Current-limiting fuse used for protecting ozone high-frequency discharge unit

A high-frequency discharge and fuse technology, which is applied in the field of current-limiting fuses for the protection of ozone high-frequency discharge units, can solve the problems of poor arc extinguishing effect and weak breaking capacity of the fuse, and achieves simple structure and improved opening. The effect of breaking capacity and enhancing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

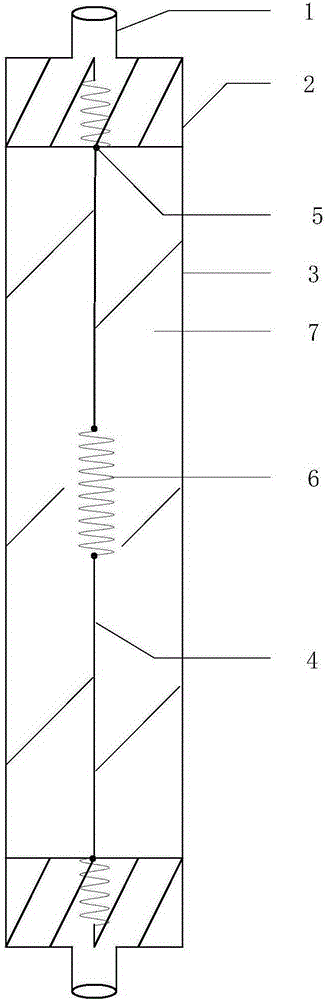

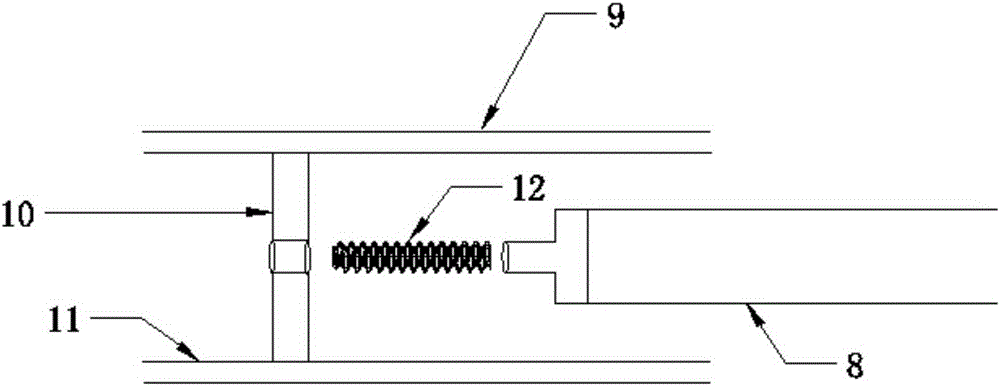

[0058] This embodiment discloses a current-limiting fuse for ozone high-frequency discharge unit protection that can cut off the circuit in time in a fault state. Its structure is as follows: figure 1 Shown; Also disclose the structure of part reactor electrode at the same time, as image 3 shown. It includes a cylindrical housing 3 which is an epoxy resin tube. The two ends of the cylindrical shell 3 are respectively compressed by the copper caps 2. Nuts 1 are arranged on the two copper caps 2. The inner side of the nut 1 has a screw thread that cooperates with the screw rod 12. The nut 1 is connected to the ozone reaction through the screw rod. The copper rod 10 in the reactor is connected, and the copper rod 10 is connected to the reactor electrode 11. The length of the housing 3 is determined according to the minimum length of the fuse tube. The length of the fuse tube is 240 mm. The cross section of the housing is selected according to the requirements of mechanical st...

Embodiment 2

[0079] This embodiment discloses a current-limiting fuse for ozone high-frequency discharge unit protection that can cut off the circuit in time in a fault state. Its structure is basically the same as that of Embodiment 1. The difference is that the housing of this embodiment is a ceramic tube. And because the position of the electrodes inside the reactor is different, considering the insulation problem, the length of the fuse needs to be changed, that is, the length of the melt and the shell should be adjusted appropriately. The shell is 260 mm long, 18 mm in outer diameter, and 2.5 mm thick. The melt is 65mm long and 0.09mm in diameter. The filling rate of quartz sand is 92%.

Embodiment 3

[0081] This embodiment discloses a current-limiting fuse for ozone high-frequency discharge unit protection that can cut off the circuit in time in a fault state. A melt unit, the shell is filled with quartz sand; the melt unit includes a melt, and the melt is provided with a metal or an alloy with a lower melting point than the melt. The melt is simple copper, and the metal whose melting point is lower than that of the melt is tin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com