Resistive random access memory for inhibiting excessive growth of silver conductive channel and preparation method thereof

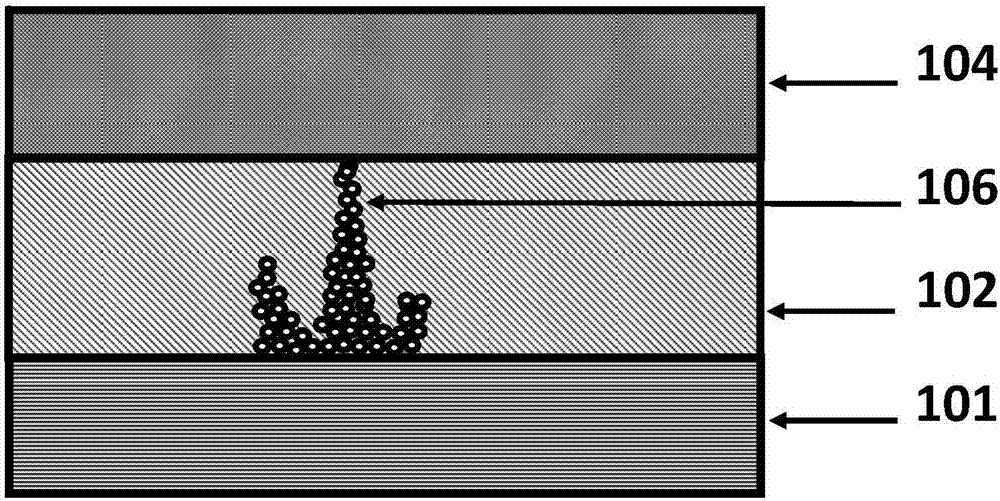

A resistive memory and conductive channel technology, applied in electrical components and other directions, can solve the problems of poor electrical uniformity of devices, inability to apply resistive memory, and increased peripheral control design, to achieve improved uniformity, low thermal conductivity, and improved The effect of productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

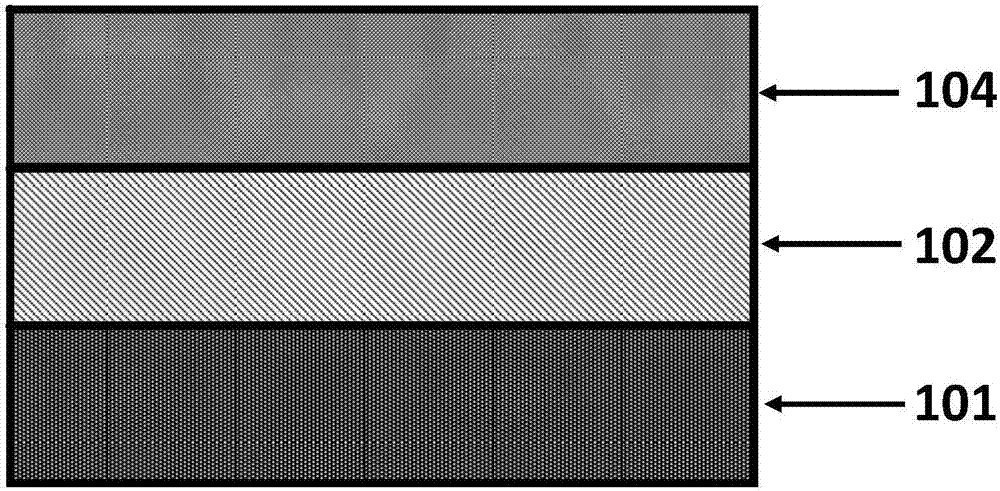

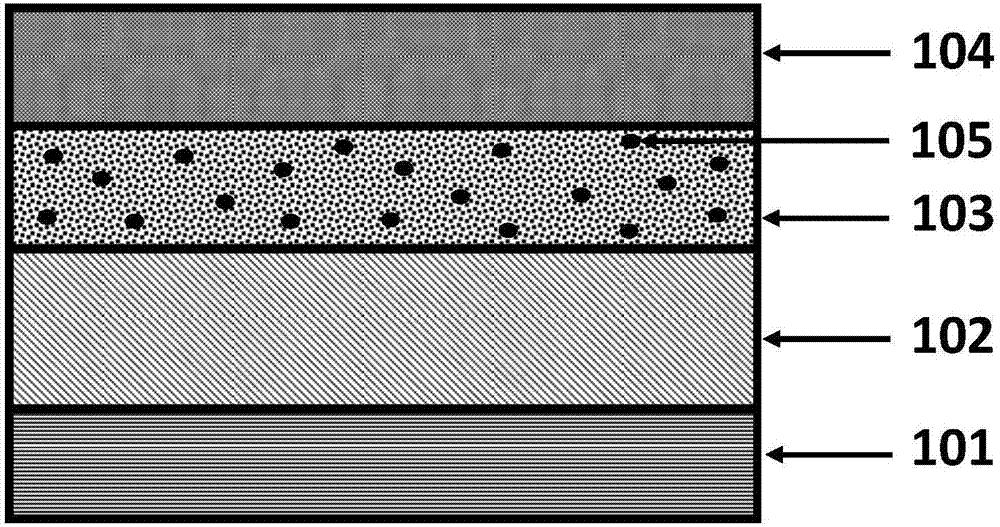

[0040] Embodiment 1: A preparation method of a resistive memory that suppresses the excessive growth of silver conductive channels of the present invention has the following steps:

[0041] Step 1: Clean the bottom electrode, put the bottom electrode into a beaker, pour acetone until the liquid level exceeds the bottom electrode by more than 1cm, and ultrasonically clean the bottom electrode for 10 minutes; replace the beaker, put the bottom electrode into the beaker and pour ethanol , so that the liquid level exceeds the bottom electrode by more than 1cm, sonicate in the ultrasonic cleaner for 10 minutes; then replace the beaker, pour in secondary deionized water, and cause the liquid level to exceed the bottom electrode by more than 1cm, sonicate in the ultrasonic cleaner for 10 minutes;

[0042] Step 2: On the cleaned bottom electrode, use the method of magnetron sputtering, that is, argon gas is introduced in a high vacuum, and hundreds of kilovolts are applied between the ...

Embodiment 2

[0045] Embodiment 2: A method for preparing a resistive memory that suppresses the excessive growth of silver conductive channels of the present invention has the following steps:

[0046] Step 1: Clean the bottom electrode, put the bottom electrode into a beaker, pour acetone until the liquid level exceeds the bottom electrode by more than 1cm, and ultrasonically clean the bottom electrode for 15 minutes; replace the beaker, put the bottom electrode into the beaker and pour ethanol , so that the liquid level exceeds the bottom electrode by more than 1cm, sonicate in the ultrasonic cleaner for 15 minutes; then replace the beaker, pour in secondary deionized water, and cause the liquid level to exceed the bottom electrode by more than 1cm, sonicate in the ultrasonic cleaner for 15 minutes;

[0047] Step 2: On the cleaned bottom electrode, use the method of magnetron sputtering, that is, argon gas is introduced in a high vacuum, and hundreds of kilovolts are applied between the c...

Embodiment 3

[0050] Embodiment 3: A preparation method of a resistive variable memory that suppresses the excessive growth of silver conductive channels of the present invention has the following steps:

[0051] Step 1: Clean the bottom electrode, put the bottom electrode into a beaker, pour acetone until the liquid level exceeds the bottom electrode by more than 1cm, and ultrasonically clean the bottom electrode for 12 minutes; replace the beaker, put the bottom electrode into the beaker and pour ethanol , so that the liquid level exceeds the bottom electrode by more than 1cm, sonicate in the ultrasonic cleaner for 12 minutes; then replace the beaker, pour in secondary deionized water, and cause the liquid level to exceed the bottom electrode by more than 1cm, sonicate in the ultrasonic cleaner for 12 minutes;

[0052] Step 2: On the cleaned bottom electrode, use the method of magnetron sputtering, that is, argon gas is introduced in a high vacuum, and hundreds of kilovolts are applied bet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com