Air source device for compressor closed type experiment system and control method thereof

A technology of air source device and experimental system, which is applied in the field of compressed air energy storage, can solve problems such as high control accuracy requirements for air supply cylinders, environmental hazards, and untimely air supply, and achieve expanded testing capabilities, high degree of automation, and realization of The effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

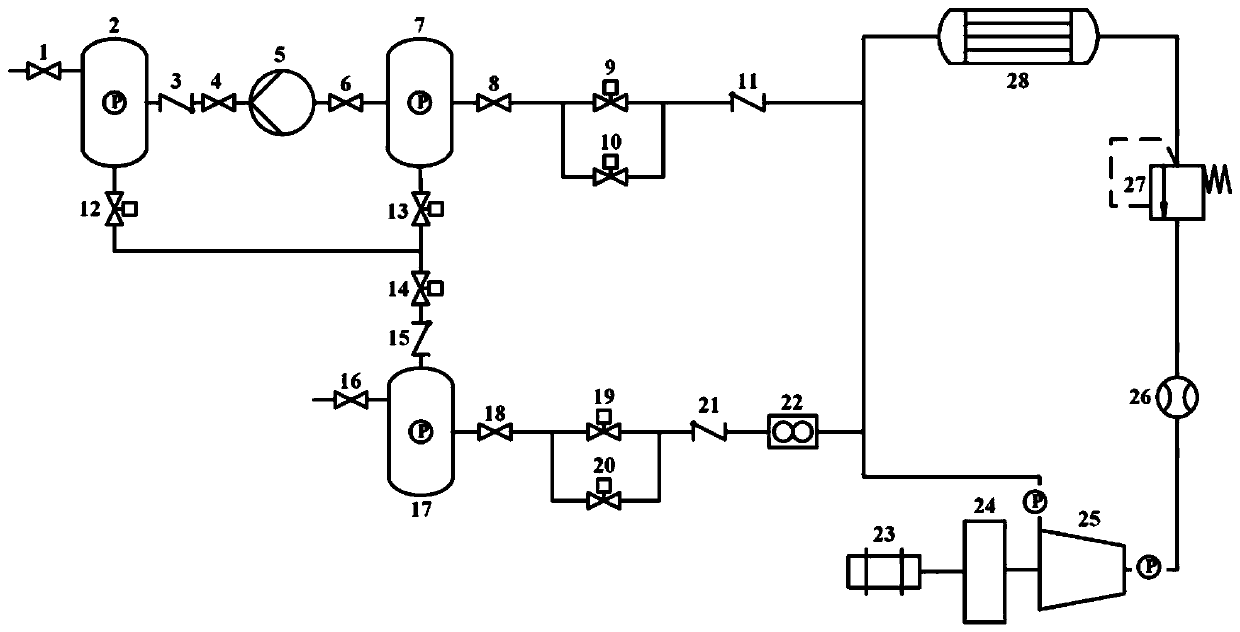

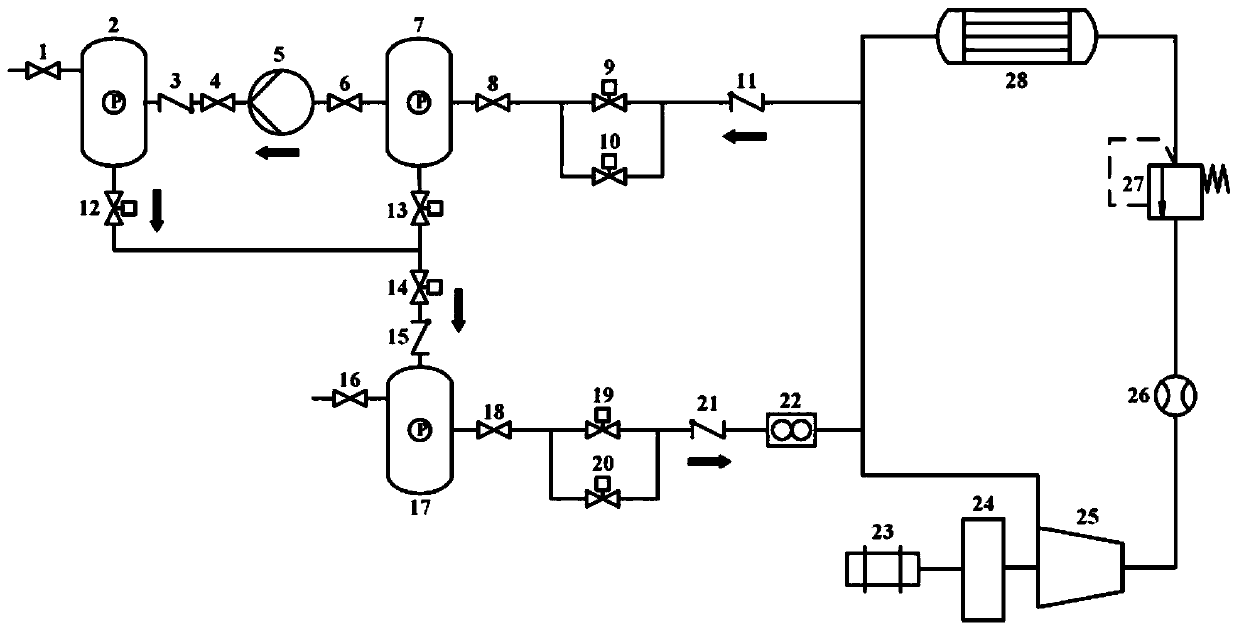

[0047] Such as figure 2 As shown, under general working conditions, during the experiment of the compressor closed-circuit experimental system, the air supply cut-off valve 16, the air supply cut-off valve 18, the main flow regulating valve 19 and the auxiliary flow regulating valve 20 are first opened, and the air discharge stop valve is closed. 8. The main air release valve 9 and the auxiliary air release valve 10, when the pressure of the working medium in the compressed gas pipeline of the compressor closed experimental system reaches the required value of the experimental inlet pressure of the tested compressor 25, close the main flow adjustment Valve 19 and auxiliary flow regulating valve 20. Afterwards, when the pressure of the working medium in the gas supply tank 17 reaches the required value of the gas supply pressure (the required value of the gas supply pressure is obtained according to the leakage of the measured compressor 25 and the test time), the gas supply c...

Embodiment 2

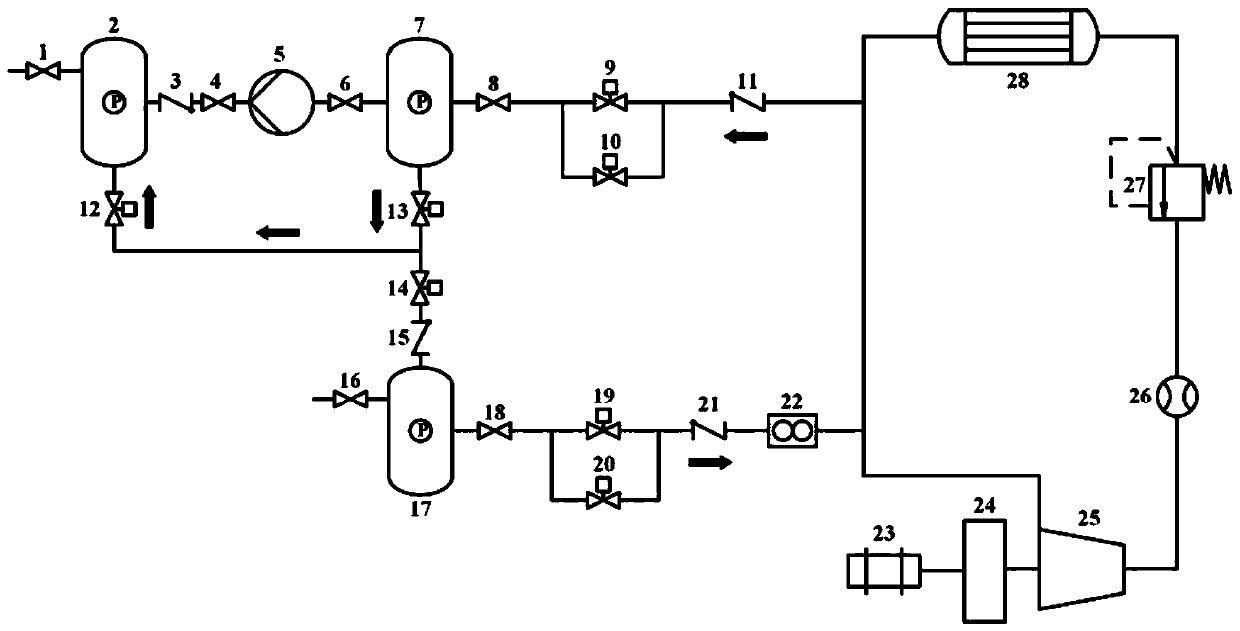

[0055] see image 3 , the difference between this embodiment and Embodiment 1 is that in this embodiment, since the test pressure of the compressor 25 under test is relatively high, the closed experimental system of the compressor is in a high-pressure working condition, and the pressure stabilizing unit of the gas source device is not connected during the test. Do not run, now the pressure of the working medium in the buffer tank 7 and the surge tank 2 is relatively low, and the pressure in the gas storage tank 17 is relatively high (guaranteeing the gas replenishment capacity of the compressor 25 under test and the requirements of the test time), and the solenoid valve 14 maintains In the closed state, the solenoid valves 12 and 13 remain open, and the working medium flows into the buffer tank 7 and the surge tank 2 through the deflation unit for storage.

[0056] To sum up, the gas source device used in the compressor closed experimental system proposed by the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com