Automatic threading equipment for venetian blind slats

A venetian blind and threading technology, which is applied to door/window protection devices, metal processing, windows/doors, etc., can solve the problems of slow processing speed, different positions of blind piercing, and increased labor intensity of workers, etc., to achieve Improve production efficiency and processing accuracy, ensure connection stability, and save labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with the drawings and embodiments:

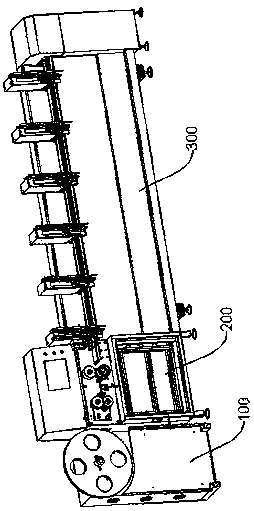

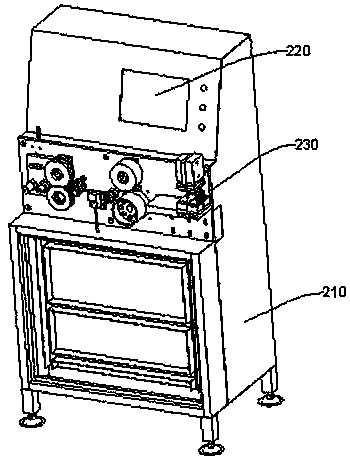

[0053] Such as figure 1 As shown, an automatic threading equipment for venetian blinds, the threading device 300 also includes a discharge device 100, an arc pressing and punching device 200, and a threading device 300. The curtain sheet 400 on the discharge device 100 is unrolled and passed through the arc pressing After the punching device 200 performs arc pressing, punching and slicing, it enters the threading device 300. The unwinding device 100 and the arc pressing and cutting device 200 can be fixed to each other or separated from each other. In this embodiment, they are separated from each other.

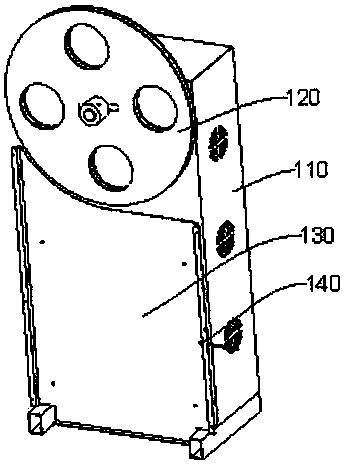

[0054] 1. Unwinding device 100

[0055] Such as figure 2 As shown, the discharging device 100 includes a discharging cabinet 110 and a material tray 120. The curtain sheet is sleeved on the material tray 120. The lower side of the material tray 120 is provided with a ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com