Tubular fuse

A fuse and tube-type technology, which is applied in the field of tube-type fuses, can solve the problems of inconvenient installation, high cost, complex fuse structure, etc., and achieve the effect of firm and reliable installation, light weight and good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

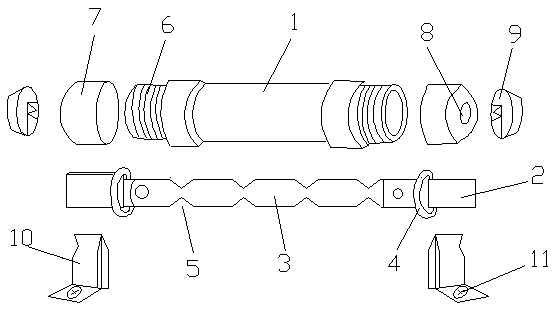

[0015] refer to figure 1 As shown, a tubular fuse includes a fiber tube 1, a contact piece 2 and a melting piece 3, the contact piece 2 and the melting piece 3 are arranged in the fiber tube 1, and the contact piece 2 is arranged end, the contact piece 2 is hinged with the melting piece 3, the connection between the contact piece 2 and the melting piece 3 is provided with an insulating washer 4, the upper and lower ends of the melting piece 3 are provided with V-shaped grooves 5, and the fiber tube 1 There are thread rings 6 at both ends, and nuts 7 are provided on the outside of the fuse 3. When in use, the tubular fuse is installed in the working area through the support 10, and the circuit is installed on the contact piece 2 through the wiring hole 8. On the other hand, when the circuit is overloaded, the V-shaped groove 5 on the fuse 3 will fuse quickly, so as to keep the circuit safe. The nut 7 is threadedly connected with the threaded ring 6, and the nut 7 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com