An energy-saving suspending wire clamp

A suspension wire clip and wire clip technology are applied in the field of energy-saving suspension wire clips, which can solve the problem of large loss of suspension wire clips, and achieve the effects of improving crystallization nucleation rate, refining magnetic domains, and reducing eddy current loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

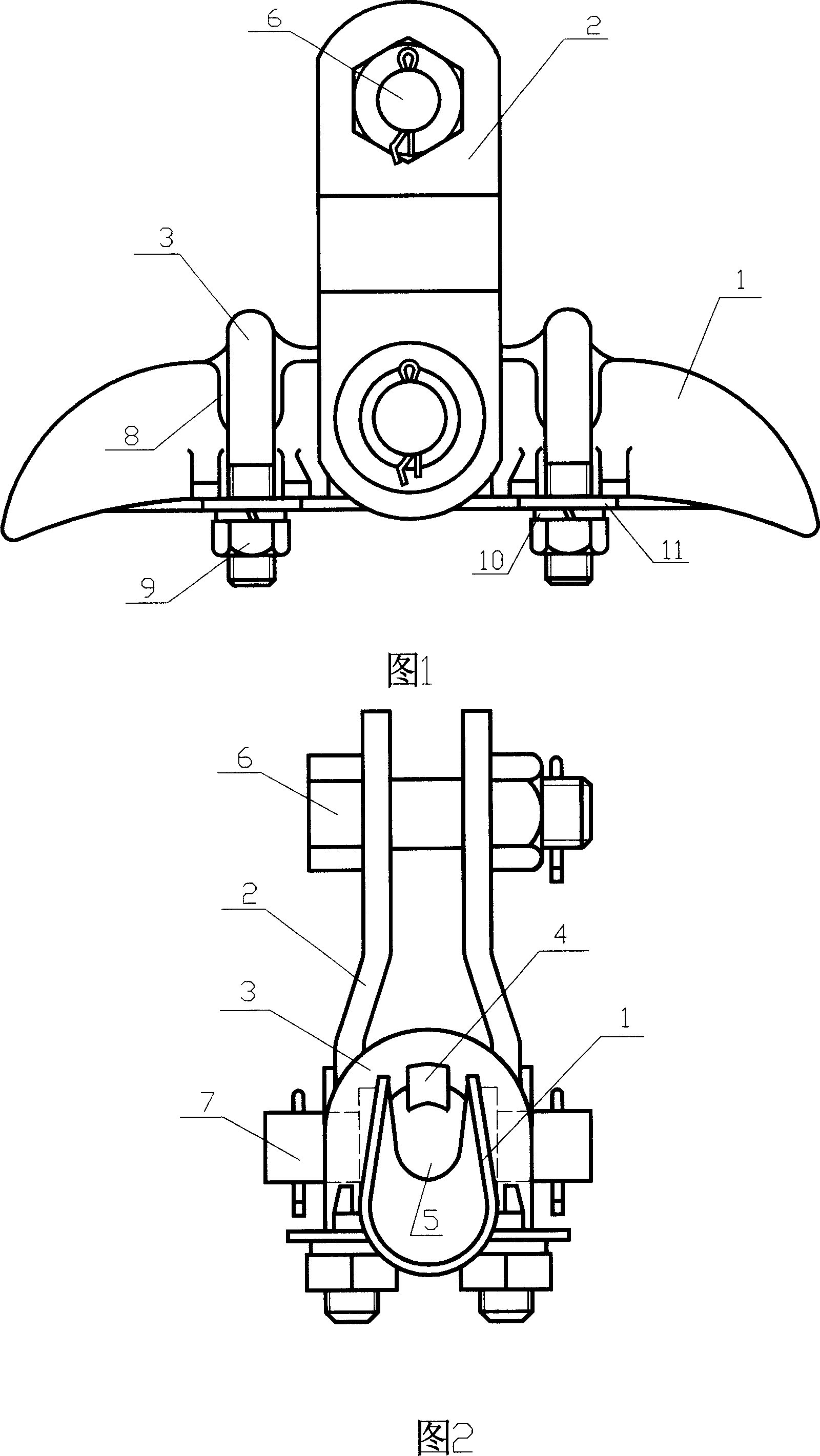

[0037] An energy-saving suspension clamp as shown in Figure 1 and Figure 2, including a clamp body 1, a U-shaped screw 3, a bead 4 and a hanging plate 2, and the hanging plate 2 is fixed on both sides of the clamp body 1 through a cotter pin 7 On the side, bolts 6 with holes are arranged on the top of the hanging plate 2, and the bead 4 is fixed above the wire groove 5 of the wire clamp main body 1 through U-shaped screws 3, and U-shaped screws are installed on the corresponding positions on both sides of the wire clamp main body 1. port 8, the U-shaped screw 3 is buckled on the installation port 8, a nut 9 is provided below the U-shaped screw 3, and an elastic gasket 10 is provided above the nut 9. A washer 11 is arranged above the elastic washer 10 . Wherein the hanging plate 2 and the U-shaped screw 3 are made of non-magnetic steel material.

[0038] The composition of austenitic non-magnetic steel is as follows: 20% manganese, 1% aluminum, 3% chromium, 0.2% carbon, 0.1% c...

Embodiment 2

[0040] The composition of the austenitic non-magnetic steel is as follows: 22% manganese, 3% chromium, 1.5% aluminum, 0.21% carbon, 0.2% complex rare earth elements, sulfur<0.04%, phosphorus<0.04%, and the rest is iron.

[0041] The structure of the suspension clamp is as in Example 1.

Embodiment 3

[0043] The composition of the austenitic non-magnetic steel is as follows: 22% manganese, 3% chromium, 1.5% aluminum, 0.19% carbon, 0.2% complex rare earth elements, sulfur<0.04%, phosphorus<0.04%, and the rest is iron.

[0044] The structure of the suspension clamp is as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| magnetic permeability | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com