Battery lug and battery module

A technology of battery tabs and tabs, which is applied in the field of battery components, can solve problems such as unreasonable battery tab fusing positions, poor shock resistance of battery tabs, and insufficient battery fusing technology. Easy to design and fuse, simple process and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

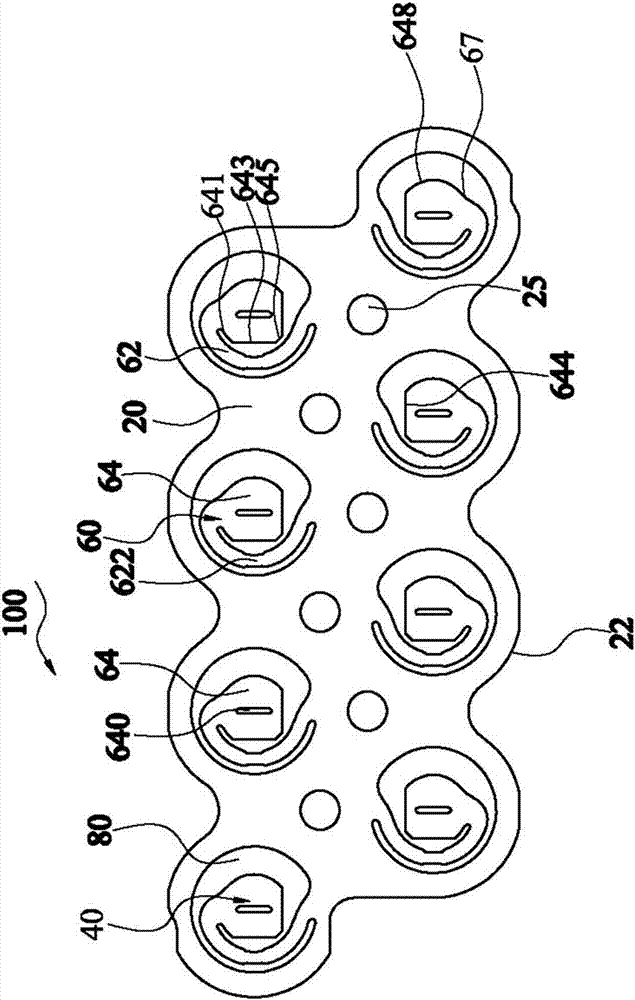

[0022] like figure 1 As shown, the battery tab 100 according to an embodiment of the present invention includes: a body 20 , and a tab unit 40 disposed on the body 20 and extending from the body 20 . The tab unit 40 includes: an elastic piece 60 extending from the body 20 , and an irregular spiral elastic piece groove 80 formed around the elastic piece 42 .

[0023] In order to make the lug unit 40 have better elasticity and be compatible with the height difference of the incoming materials of the battery core, the elastic piece 60 of this embodiment includes: a guide part 62 of a narrow and long arc-shaped main body formed by extending the body 20, and a guide part 62 formed by the guide part 62. The other end extends to form a main body portion 64 . The fuse part 622 is provided on the guide part 62 . A through hole 640 is disposed on the main body portion 64 . Preferably, the ends of the through hole 640 on the main body 64 are connected to both sides by a circular arc t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com