A fully automatic punching and shearing machine

A punching and shearing machine, fully automatic technology, applied to metal processing equipment, feeding devices, manufacturing tools, etc., to achieve a wide range of applications and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

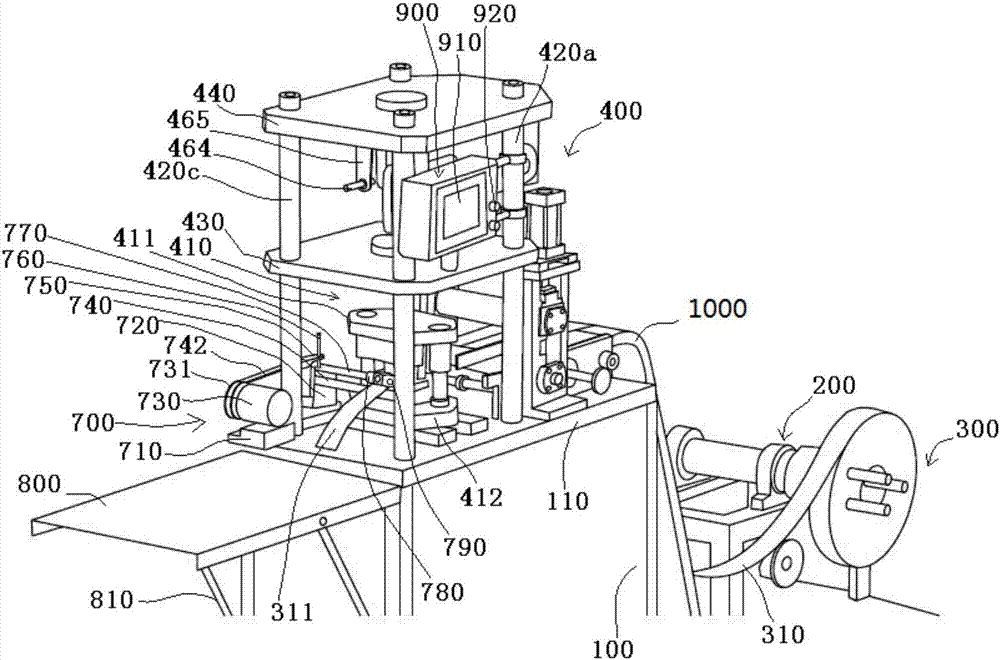

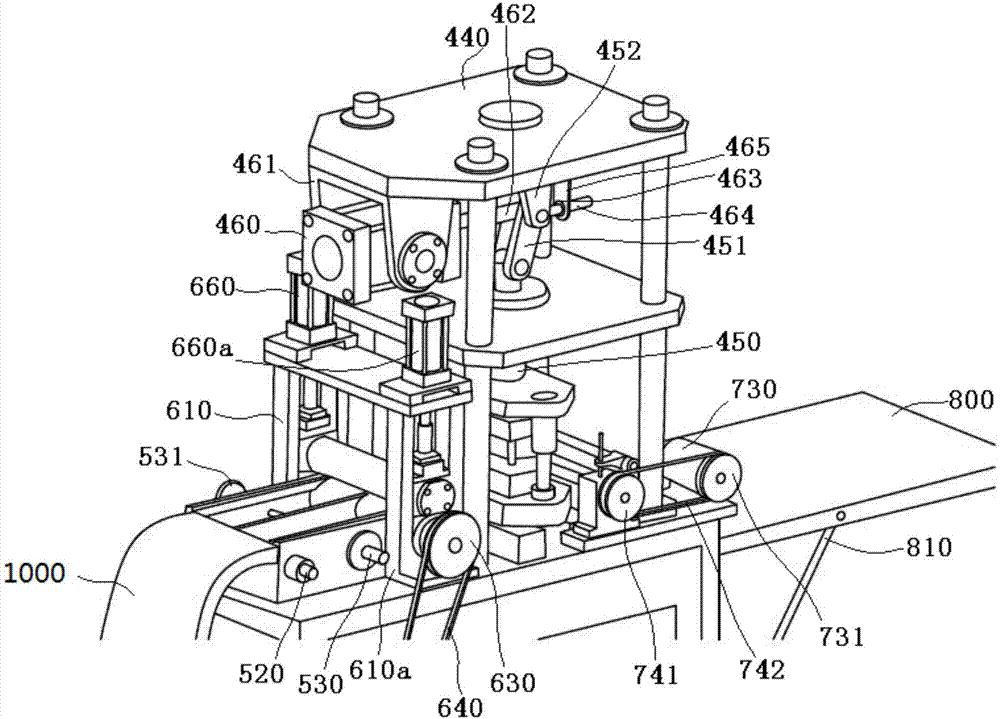

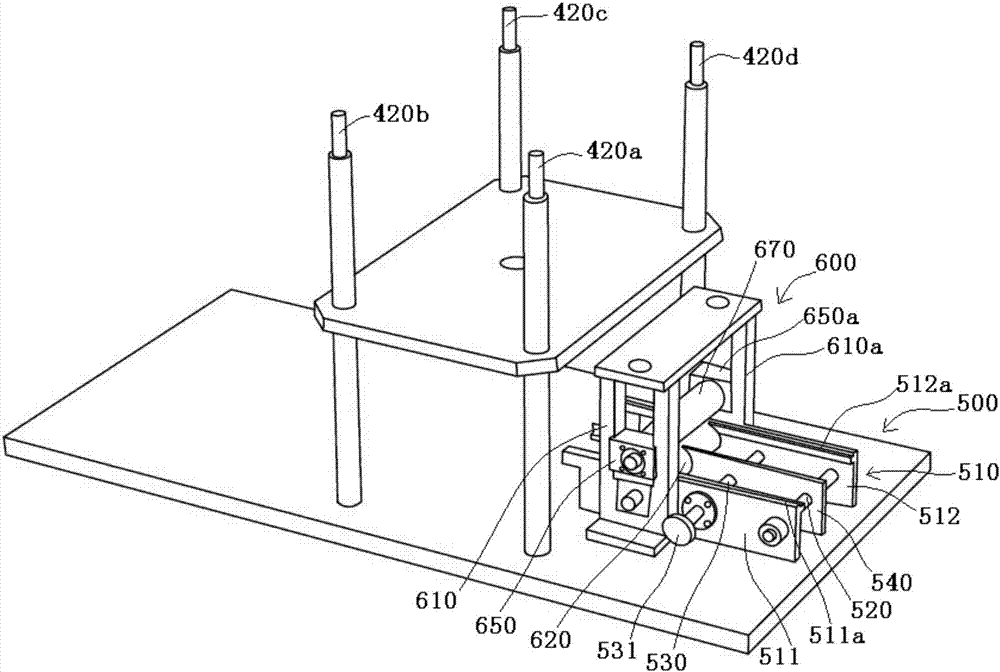

[0057] See attached Figure 1-3 As shown, the fully automatic punching and shearing machine shown in the figure includes a punching and shearing machine frame 100 with a mounting platform 110 on the punching and shearing machine frame 100 .

[0058] The fully automatic punching and shearing machine also includes an uncoiler 200, which is not much different in structure from the existing strip coil uncoiler, and will not be repeated here due to space limitations. The uncoiler 200 uncoils the copper strip coil 300 and sends out the uncoiled strip 310 .

[0059] A punching and shearing machine 400 is installed on the installation platform 110 of the punching and shearing machine frame 100 . The punching and shearing machine 400 includes a secondary punching and shearing die 410 , and the punching and shearing die 410 includes an upper punching and shearing die 411 and a lower punching and shearing die 412 , wherein the lower punching and shearing die 412 is installed on the instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com