Flame resistant synthetic resin composition

一种合成树脂、阻燃性的技术,应用在防火阻燃长丝制造、单组分聚酯人造长丝、单组分聚酰胺人造长丝等方向,能够解决未曾记载树脂材料影响、抽气效率不足等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

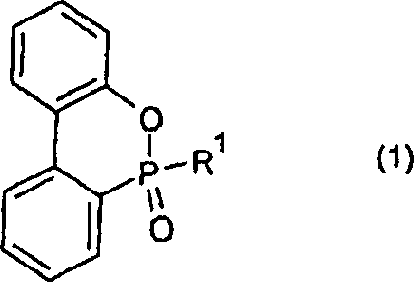

[0057] 5 parts by mass of the organophosphorus compound of the above chemical formula (3) was added to 100 parts by mass of the polycarbonate resin PANlight L-1225WP (manufactured by Teijin Chemical Co., Ltd.), and it was made by a twin-screw kneading extruder (ペルストルフZE40A). grain. The pellets were made into test pieces using an injection molding machine (N40BII, Nippon Steel Works), and the flame retardancy of the test pieces with a thickness of 1 / 8 inch was evaluated according to the UL-94 test method. The results are shown in Table 1.

Embodiment 2

[0059] A test piece was prepared in the same manner as in Example 1, except that 10 parts by mass of the organic phosphorus compound of the above chemical formula (3) was used instead of 5 parts by mass of the organic phosphorus compound of the above chemical formula (3), and the same flame retardancy evaluation was performed. The results are shown in Table 1.

Embodiment 3

[0061] A test piece was prepared in the same manner as in Example 1, except that 5 parts by mass of the organic phosphorus compound of the above chemical formula (4) was used instead of 5 parts by mass of the organic phosphorus compound of the above chemical formula (3), and the same flame retardancy evaluation was performed. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com