Drying device for pipe parts

A drying device and a technology for pipe parts, which are applied in the field of mechanical parts processing, can solve problems such as parts damage, affecting the service life of mechanical parts, and water droplets are not easy to clean, so as to improve the rebound effect and improve the drying efficiency. Efficiency, the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

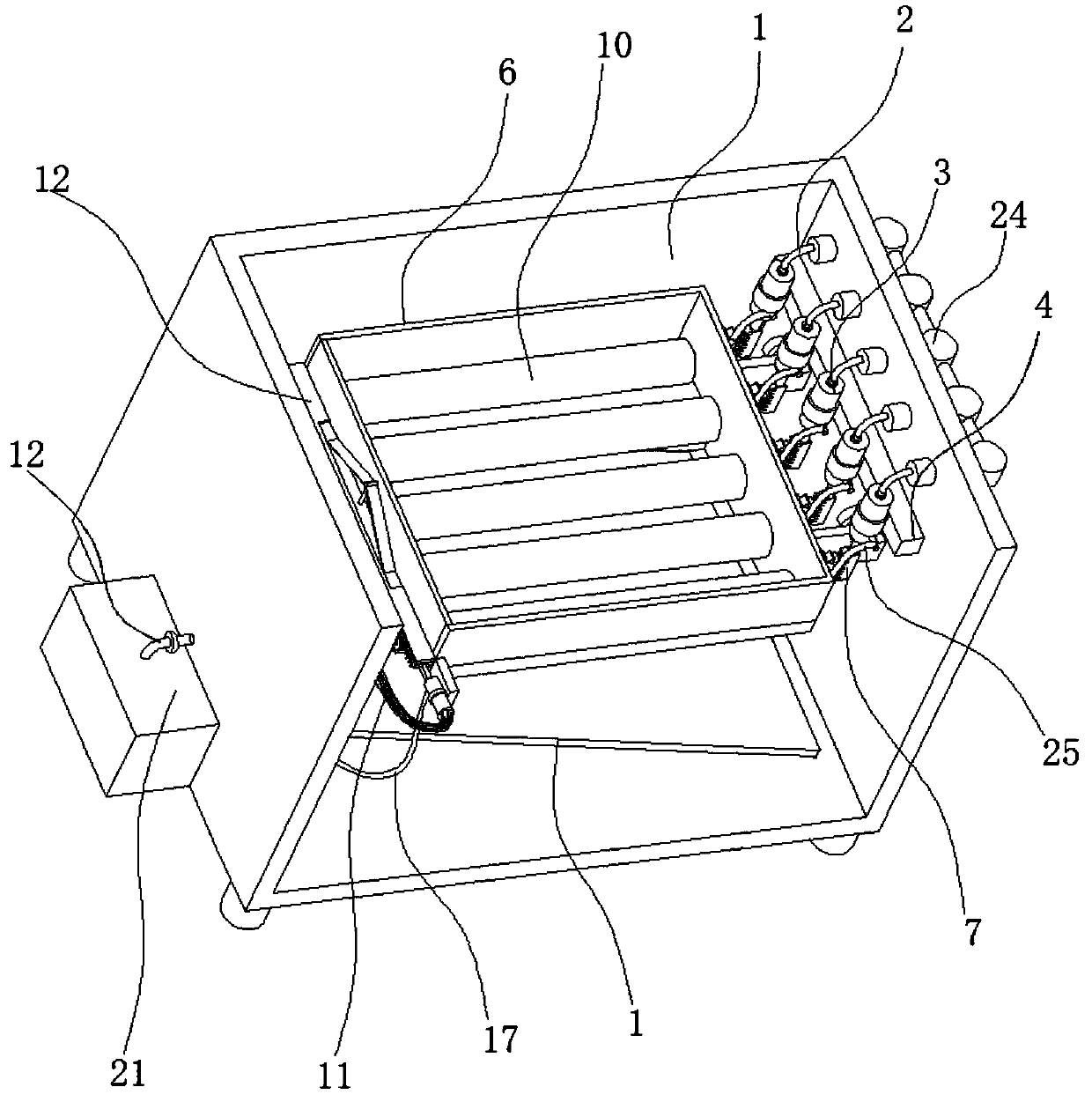

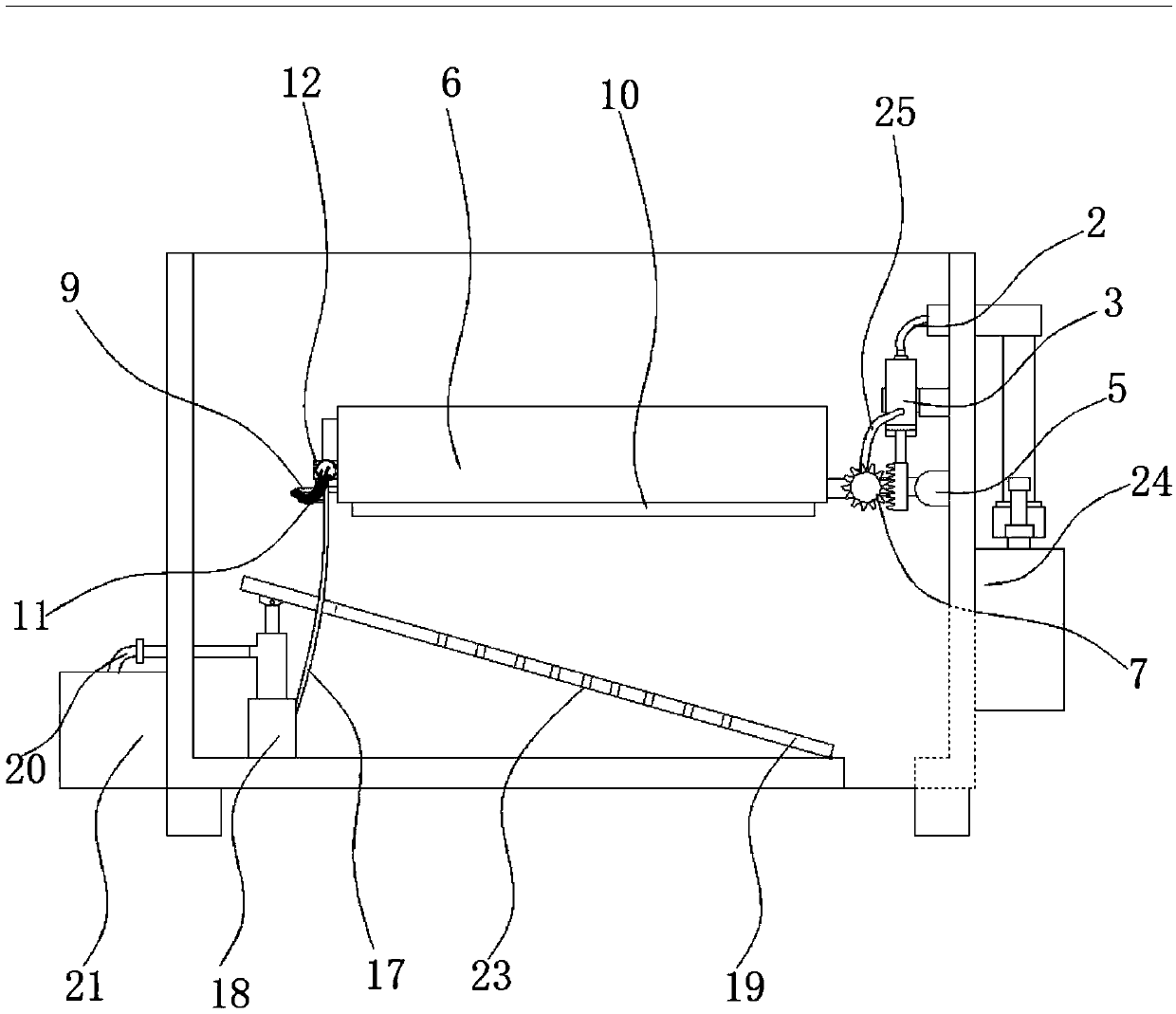

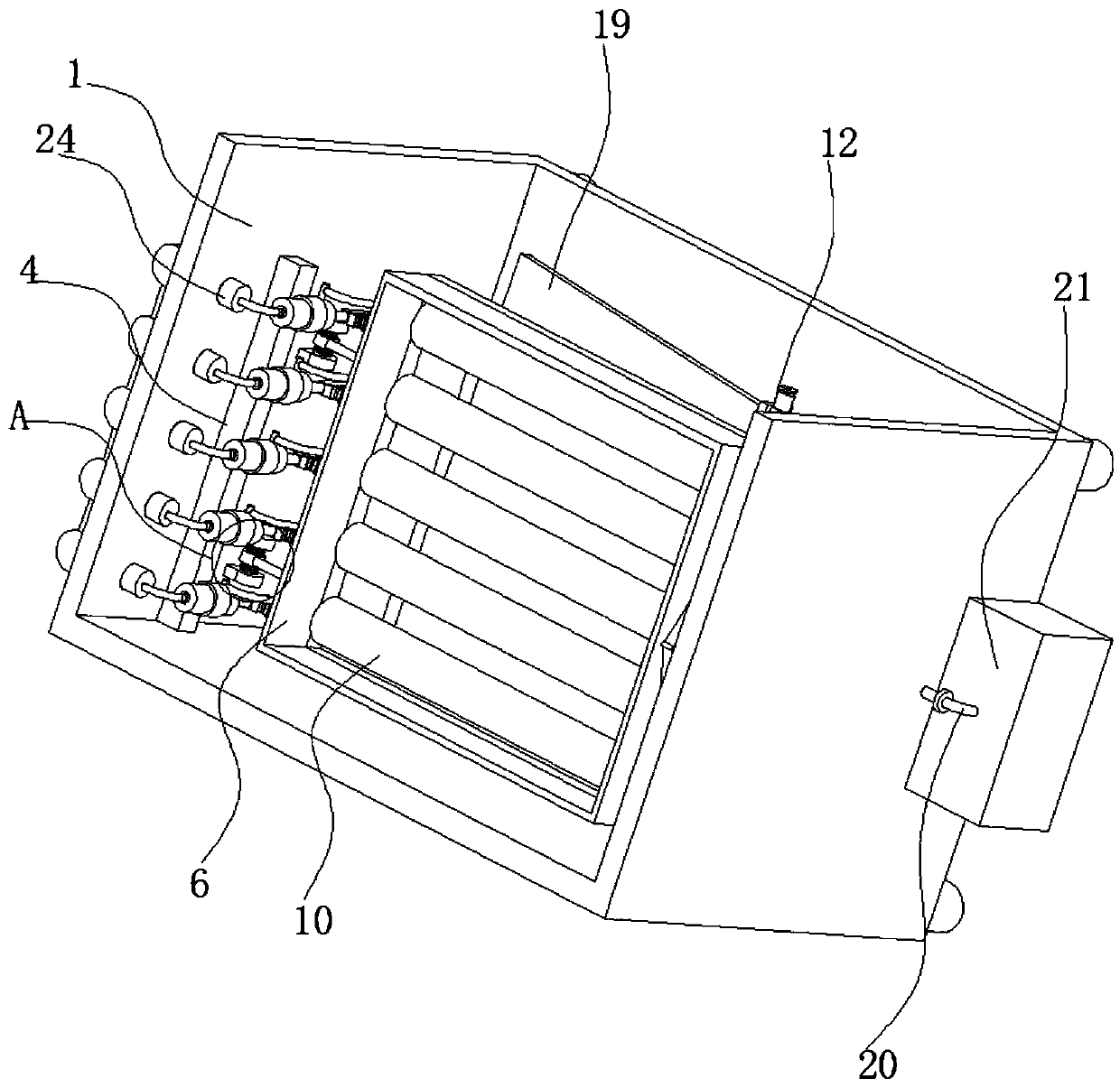

[0037] refer to figure 1 , figure 2 , image 3 and Figure 5, a drying device for pipe parts, including a box body 1 and an electrically heated steam generating mechanism 24, and the electrically heated steam generating mechanism 24 is connected to the outer wall of the box body 1, and the gas outlet of the electrically heated steam generating mechanism 24 passes through the first A connecting hose 2 is connected with a first drive assembly 3, the longitudinal inner wall of the box body 1 is connected with a fixed part 4 and a movable connection part 5 along the vertical direction, the first drive assembly 3 is connected with the fixed part 4, and the movable connection part 5 The end far away from the inner side wall of the box body 1 is connected with a fixed frame 6, the driving end of the first drive assembly 3 is connected with a transmission assembly 7 acting on the fixed frame 6, and the outer side wall of the fixed frame 6 close to the movable joint 5 is connected w...

Embodiment 2

[0039] refer to figure 1 , figure 2 , image 3 , Figure 5 , Figure 7 and Figure 8 , a drying device for pipe parts, which is basically the same as that of Embodiment 1, furthermore, the first drive assembly 3 includes a sleeve 31, the top of the sleeve 31 is connected with an air intake pipe 32, and the air intake pipe 32 passes through the first A connecting hose 2 communicates with the air outlet of the electric heating steam generating mechanism 24, and the outer wall of the sleeve 31 near the bottom is connected with an air outlet pipe 33, and the air outlet pipe 33 is connected with the first connecting pipe 8 through the fourth connecting hose 25, and the sleeve A piston 34 is slidably connected in the cylinder 31, and the side of the piston 34 away from the intake pipe 32 is connected with an adjustment rod 35. The outer wall of the adjustment rod 35 located in the sleeve 31 is covered with a return spring 36, and the two ends of the return spring 36 are respect...

Embodiment 3

[0043] refer to Figure 1-5 , a drying device for pipe parts, which is basically the same as Embodiment 1, furthermore, the movable joint 5 includes a U-shaped fixed rod 51, and the horizontal section of the U-shaped fixed rod 51 is covered with a sleeve rod 52, and the sleeve rod 52 is connected with connecting rod 53 between fixed frame 6, and the two ends of cover rod 52 are connected with power spring 54, and power spring 54 is enclosed within on the bar wall of U-shaped fixed rod 51 horizontal section; Fixed box 6 bounce effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com