Protection element

A technology for protecting components and protecting objects, which is applied to electrical components, contacts, electrical switches, etc., can solve the problems of high manufacturing costs, difficulty in melting the fusible conductor 3, and prolonged time, so as to achieve low environmental burden and prevent active The effect of unevenness and size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

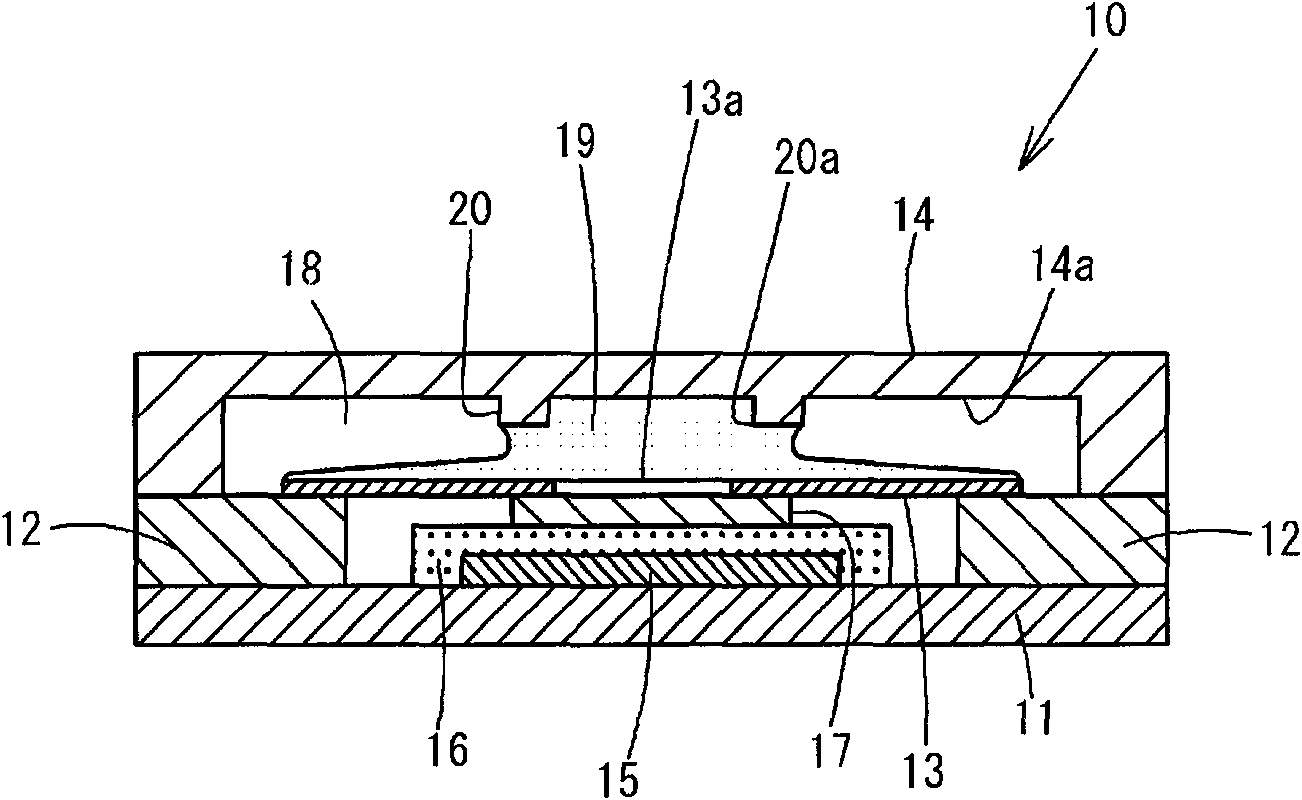

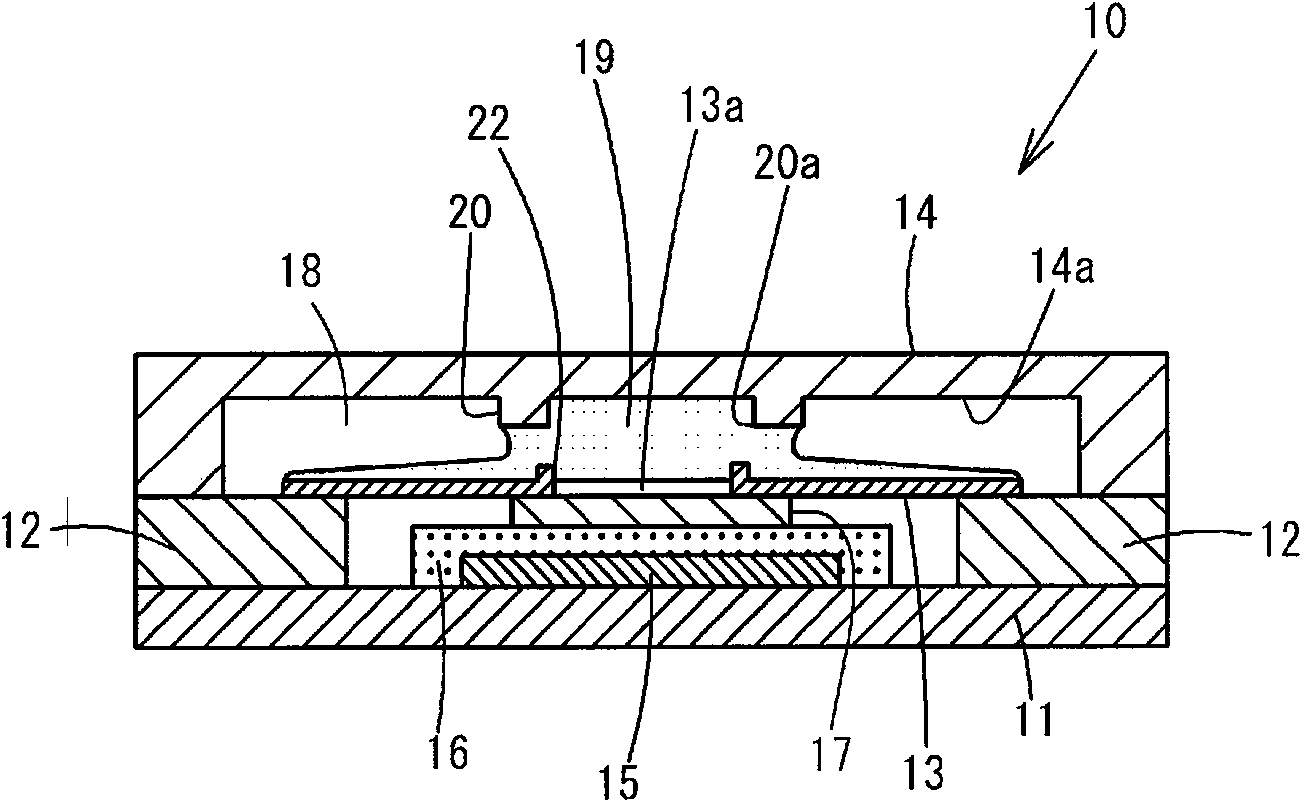

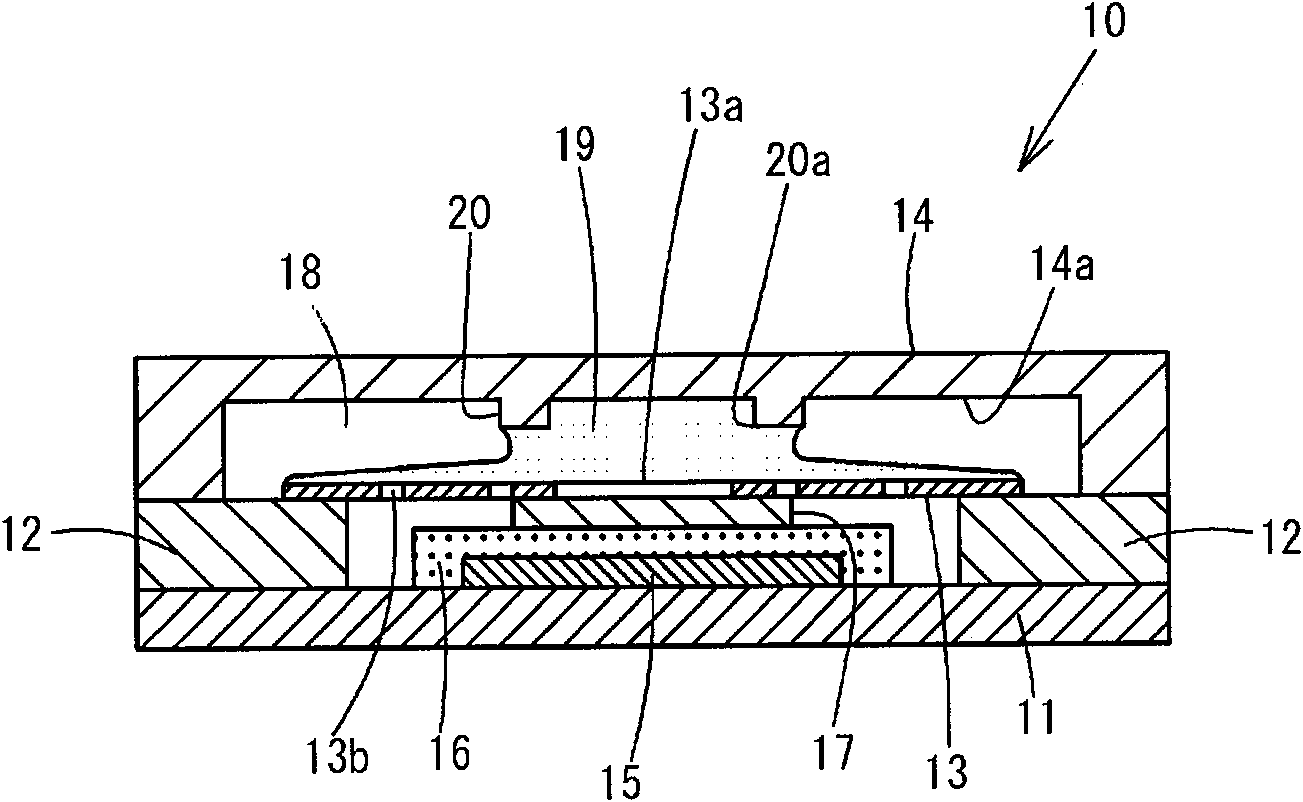

[0048] Hereinafter, for the first embodiment of the protection element of the present invention, according to Figure 1 to Figure 5 Be explained. The protective element 10 of this embodiment has a pair of electrodes 12 formed on both ends of the upper surface of an insulating base substrate 11 , and another pair of electrodes 21 is also provided on opposing edges perpendicular to the pair of electrodes 12 . Between the electrodes 21, a heating element 15 made of a resistor is connected. A conductive layer 17 connected to one of the electrodes 21 is laminated on the heating element 15 via the insulating layer 16 . On the conductor layer 17, the central part of the fusible conductor 13 of the fuse made of low-melting-point metal connected to the pair of electrodes 12 is connected. Furthermore, an insulating cover 14 made of an insulator is provided on the base substrate 11 so as to face the soluble conductor 13 .

[0049] As the material of the base substrate 11 , any material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com