Patents

Literature

46results about How to "To achieve the purpose of delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

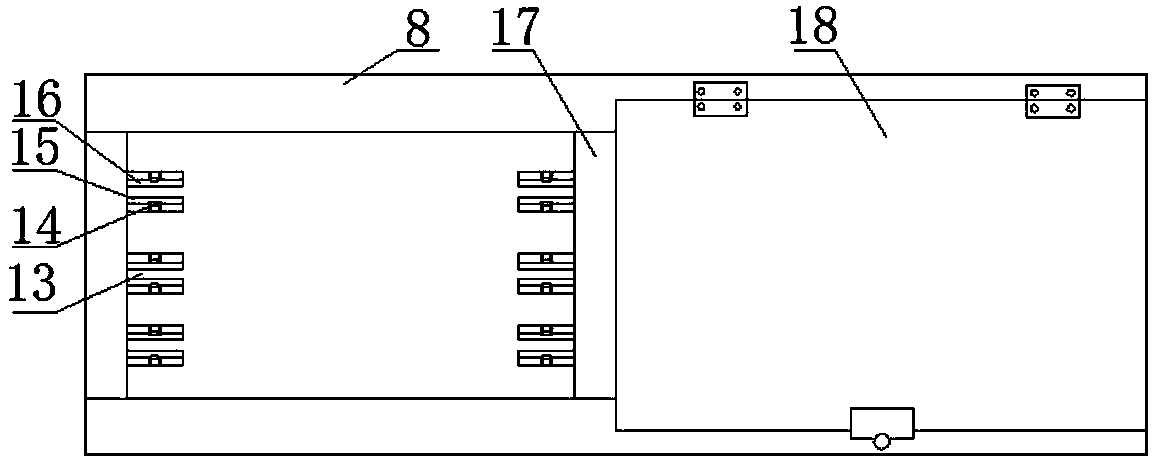

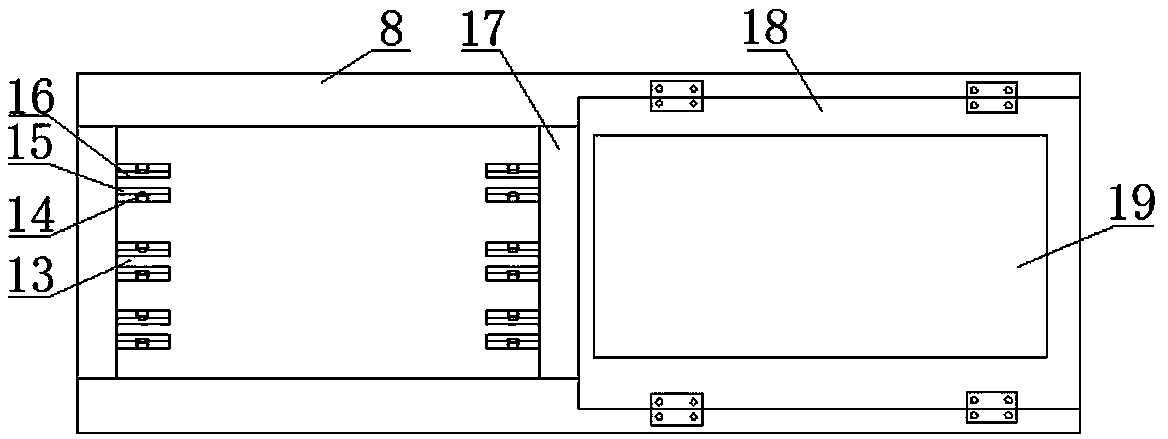

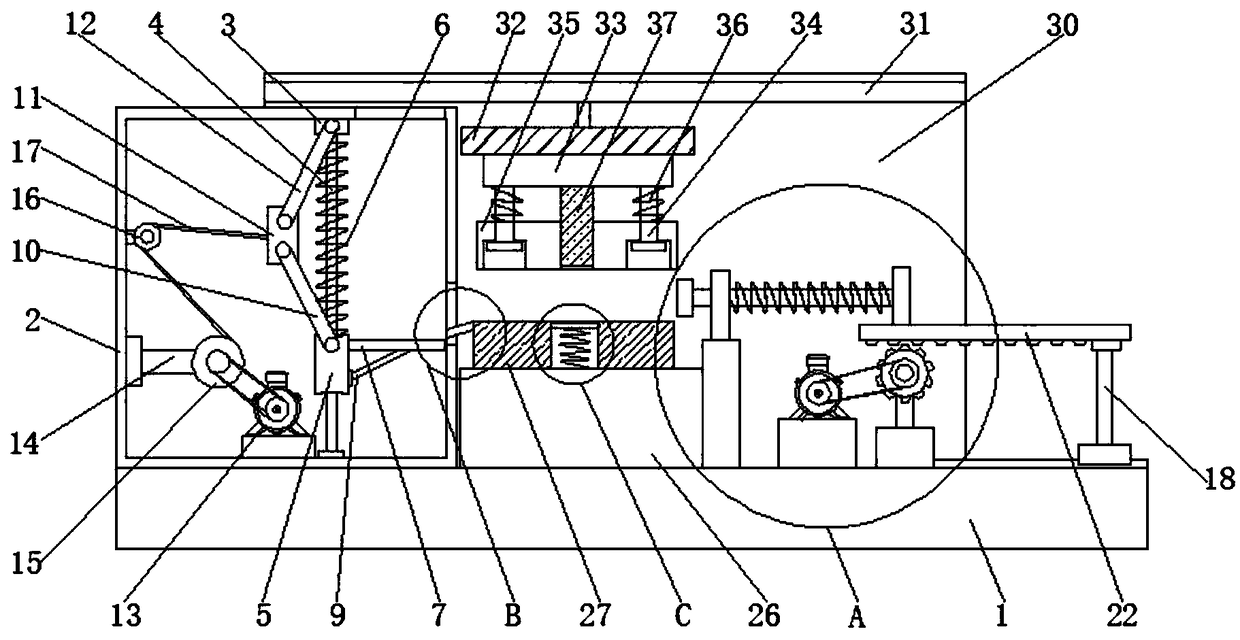

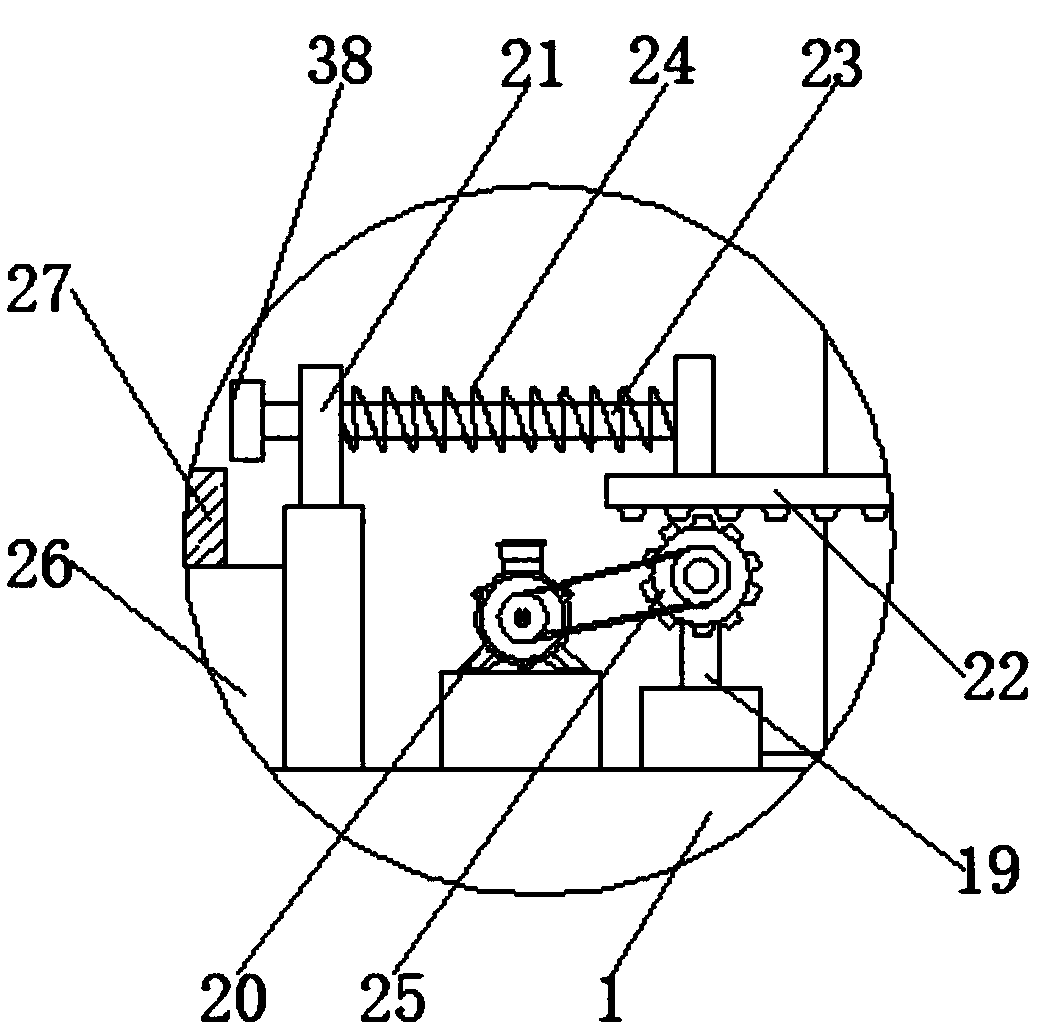

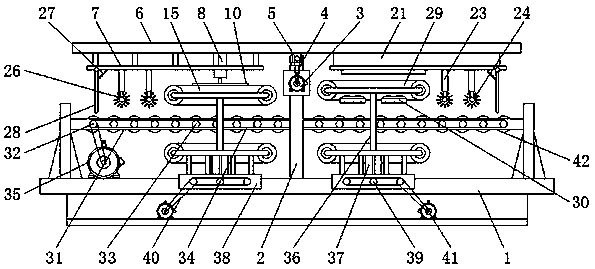

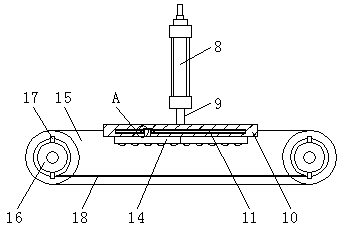

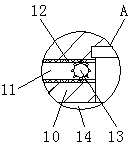

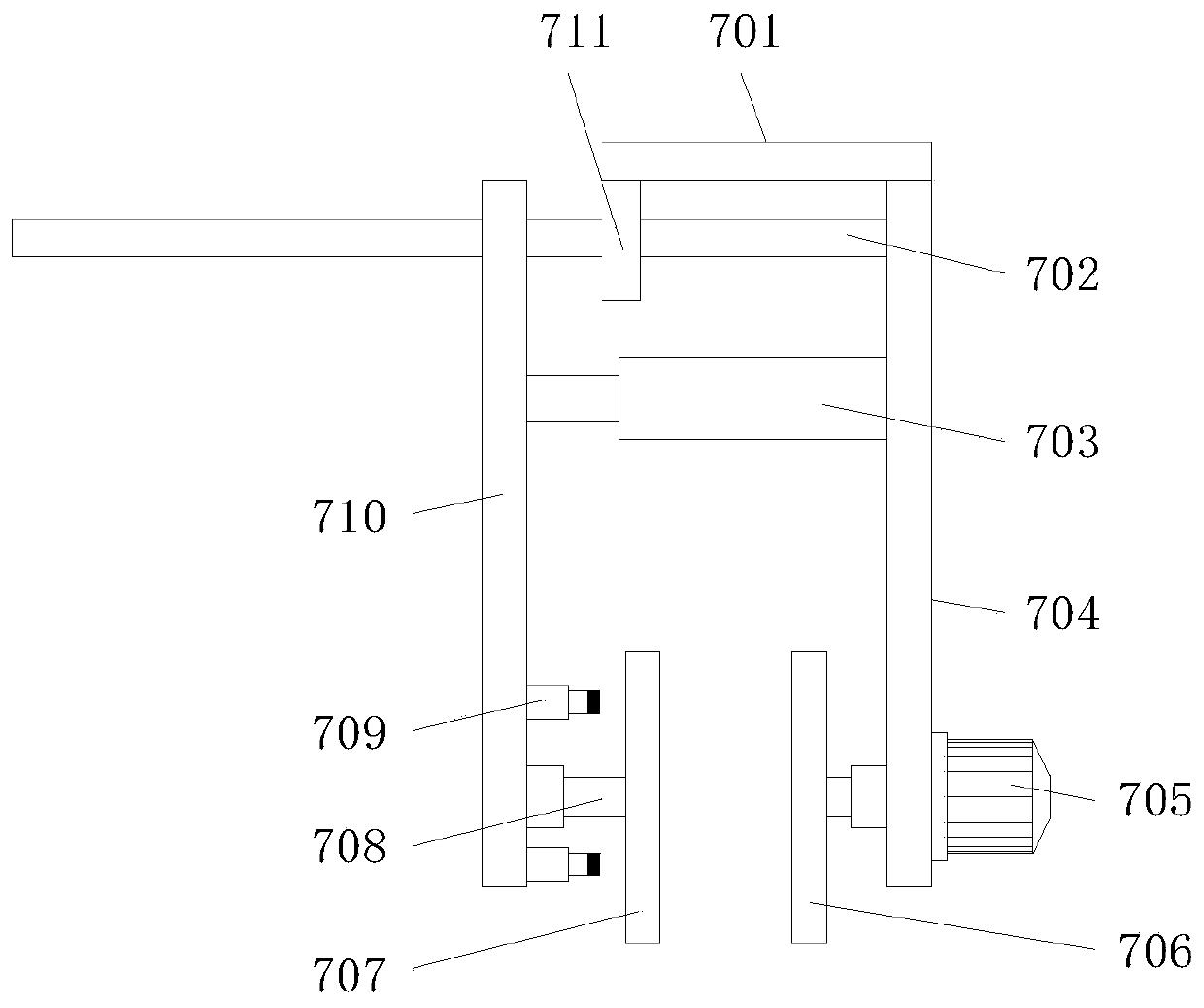

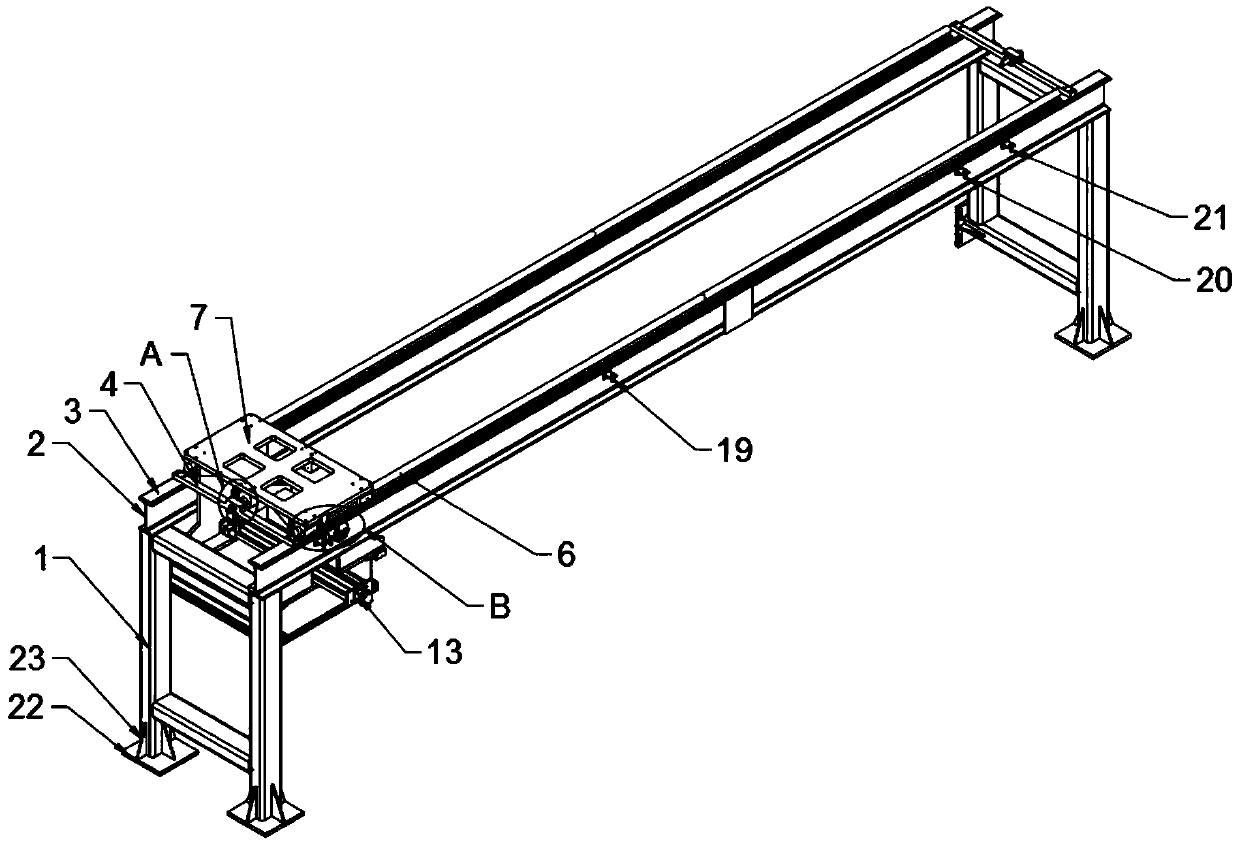

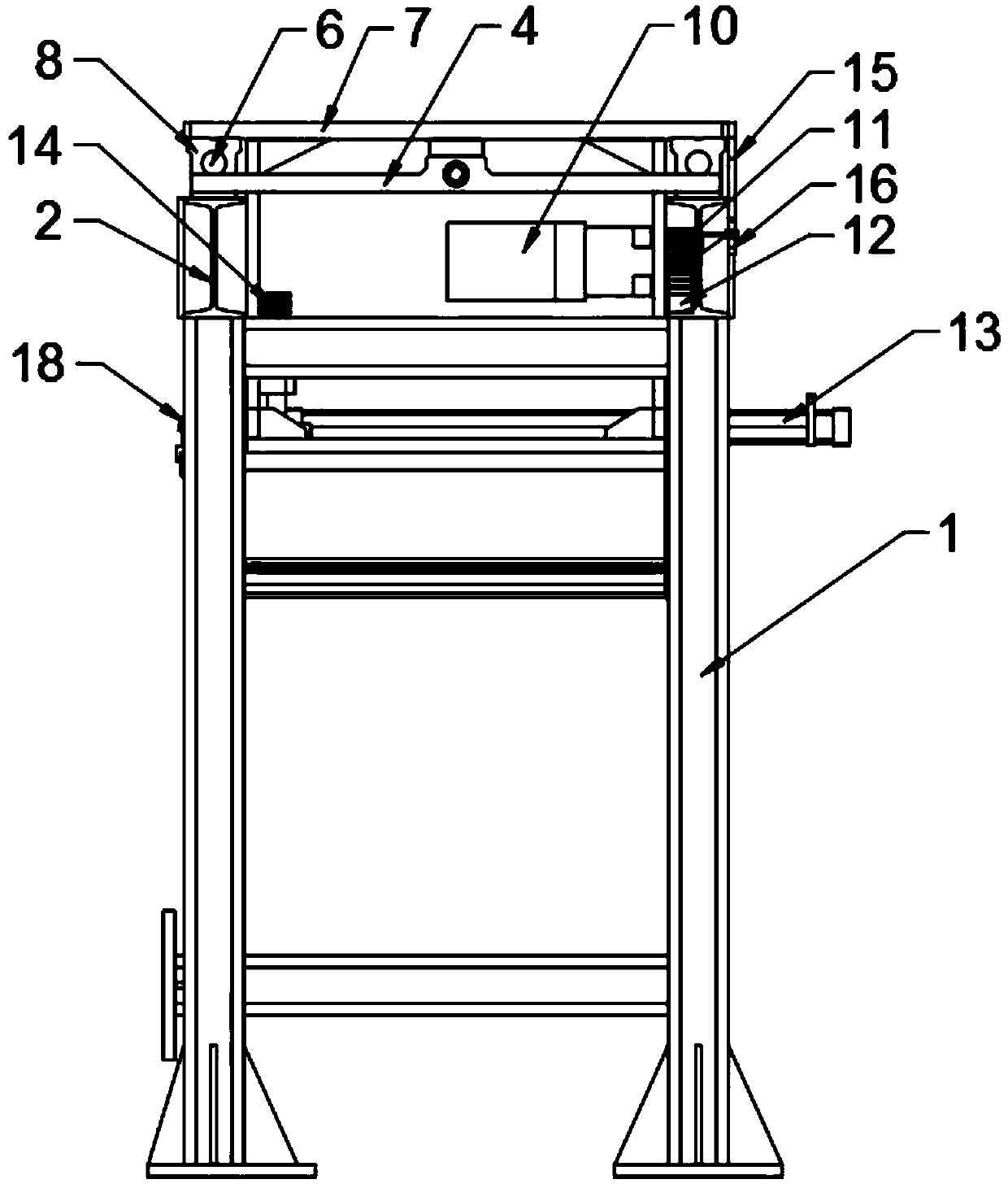

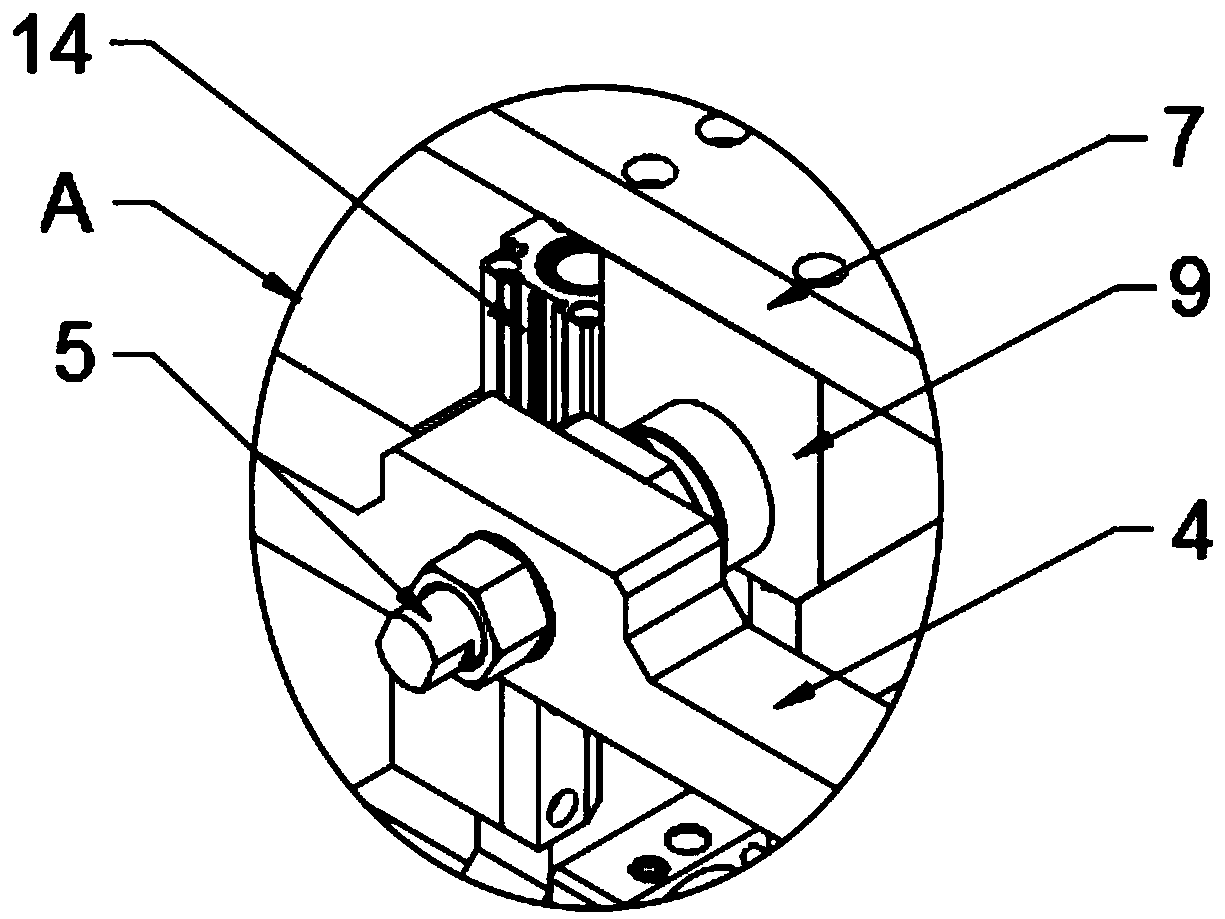

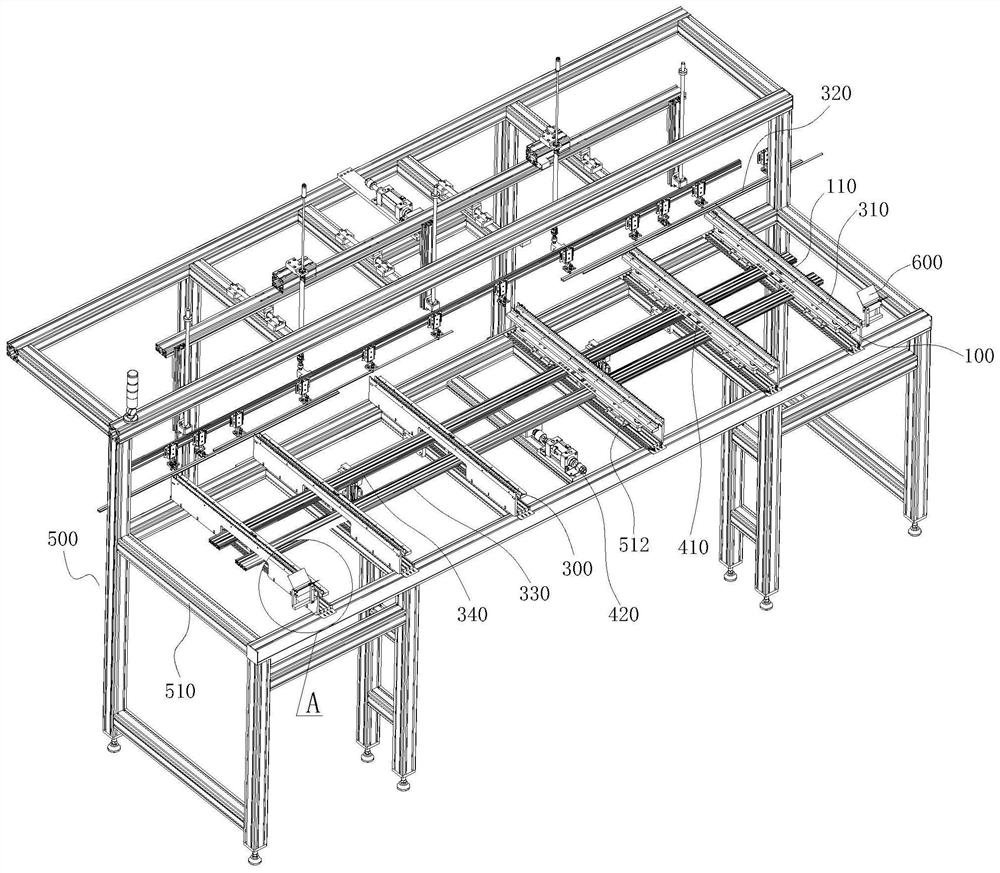

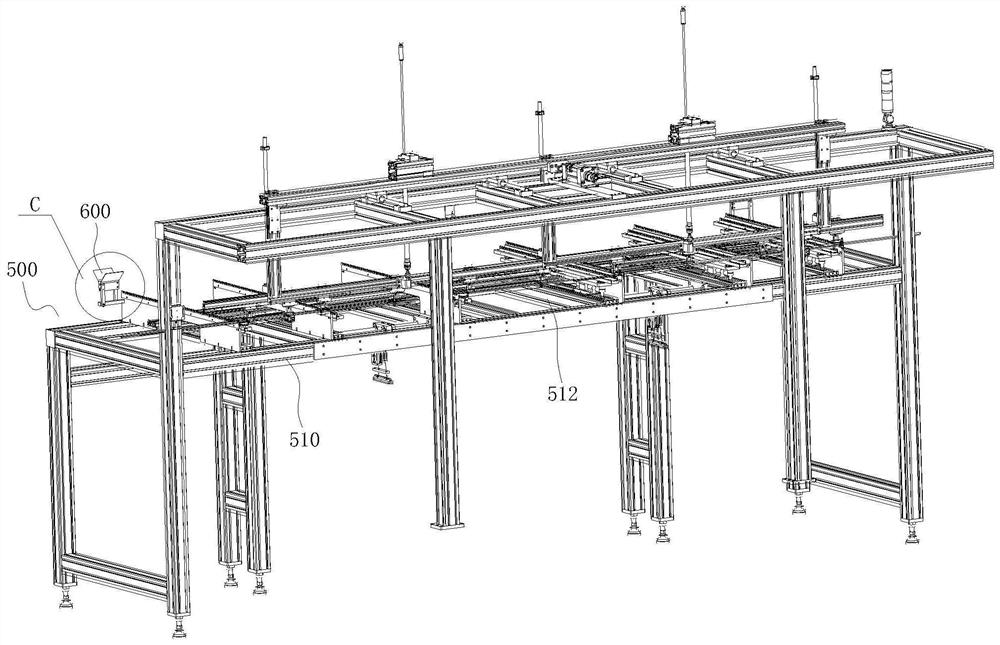

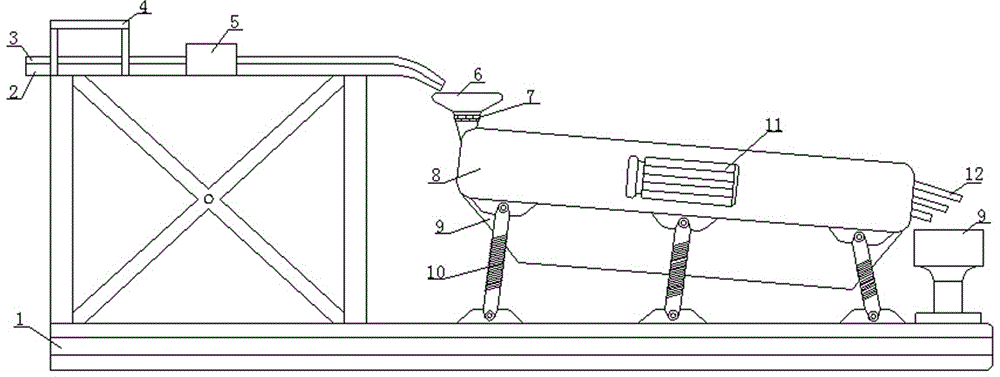

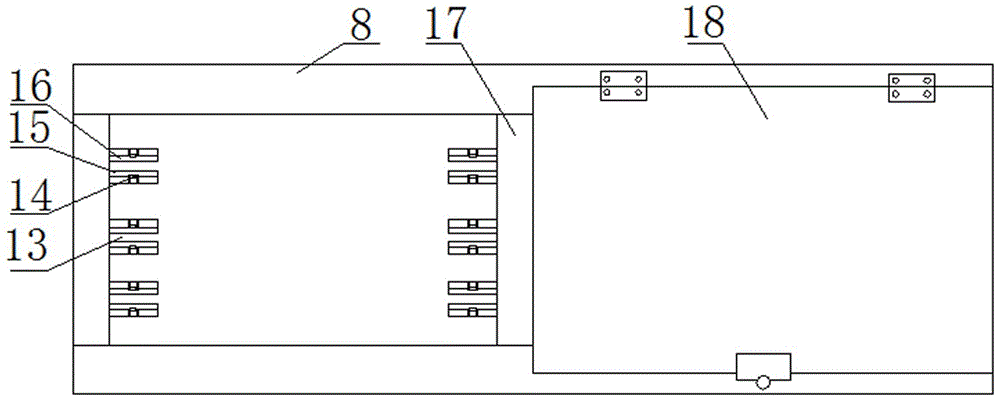

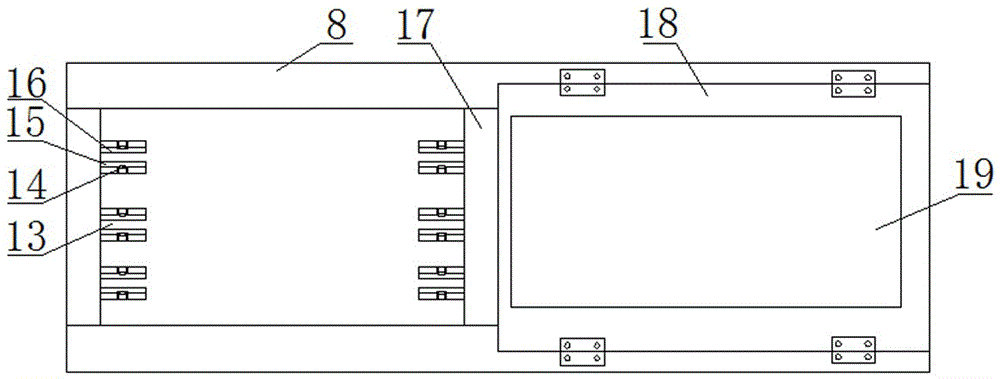

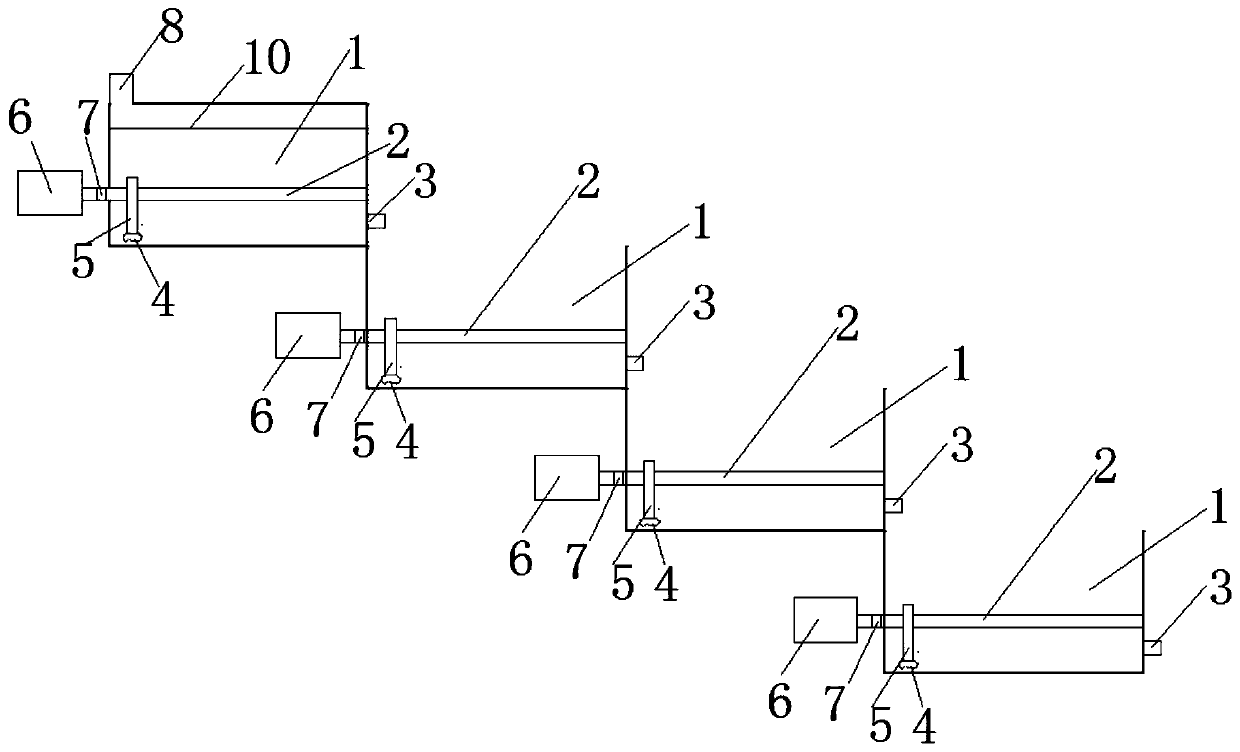

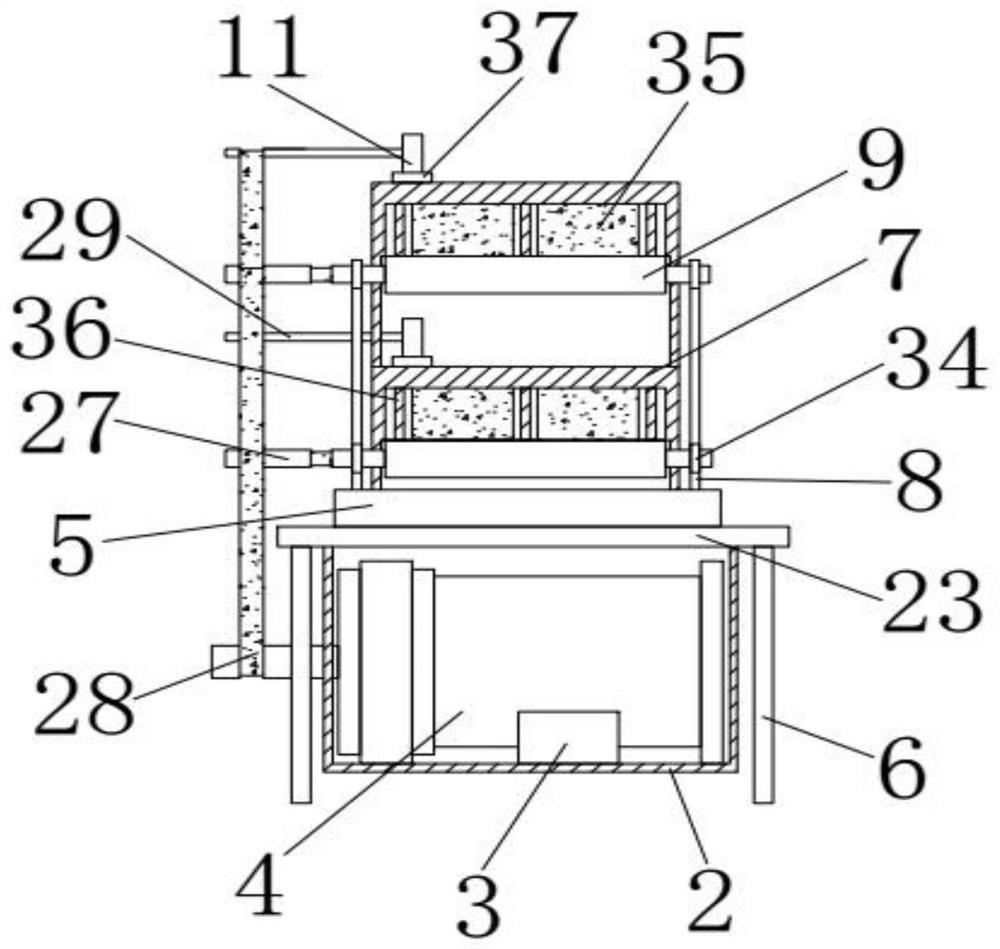

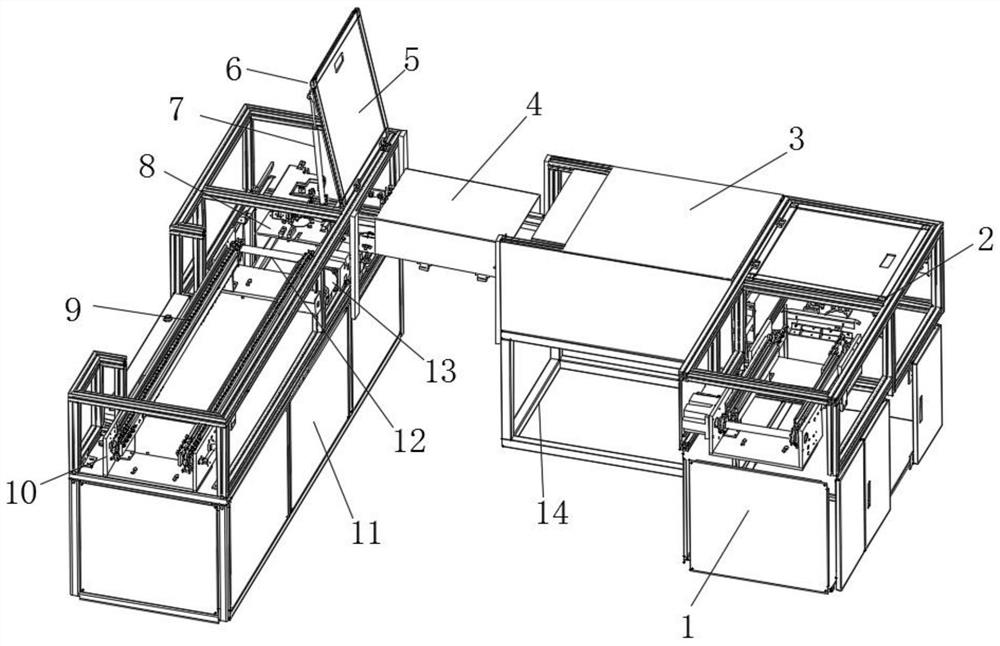

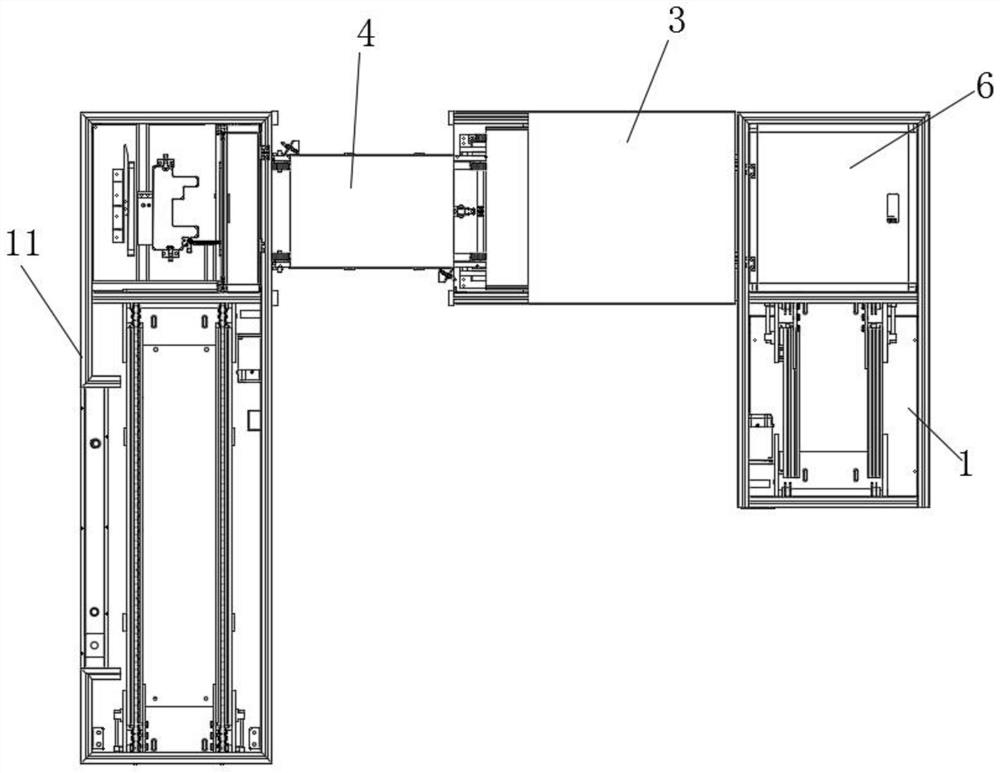

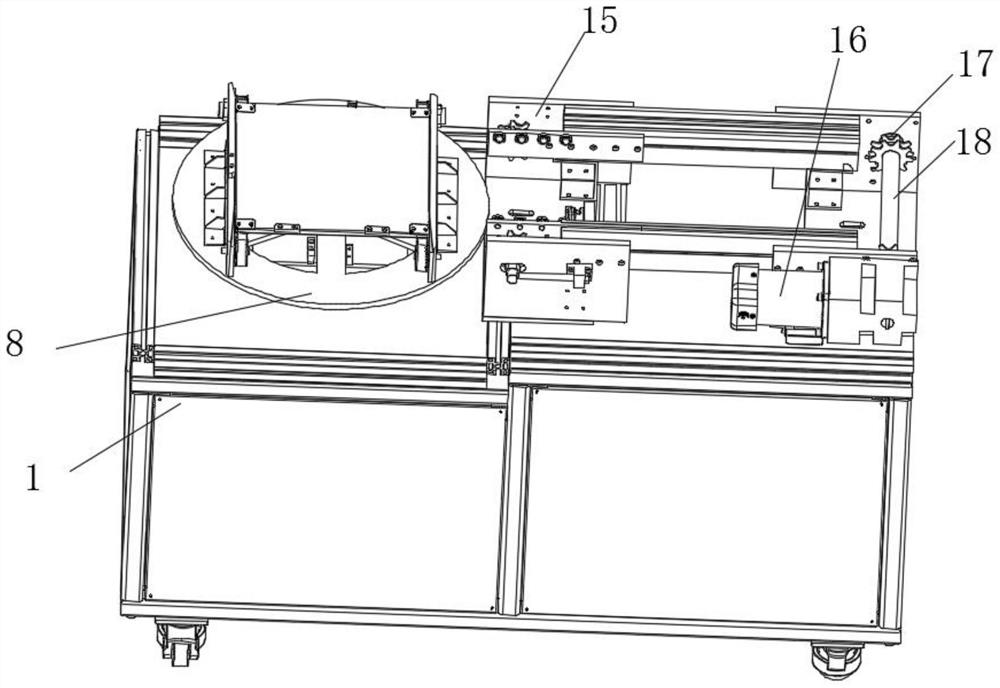

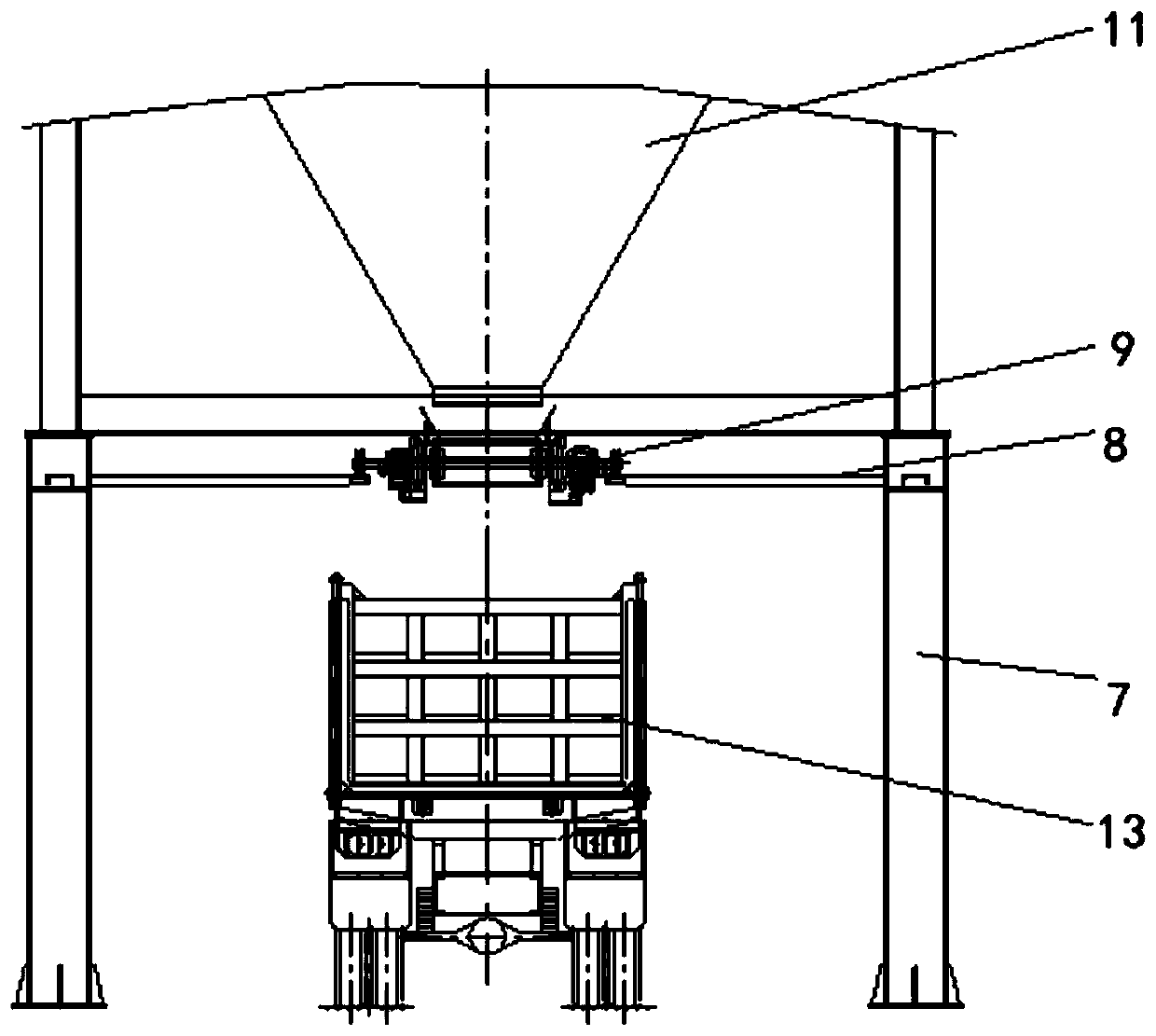

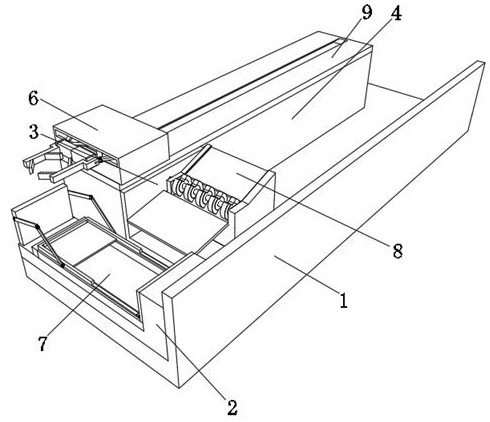

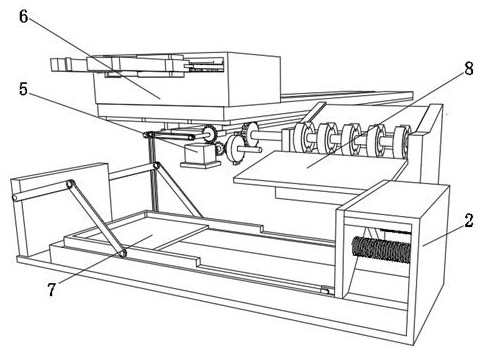

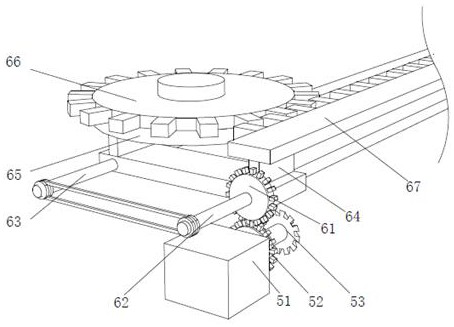

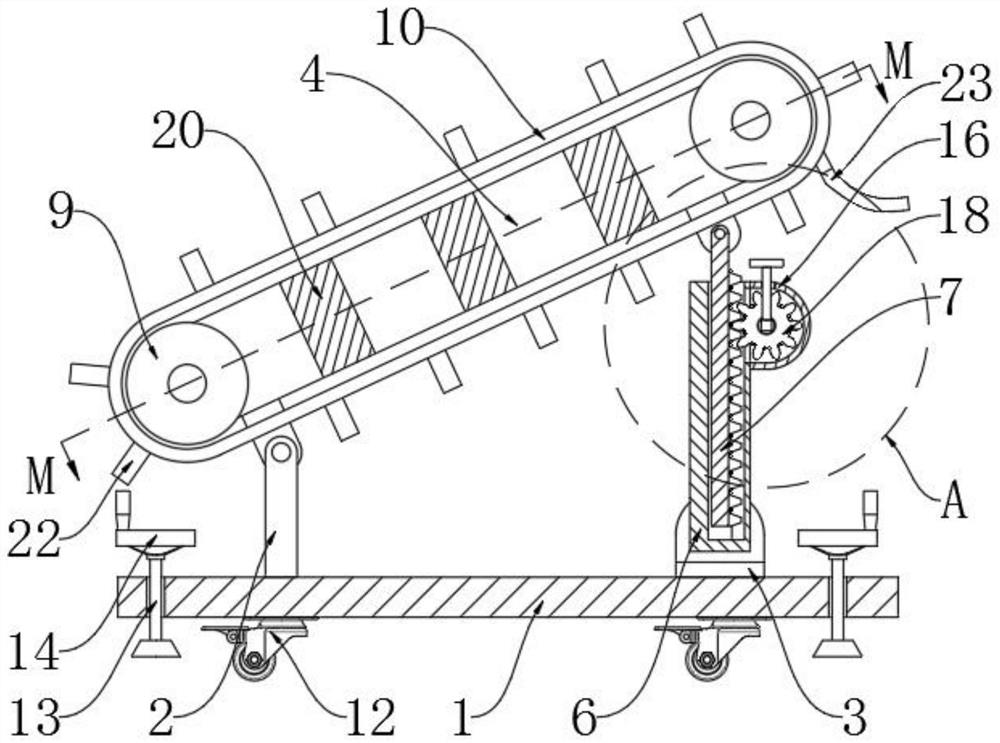

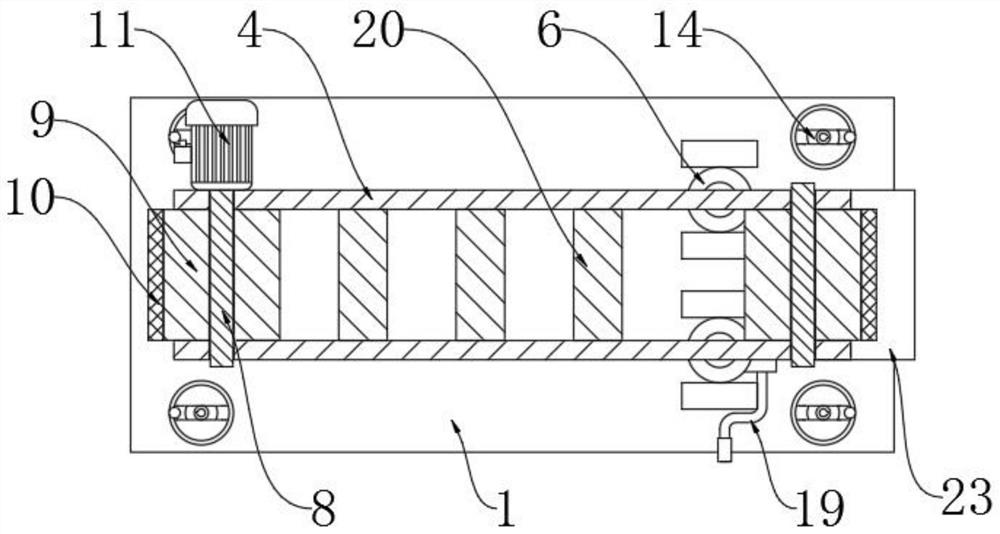

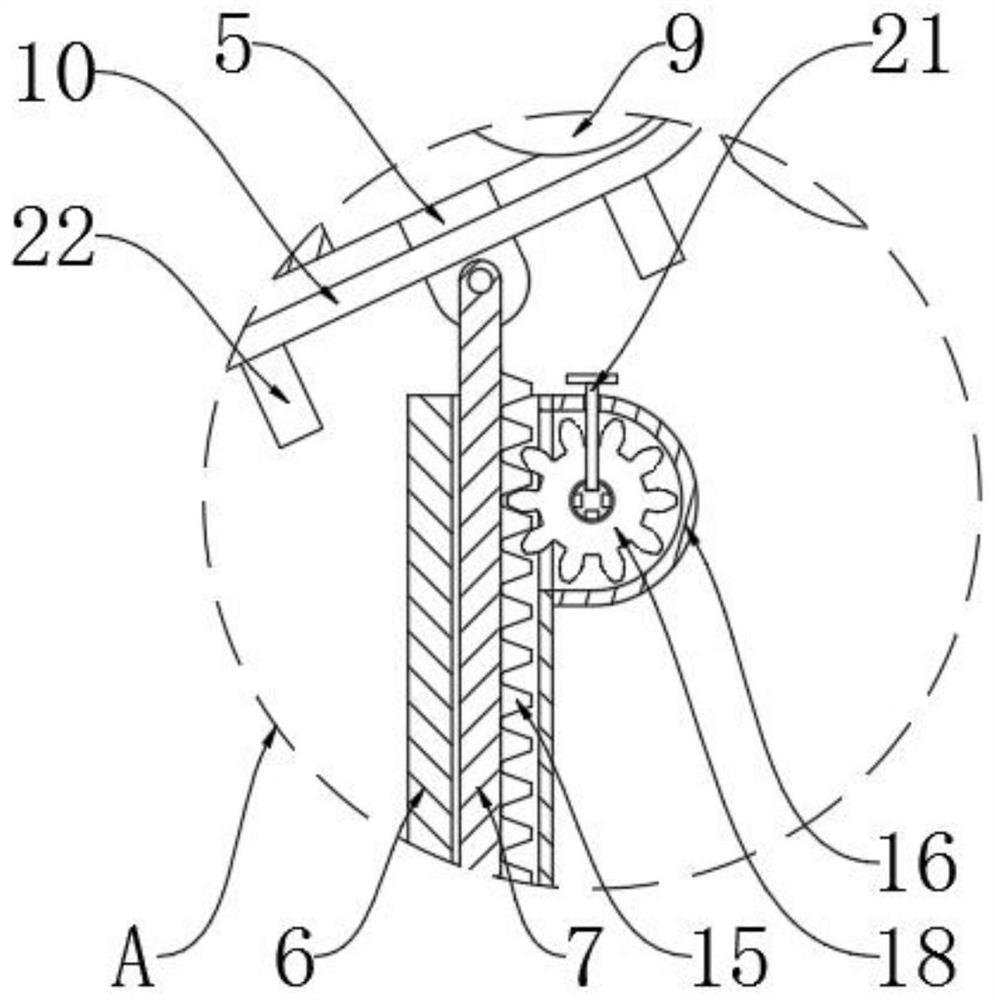

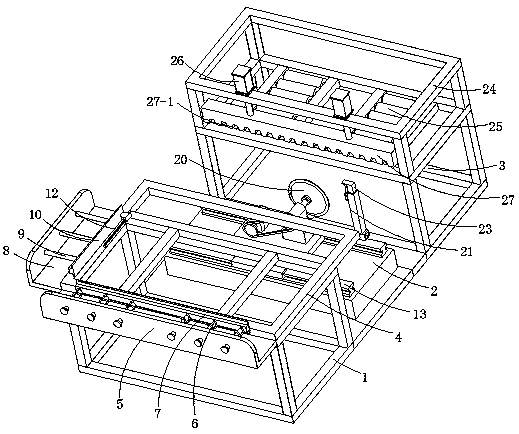

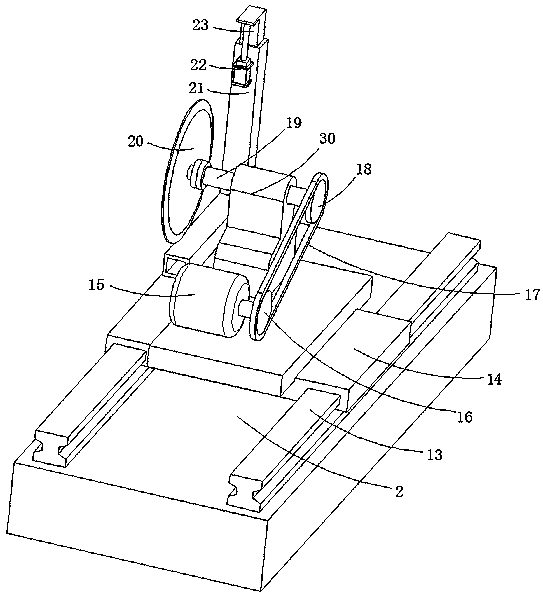

Horizontal type conveying and rotating device for cylindrical workpiece

PendingCN107265077AImprove efficiencyEasy to operateRollersMechanical conveyorsEngineeringMechanical engineering

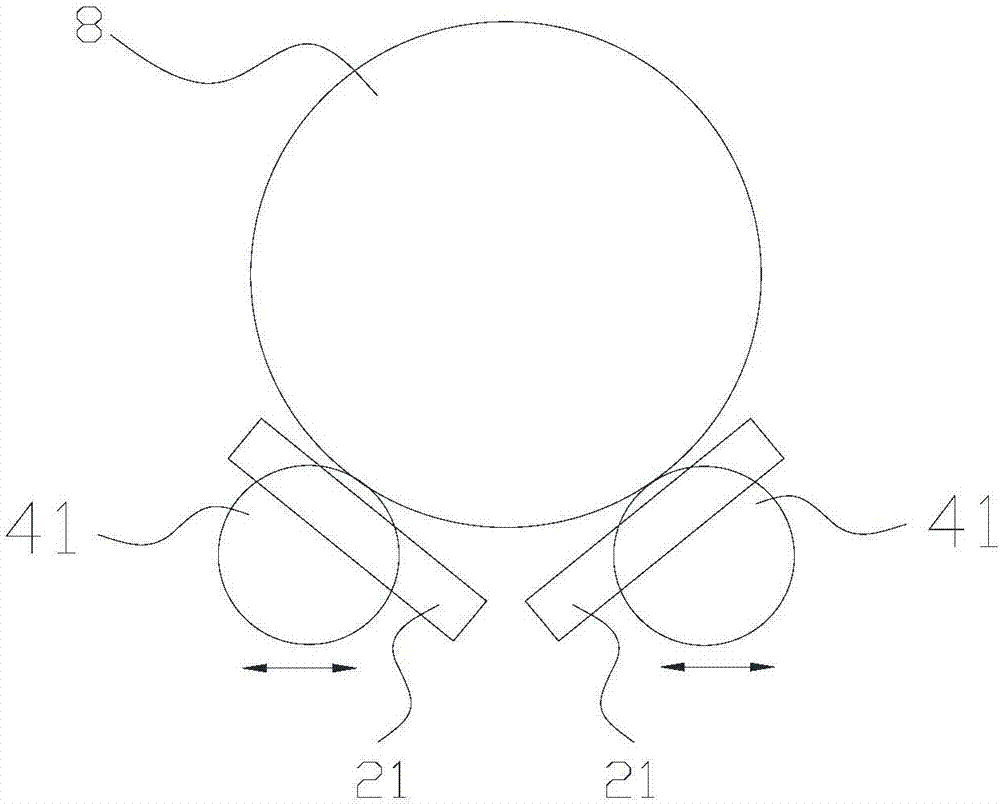

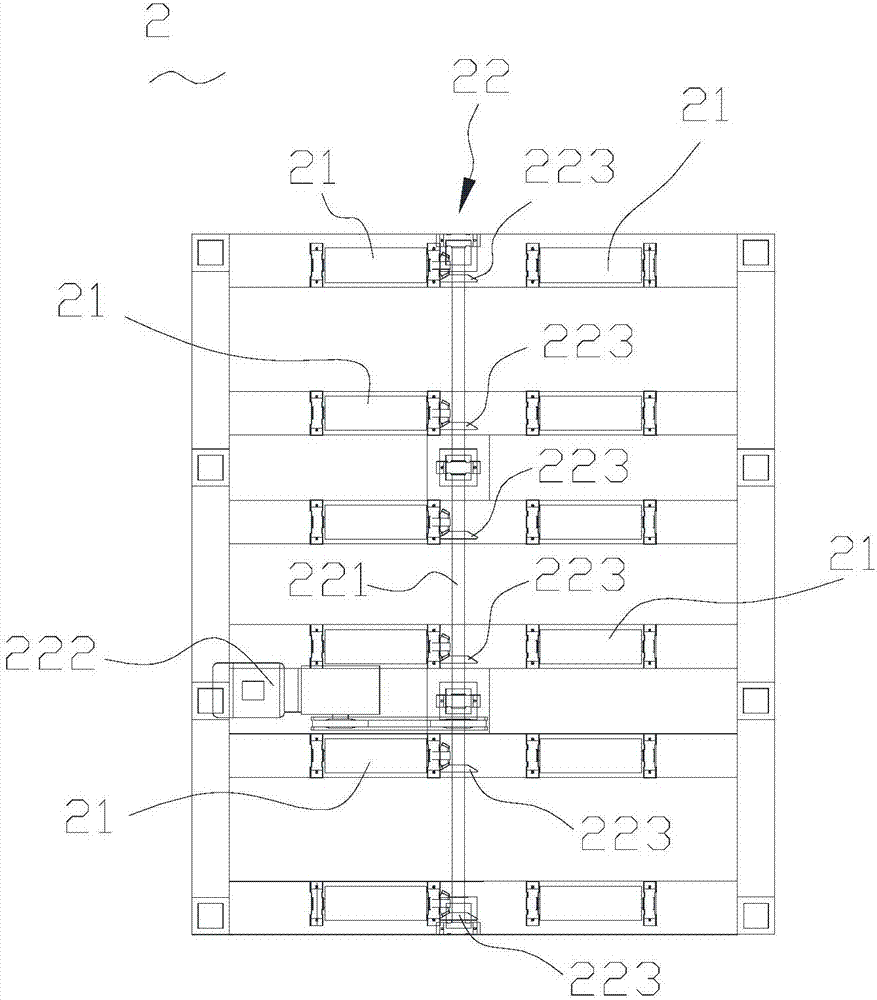

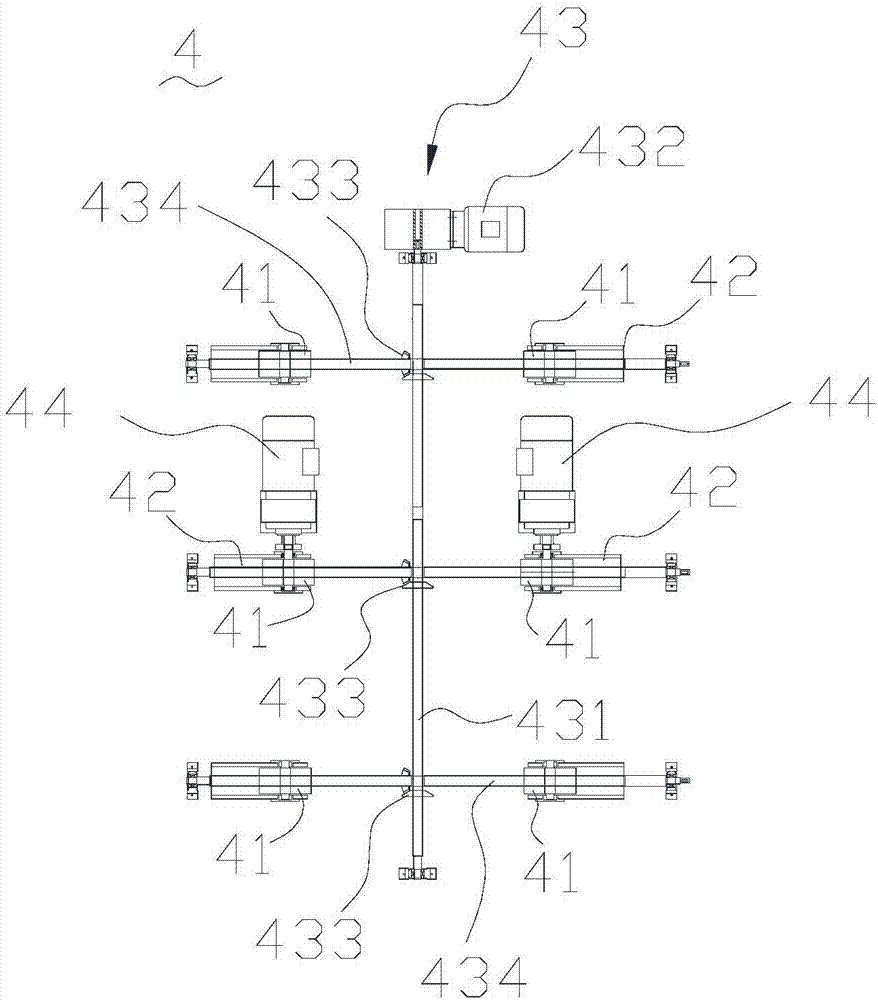

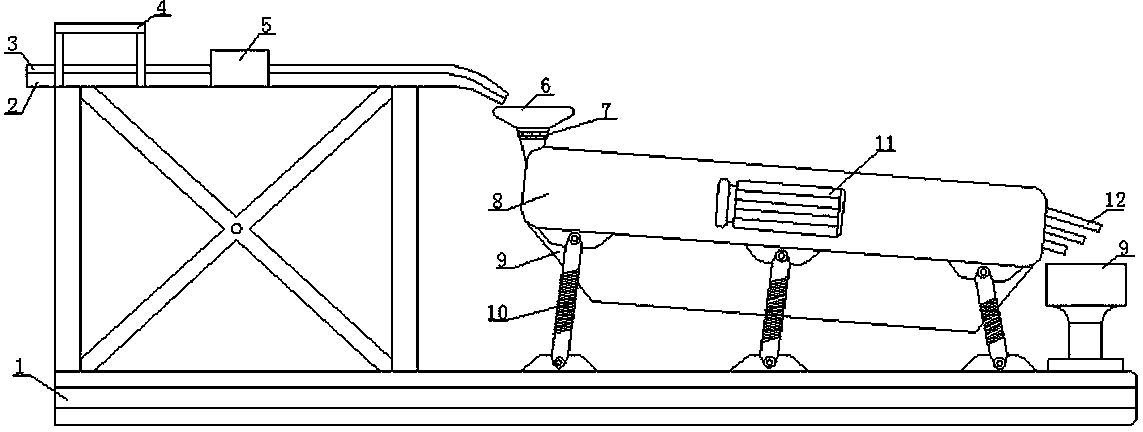

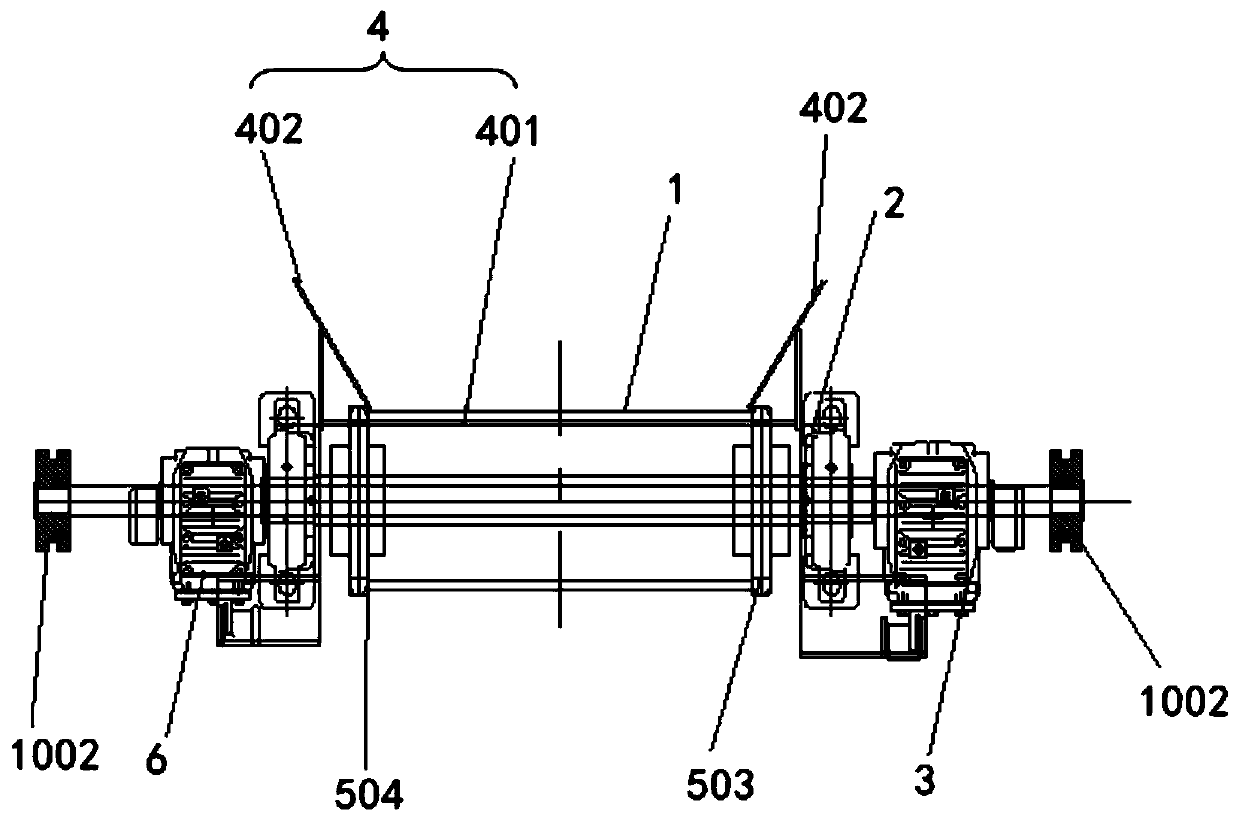

A horizontal type conveying and rotating device for a cylindrical workpiece comprises a roller bed assembly and a rolling wheel assembly. The roller bed assembly comprises multiple conveying rollers and a roller bed drive mechanism, wherein the multiple conveying rollers are used for conveying the cylindrical workpiece arranged on the conveying rollers in the axial direction, and the roller bed drive mechanism is connected with at least one conveying roller and drives the conveying rollers to rotate. The rolling wheel assembly comprises multiple rolling wheels, rolling wheel rotation drive mechanisms and a rolling wheel movement drive mechanism, wherein the multiple rolling wheels are distributed into two groups of rolling wheels, the two groups of rolling wheels are separated from each other, the rolling wheels are arranged between the conveying rollers in a clamped manner, each rolling wheel rotation drive mechanism is connected with at least one rolling wheel and drives the rolling wheels to rotate, and the rolling wheel movement drive mechanism is connected with the two groups of rolling wheels correspondingly and drives the two groups of rolling wheels to move in the direction parallel to the axial direction of the conveying rollers so as to enable the two groups of rolling wheels to be close to each other or far away from each other or drive all the rolling wheels to ascend or descend relative to the conveying rollers to upwards protrude from the top faces of the conveying rollers or be lower than the top faces of the conveying rollers. The horizontal type conveying and rotating device for the cylindrical workpiece is safe, efficient and low in cost.

Owner:NANTONG CIMC ENERGY EQUIP CO LTD

Clean production process of jasmine tea

The invention discloses a clean production process of jasmine tea. The process mainly comprises the steps of curing fresh flowers, scenting, cleaning, holding out of scented flowers, baking, conveying while vibrating, and packaging. The jasmine tea prepared by adopting the process is long-lasting in aroma, fresh, rich and mellow in taste and clear, and yellow and bright in color of soup. The fresh flowers are cured, scented and cleaned on an operation platform, so that the cleanness of the jasmine tea can be ensured and the grade of the jasmine tea can not be influenced.

Owner:四川省炒花甘露茗茶有限公司

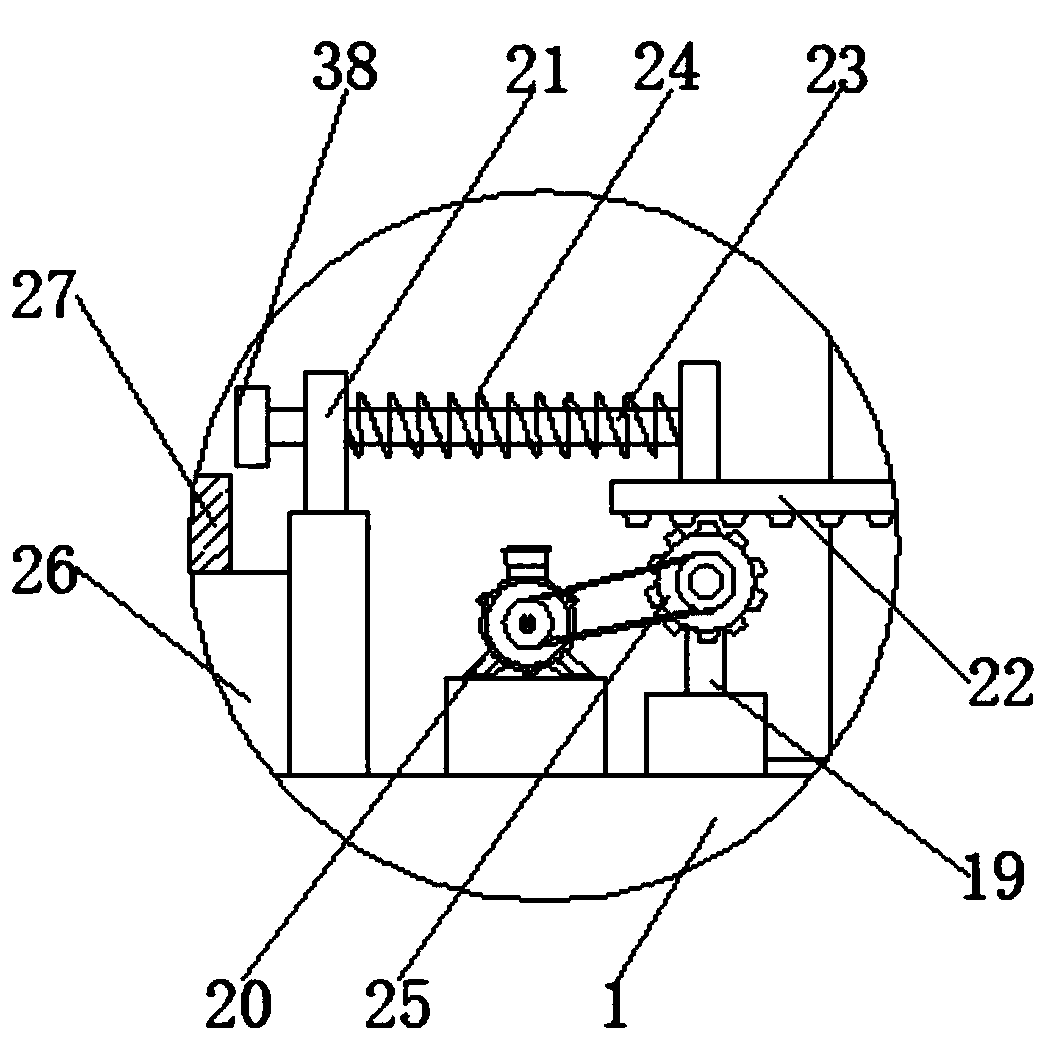

Material collecting robot for stamping equipment

The invention discloses a material receiving robot for stamping equipment. The robot comprises a base, and one side of the top of the base is fixedly connected with a box body. The top of the inner wall of the box body is fixedly connected with a stabilizing block. A sliding rod is fixedly connected between the bottom of the stabilizing block and the bottom of the inner wall of the box body. The surface of the sliding rod is connected with a sliding block in a sliding mode. A first spring is fixedly connected with the surface of the sliding rod, and is positioned between the bottom of the stabilizing block and the top of the sliding block. The right side of the sliding block is fixedly connected with a material receiving plate. The invention relates to the technical field of stamping equipment. Through the cooperation arrangement of a supporting rod, a tooth plate, a gear, a second motor, a material pushing rod, a material pushing block and a second spring, the material receiving robotfor the stamping equipment realizes the purpose of pushing and taking a workpiece by a stamping die after stamping, avoids the dangerous operation that an operator needs to take the workpiece out from the stamping die, lowers the probability of stamping equipment accident, and increases the production efficiency.

Owner:江苏迪普实业股份有限公司

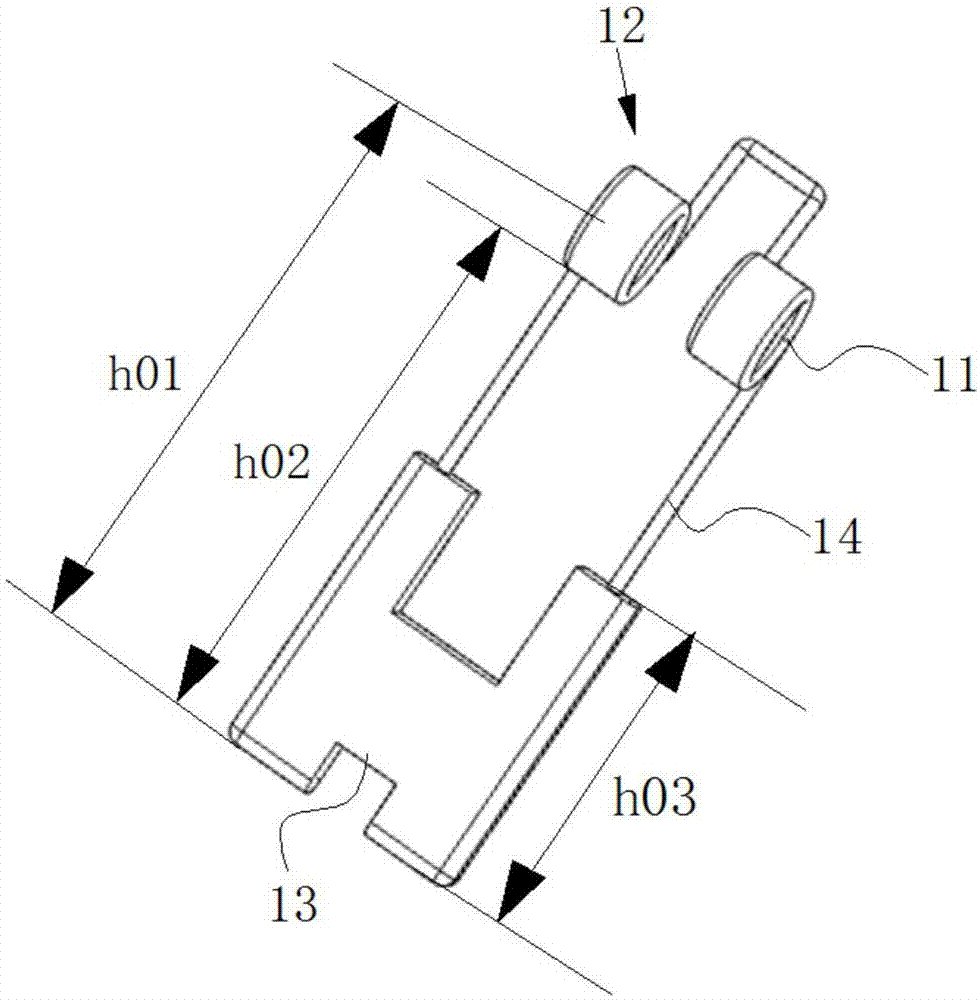

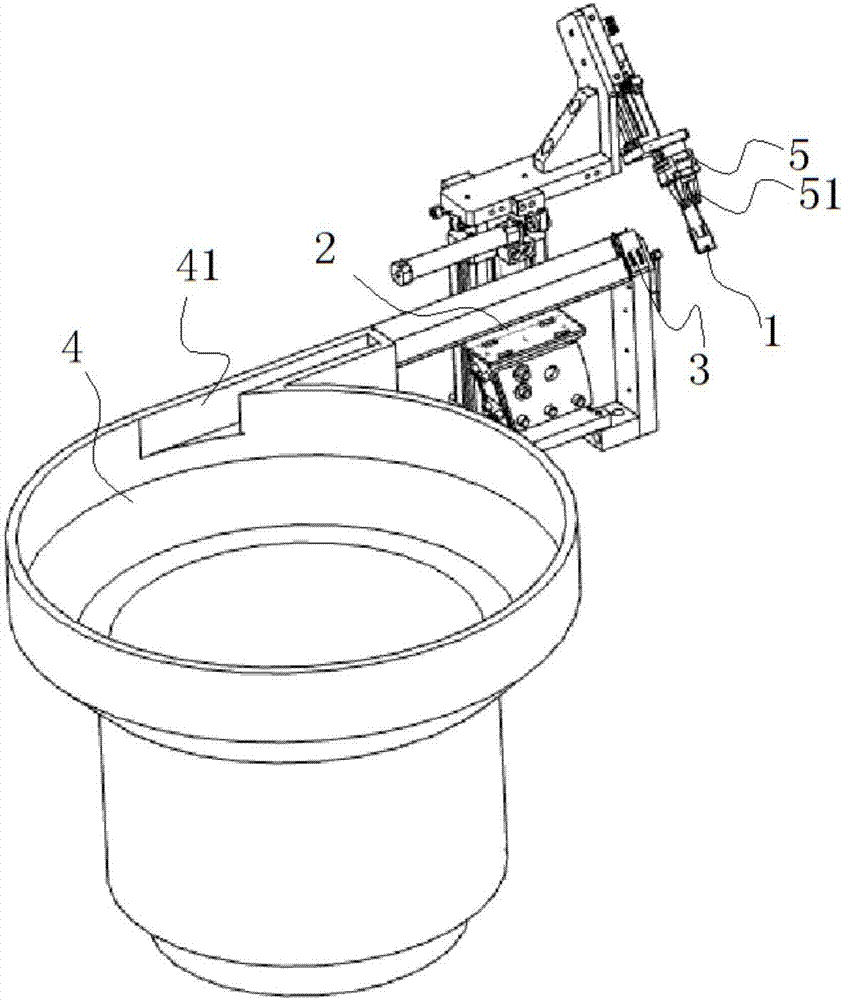

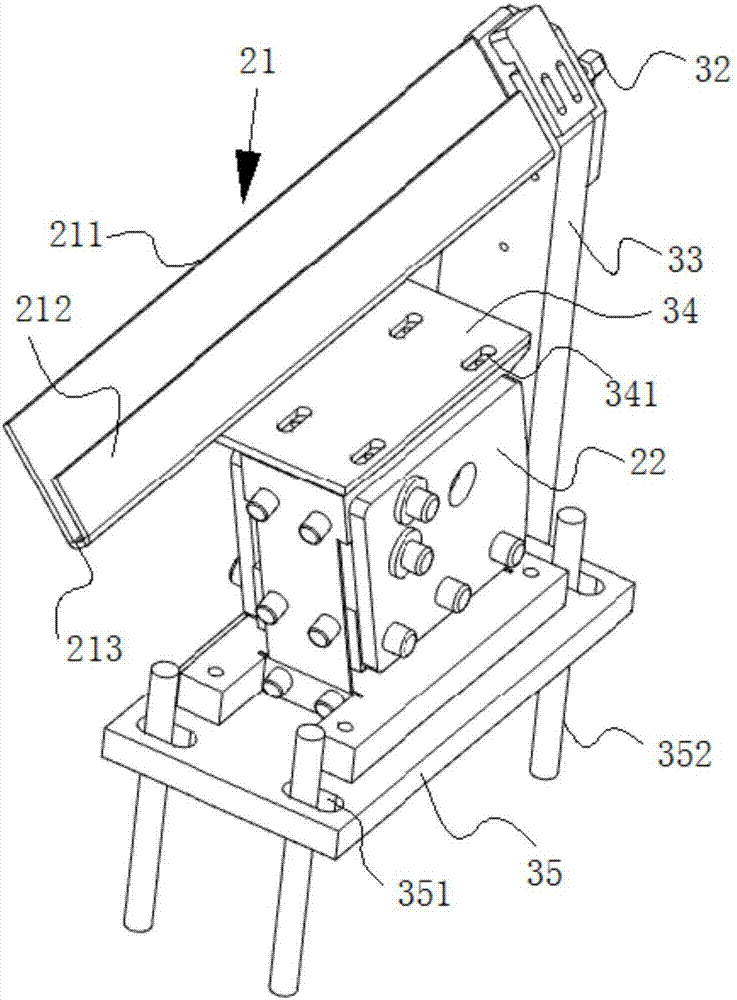

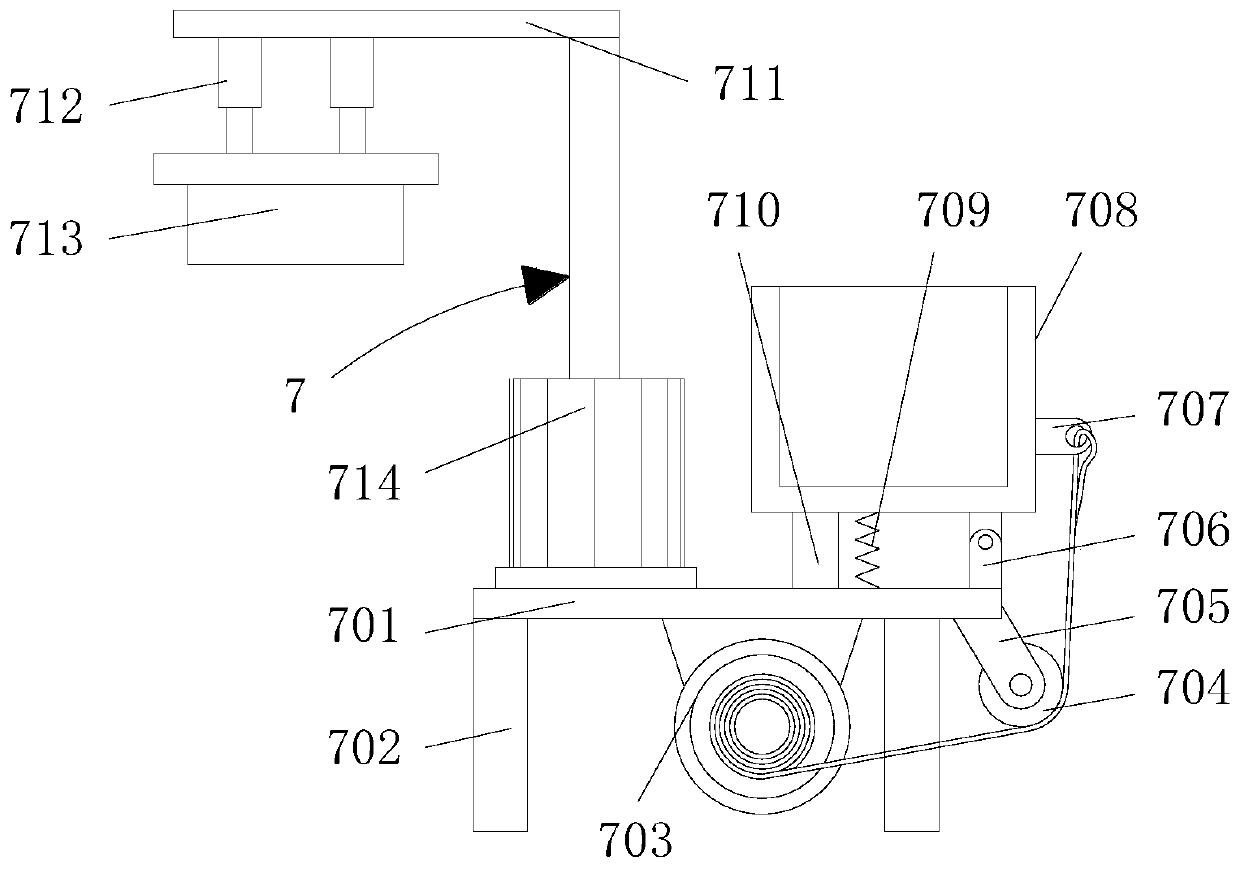

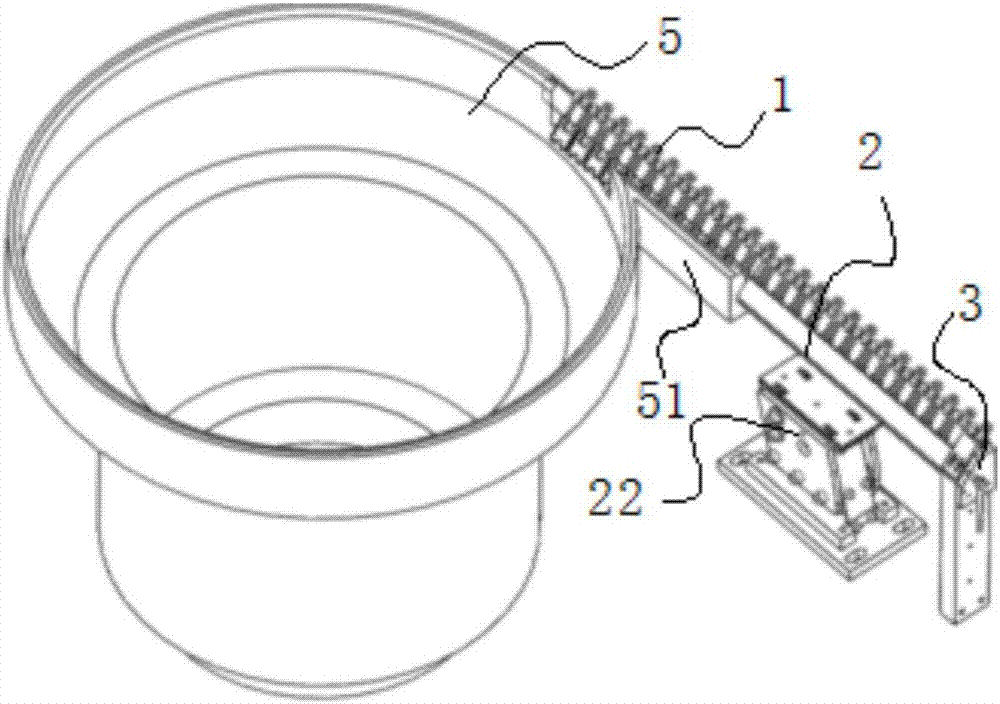

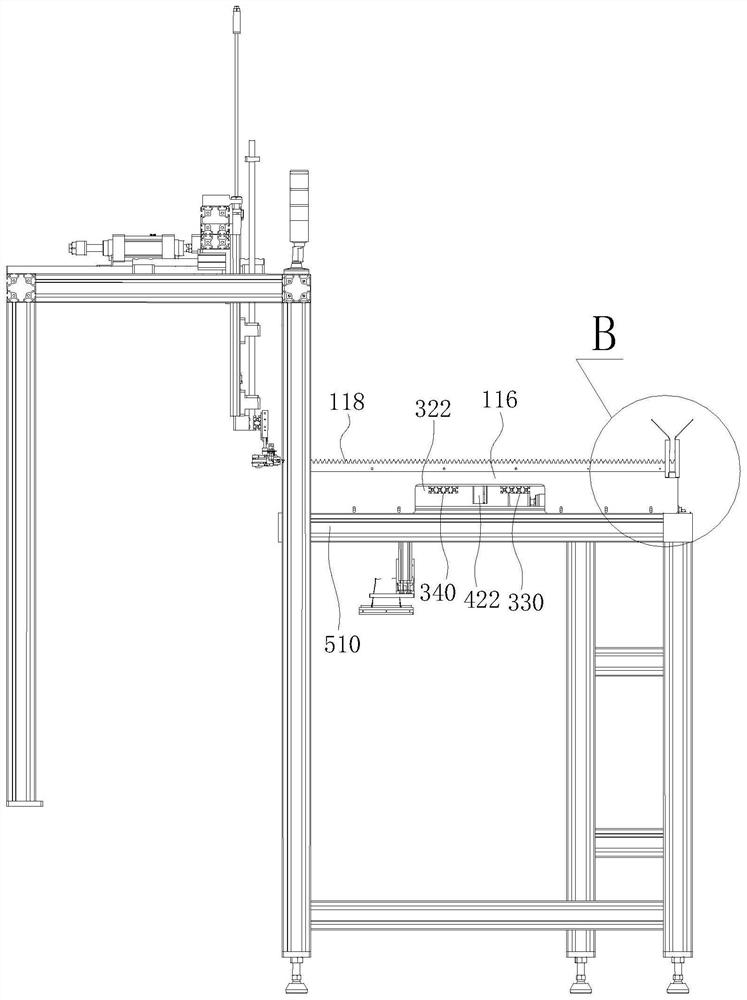

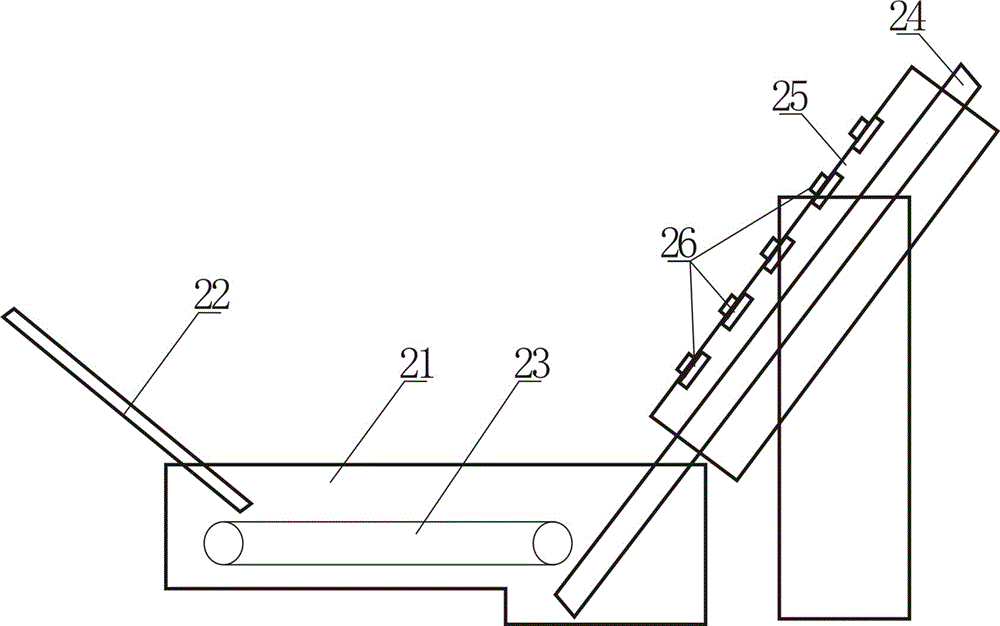

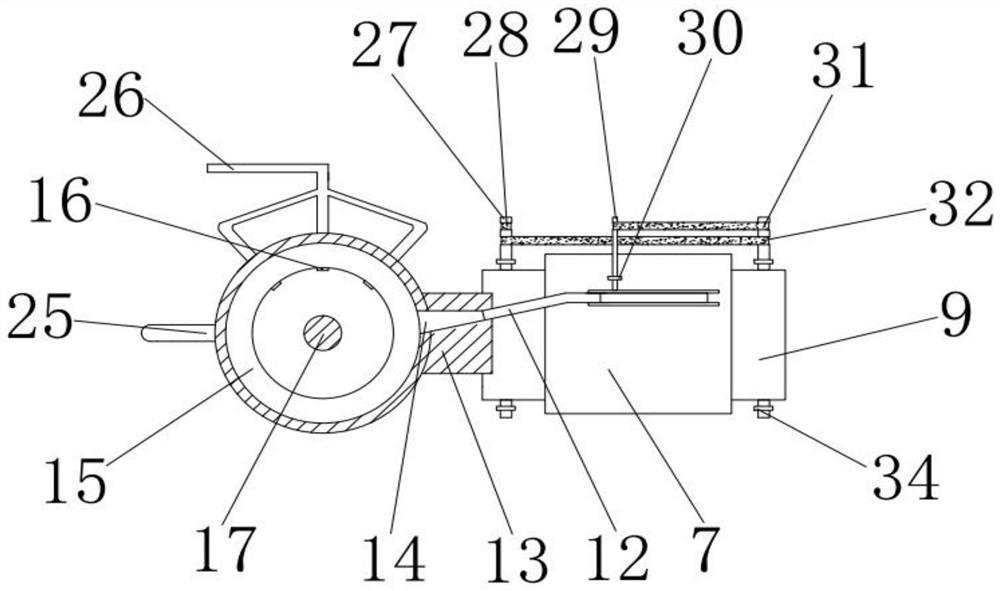

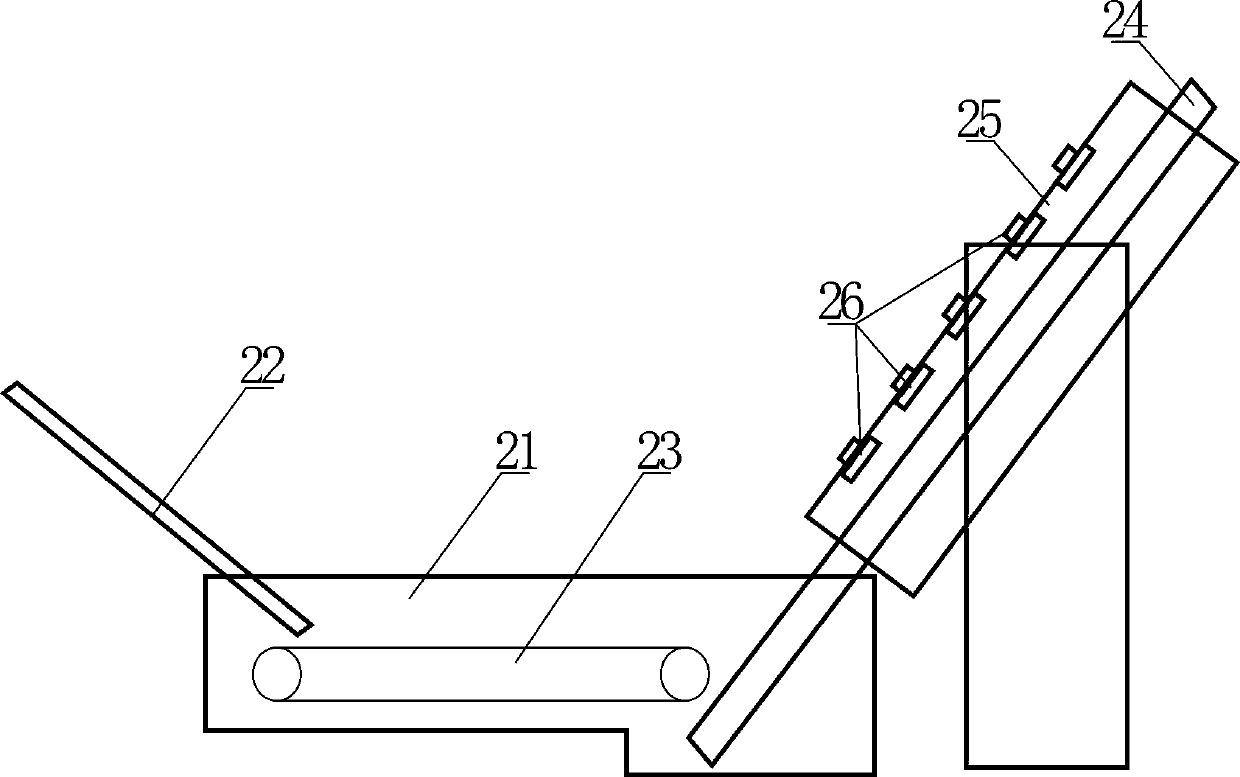

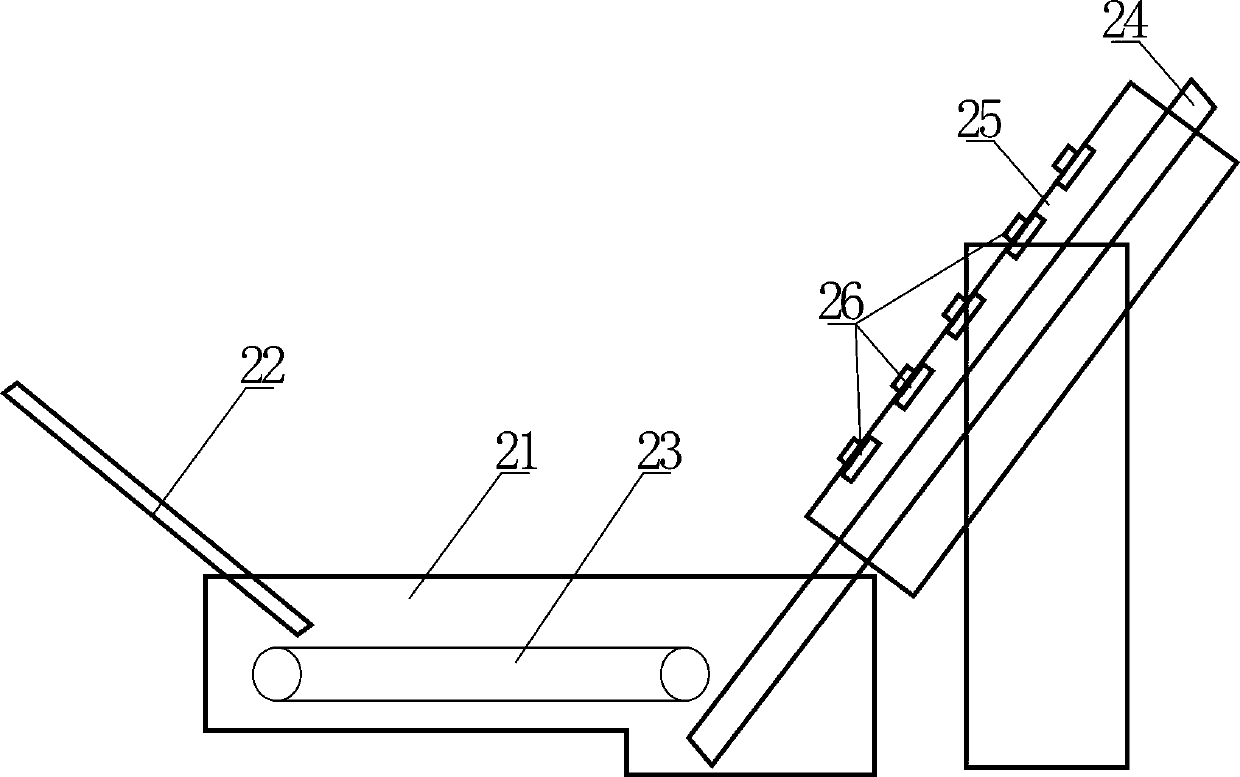

Automatic feeding and taking device for downlight spring

The invention discloses an automatic feeding and taking device for a downlight spring. The automatic feeding and taking device for the downlight spring comprises a feeding mechanism, a spring in-place mechanism and a material clamping mechanism; the feeding mechanism comprises a feeding tank and a direct vibration auxiliary feeder; the discharging end of the feeding tank is in butt joint with the spring in-place mechanism; the spring in-place mechanism comprises a bearing groove capable of containing one spring; the bearing groove is used for bearing the spring; a spring supplying in-place sensor is further included; the material clamping mechanism comprises a spring clamping claw and a clamping cylinder driving the spring clamping claw to perform clamping or loosening; an upper clamping claw body and a lower clamping claw body of the spring clamping jaw are symmetrically arranged; and during clamping, the end portions of the upper clamping claw body and the lower clamping claw body form a clamping part matched with a spring coil of the spring. According to the automatic feeding and taking device for the downlight spring, a spring material is conveyed to the assigned position by adopting an automatic operation mode so that the subsequent operation procedure can be facilitated, and lots of human power is saved; and meanwhile, due to the existence of the automatic feeding and taking device for the downlight spring, achievement of full-automatic assembly of the downlight spring is made possible, and the achievement pace of full-automatic assembly of the downlight spring is accelerated.

Owner:KUNSHAN TUOYU AUTOMATION TECH CO LTD

Trademark marking device for packages

InactiveCN108944070AChange positionGood structural foundationTypewritersOther printing apparatusHydraulic cylinderTrademark

The invention discloses a trademark marking device for packages. The device comprises a substrate and a horizontal support bench. A vertical rack is fixed on the middle part of the substrate. A support rack is installed on the vertical rack. A marking rack is arranged on the left side of the vertical rack. A monitoring rack is installed on the right side of the vertical rack. An active shaft penetrates through the interior of the left side of the horizontal support bench. The horizontal support bench is arranged under the marking rack and the monitoring rack. According to the invention, by setting the pressing plate, marking processes can be smoothly performed; under the hydraulic combined effects of a first hydraulic cylinder and a first hydraulic rod, the pressing plate carries out up-down rising and descending, thereby finishing marking interrupted and continuous actions. The position of a moving plate on the pressing plate can be left-right adjusted, and by use of the engagement functions between steel teeth and a gear, the moving plate is allowed to be not liable to slide on the pressing plate, so it is ensured that the pressing plate has good and stable force bearing structure. The pressing plate carries out downwards pressing and moving, so spinning belts are allowed to contact with a to-be-marked surface of a commodity finally along with the pressing actions of the pressing plate.

Owner:邹玉芬

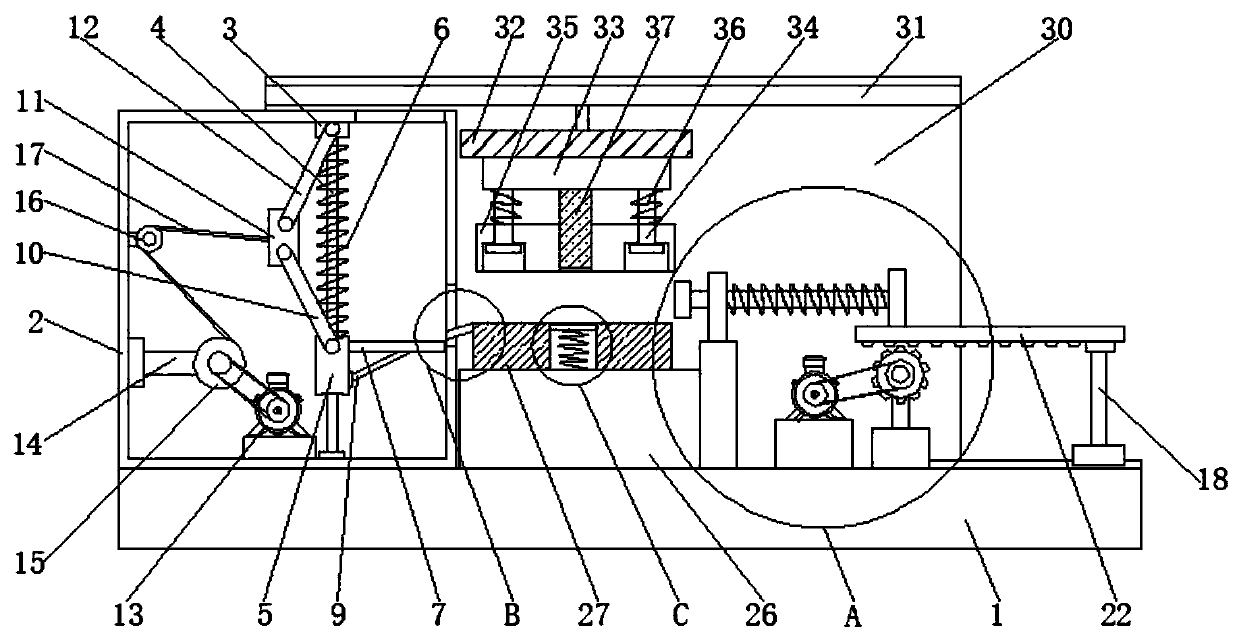

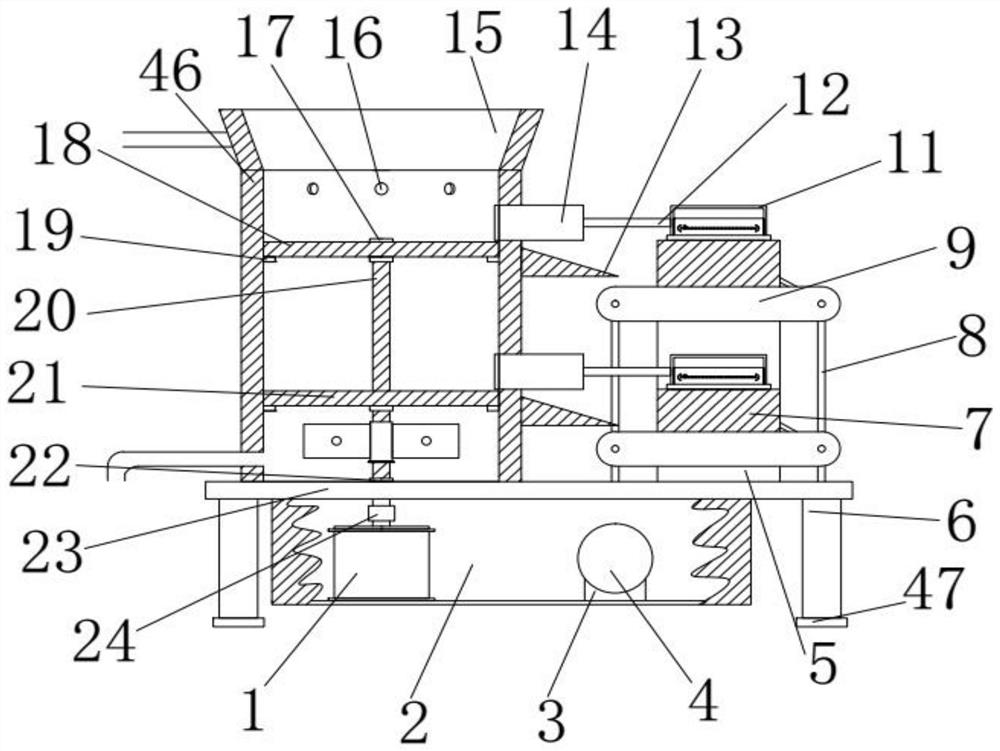

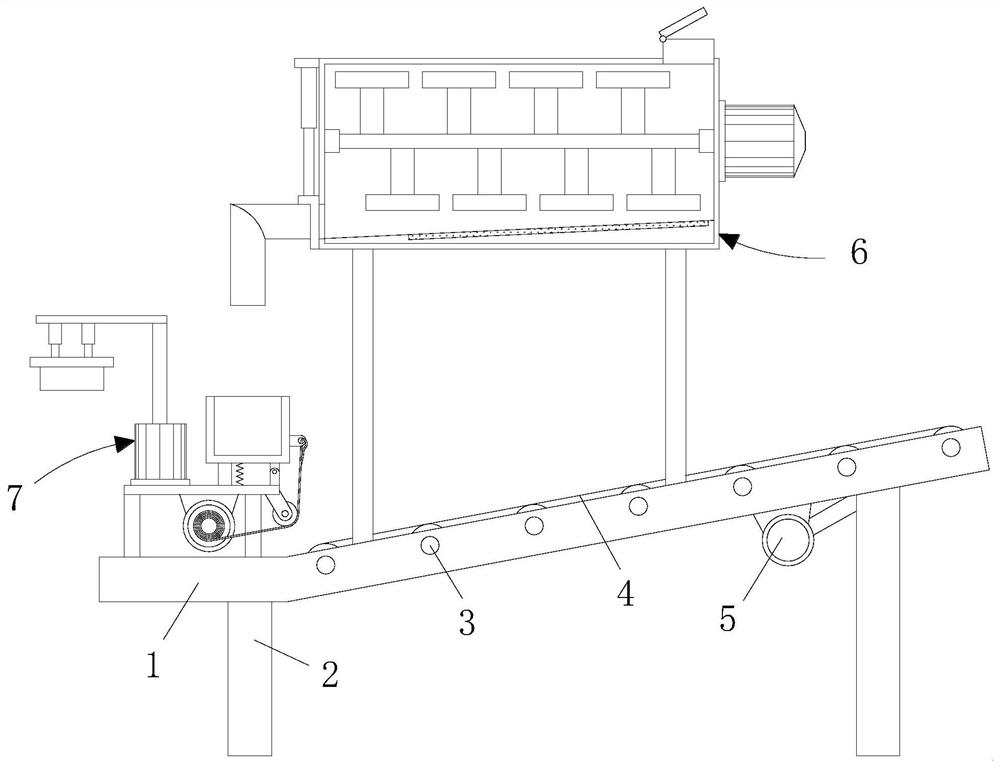

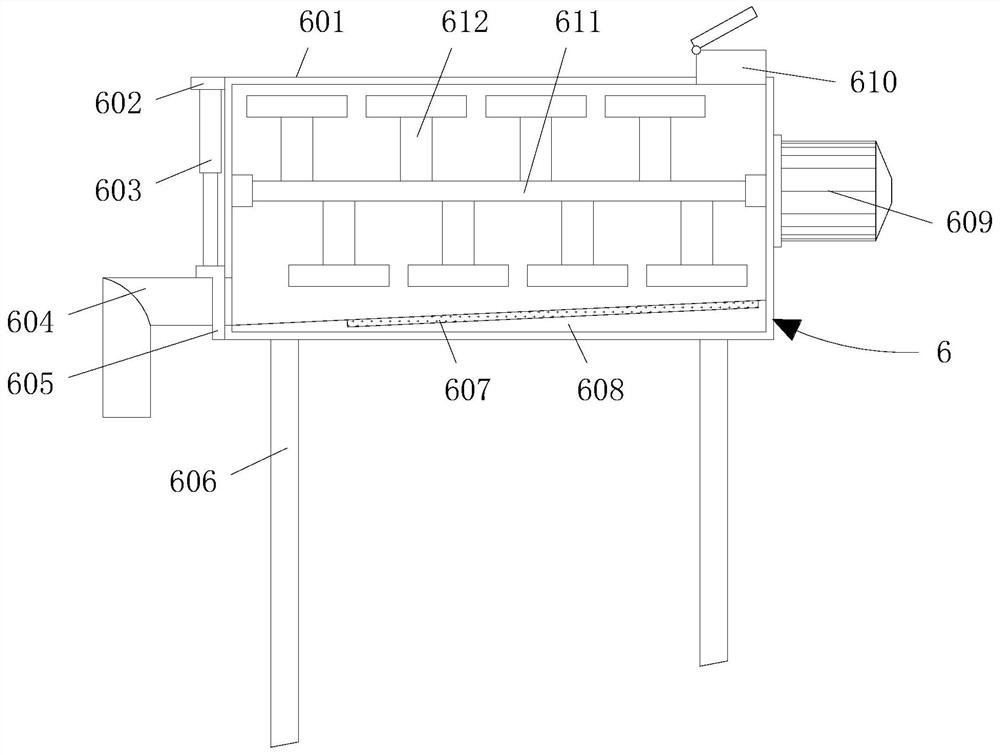

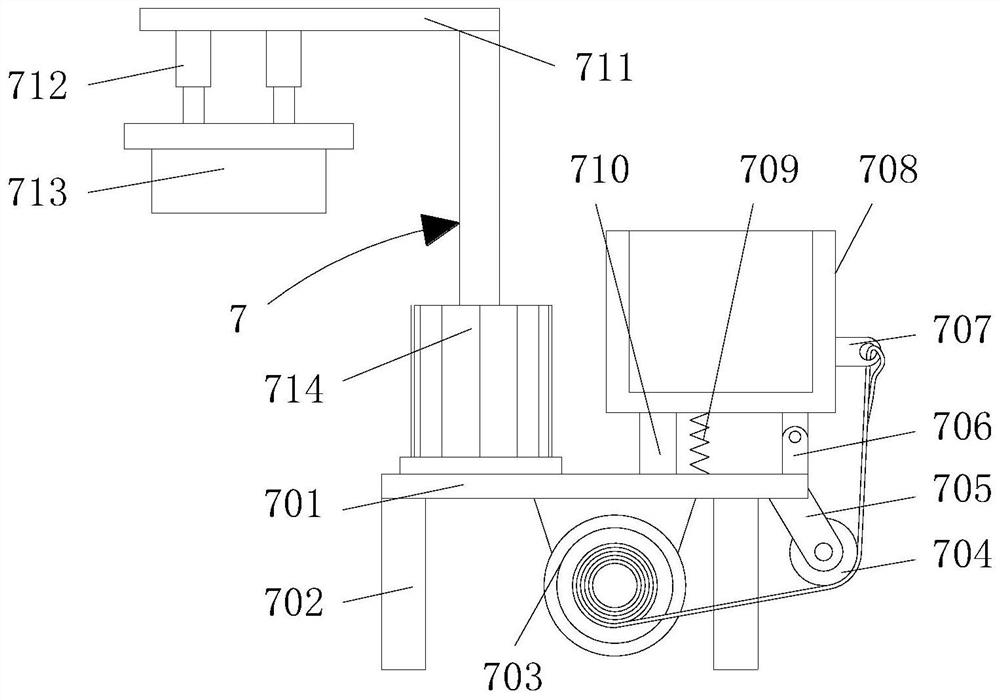

Automatic forming device for rubber products processing and use method thereof

The invention discloses an automatic forming device for rubber products processing and a use method thereof. The automatic forming device comprises a supporting seat, the right end of the inner surface of the supporting seat is movably provided with a plurality of conveying rollers which are equidistantly distributed and are connected in a transmission manner through a conveyor belt, the right rear end of the bottom part of the supporting seat is fixedly provided with a conveying motor, and the output shaft of the conveying motor is connected with the conveying rollers at the most right end ofthe inner surface of the supporting seat a transmission manner through a belt. According to the automatic forming device for rubber products processing and the use method of the automatic forming device, a stirring and heating mechanism is arranged and has the function of stirring and heating materials, so that the solidification of the materials in the process is avoided, the subsequent processing quality is guaranteed; a forming mechanism is arranged and can carry out injection molding treatment of the materials, so that the forming efficiency is of the materials improved; and the conveyingrollers, the conveyor belt, the belt and the conveying motor are arranged, the conveying motor is started, the conveying motor drives the conveying rollers to rotate through the belt, then the conveying rollers drive the materials to move through the conveyor belt, so that the purpose of feeding is achieved.

Owner:浙江橡企科技有限公司

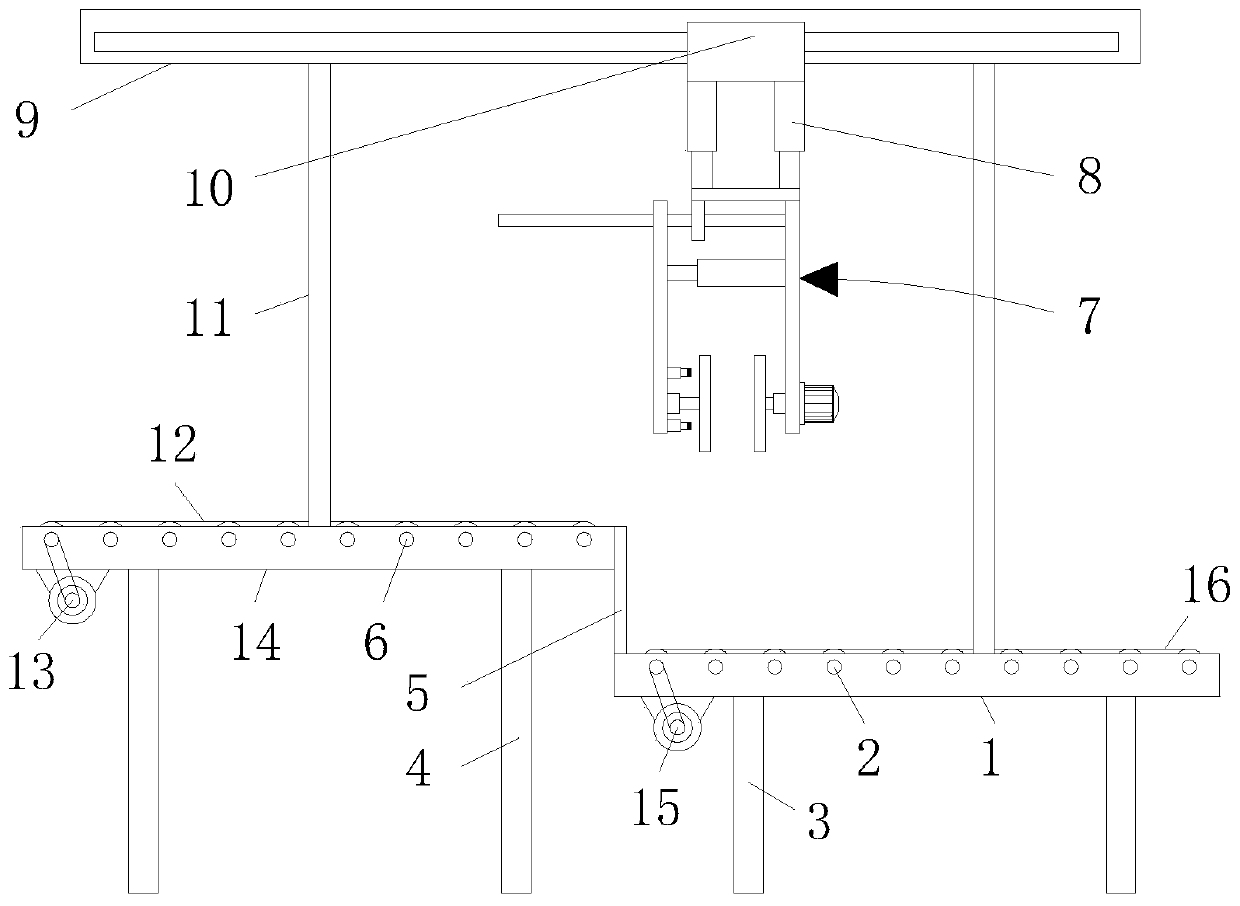

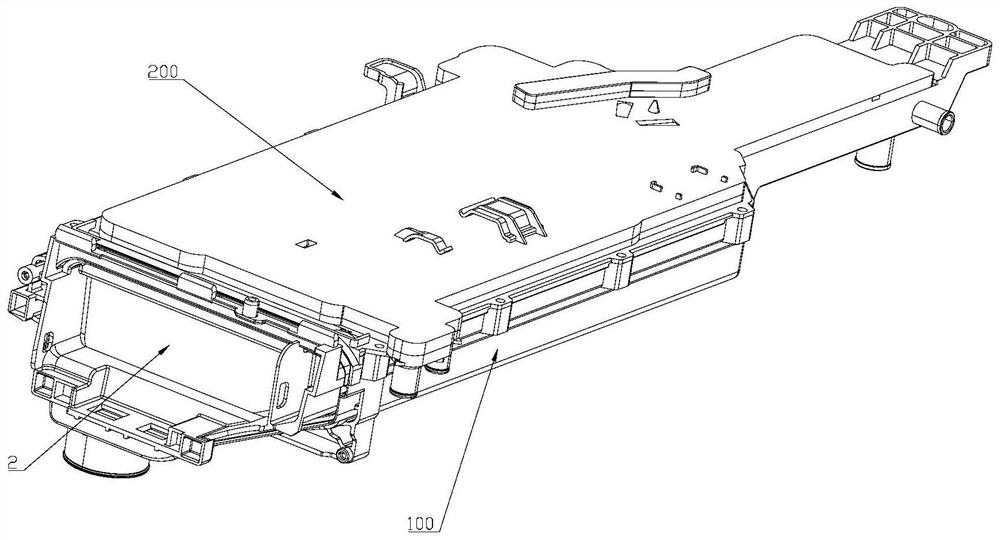

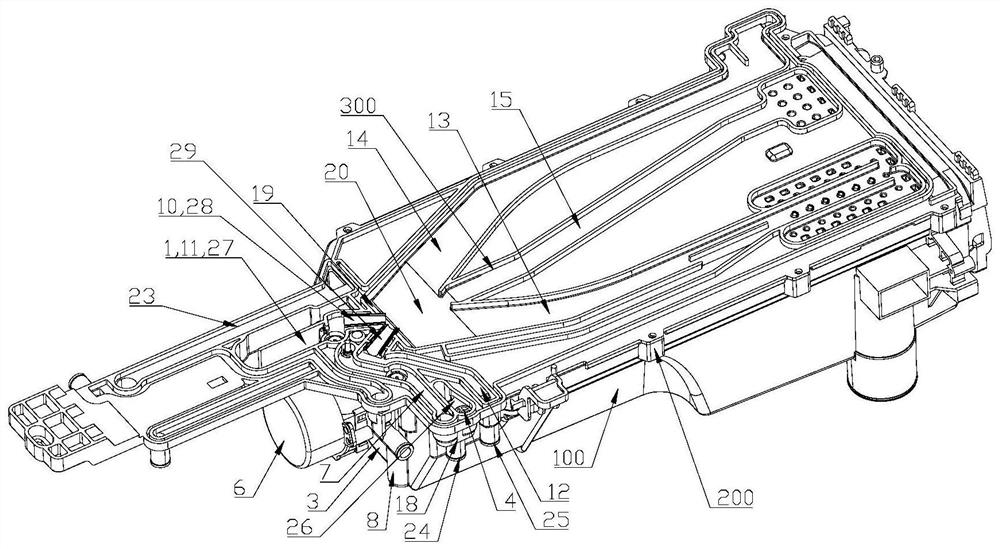

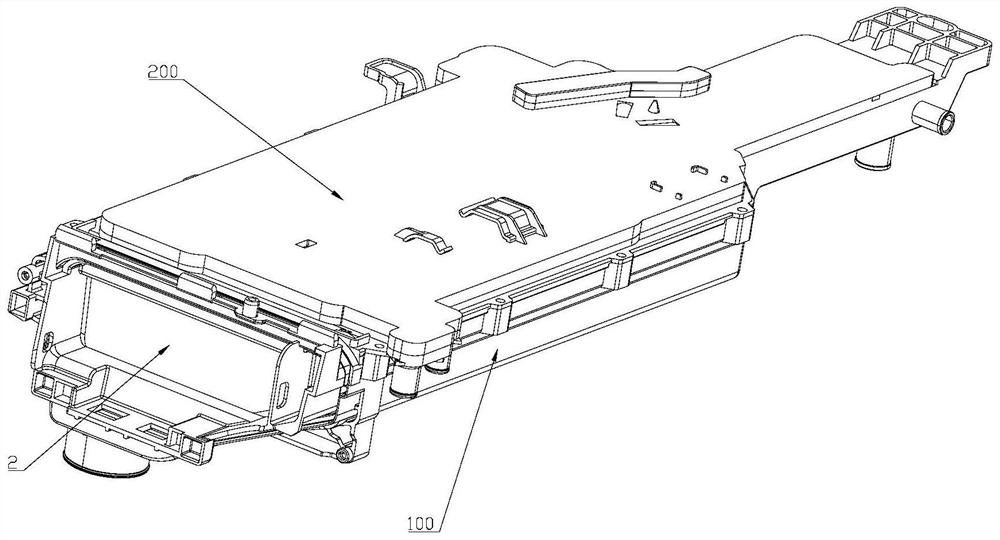

Clamping device for battery of new energy vehicle

ActiveCN111573129AAchieve the purpose of clampingAchieve the purpose of turningConveyorsCell component detailsElectrical batteryAutomotive battery

The invention discloses a clamping device for a battery of a new energy vehicle. The clamping device comprises a first support and a second support, a plurality of first conveying rollers which are distributed at equal distances and are in transmission connection through a first conveying belt are movably mounted on the inner surface of the first support, and a first motor is fixedly mounted at the front left end of the bottom of the first support, wherein an output shaft of the first motor is in transmission connection with the first conveying roller located at the leftmost end of the inner surface of the first support through a belt. A sliding seat and a slider are arranged so that the purpose of driving a clamping mechanism to move left and right can be achieved, a first electric telescopic rod is arranged so that the purpose of driving the clamping mechanism to move up and down can be achieved, the clamping mechanism is arranged so that the purposes of clamping the battery througha first clamping plate and a second clamping plate and steering the clamped battery can be achieved, through cooperation of the structures, the clamping efficiency of the clamping device for batteriesof different types is effectively improved, and great convenience is brought to use by people.

Owner:上海航空发动机制造有限公司

Truss moving mechanism

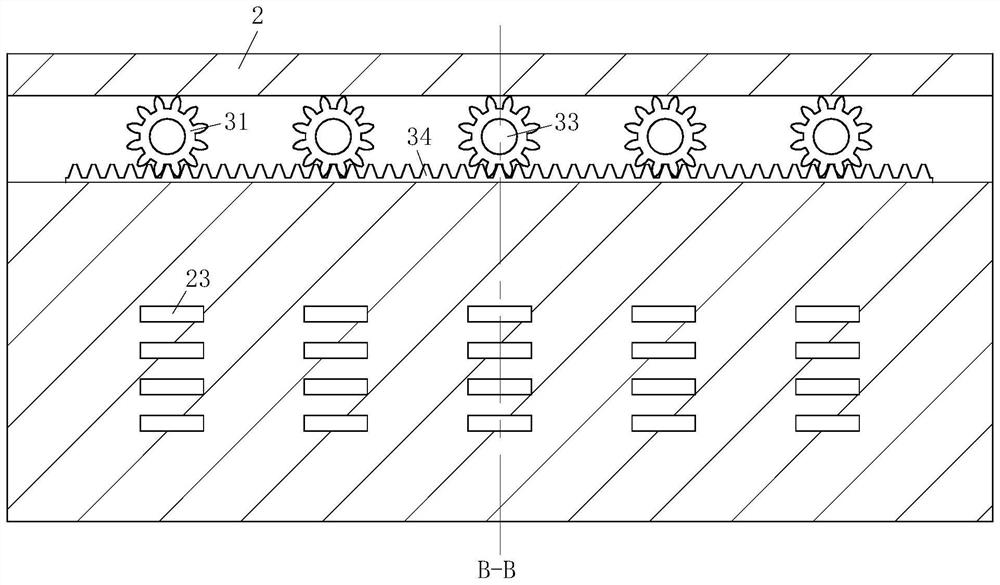

The invention discloses a truss moving mechanism. The truss moving mechanism comprises a bracket, inverted-H-shaped steel, a mounting plate, limiting rods, gear levers, slide rails, a movable frame, aslide block, a baffle block, a motor, a transmission gear, a rack, a first gas cylinder, a second gas cylinder, an induction rod, a first induction switch, a second induction switch, a magnetic switch, a third induction switch, a fourth induction switch, a fifth induction switch and an L-shaped frame, wherein the inverted-H-shaped steel is arranged at the two sides of the upper end of the bracket; the mounting plate is arranged at the upper end of the inverted-H-shaped steel; the two sides of the upper end of the mounting plate are equipped with limiting rods; the middle part of one end of each limiting rod is equipped with the gear lever; and the upper end of the mounting plate is equipped with the slide rails relative to sides of the limiting rods. According to the truss moving mechanism disclosed by the invention, the movable frame drives the transmission gear to be in engaged connection to the rack through the motor, so that the movable frame moves along the slide rails, operationis stable, and blocking is avoided; besides, the gear levers are mounted on the limiting rods, so that when the movable frame moves, the baffle block and the gear levers achieve limiting and buffering effects.

Owner:YANCHENG HUASEN MACHINERY

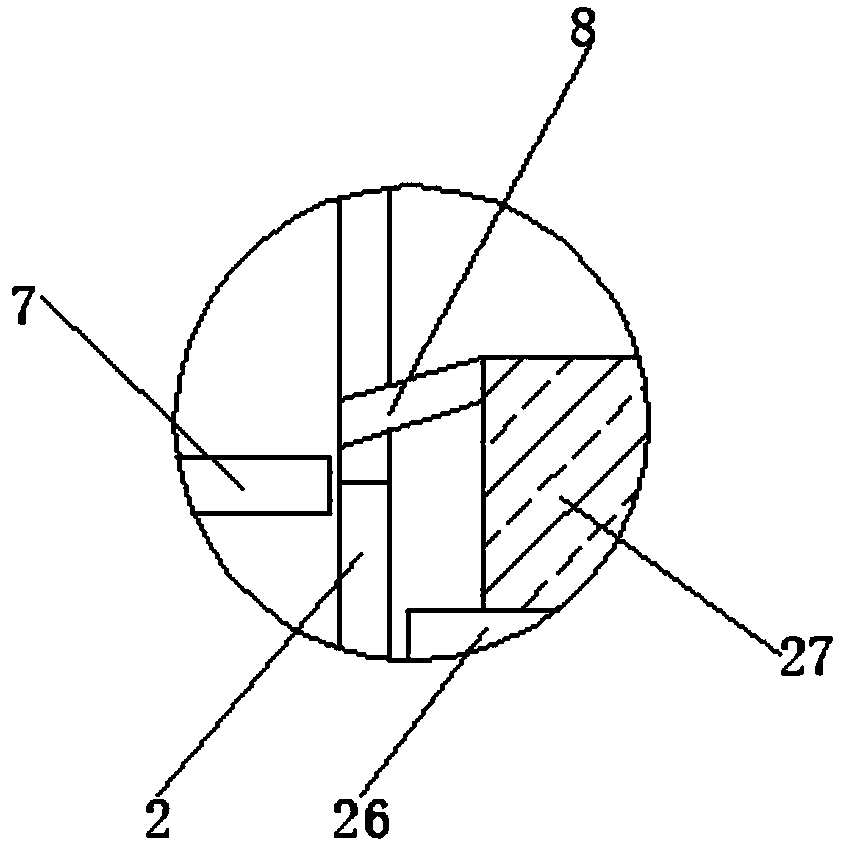

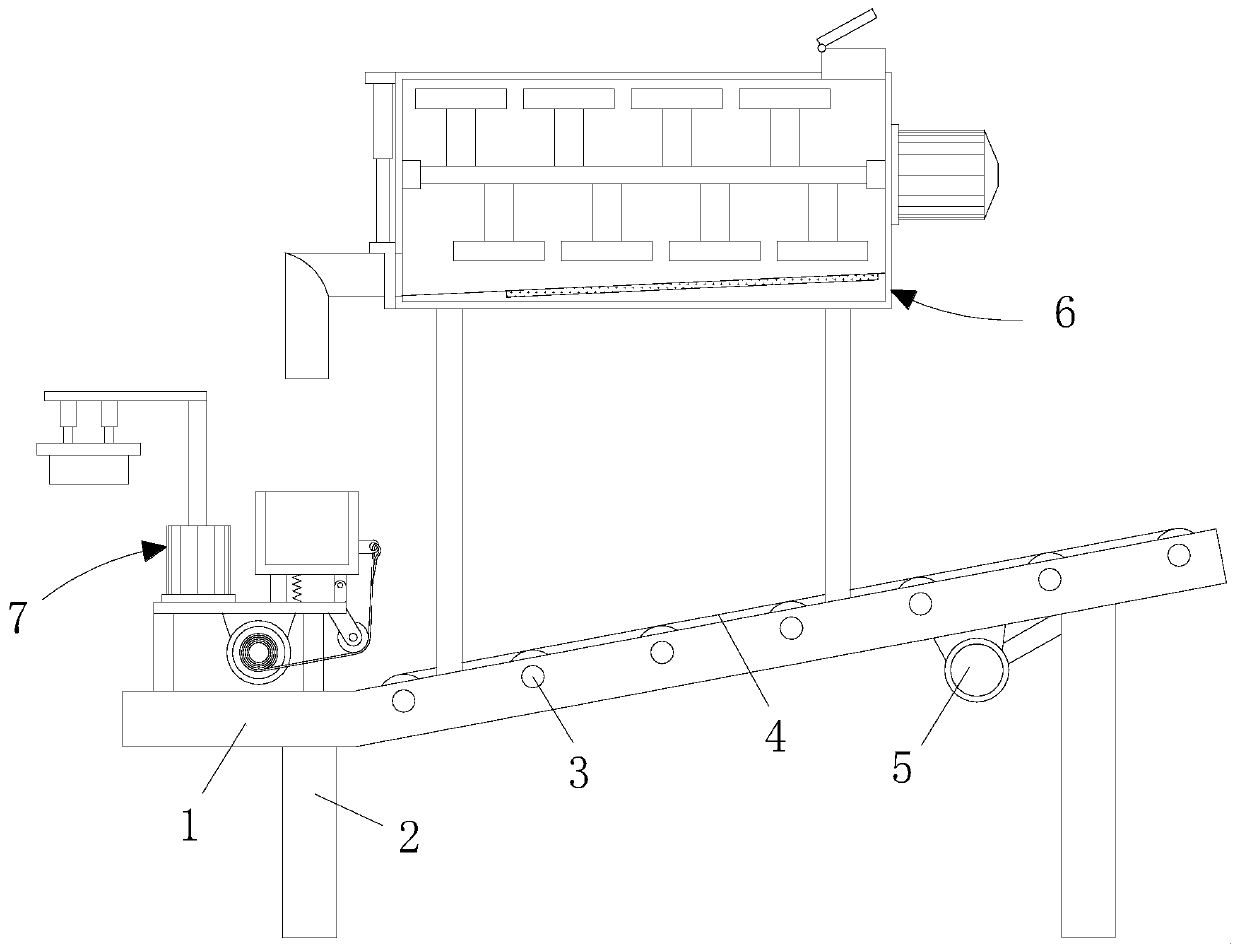

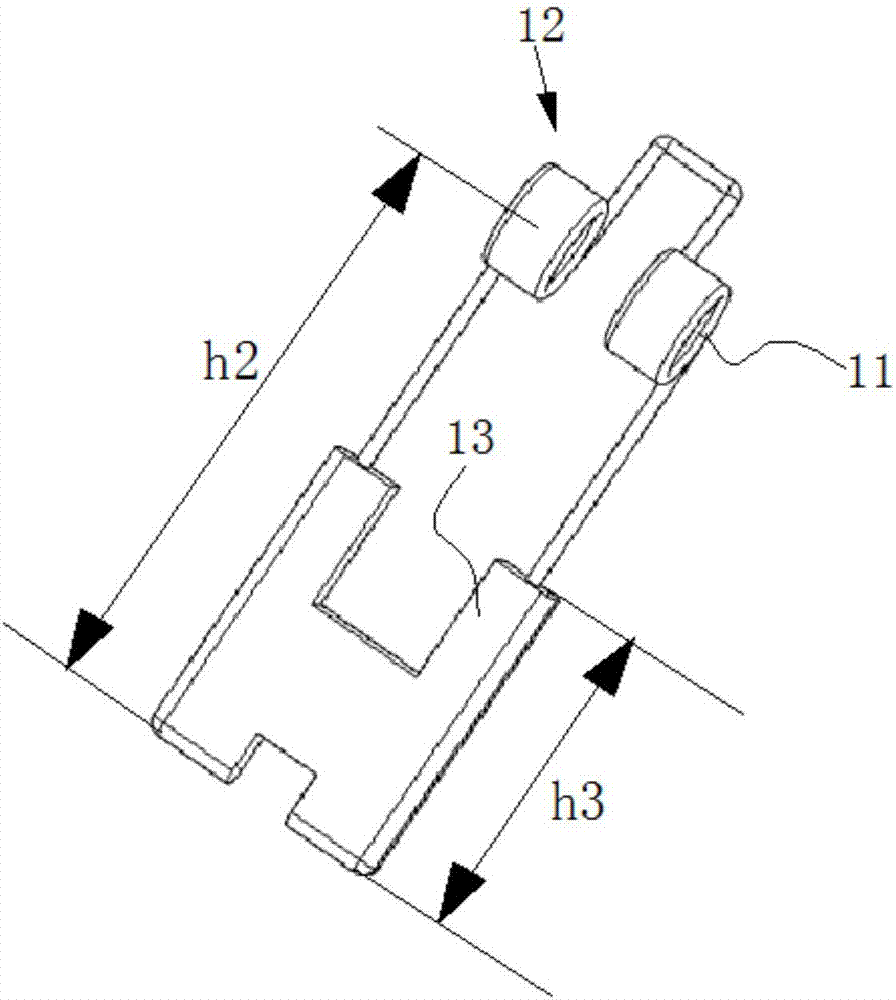

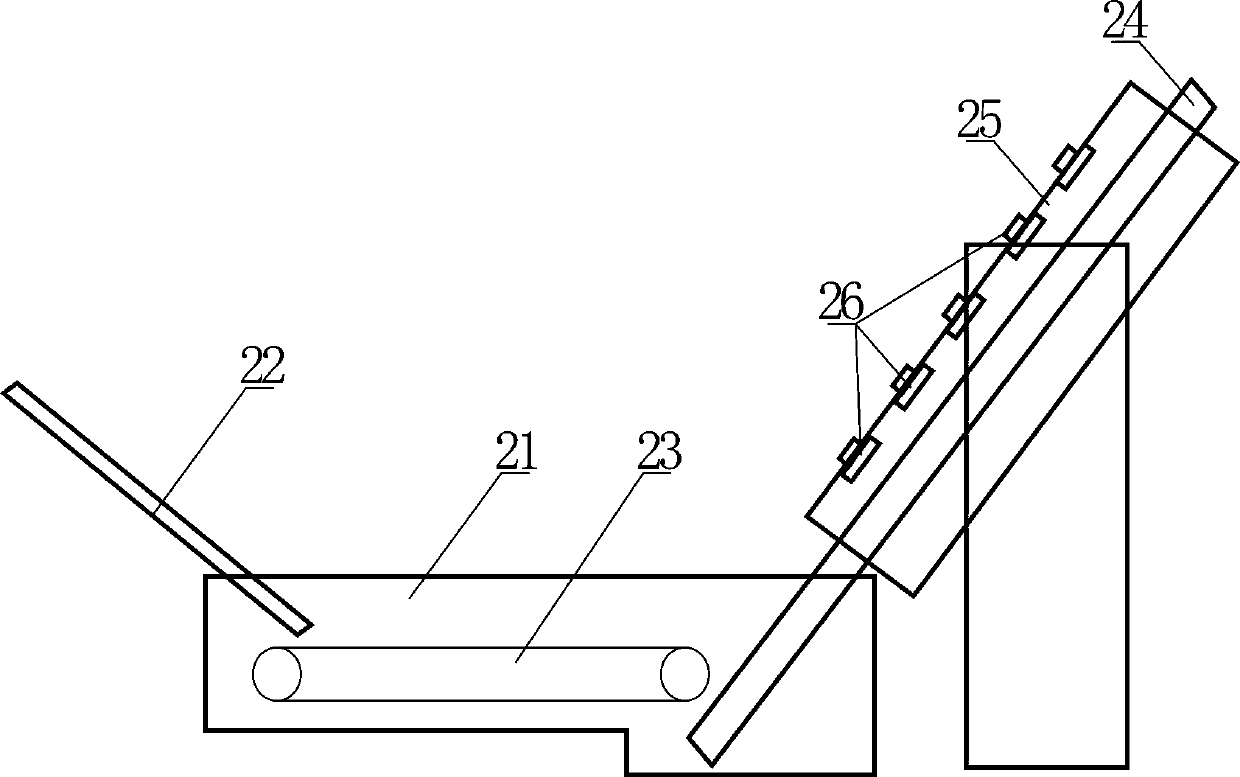

Leaning type automatic feeding device for down lamp springs

PendingCN107309624AFully automatedImprove continuityMetal working apparatusButt jointAgricultural engineering

The invention discloses a leaning type automatic feeding device for down lamp springs. The leaning type automatic feeding device comprises a feed mechanism and a spring in-place mechanism, wherein the spring in-place mechanism is located in front of the feed mechanism; the feed mechanism comprises a feed trough and a straight shake auxiliary feeder mounted below the feed trough, and a discharge end of the feed trough is in butt joint with the spring in-place mechanism; the spring in-place mechanism comprises a bearing groove capable of accommodating a spring, the discharge end is arranged at the front end of the feed trough of the feed mechanism and is in butt joint with the bearing groove which is used for bearing the spring, the tail end of the spring is located in the bearing groove, and the head end of the spring is exposed out of the bearing groove; the spring in-place mechanism further a spring supply in-place sensor. With adoption of an automatic operation mode, the springs are conveyed to a specific location to facilitate follow-up operation process, and a large amount of labor is saved; meanwhile, by means of the leaning type automatic feeding device for the down lamp springs, possibilities are provided for realizing full-automatic assembly of the down lamp springs, and the pace for realizing full-automatic assembly of the down lamp springs is quickened.

Owner:KUNSHAN TUOYU AUTOMATION TECH CO LTD

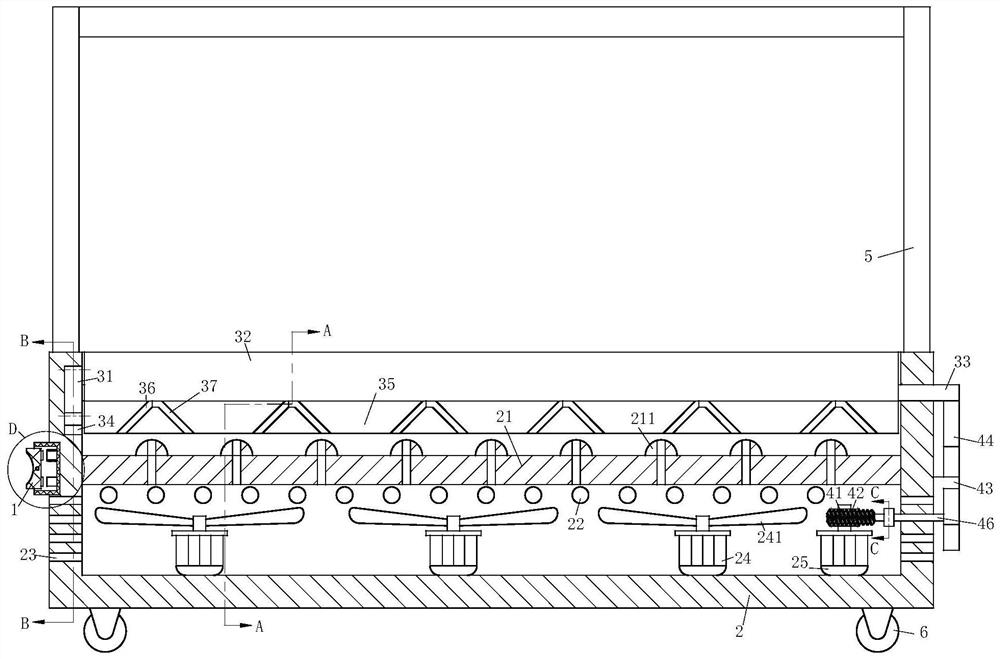

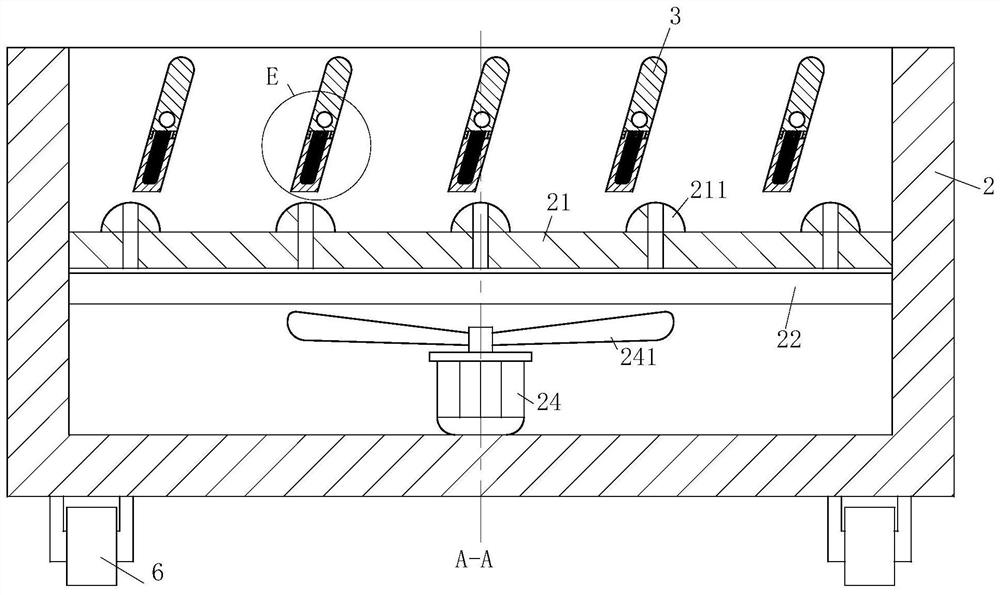

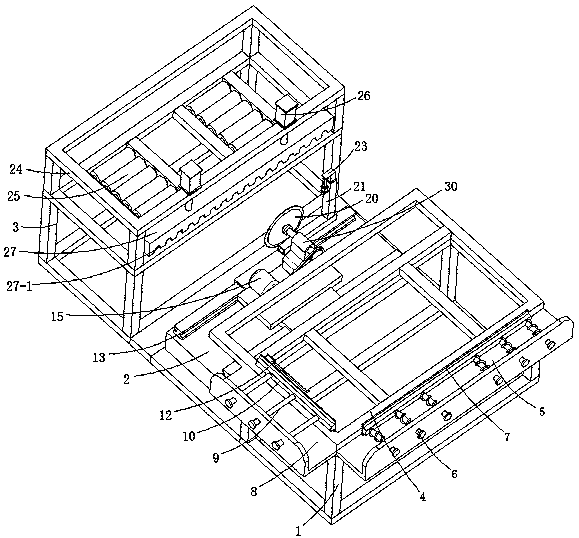

Television frame manufacturing feeding mechanism

PendingCN112024749ATo achieve the purpose of deliveryIncrease the feeding speedMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention relates to a television frame manufacturing feeding mechanism. The television frame manufacturing feeding mechanism comprises a fixed feeding unit, a material conveying unit and drivingunits, wherein the fixed feeding unit comprises a first material placing plate, a plurality of first tooth grooves are formed in the top of the first material placing plate, the material conveying unit comprises a second material placing plate, the second material placing plate is parallel to the first material placing plate and is lower than the horizontal position of the first material placing plate, after the second material placing plate moves upwards to be higher than the horizontal position of the first material placing plate through a vertical driving unit, the frame profile and secondtooth grooves are fixed and separated from the first tooth grooves, the second material placing plate moves forwards through a horizontal driving unit to enable the frame profile to move to the position above the front adjacent first tooth grooves, then the second material placing plate moves downwards through the vertical driving unit to enable the frame profile to be fixed to the first tooth grooves adjacent to the front face, and finally the second material placing plate moves backwards to the original position through the horizontal driving unit. The television frame manufacturing feedingmechanism has the advantages of being free of displacement deviation in the conveying process, high in automation degree and low in manufacturing cost.

Owner:湖南捷创新材料有限公司

A receiving robot for stamping equipment

The invention discloses a material receiving robot for stamping equipment. The robot comprises a base, and one side of the top of the base is fixedly connected with a box body. The top of the inner wall of the box body is fixedly connected with a stabilizing block. A sliding rod is fixedly connected between the bottom of the stabilizing block and the bottom of the inner wall of the box body. The surface of the sliding rod is connected with a sliding block in a sliding mode. A first spring is fixedly connected with the surface of the sliding rod, and is positioned between the bottom of the stabilizing block and the top of the sliding block. The right side of the sliding block is fixedly connected with a material receiving plate. The invention relates to the technical field of stamping equipment. Through the cooperation arrangement of a supporting rod, a tooth plate, a gear, a second motor, a material pushing rod, a material pushing block and a second spring, the material receiving robotfor the stamping equipment realizes the purpose of pushing and taking a workpiece by a stamping die after stamping, avoids the dangerous operation that an operator needs to take the workpiece out from the stamping die, lowers the probability of stamping equipment accident, and increases the production efficiency.

Owner:江苏迪普实业股份有限公司

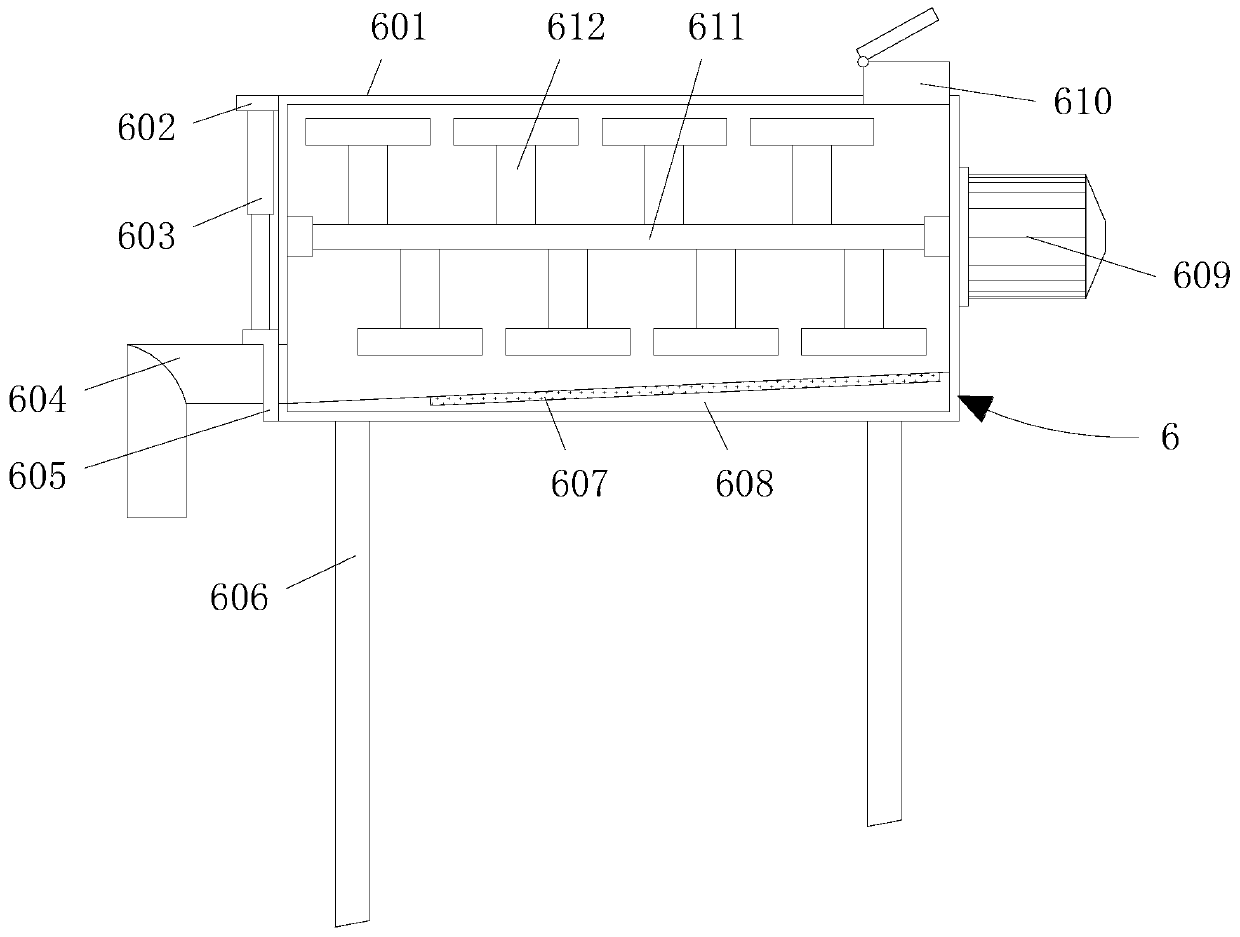

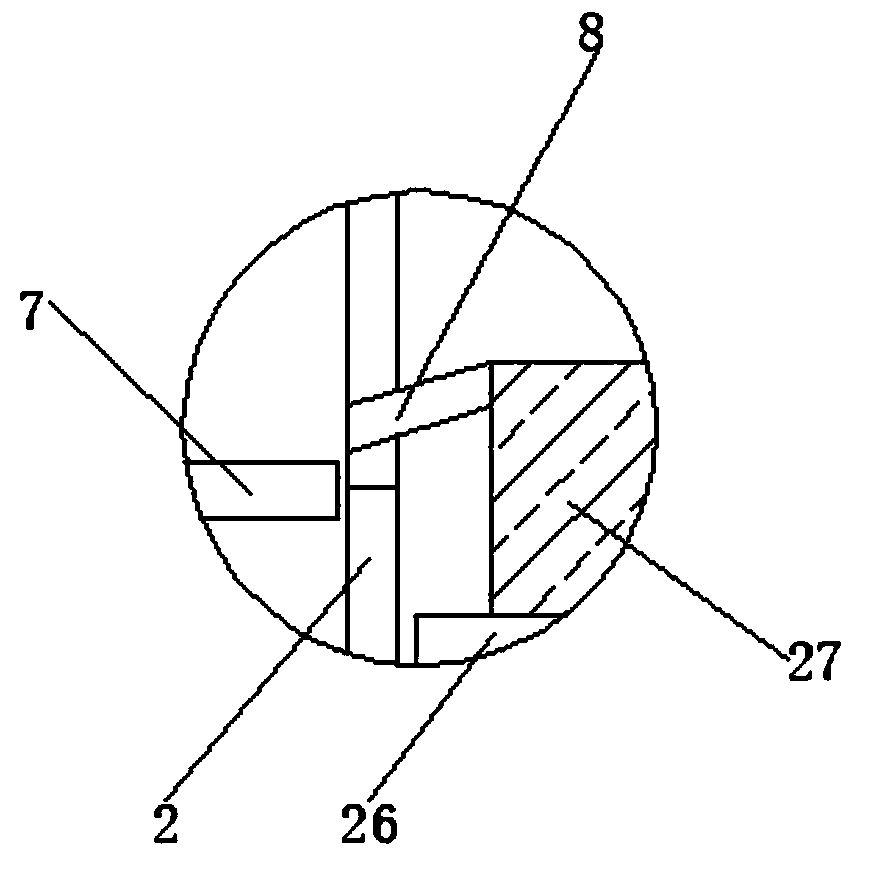

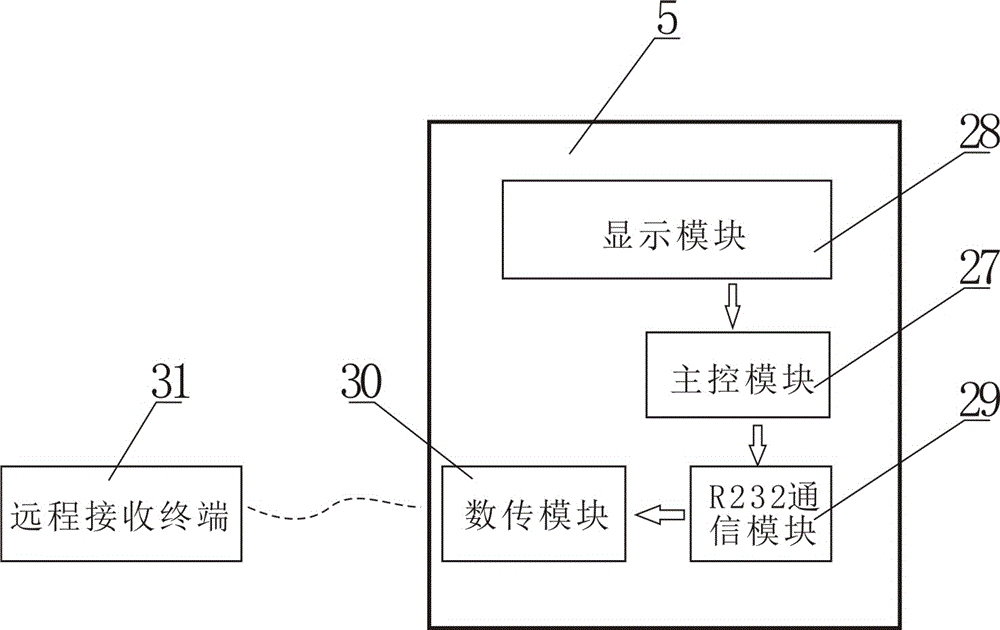

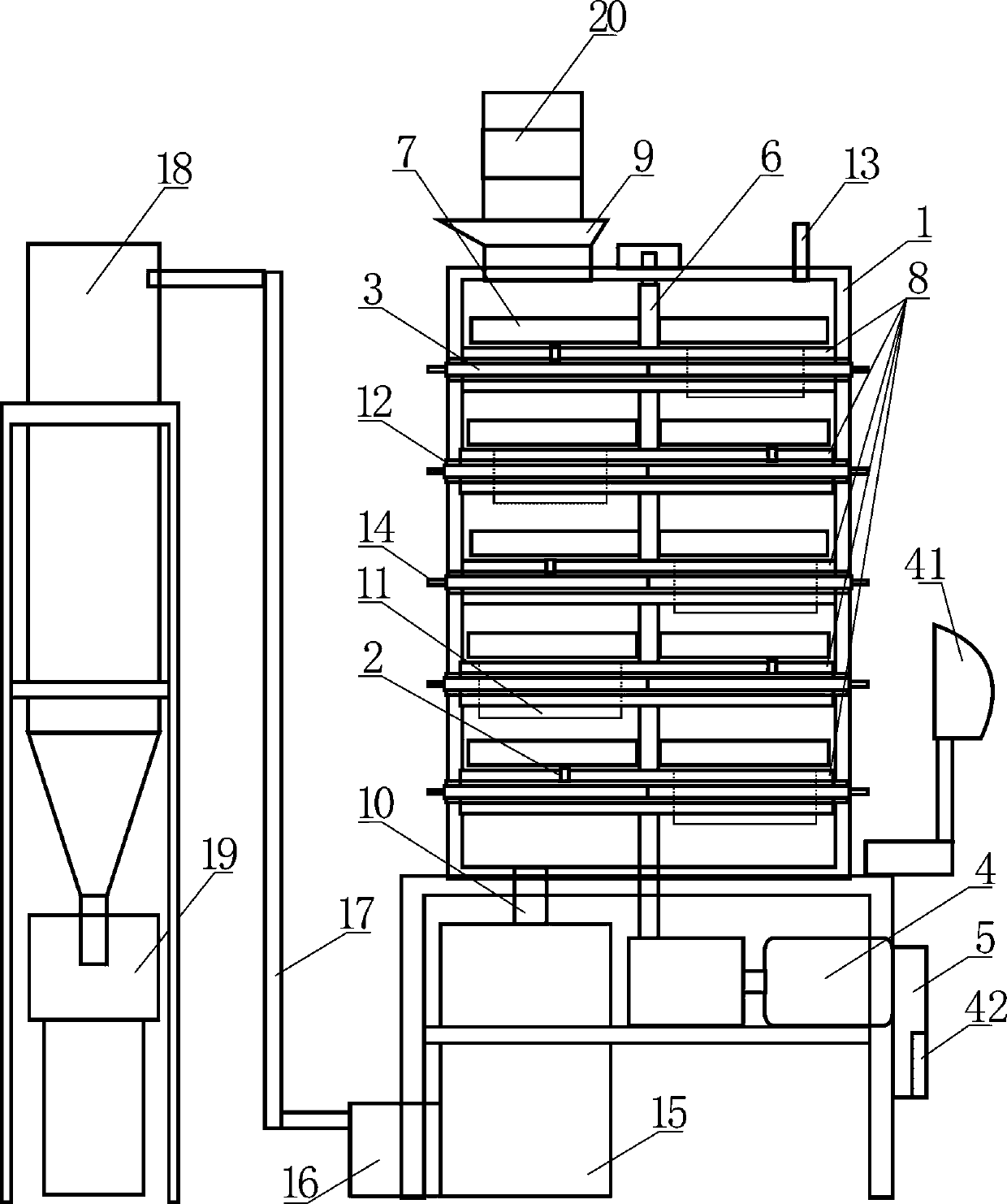

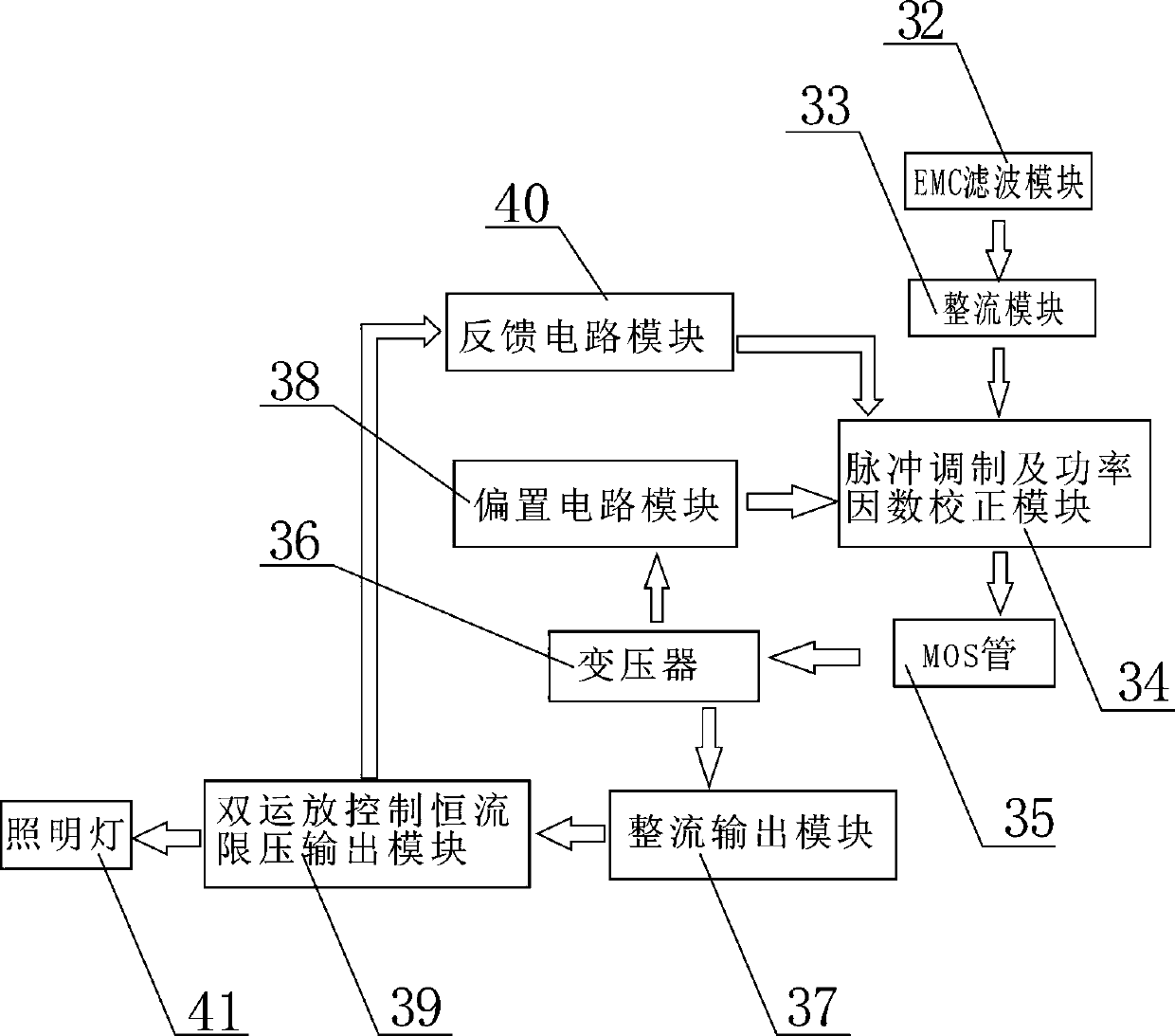

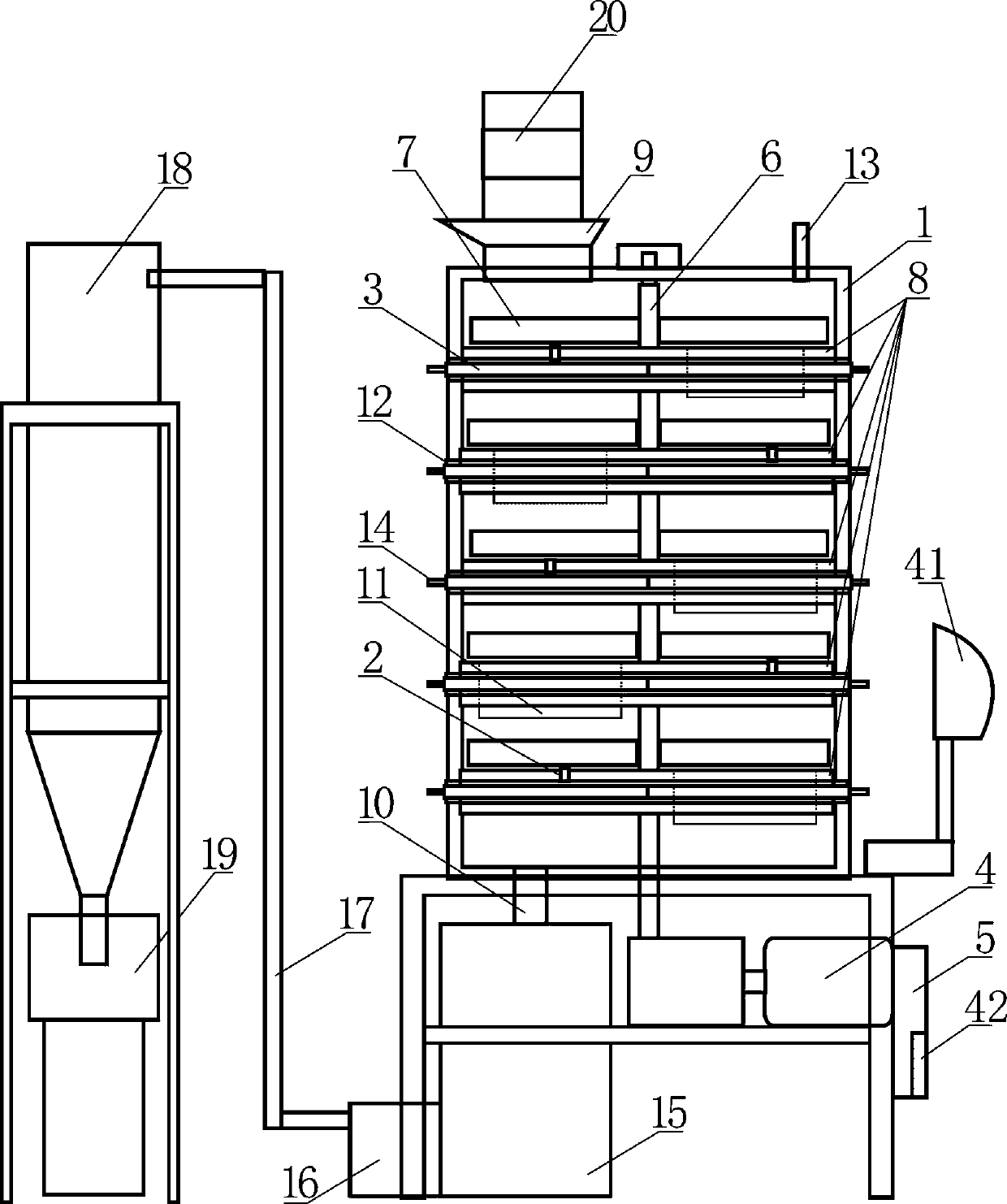

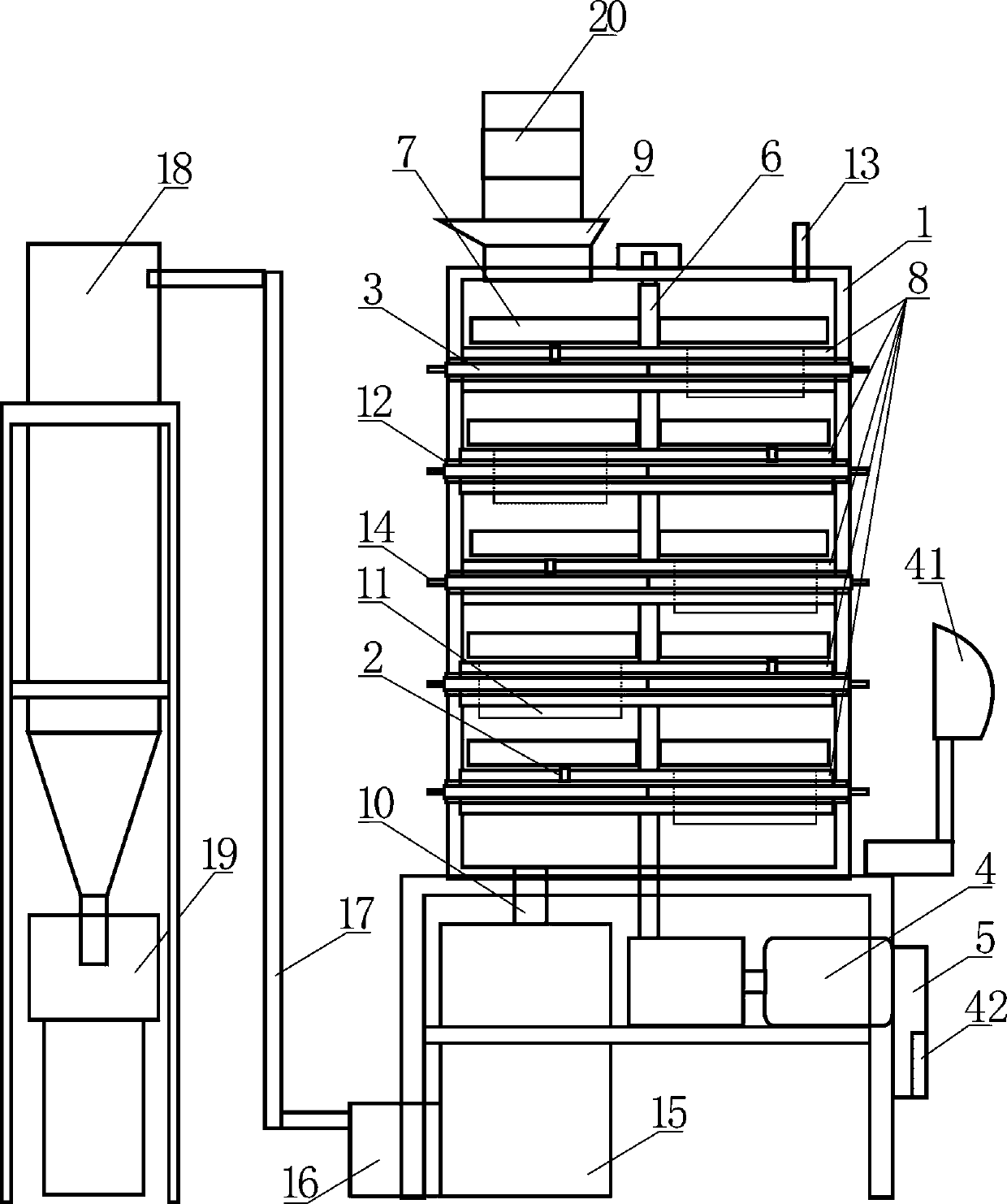

Kaolin calcining furnace with circuit break warning device

ActiveCN106705668AEasy maintenanceEasy to replaceElectrical apparatusElectroluminescent light sourcesButt jointComputer module

The invention discloses a kaolin calcining furnace with a circuit break warning device. The kaolin calcining furnace comprises a furnace body, temperature sensors, heating electric diaphragm plates, motors, an electric control box, a rotating shaft and pushing scrapers, and further comprises an illuminating lamp and a constant current driving power supply, wherein an electric input end of the electric control box is connected on a mains supply circuit; the circuit break warning device is connected on the mains supply circuit; and the circuit break warning device comprises voltage reduction rectifier filer modules and a warner. According to the kaolin calcining furnace, each heating electric diaphragm plate is formed through butt joint of two parts, and the two parts respectively penetrate through electric diaphragm plate mounting holes in the two sides of the furnace body and enter interlayers of hearths, so that maintenance and changing of the heating electric diaphragm plates are greatly facilitated; the remote monitoring manner is adopted, so that the device can be monitored while workers are not beside the device; and the circuit break warning device adopts the technical scheme, so that the circuit structure is greatly simplified, cost is reduced, and the warning effect is quite good.

Owner:高州市兆翔新材料有限公司

Jasmine tea clean production process

The invention discloses a clean production process of jasmine tea. The process mainly comprises the steps of curing fresh flowers, scenting, cleaning, holding out of scented flowers, baking, conveying while vibrating, and packaging. The jasmine tea prepared by adopting the process is long-lasting in aroma, fresh, rich and mellow in taste and clear, and yellow and bright in color of soup. The fresh flowers are cured, scented and cleaned on an operation platform, so that the cleanness of the jasmine tea can be ensured and the grade of the jasmine tea can not be influenced.

Owner:四川省炒花甘露茗茶有限公司

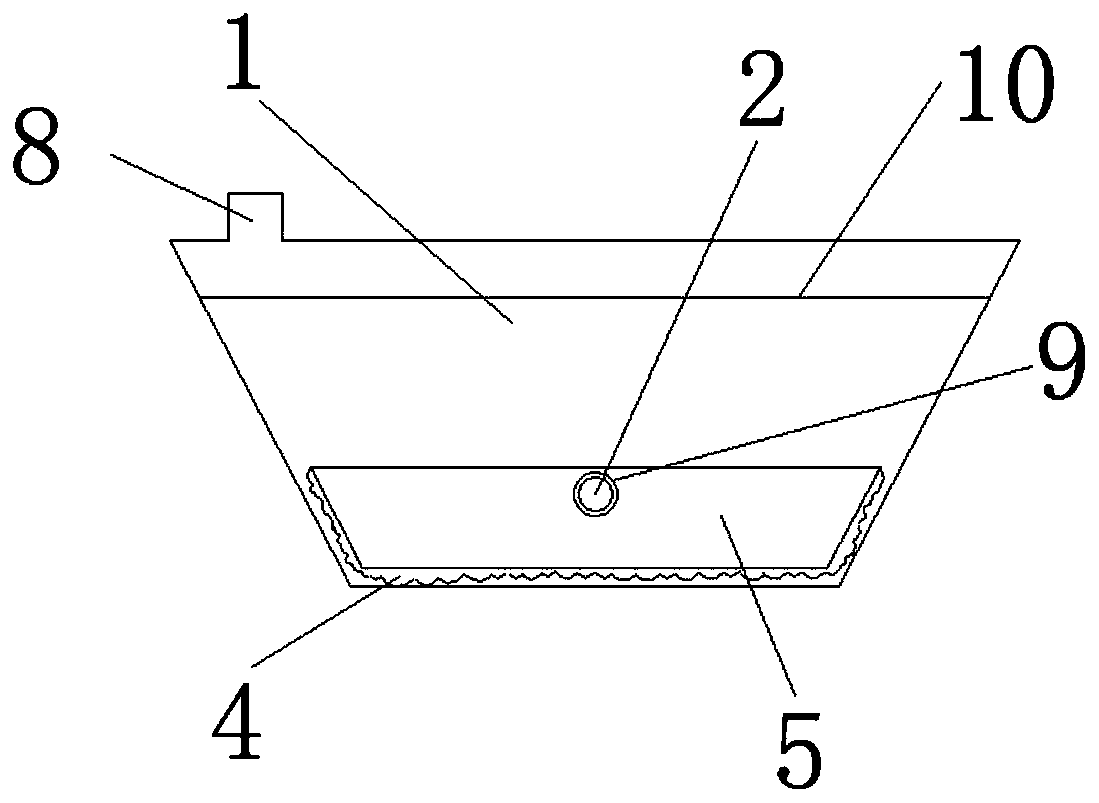

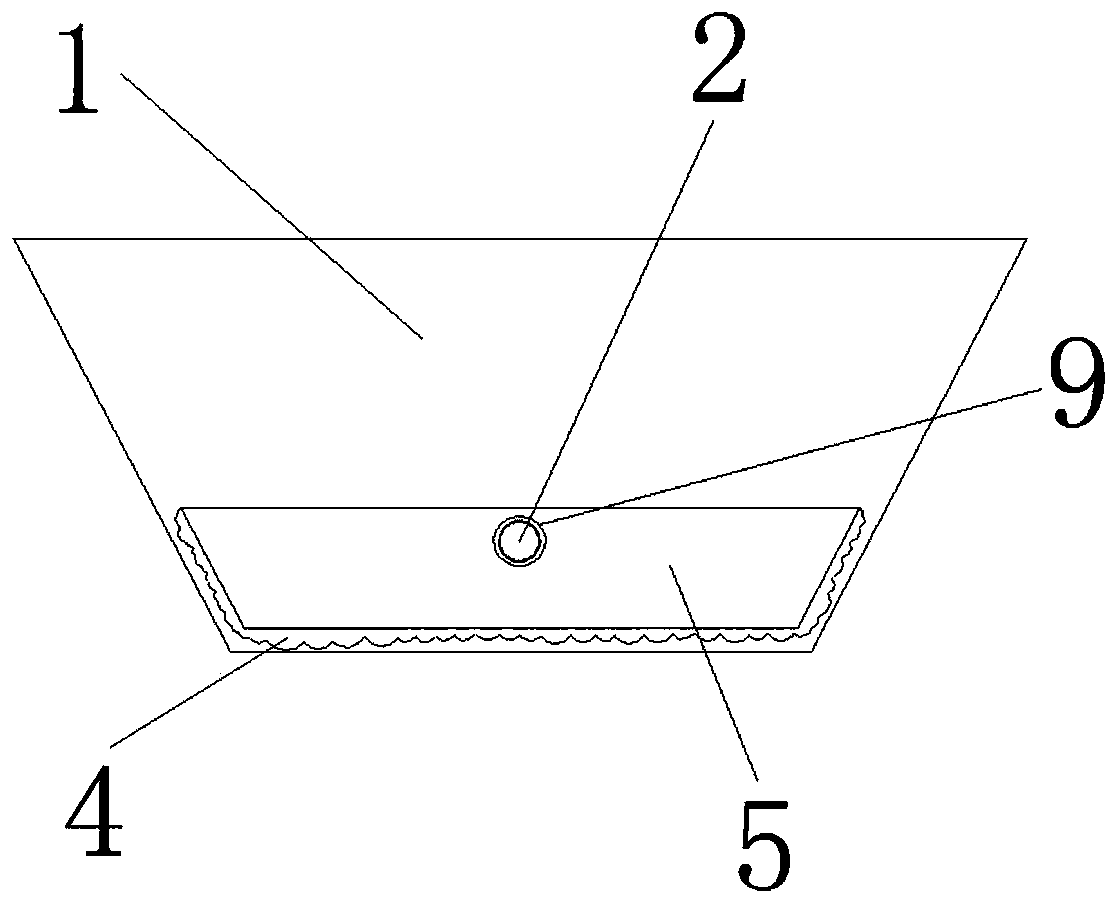

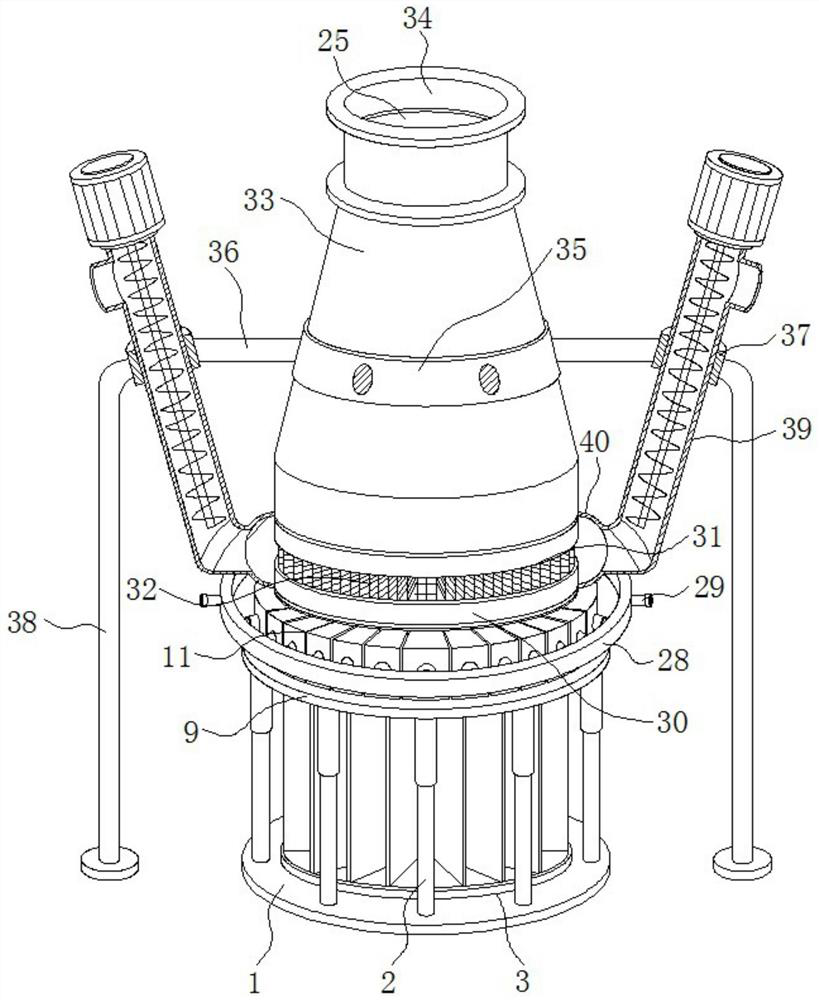

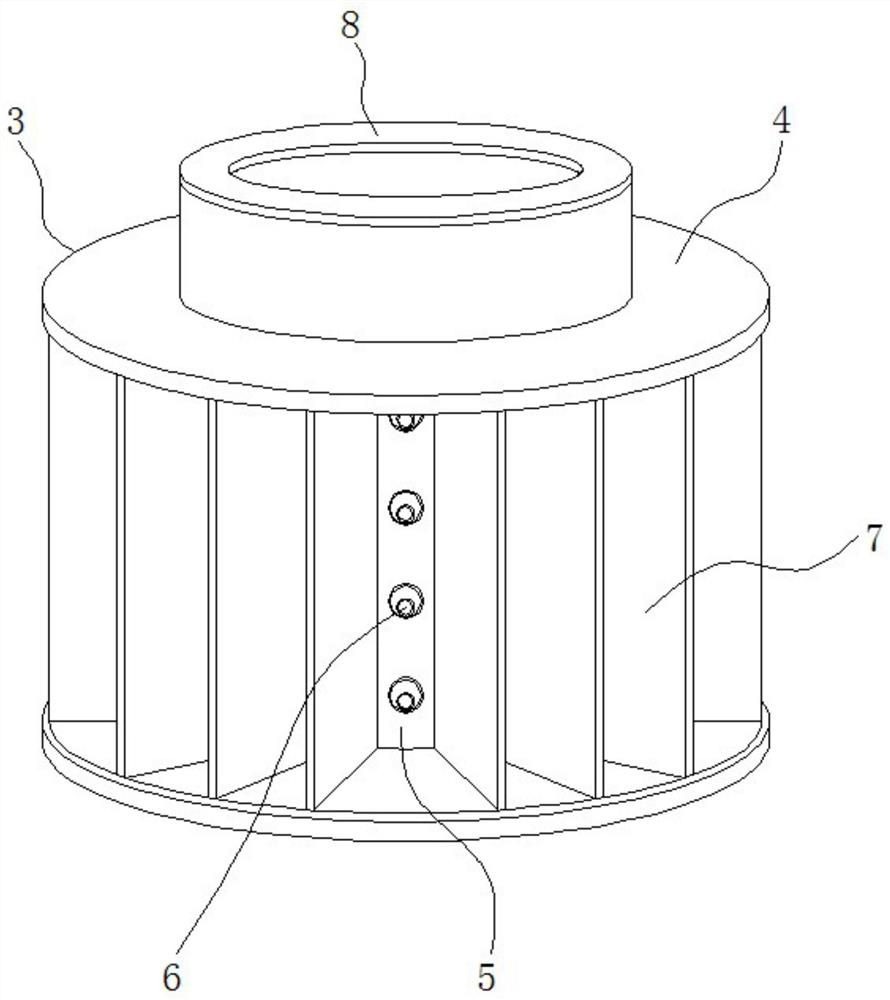

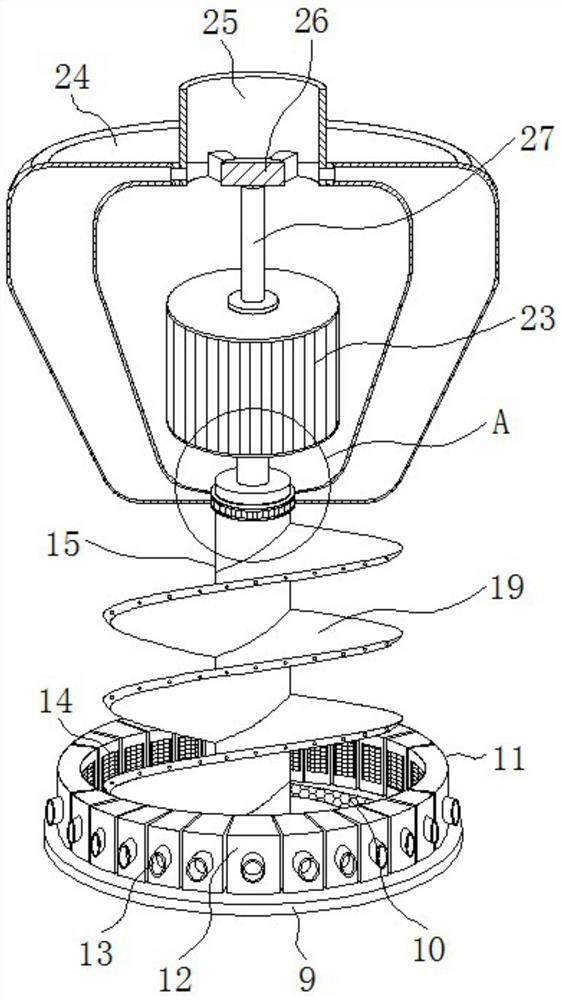

Precipitation device for sewage treatment

InactiveCN110917668ATo achieve the purpose of deliveryGood for sedimentationSedimentation settling tanksSludgeSewage treatment

The invention discloses a precipitation device for sewage treatment. The device comprises a plurality of precipitation tanks which are arranged in a stepped manner, the bottom of the upper precipitation tank is connected with the top of the lower precipitation tank, the adjacent precipitation tanks are communicated through a liquid discharge pipe, and a sludge scraper which is horizontally arranged is arranged in each precipitation tank. Precipitation is carried out for multiple times in the stepped arrangement manner, the adjacent lower precipitation tank can carry out receiving and precipitation on a liquid in the upper precipitation tank for multiple times to facilitate the precipitation work, and the gravitational potential energy of the liquid is converted into kinetic energy throughstepped arrangement to achieve the purpose of conveying the liquid between the precipitation tanks without power.

Owner:西安润川环保科技有限公司

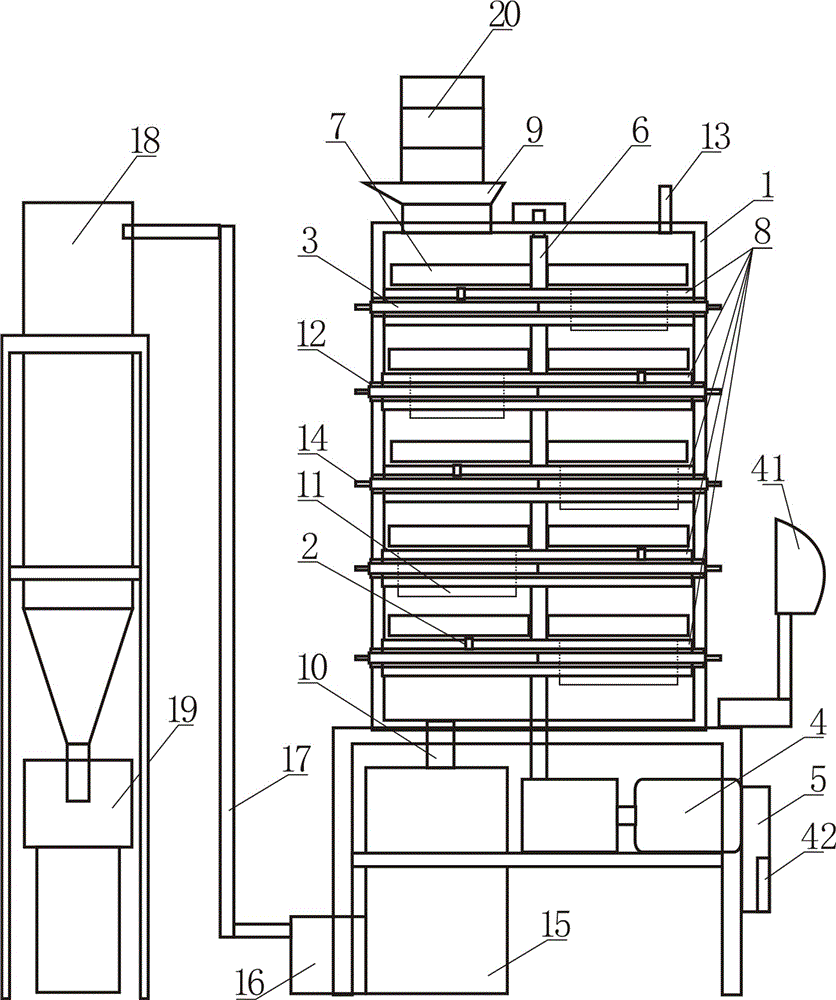

Efficient coal mine classification equipment

InactiveCN112246591AImprove filtration efficiencyRealize reciprocating motionSievingScreeningInterference fitElectric machine

The invention discloses efficient coal mine classification equipment. The efficient coal mine classification equipment comprises a body and a fixing plate, the body is fixedly connected to the left side of the upper surface of the fixing plate, an output shaft of a first motor is fixedly connected with a main shaft through a coupler, a first gasket is arranged on the left side of the upper surfaceof the fixing plate and is in interference fit with the main shaft, and a water outlet is formed in the lower end of the left side of the body. Supporting blocks are fixedly connected to the upper portion and the lower portion of an inner cavity of the body correspondingly, the upper ends of the supporting blocks are provided with a first filter net and a second filter net, and the main shaft penetrates through the first filter net and the second filter net. According to the efficient coal mine classification equipment, through fixed connection of the main shaft and an output shaft of a firstmotor, the main shaft can be indirectly driven by the motor to rotate, thus equipment on the main shaft obtains torque, through the interference fit between the main shaft and the filter nets, the filter nets can rotate along with the main shaft, so that the filtering efficiency of the filter nets is improved, and the use requirements of customers are met.

Owner:诸暨慧达机电有限公司

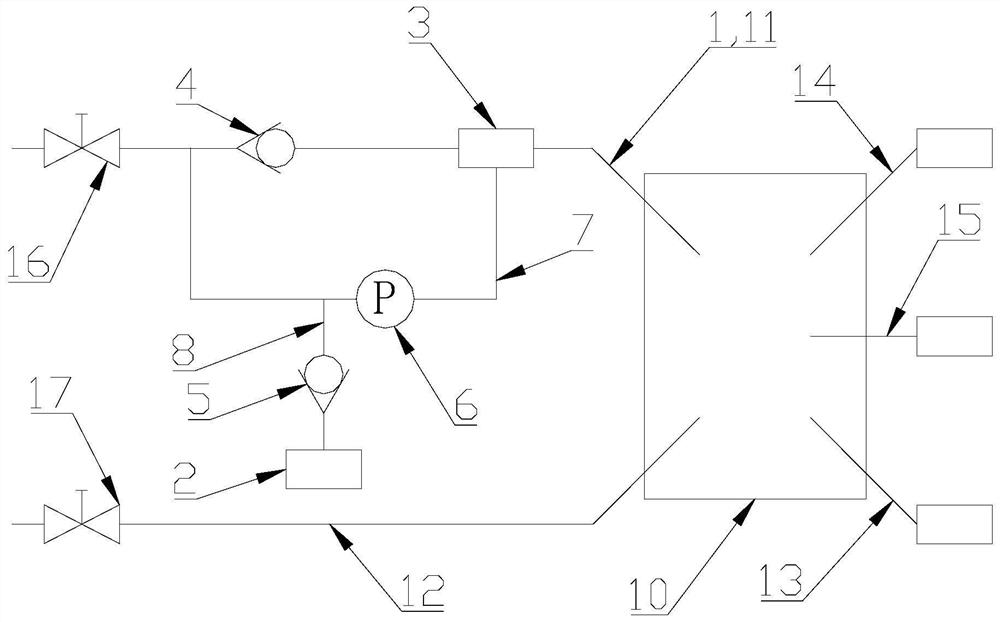

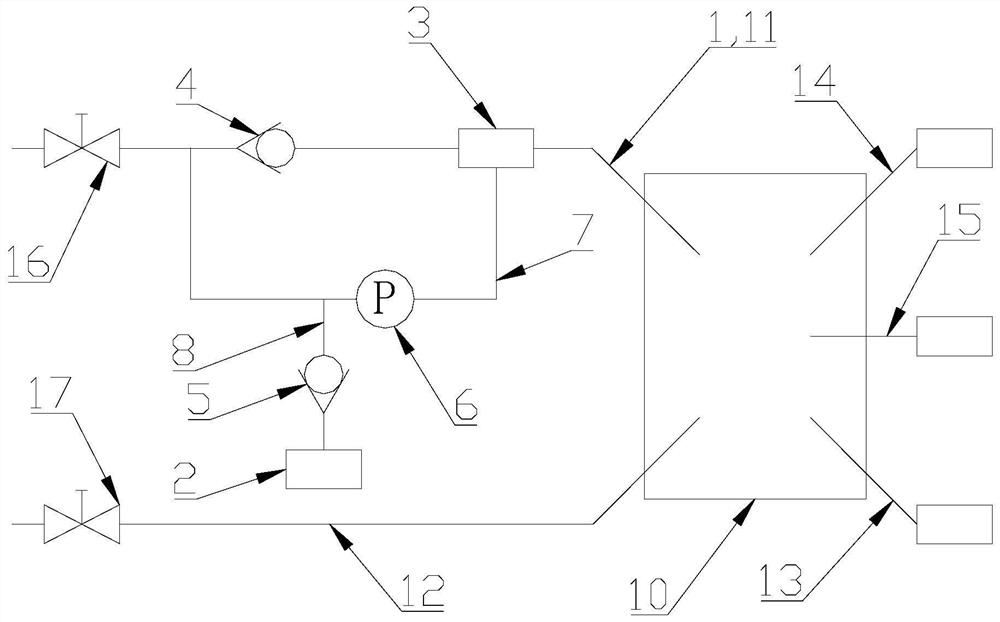

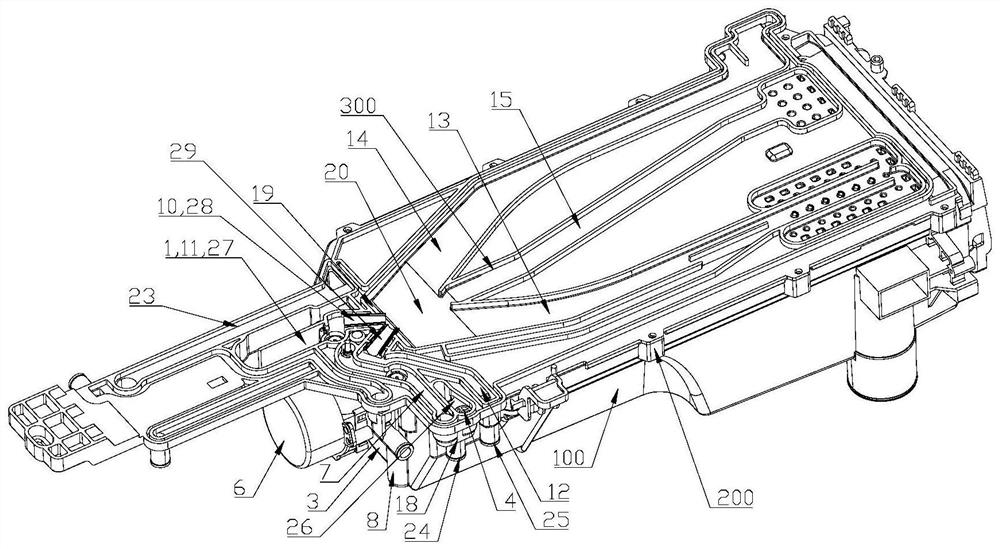

Additive feeding device and washing machine

ActiveCN112301667ARich flow formSimple structureOther washing machinesTextiles and paperLaundry washing machineWater flow

The invention discloses an additive feeding device which comprises a liquid storage box for accommodating an additive and a water path for feeding water, wherein the water path comprises a first watersupply pipeline and a second water supply pipeline which are connected with a hedging mechanism and are used for respectively or simultaneously feeding water to form multiple paths of feeding water flow; the first water supply pipeline is connected with the liquid storage box through a pumping structure, a liquid storage cavity is formed in the first water supply pipeline, and the pumping structure is used for pumping the additive in the liquid storage box into the liquid storage cavity and then flushing the additive to the hedging mechanism along with fed water of the first water supply pipeline for feeding correspondingly . Through the above-mentioned arrangement, the water supply pipeline with an additive feeding function forms one path of feeding water flow of the hedging mechanism, and an automatic feeding device can use the hedging mechanism to correspondingly feed the liquid additive. Meanwhile, the invention further comprises a washing machine which is provided with the additive feeding device.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Workpiece sliding-down device

The invention belongs to the technical field of logistics equipment and relates to a workpiece sliding-down device which comprises a base. A supporting base is installed on the base. An installing face of the supporting base is arranged in an inclined manner. A track is fixed to the installing face of the supporting base. A first air cylinder base is arranged on the portion, corresponding to one side of the track, of the top face of the base, and a second air cylinder base is arranged on the portion, corresponding to the other side of the track, of the top face of the base. A first blocking air cylinder is installed on the first air cylinder base, and a second blocking air cylinder is installed on the second air cylinder base. A piston rod of the first blocking air cylinder and a piston rod of the second blocking air cylinder face one side of the track. The sliding-down device utilizes the self-weight of workpieces to achieve the transferring effect, and the workpiece collecting effect is good.

Owner:WUXI TEHENG TECH CO LTD

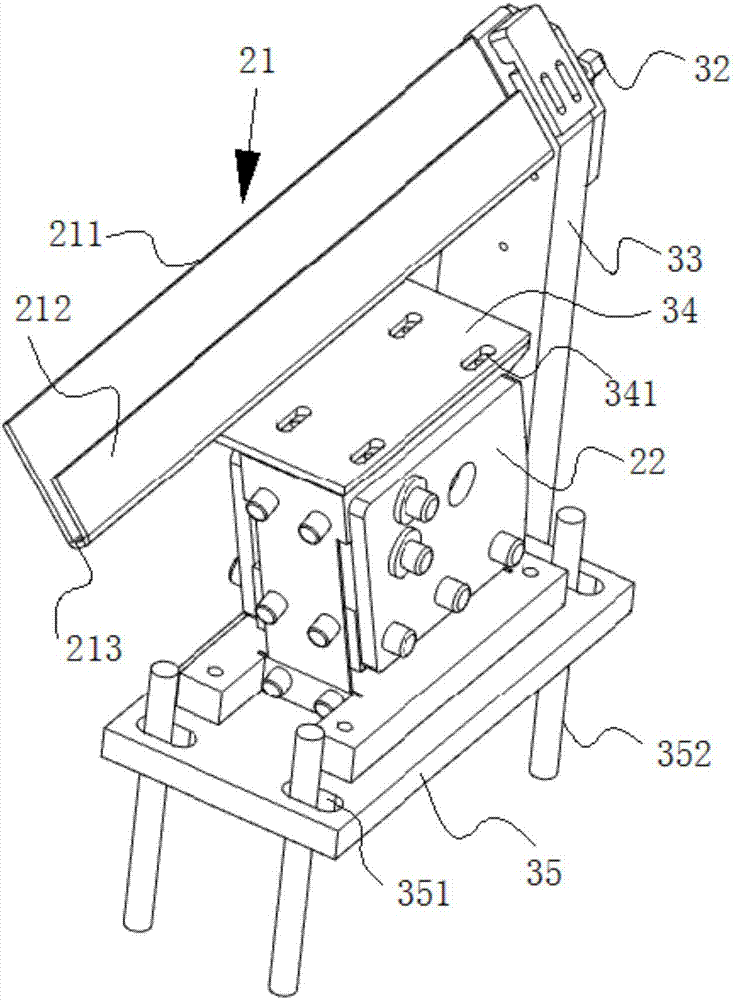

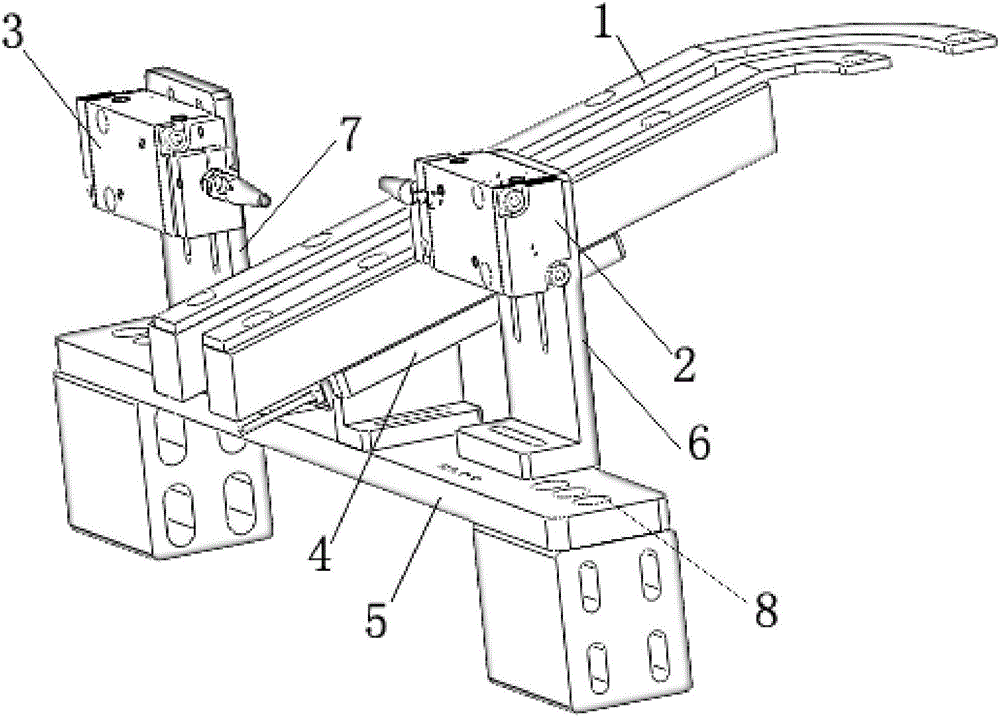

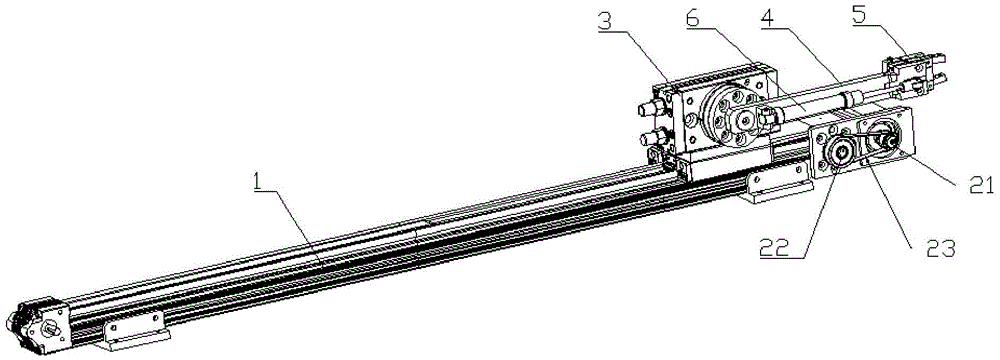

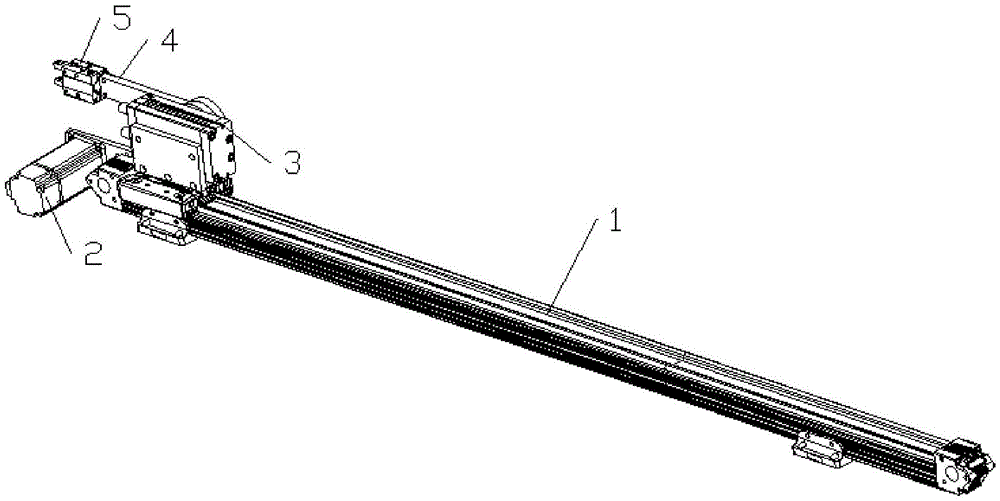

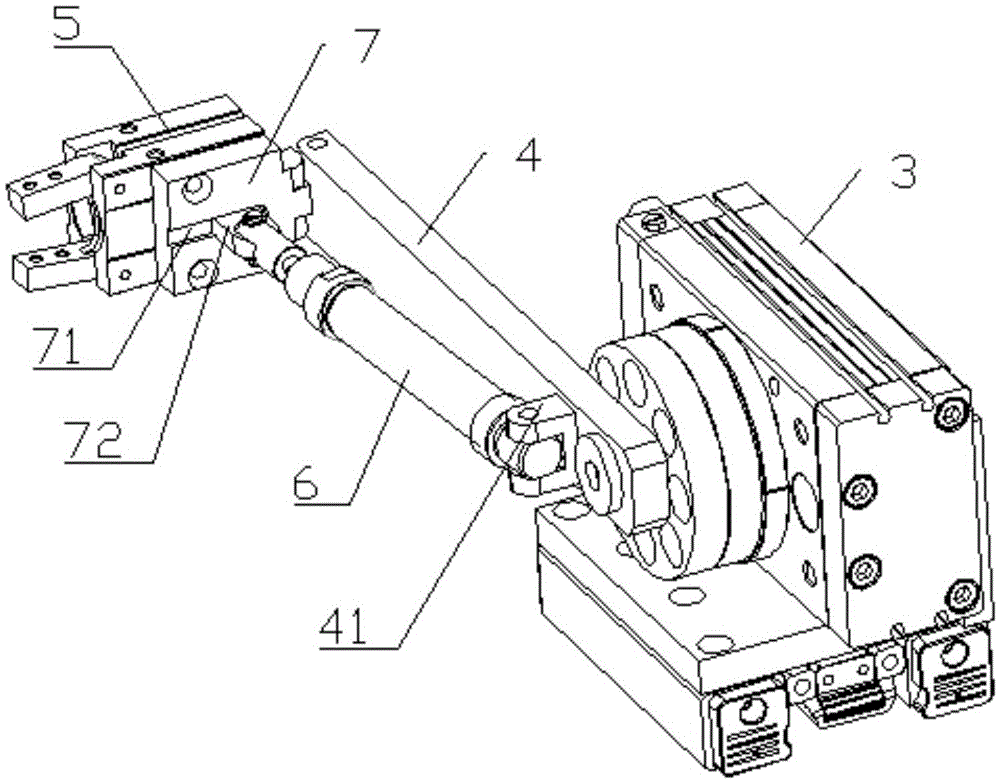

Conveying manipulator of half divider

InactiveCN105460602ATo achieve the purpose of deliverySimple structureConveyor partsEngineeringManipulator

The invention provides a conveying manipulator of a half divider. The conveying manipulator comprises a horizontal movement mechanism and a vertical rotating mechanism, wherein the horizontal movement mechanism comprises a sliding rail and a support base in sliding fit with the sliding rail and further comprises a power assembly providing the support base with power sliding in the arrangement direction of the sliding rail; and the vertical rotating mechanism comprises a rotating motor, a clamp, a linkage rod and a rotating air cylinder, the rotating motor is fixed to the support base, the rotating air cylinder provides the linkage rod with power rotating around the rotating air cylinder, one end of the linkage rod is connected with an output shaft of the rotating air cylinder, and the other end of the linkage rod is hinged to the clamp. According to the invention, the purpose of two-dimensional workpiece conveying can be achieved through the cooperation arrangement of the horizontal movement mechanism and the vertical rotating mechanism, and at the same time, the used structure is relatively simpler, so that actual production requirements can be met, and the investment cost can be further saved.

Owner:TIANJIN SHIDAI CHUANGYE TECH CO LTD

Breakage-proof glass product conveying device

ActiveCN112047110AAvoid offsetImprove stabilityCharge manipulationConveyor partsHydraulic cylinderStructural engineering

The invention discloses a breakage-proof glass product conveying device. The glass product conveying device comprises a discharging box, a feeding box and a transition frame, wherein a protection frame is arranged at the top of the discharging box, the transition frame is arranged on one side of the discharging box, a transition protection plate is arranged on the transition frame, the feeding boxis arranged on one side of the transition frame, a protection frame is arranged at the top of the feeding box, and feeding plates are arranged at the two ends of the top face of the feeding box correspondingly. According to the glass product conveying device, a transition hydraulic cylinder controls a transition piston rod therein to move towards the outer side of a cylinder body, the transitionpiston rod pushes a connecting block to enable two adjusting plates to rotate along a steering shaft, the position adjustment of one ends of the two adjusting plates is achieved, the butt joint with atransferring device on the feeding box is facilitated, and the transferring work of a conveying plate is achieved; and then through the transferring device on the discharging box, the conveying plateis conveyed to the position between two discharging plates on the discharging box, glass products on the conveying plate are conveyed to the outer side, steering conveying of the glass products is achieved, the manual participation is not needed in the whole conveying process, and the conveying efficiency is greatly improved.

Owner:安徽艺云玻璃有限公司

Finished product warehouse discharging and transferring device

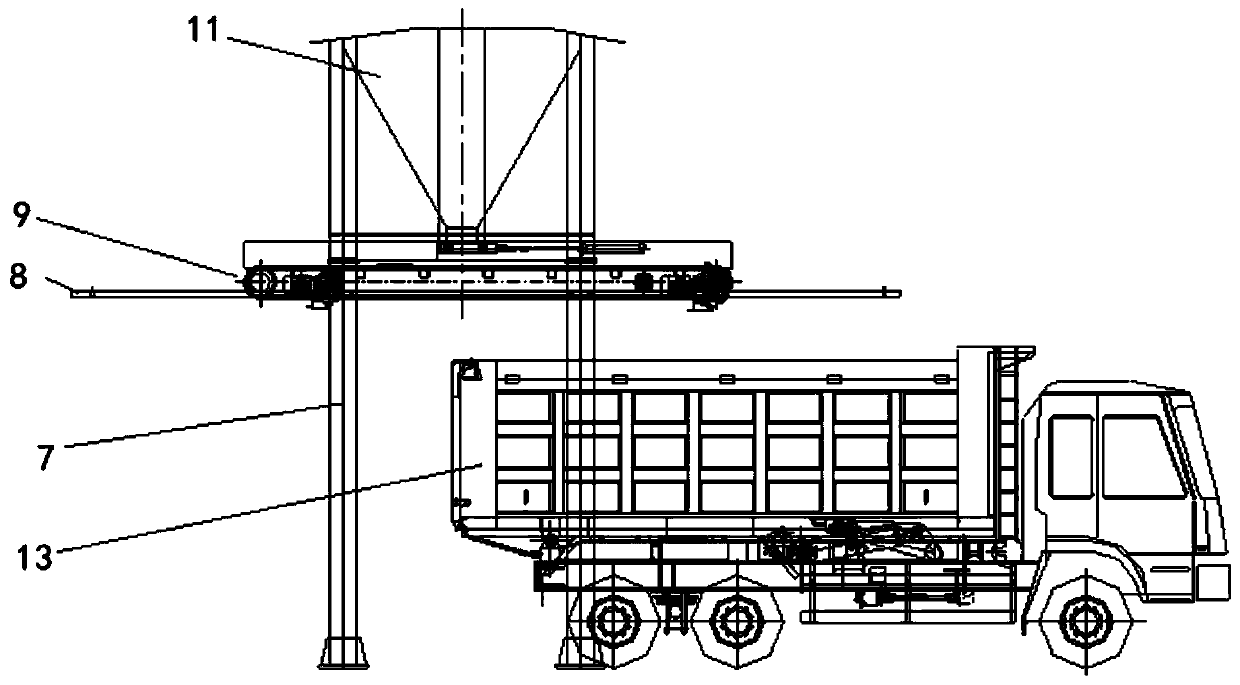

PendingCN110436219AReduce segregationControl the amount of dischargeLarge containersLoading/unloadingEngineeringSprocket

The invention belongs to a discharging device in an asphalt mixing device. In order to solve the problems that in the prior art, the discharging amount is difficult to master due to the fact that a finished product warehouse directly discharges materials to a receiving vehicle, and operation is tedious due to the fact that the vehicle needs to be frequently moved, and in order to solve the technical problem that separation is prone to being caused due to too high material stacking during discharging, a finished product warehouse discharging and transferring device is provided and comprises a first driver, a bracket, a track and a conveying mechanism; the track is fixed on the bracket; the conveying mechanism is matched with the track through a sliding component; the conveying mechanism islocated under a finished product warehouse; the output end of the first driver is connected to the sliding component; and the conveying mechanism has a plurality of modes that a chain wheel chain is in transmission fit with a scraper blade and a belt wheel belt, or the chain wheel chain is in transmission fit with a belt. During discharging, only the first driver is used for driving the conveyingmechanism to move, the receiving vehicle does not need to be moved frequently, and operation is easier and more convenient to achieve; and through simple and convenient multi-point discharging, segregation of materials is greatly reduced.

Owner:陕西达刚筑路环保设备有限公司

Kaolin calciner with control cable

ActiveCN106705647BEasy maintenanceEasy to replaceCharge treatment typeElectric heating for furnacesPolyesterGlass fiber

The invention discloses a kaolin calcining furnace with a control cable. The kaolin calcining furnace comprises a furnace body, a temperature sensor, a heating electric film plate, a motor, an electric control box, a rotating shaft and a pushing and scraping plate, a lighting lamp which is an LED lamp, a constant-current driving power supply and a control cable connected with the electric control box, wherein the control cable comprises four cable cores; each cable core group is composed of two cable core conductors with insulation layers; a glass silk filling rope is arranged between the four cable core groups; a glass fiber coating tape is arranged at the periphery of the four cable core groups; a metal shielding layer is arranged at the periphery of the glass fiber coating tape; an outer sheath made of a flame-retardant polyether type thermoplastic polyurethane elastic material is arranged at the periphery of the metal shielding layer; a polyester film coating tape is arranged between the metal shielding layer and the outer sheath. The cable adopts the outer sheath made of the flame-retardant polyether type thermoplastic polyurethane elastic material, so that the cable can operate in the high-temperature or low-temperature environment; the cable is not easy to crack; the low-temperature impact capability is improved.

Owner:高州市兆翔新材料有限公司

An automatic molding device for rubber product processing and its use method

The invention discloses an automatic molding device for processing rubber products and a method for using the same. The right rear end of the bottom is fixedly equipped with a conveying motor whose output shaft is driven and connected with the conveying roller located at the rightmost end of the inner surface of the support through a belt. The invention is equipped with a stirring and heating mechanism, which can play the role of stirring and heating the material, so as to avoid the phenomenon of solidification of the material in the process, ensure the quality of subsequent processing, and set up a molding mechanism, which can perform injection molding on the material Processing, so as to improve its molding efficiency, set up the conveying roller, conveyor belt, belt and conveying motor, start the conveying motor, the conveying motor drives the conveying roller to rotate through the belt, and the conveying roller drives the material to move through the conveying belt, so as to achieve the purpose of feeding.

Owner:浙江橡企科技有限公司

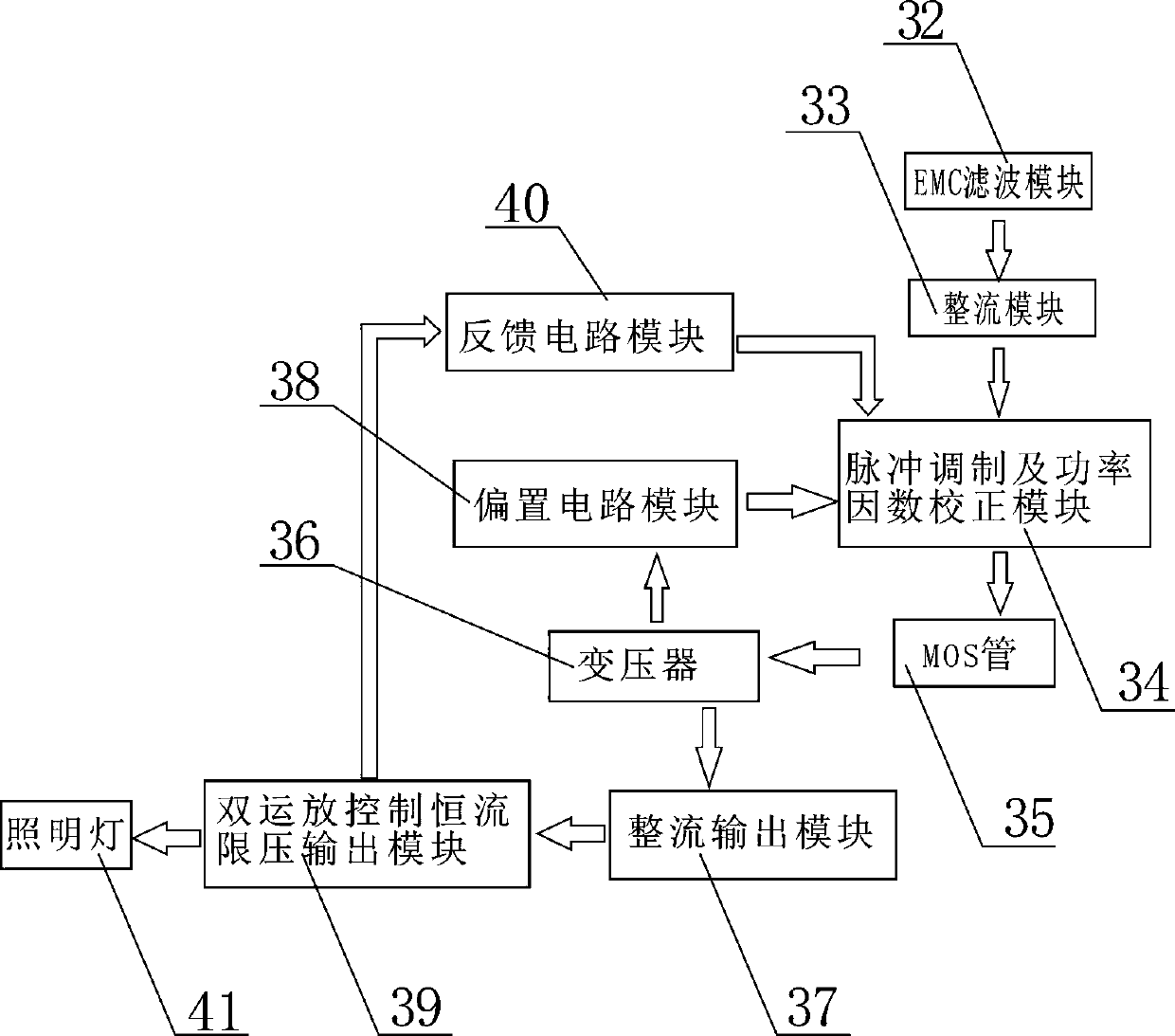

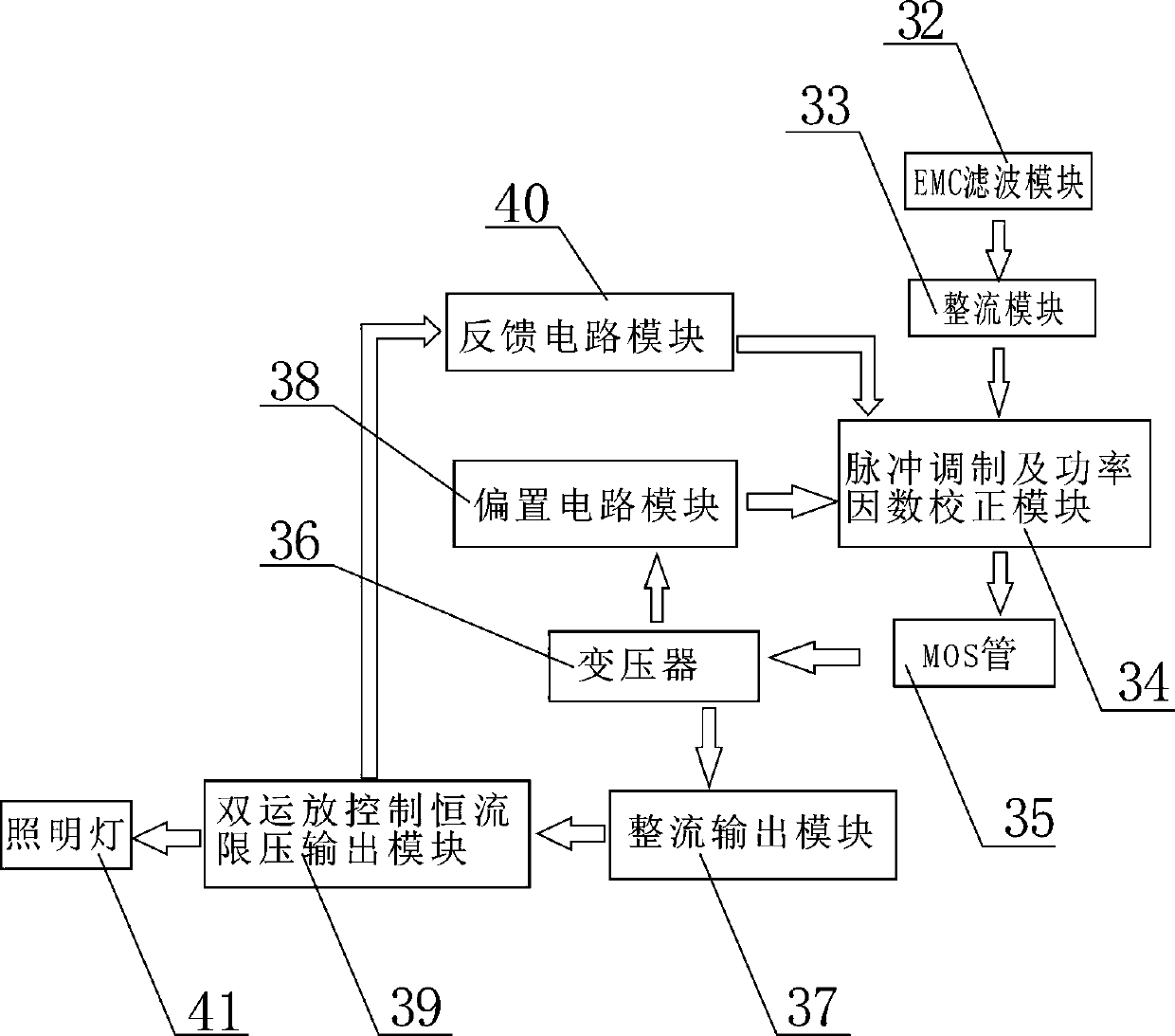

Kaolin calciner with lighting

ActiveCN106679403BEasy maintenanceEasy to replaceCharge treatment typeVertical furnacesTransformerButt joint

The invention discloses a kaolin calcining furnace with an illuminating lamp. The kaolin calcining furnace comprises a furnace body, temperature sensors, heating electric membrane plates, a motor, an electric control cabinet, a rotary shaft, material pushing scrapers, the illuminating lamp and a constant-current drive power supply; the illuminating lamp is an LED lamp; and the constant-current drive power supply is composed of an EMC filtering module, a bridge type rectifier module, a pulse modulation and power factor correction module, an MOS tube, a transformer and a rectifier output module. As each heating electric membrane plate is formed by butt jointing two half parts, and each two half parts penetrate through electric membrane plate mounting holes formed in the two sides of the furnace body respectively and enter an interlayer of a furnace bottom, each heating electric membrane plate is greatly convenient to maintain and change; with adoption of a mode of remote monitoring, a worker can monitor equipment without being beside the equipment; and in the constant-current drive power supply, as PFC correction and DC-DC conversion can be realized by using a single transformer, the kaolin calcining furnace has the characteristics of simpleness in circuit, small amount of elements and low cost.

Owner:高州市兆翔新材料有限公司

Self-locking function type clamping device based on textile bobbin

InactiveCN112660808APrevent fallingServing as an auxiliary snap-inConveyor partsTextile technologyStructural engineering

The invention relates to the technical field of textile, and discloses a self-locking function type clamping device based on textile bobbin. The self-locking function type clamping device based on the textile bobbin comprises a textile frame, a supporting seat is arranged at the upper end of the textile frame, a base is arranged on a position, on the outer side of the supporting seat, at the upper end of the textile frame, a mounting box is arranged on the position, on the left side of the base, at the upper end of the textile frame, a transmission mechanism is arranged on the inner side of the mounting box, a clamping mechanism is arranged at the upper end of the transmission mechanism, a overturning mechanism is arranged at the upper end of the supporting seat, a conveying mechanism is arranged at the top end of the base, and a top plate is arranged at the upper end of the mounting box. According to the self-locking function type clamping device based on the textile bobbin, clamping can be carried out on the bobbin through the clamping mechanism, meanwhile, a clamping self-locking structure is arranged in the clamping mechanism, the purpose of auxiliary clamping can be achieved when the clamping mechanism clamps the bobbin, and therefore the bobbin is prevented from falling off in the clamping process, and then the clamping firmness is improved.

Owner:诸暨市惠联精密机械制造有限公司

Safety switch for electric heater and electric heater

ActiveCN113483386AChange the cooling directionEasy to dryHeating fuelLighting and heating apparatusEngineeringClothes hanger

The invention relates to the technical field of heating equipment, in particular to a safety switch for an electric heater and the electric heater. The safety switch for the electric heater comprises a U-shaped shell, a pressing block is rotatably connected in the U-shaped shell, and a coil and a touch switch are fixed at the bottom end in the U-shaped shell. The electric heater comprises the safety switch described above and a U-shaped containing box, a heat dissipation module is rotationally connected in the U-shaped containing box, a swing mechanism is arranged in the U-shaped containing box, the swing mechanism is fixedly connected with the heat dissipation module, and a clothes hanger is fixed to the top end of the U-shaped containing box. According to the safety switch for the electric heater and the electric heater, the electric heater is used for drying clothes on the clothes hanger, and heat can be supplied to people in winter when the clothes hanger is detached; and through the heat dissipation module, on one hand, the heat dissipation module is matched with the safety switch to prevent the situation that the clothes on the clothes hanger generate heat on the electric heater to ignite the clothes, and on the other hand, the heat dissipation module is matched with the swing mechanism to guide the heat dissipation direction to better dry the clothes on the clothes hanger.

Owner:慈溪市新秀丽电器有限公司

Sand suction and mud suction circulation launching device

PendingCN111731890AImprove delivery efficiencyEffective deliveryConveyorsLoading/unloadingWater jet cutterGeotechnical engineering

The invention discloses a sand suction and mud suction circulation launching device, and relates to the technical field of sand suction and mud suction devices. The sand suction and mud suction circulation launching device comprises a chassis, a suction mechanism, an auxiliary mechanism, a water jet scalpel mechanism and mud discharge mechanisms, wherein telescopic rods are fixed to the edge of the upper surface of the chassis at equal intervals, the suction mechanism is arranged in the center between the chassis and a supporting disc, the auxiliary mechanism is installed on the edge of the upper portion of the supporting disc and composed of a unit ladder block, a through pipe, a through net, a ring pipe and an injection pipe, the water jet scalpel mechanism is arranged in the center of the upper portion of the supporting disc, and the mud discharge mechanisms penetrate through positioning sleeves. According to the sand suction and mud suction circulation launching device, the water jet scalpel mechanism is assisted through the auxiliary mechanism, so that mud and sand can be quickly scattered after passing through a mud passing net, on one hand, the operation pressure of the water jet scalpel mechanism is reduced, and on the other hand, a large amount of mud and sand cannot be left at dead corners around the water jet scalpel mechanism, complete output of the mud and sand canbe guaranteed, and the mud and sand conveying efficiency is improved.

Owner:WUXI SANHE HEAVY MACHINERY

Adjustable hot-blast stove feeding device

InactiveCN112484068AAvoid damagePrevent overflowFuel feeding arrangementsLump/pulverulent fuel feeder/distributionHot air ovenTransmission belt

The invention discloses an adjustable hot-blast stove feeding device. The adjustable hot-blast stove feeding device comprises a bottom plate, the upper surface of the bottom plate is fixedly connectedwith a supporting column and a fixing base, the top end of the supporting column is rotationally connected with a supporting plate, the lower surface of the supporting plate is fixedly connected witha rotating base, the inner wall of the fixing base is rotationally connected with a connecting pipe through a rotating shaft, a sliding column is slidably connected to the inner wall of the connecting pipe, the top end of the sliding column is rotatably connected with the inner wall of the rotating base through the rotating shaft, a through hole is formed in the front face of the supporting plate, and a rotating shaft is rotatably connected to the inner wall of the through hole through a bearing. According to the adjustable hot-blast stove feeding device, by arranging a rotating handle, a rotating gear, a spur rack and the sliding column, the rotating handle rotates conveniently to enable the rotating gear to drive the spur rack to move up and down, the sliding column moves up and down onthe inner wall of the connecting pipe, therefore, the adjustable hot-blast stove feeding device can adjust the height of a transmission belt according to the requirements of a hot-blast stove, and ismore convenient.

Owner:铜陵美天新能源科技有限公司

Plate fixed-length intelligent cutting equipment

InactiveCN110899815AEasy to cutTo achieve the purpose of fixed-length cuttingShearing machinesShearing machine accessoriesStructural engineeringIndustrial engineering

The invention discloses plate fixed-length intelligent cutting equipment and belongs to the technical field of plate intelligent production equipment. The equipment comprises a first bracket, a mounting plate fixedly connected with the first bracket, and a second bracket fixedly connected with the mounting plate, wherein a storage rack is fixedly arranged at the top of the first bracket, a first mounting plate is fixedly arranged on a transverse side wall of the storage rack, a sliding rod is fixedly arranged on the first mounting plate, a first baffle is slidably connected with the end, arranged on an inner side of the first mounting plate, of the sliding rod, a second mounting plate is fixedly arranged on a longitudinal side wall of the storage rack, a connecting rod is fixedly arrangedon the second mounting plate, a second baffle is fixedly arranged at the end, away from the second mounting plate, of the connecting rod, and a measuring tape is fixedly arranged on a side wall of thesecond baffle. The equipment is advantaged in that the plate can be measured in the plate conveying process so that a purpose of fixed-length cutting is achieved, and the cut plate can be pushed outafter cutting contact.

Owner:南京丰濠网络科技有限公司

Additive injection device and washing machine

ActiveCN112301667BWith delivery functionTo achieve the purpose of deliveryOther washing machinesTextiles and paperLaundry washing machineWater flow

The invention discloses an additive feeding device, which comprises a liquid storage box containing the additive and a water channel for water intake; the water channel includes a first water supply pipeline and a second water supply pipeline connected with a hedging mechanism, which are used for respectively At the same time, the water enters to form multiple water inlet flows; the first water supply pipeline is connected to the liquid storage box through the suction structure, and the first water supply pipeline is provided with a liquid storage cavity, and the suction structure is used to suck the additives in the liquid storage box into the liquid storage box. In the liquid storage chamber, the water is flushed to the hedging mechanism along with the first water supply pipeline for corresponding delivery. Through the above arrangement, the water supply pipeline with the additive injection function constitutes one water inlet flow of the hedging mechanism, and the automatic injection device can use the hedging mechanism to perform corresponding injection of liquid additives. At the same time, the present invention also includes a washing machine, which is equipped with the above-mentioned additive feeding device.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Kaolin calciner with wire break alarm device

ActiveCN106705668BEasy maintenanceEasy to replaceElectrical apparatusElectroluminescent light sourcesElectrical controlElectric control

The invention discloses a kaolin calcining furnace with a disconnection alarm device, which includes a furnace body, a temperature sensor, a heating electric film plate, a motor, an electric control box, a rotating shaft and a pushing scraper, and also includes an illuminating lamp and a constant current Drive power supply; the electric input terminal of the electric control box is connected to the mains circuit, and the disconnection alarm device is connected to the commercial circuit, and the disconnection alarm device includes a step-down rectification filter module and an alarm. Since the heating electric film plate is formed by butting two halves, the two halves respectively pass through the electric film plate installation ports on both sides of the furnace body and enter the interlayer of the hearth, which greatly facilitates the maintenance and replacement of the heating electric film plate . Due to the remote monitoring method, the staff can monitor the equipment without being near the equipment; because the disconnection alarm device adopts the above-mentioned technical scheme, the circuit structure is greatly simplified, thereby reducing the cost, and the alarm effect is very good.

Owner:高州市兆翔新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com