High-strength hot-rolled steel sheet and manufacturing method therefor

A technology for a hot-rolled steel sheet and a manufacturing method, applied in the field of high-strength hot-rolled steel sheet and its manufacturing, can solve problems such as toughness and reduced punching workability, achieve excellent punching workability and toughness, reduce costs, and reduce vehicle body weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

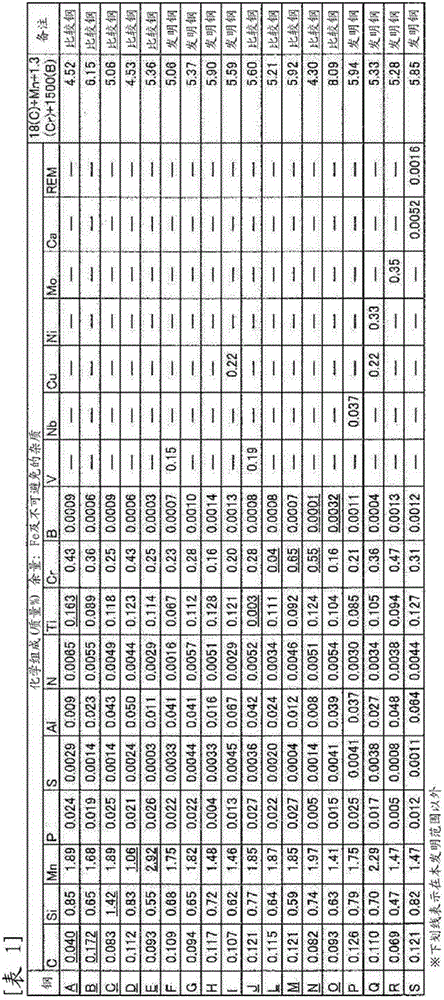

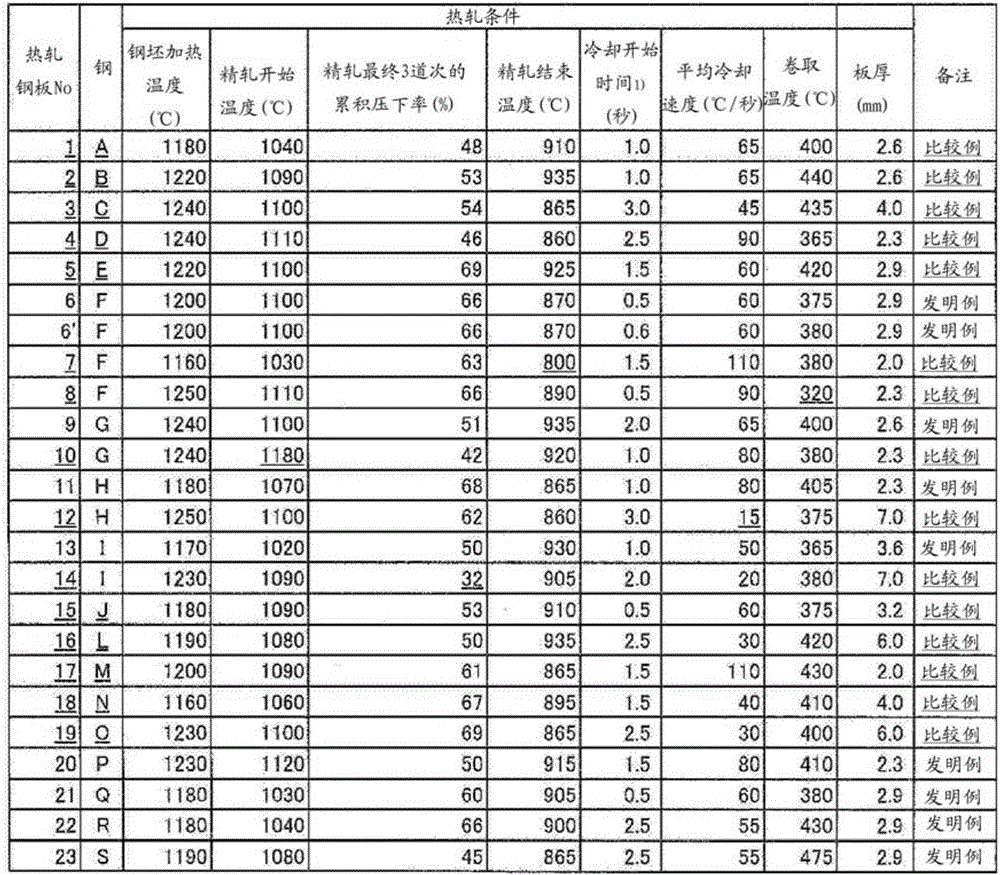

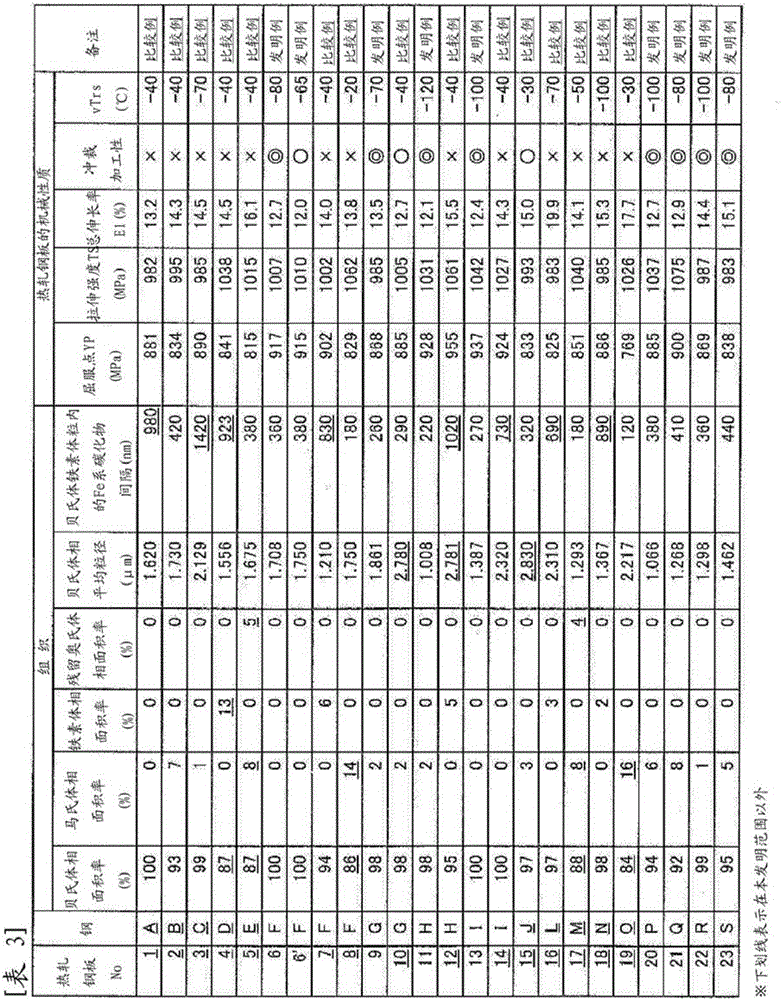

[0110] The molten steel with the composition shown in Table 1 was smelted in a converter, and a billet (steel raw material) was produced by a continuous casting method. During continuous casting, electromagnetic stirring (EMS) was performed on steel plates other than hot-rolled steel plate No. 6' (steel F) in Tables 1 to 3 described later in order to perform component segregation reduction treatment. Next, these raw steel materials were heated under the conditions shown in Table 2, and subjected to hot rolling including rough rolling and finish rolling under the conditions shown in Table 2. After finish rolling, cooling and coiling were performed under the conditions shown in Table 2 to produce hot-rolled steel sheets with thicknesses shown in Table 2. Test pieces were taken from the hot-rolled steel sheets obtained above, and microstructure observations, tensile tests, Charpy impact tests, and punching tests were performed. The tissue observation method and various test meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com