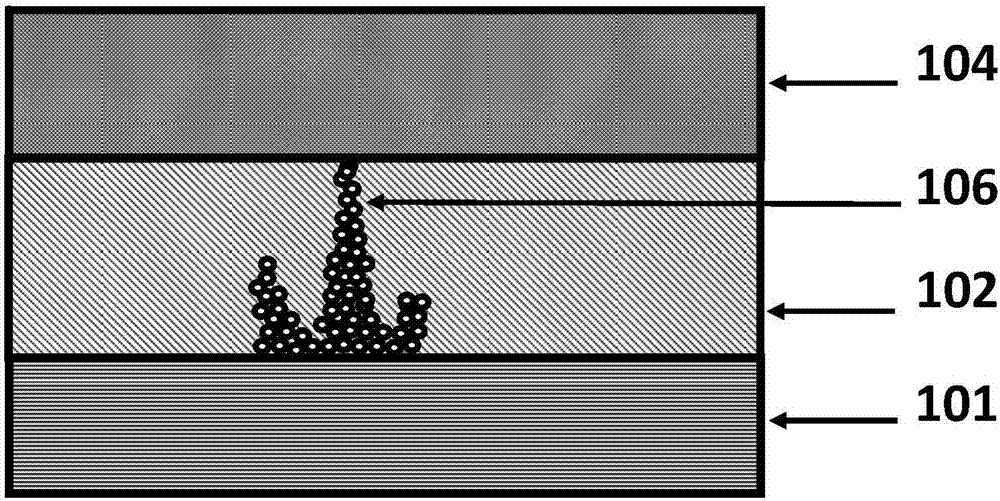

Resistive random access memory for inhibiting excessive growth of silver conductive channel and preparation method thereof

ActiveCN107394040ALower activation energyAg ion mobility is highElectrical apparatusConductive channelBatch production

The invention relates to a resistive random access memory for inhibiting the excessive growth of a silver conductive channel and a preparation method thereof. The resistive random access memory comprises a bottom electrode, a resistance transition layer, a silver solid electrolyte material buffer layer, and a top electrode. The resistance transition layer is arranged on the bottom electrode. The silver solid electrolyte material buffer layer is arranged on the resistance transition layer. The top electrode is arranged on the silver solid electrolyte material buffer layer. The preparation method of the resistive random access memory is simple, and the cost of batch production is low. According to the device prepared in the invention, the operation voltage is reduced, the channel excessive growth in starting is inhibited, the output quality is improved, the circulation uniformity is improved, and the device can be applied to the fields of resistive random access memories and artificial neural networks.

Owner:NORTHEAST NORMAL UNIVERSITY

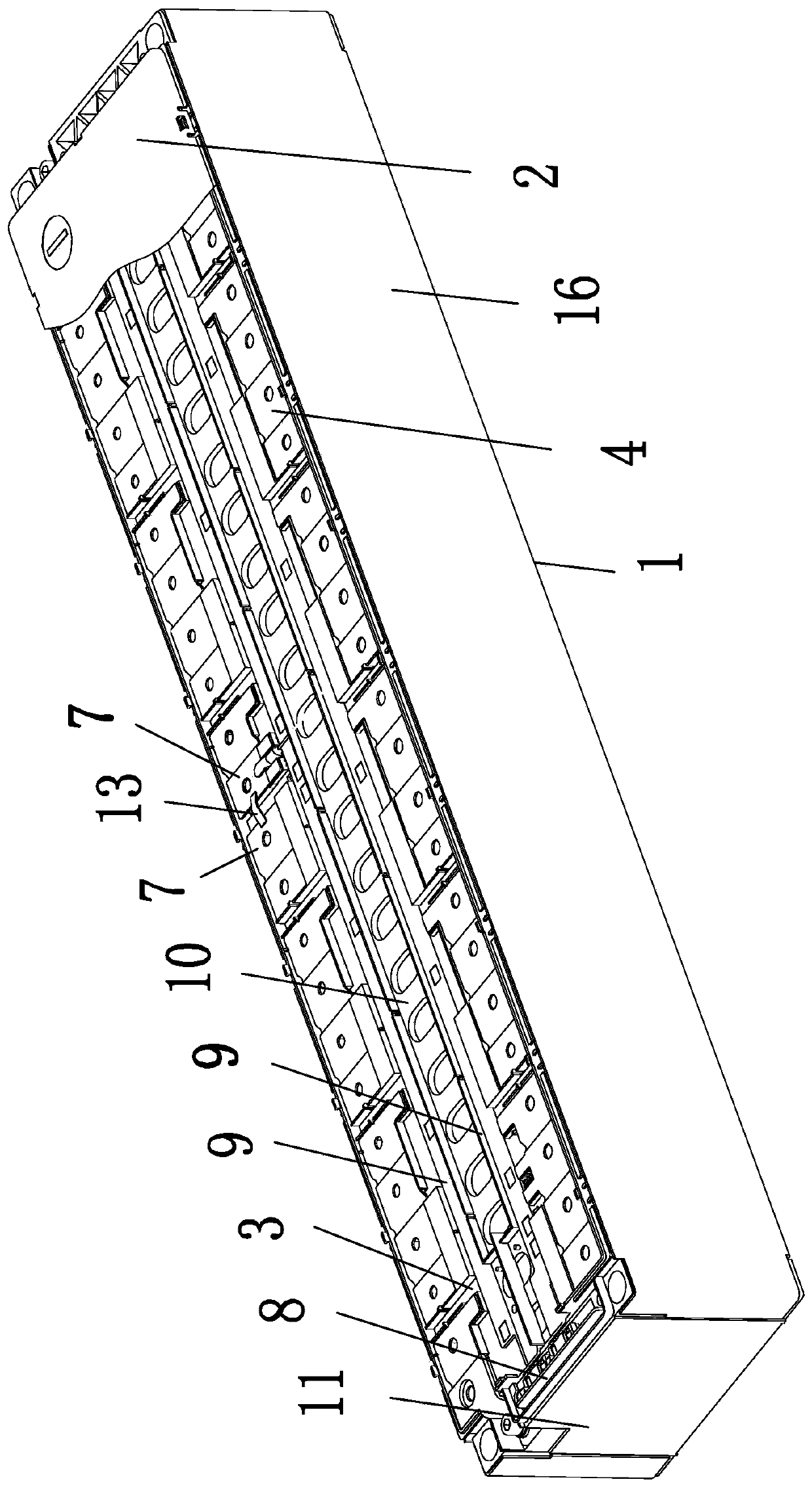

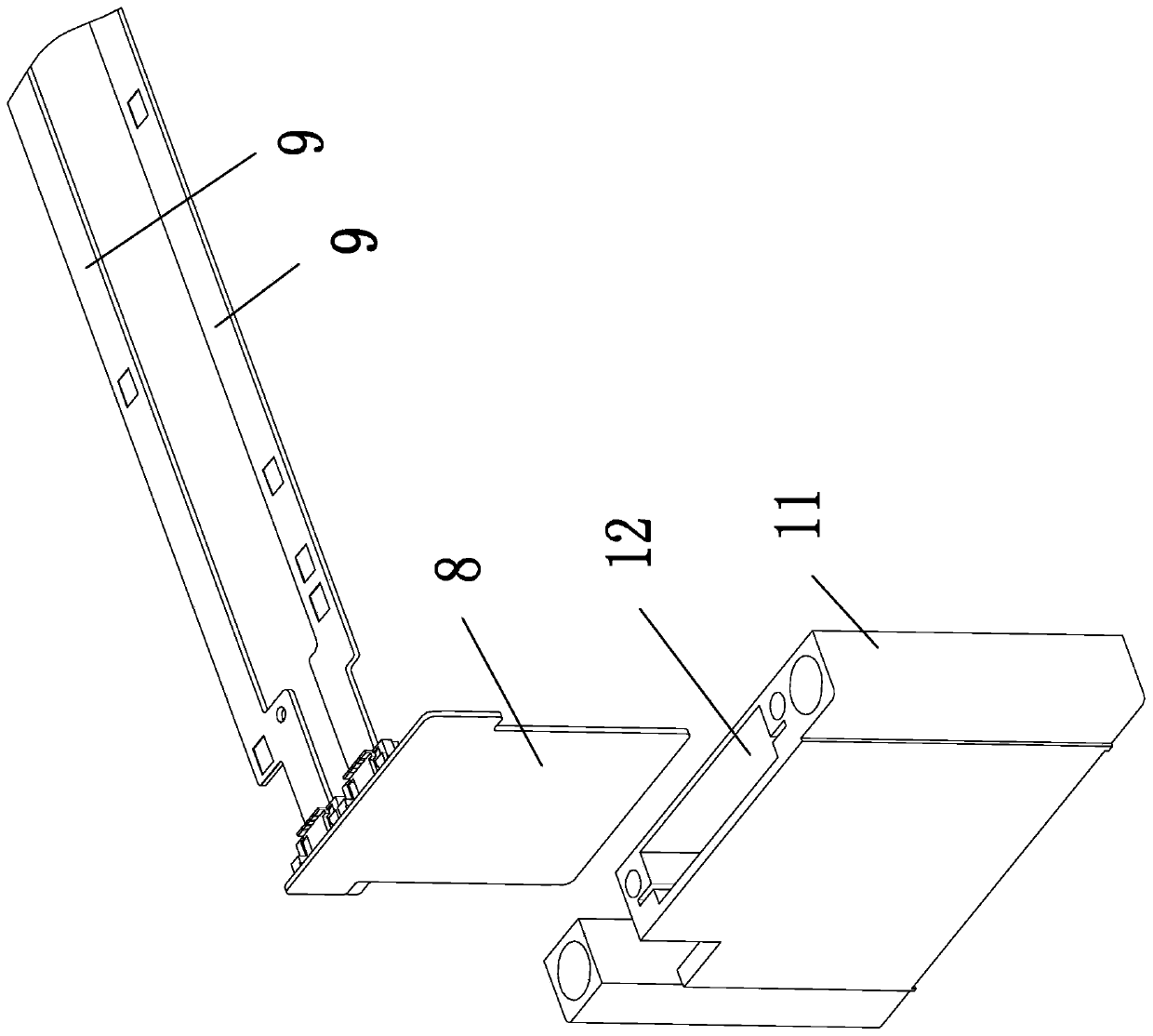

Battery lug and battery module

ActiveCN107195842AImprove protectionImprove seismic performanceCell component detailsHeight differenceBattery cell

The invention discloses a battery lug and a battery module. The lug comprises a body and a lug unit which is arranged on the body and formed by extending from the body, wherein the lug unit comprises an elastic sheet formed by extending from the body, and an irregular spiral elastic sheet groove formed around the elastic sheet; the elastic sheet comprises a guide part of a long-narrow arc-shaped main body formed by extending from the body, and a main body part formed by extending from the other end of the guide part; the guide part is provided with a fused part; and the main body part is provided with a through hole. In the battery lug and the battery module, the lug unit is provided with the guide part of the long-narrow arc-shaped main body formed by extending from the body, so that the lug unit is elastic; the height differences or height errors of different battery cells are adapted; and the welding quality is enhanced. The main body part and the battery cells are welded in a contact way, so that the lug unit and the battery cells can be connected conveniently by welding. The fused part is arranged on the guide part of the high-elasticity long-narrow arc-shaped main body, so that design and fusing are facilitated. Moreover, the fused part is a weak position of structural heat, so that the fusing position is reasonable, and the module can be protected.

Owner:深圳福源特新能源有限公司

Spinal implant and methods of using the same

ActiveUS11065039B2Easy to insertAvoid relative motionInternal osteosythesisBone implantSpinal columnSacroiliac joint

A spinal implant for implantation within a spinal facet joint is provided. The spinal implant may include a main body including opposing top and bottom surfaces, opposing front or distal and rear or proximal surfaces, and opposing side surfaces. At least one retaining feature may be associated with at least one surface of the main body to frictionally engage the implant within the spinal facet joint. At least one securement feature may be associated with at least one surface of the main body to selectively secure the implant within the spinal facet joint.

Owner:PROVIDENCE MEDICAL TECH

Posterior Lumbar Plate

InactiveUS20160166296A9Easy to fuseImprove stabilityInternal osteosythesisFastenersDiseaseStable fixation

The present invention relates to stable fixation of spine segments, allowing for fusion in, e.g., skeletally mature patients. More particularly, the invention relates to a bone fixation device that can be affixed to vertebrae of a spine to provide reduction (or enlargement) capabilities and allow for fixation in the treatment of various conditions, including, e.g., spondyloslisthesis, degenerative disc disease, fracture, dislocation, spinal tumor, failed previous fusion, and the like, in the spine. The invention also relates to a method for delivering and implanting the bone fixation device.

Owner:GLOBUS MEDICAL INC

Tubular fuse

The invention discloses a tubular fuse. The tubular fuse comprises fiber pipe, contact pieces and a fuse piece; the contact pieces and the fuse piece are arranged in the fiber pipe; the contact pieces are arranged at the two ends of the fuse piece; the contact pieces are hinged with the fuse piece; an insulating gasket is arranged in the connecting place of the contact pieces and the fuse piece; V-shaped grooves are formed in the upper and lower ends of the fuse piece; threaded rings are arranged at the two ends of the fiber pipe; a screw cap is arranged on the outer side of the fuse piece; the screw cap and the threaded rings are in threaded connection; a wiring hole is formed in the screw cap; a waterproof gasket is arranged on the outer side of the screw cap; a supporting seat is arranged below the screw cap; the supporting seat is connected with the screw cap in a clamping manner; and fixed screws are arranged on the supporting seat. The tubular fuse is simple in structure, low in cost, convenient to use, light in weight, and easy to mount.

Owner:CHENGDU KECHUANG JIASI TECH

Electrophotographic image-receiving sheet and image forming method using the same

InactiveUS20090061348A1Excellent toner fixing propertyMaintain good propertiesLayered productsElectrographic processes using charge patternImage formationEngineering

The present invention provides an electrophotographic image-receiving sheet including a support having raw paper and a resin layer on at least one surface of the raw paper; and at least one coating layer on the support, wherein the thickness of the resin layer at least on the image-forming side is 5 μm to 15 μm, the coating layer contains at least hollow particles, and the amount of the hollow particles contained in the coating layer is 0.5 g / m2 or more.

Owner:FUJIFILM CORP

Square battery module structure

ActiveCN109935775AFacilitate the realization of integrationEasy to removeCell component detailsSecondary cells servicing/maintenanceEngineeringBattery pack

The invention relates to a square battery module structure comprising a box body, a cover plate, a battery pack composed of a plurality of square batteries arranged in a row and mounted in the box body, an overload protection block and a plurality of power connection blocks. Each square battery is provided with a positive electrode and a negative electrode. The negative electrode of a square battery is connected to the positive electrode of the square battery behind through the overload protection block or a power connection block. The overload protection block includes: two connecting blockshaving the same cross sectional area as that of the power connection blocks, and an overload protection member having both ends connected to the opposite ends of the two connecting blocks one to one.The cross sectional area of the overload protection member is less than the cross sectional area of the connecting blocks. According to the square battery module structure, the square batteries are connected by the overload protection block or the power connection blocks, and the overcurrent area is reduced by the overload protection member. When the current is abnormally increased, the overload protection member is quickly fused so as to quickly and sensitively achieve overload protection for the battery module.

Owner:ZHEJIANG LEAPMOTOR TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com