Patents

Literature

37results about How to "Achieve the purpose of clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bar clamping mechanism

InactiveCN107825174AReliable clampingSimple structureThread cutting feeding devicesPositioning apparatusMotor driveHand held

Owner:余姚市奥祥轴承有限公司

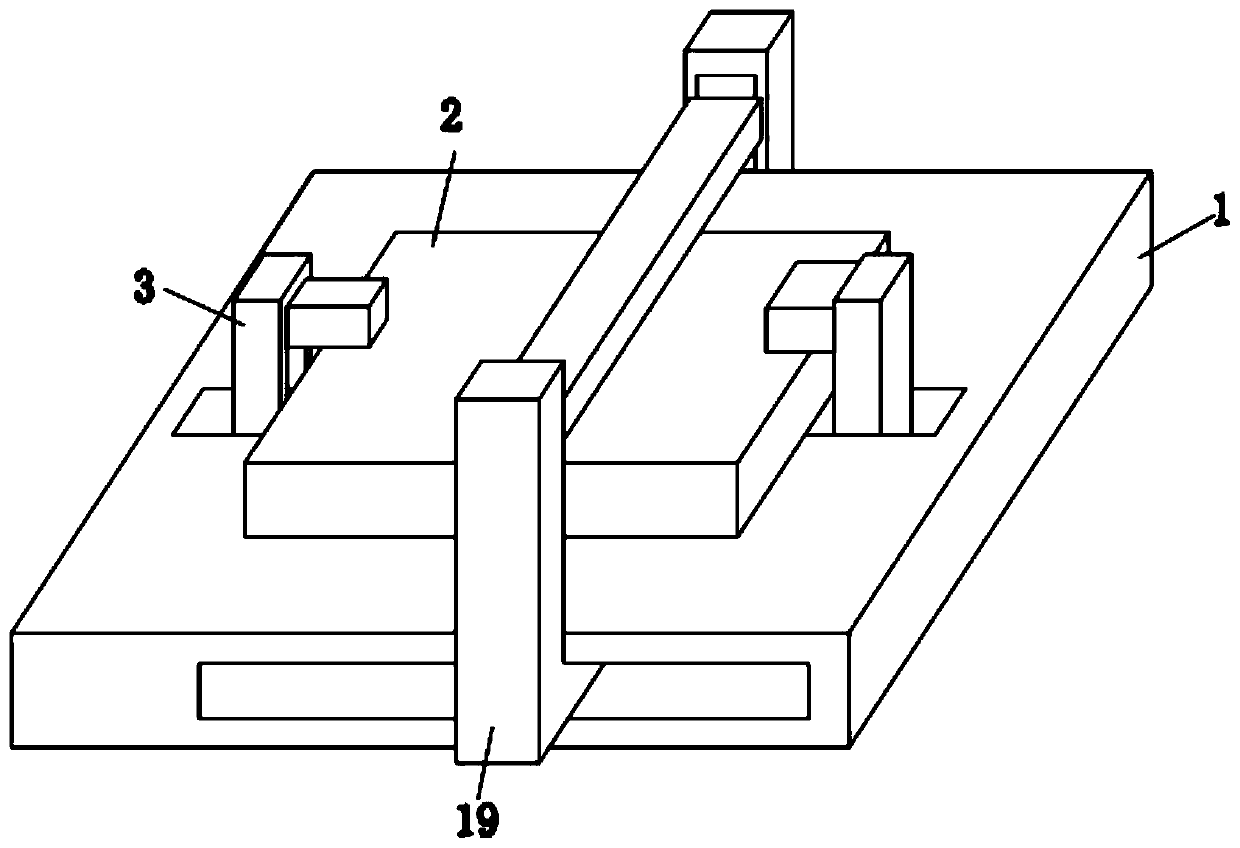

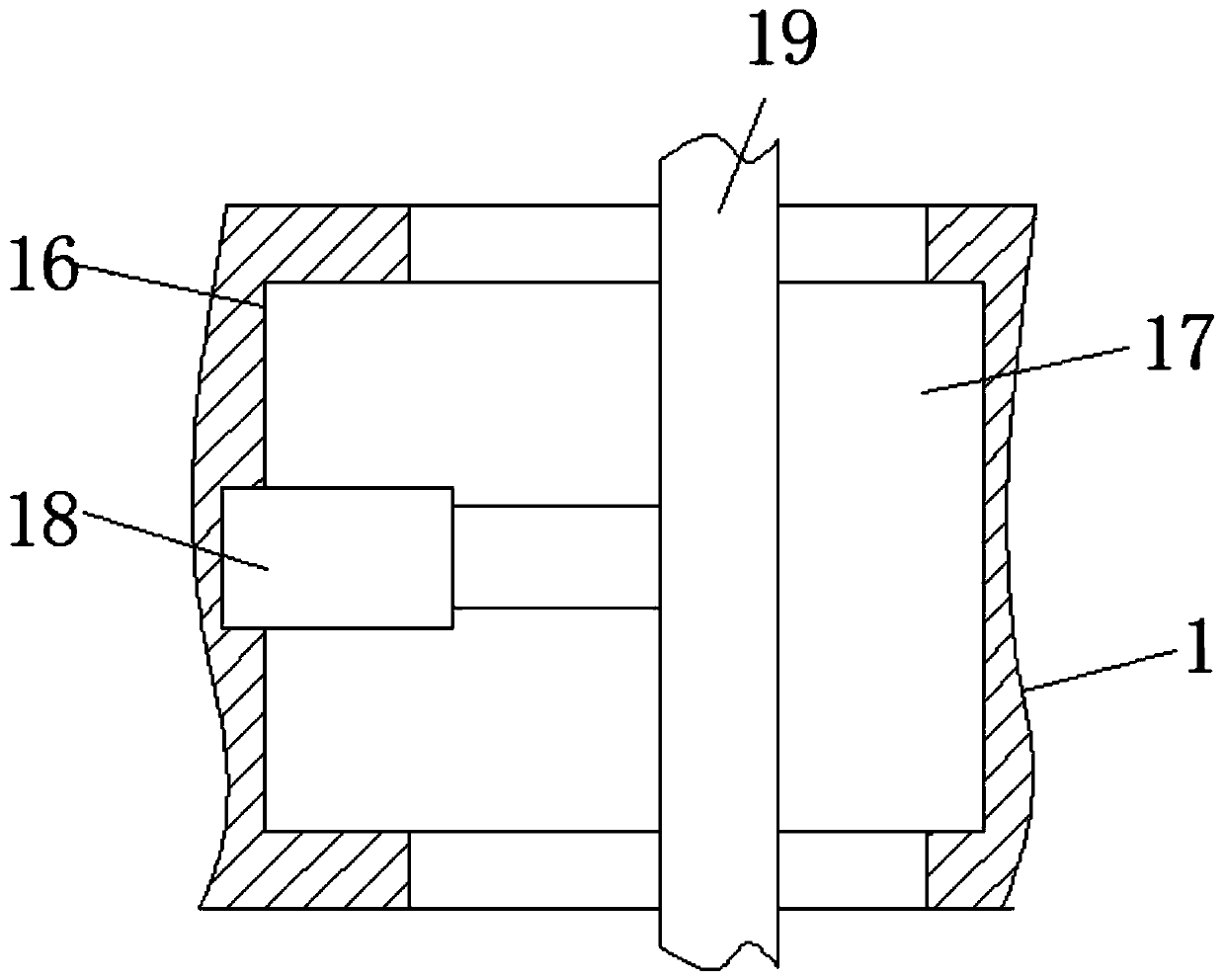

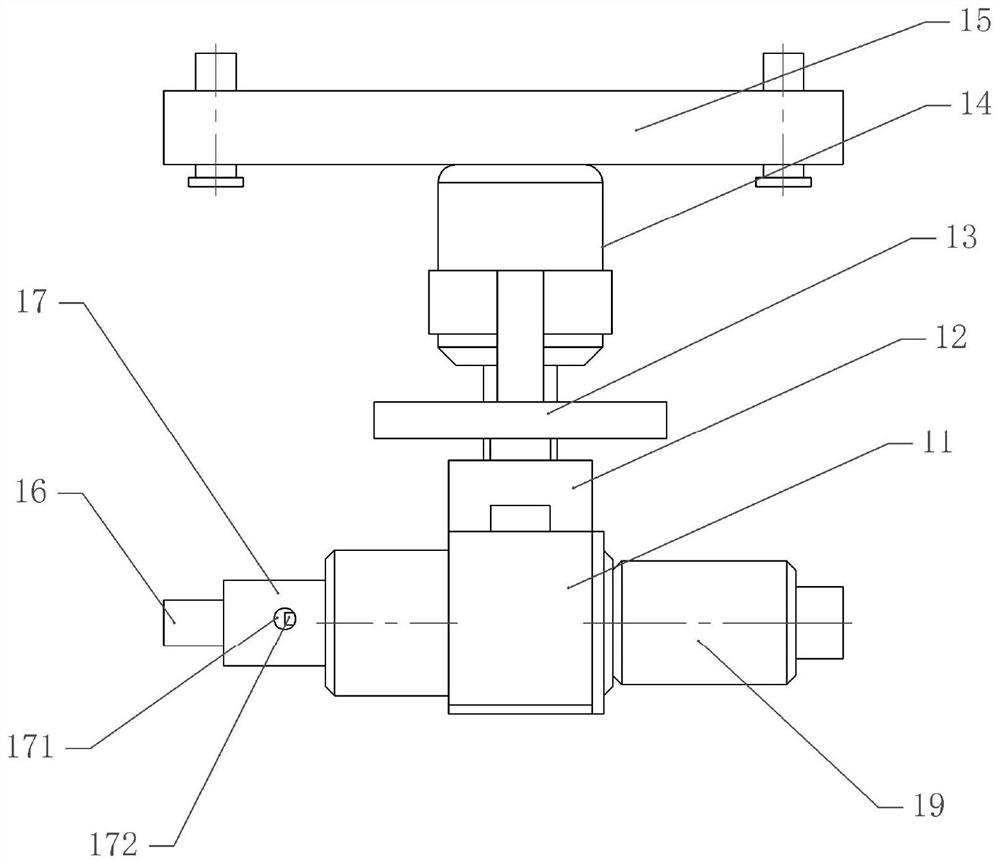

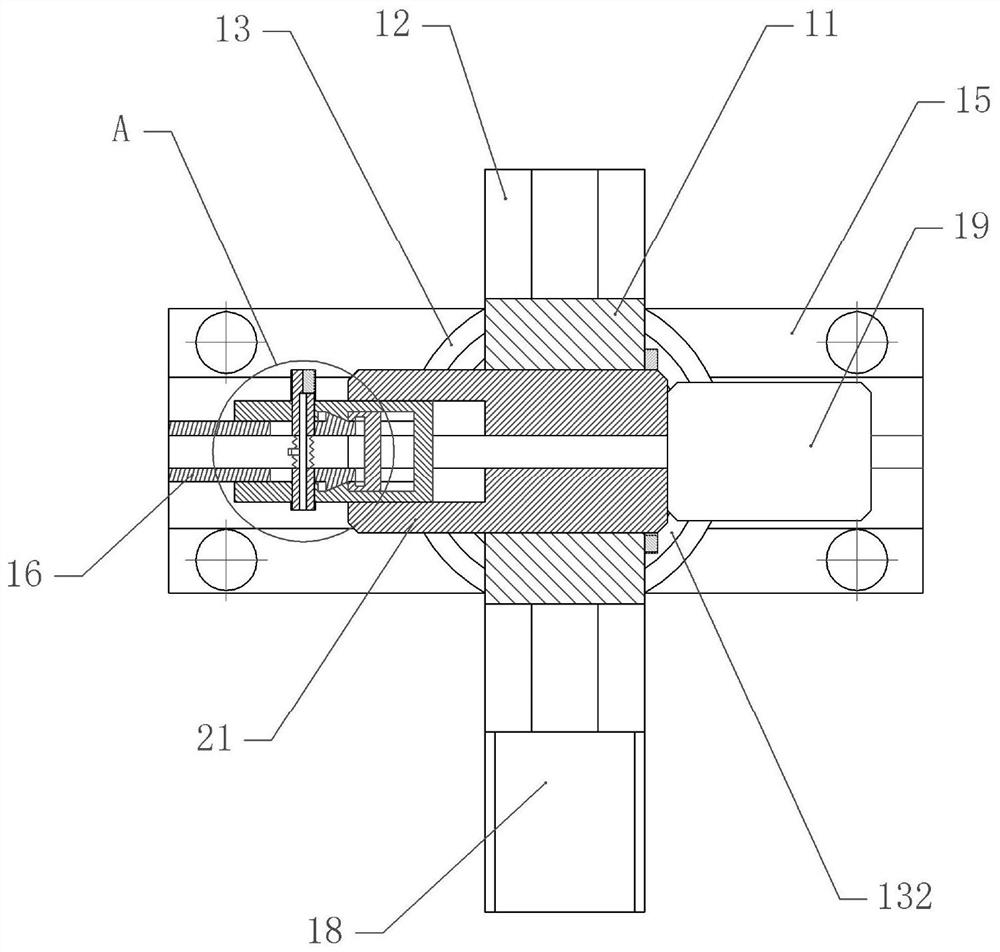

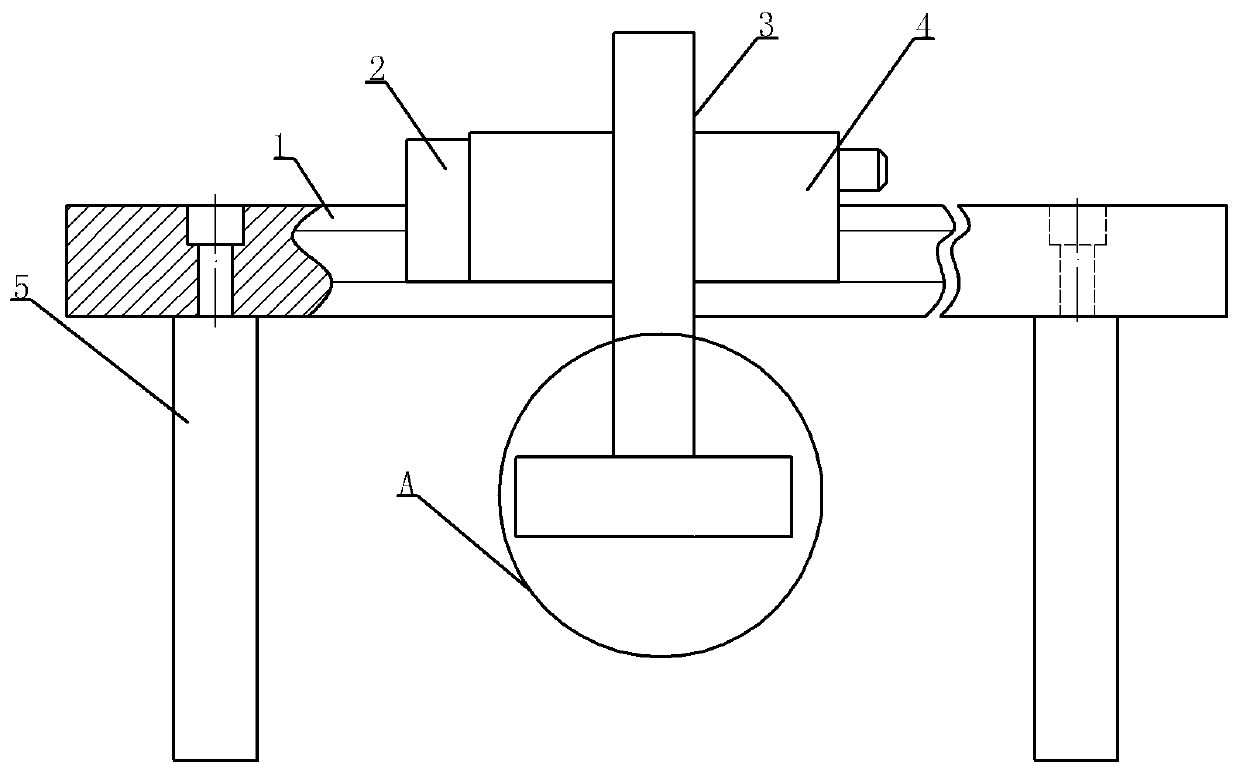

Synchronous centering and clamping mechanism

InactiveCN103495885AThe overall structure is simpleSmall footprintPositioning apparatusMetal-working holdersEngineeringMachining

The invention discloses a synchronous centering and clamping mechanism which comprises a base. Two sliding blocks are arranged on the base through sliding rails, a nut is fixedly arranged in each sliding block, the two nuts are both matched with the same lead screw, the rotating directions of the threads of the two nuts are opposite, one end of the lead screw is connected with the output shaft of a motor, a chuck is connected to each sliding block, and clamping blocks for clamping workpieces are arranged on the opposite inner sides of the two chucks. The synchronous centering and clamping mechanism is simple in overall structure, small in occupied space, accurate in centering and alignment, convenient to mount and maintain and capable of improving machining quality.

Owner:大连机床(数控)股份有限公司

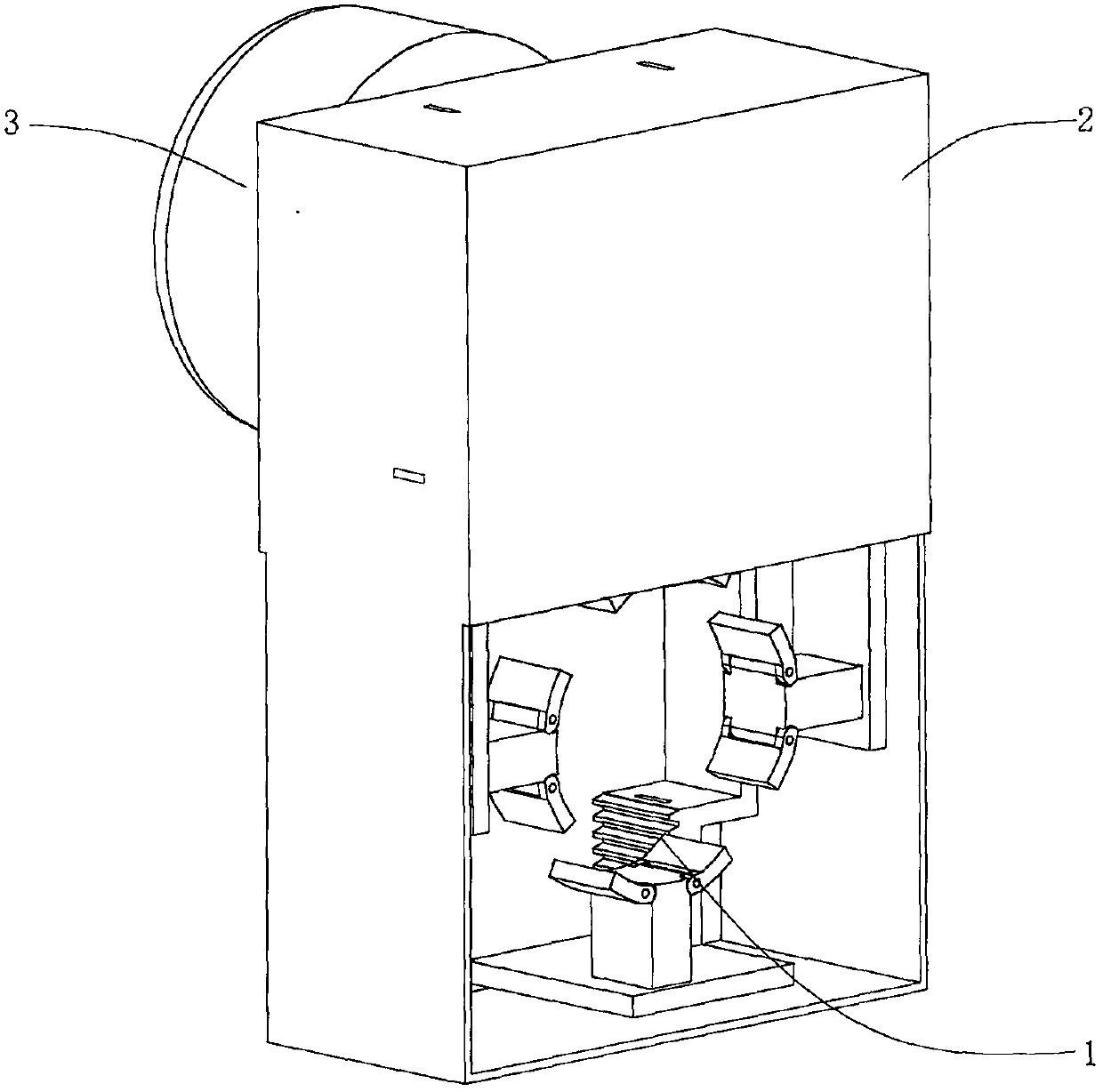

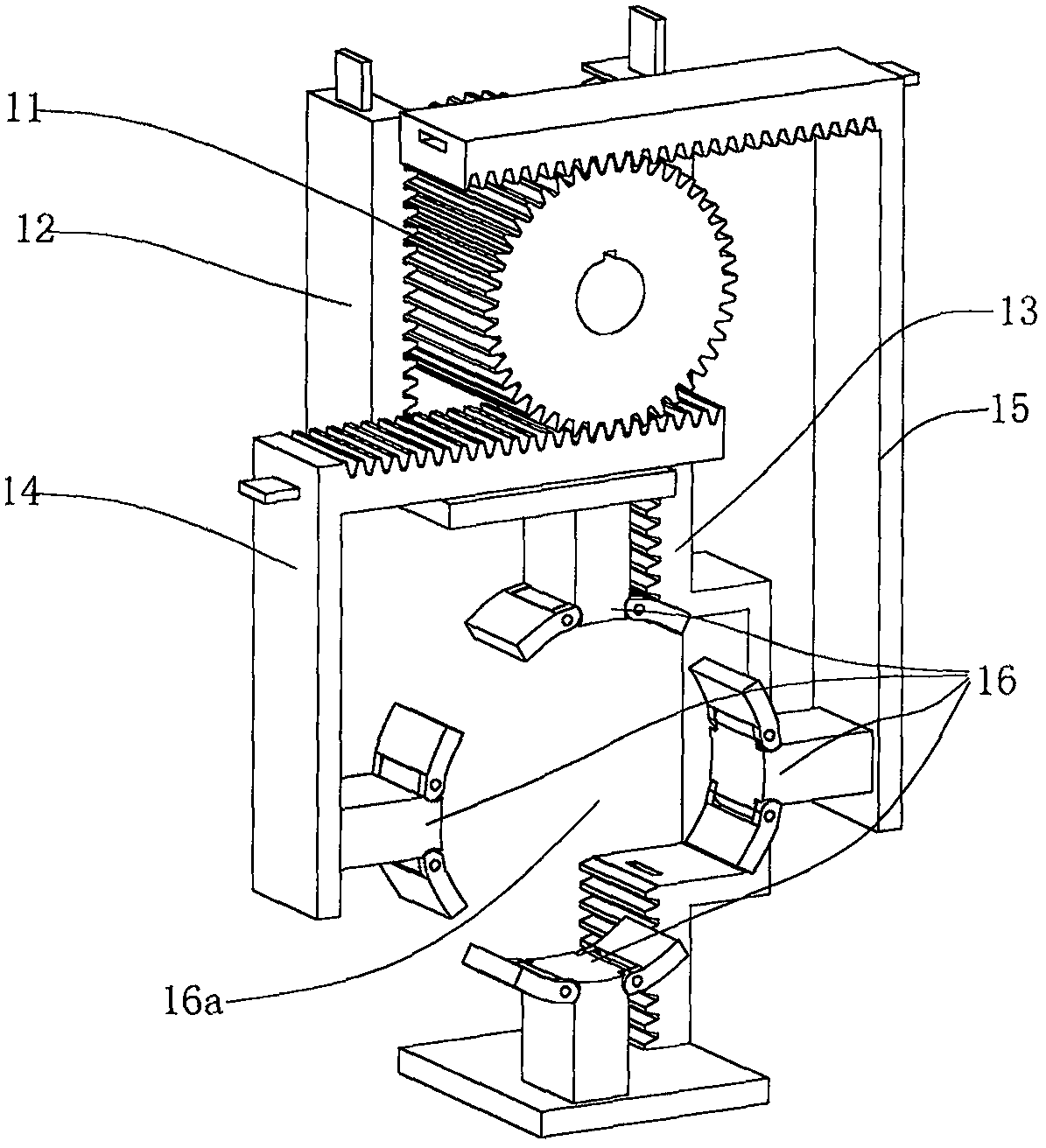

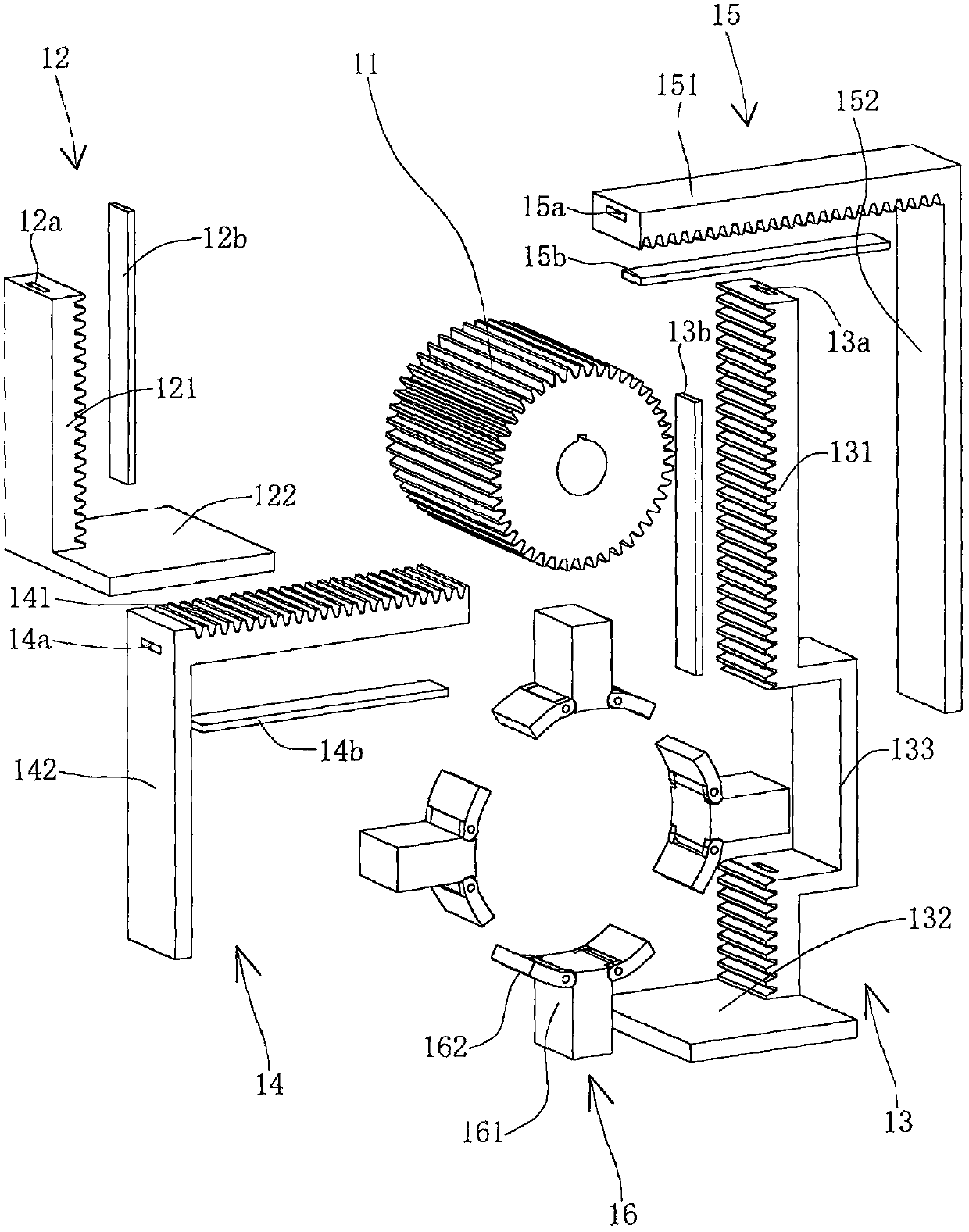

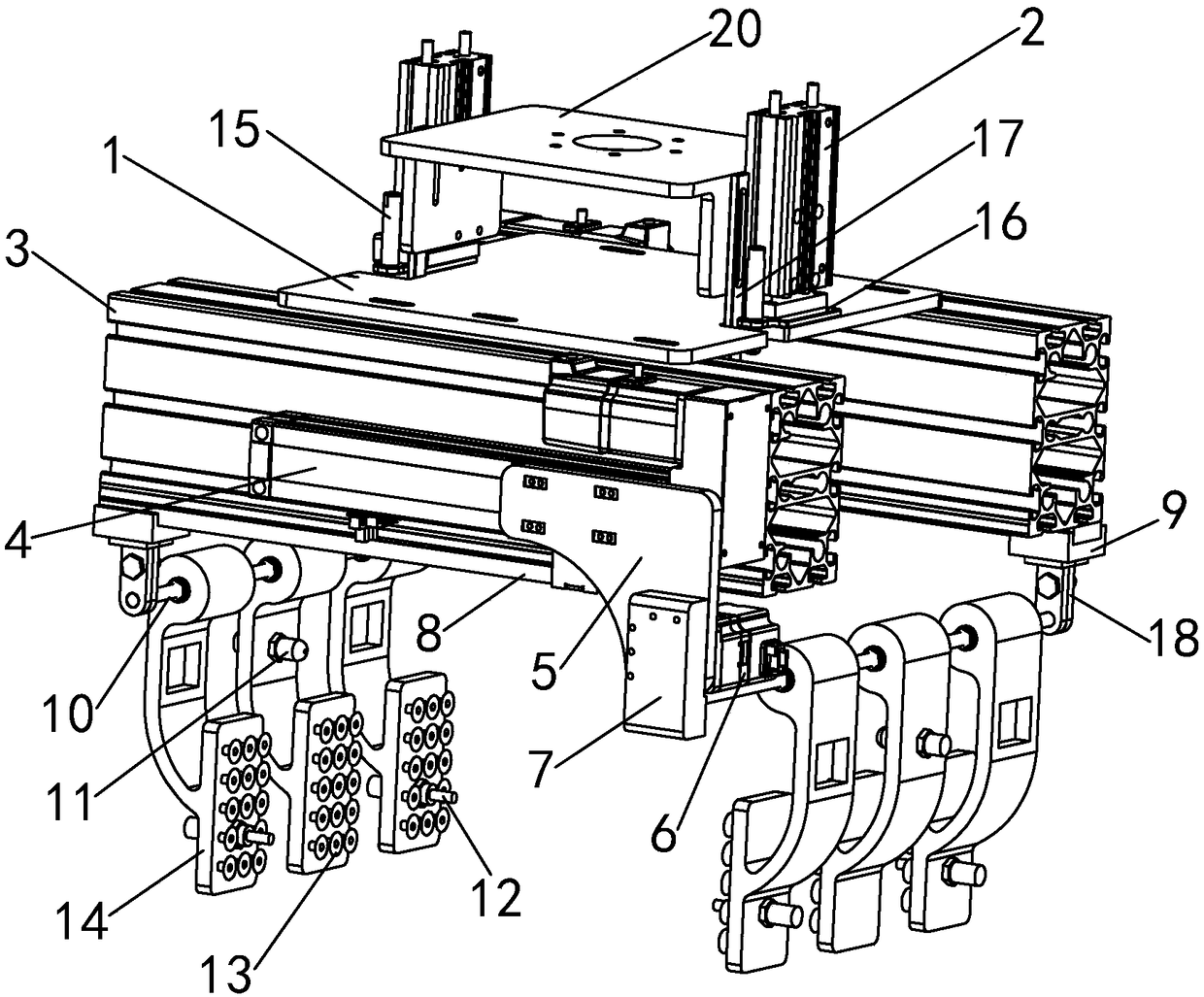

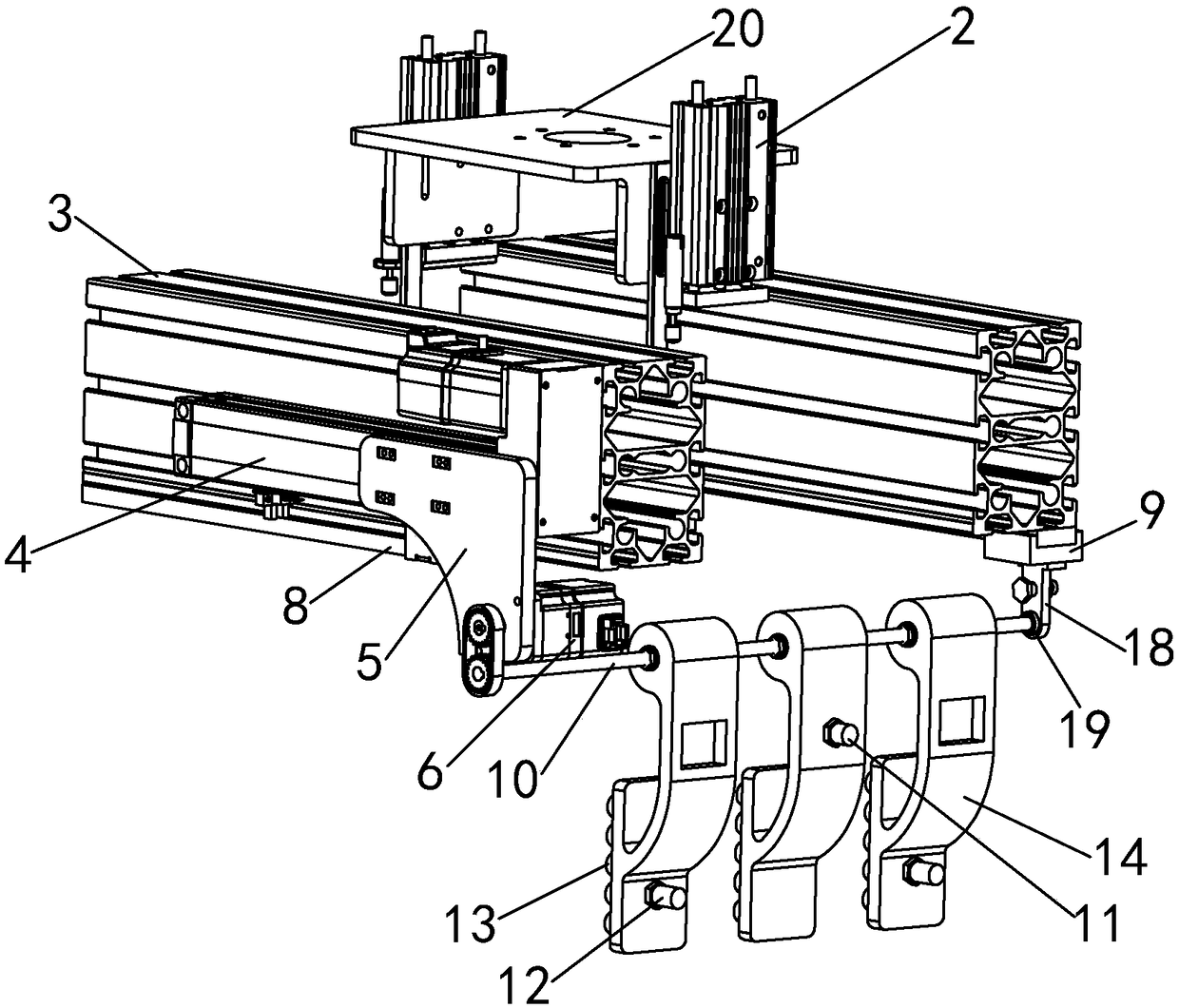

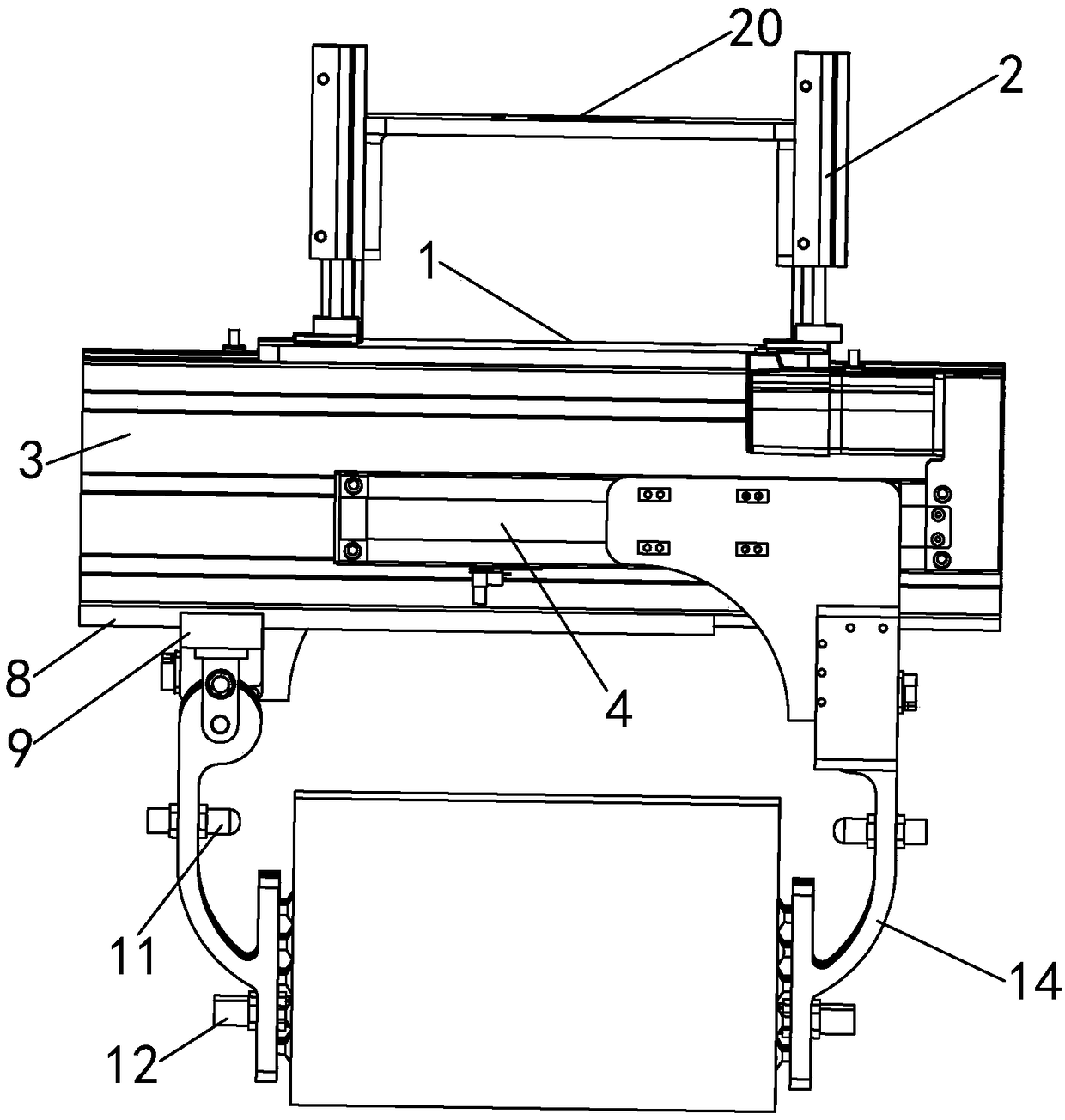

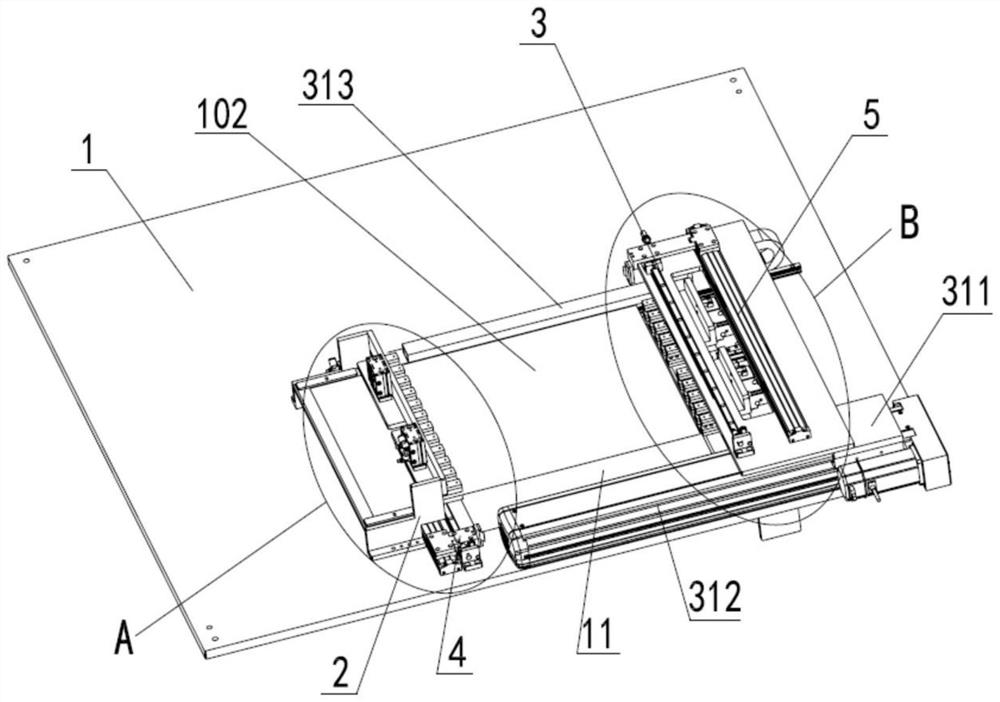

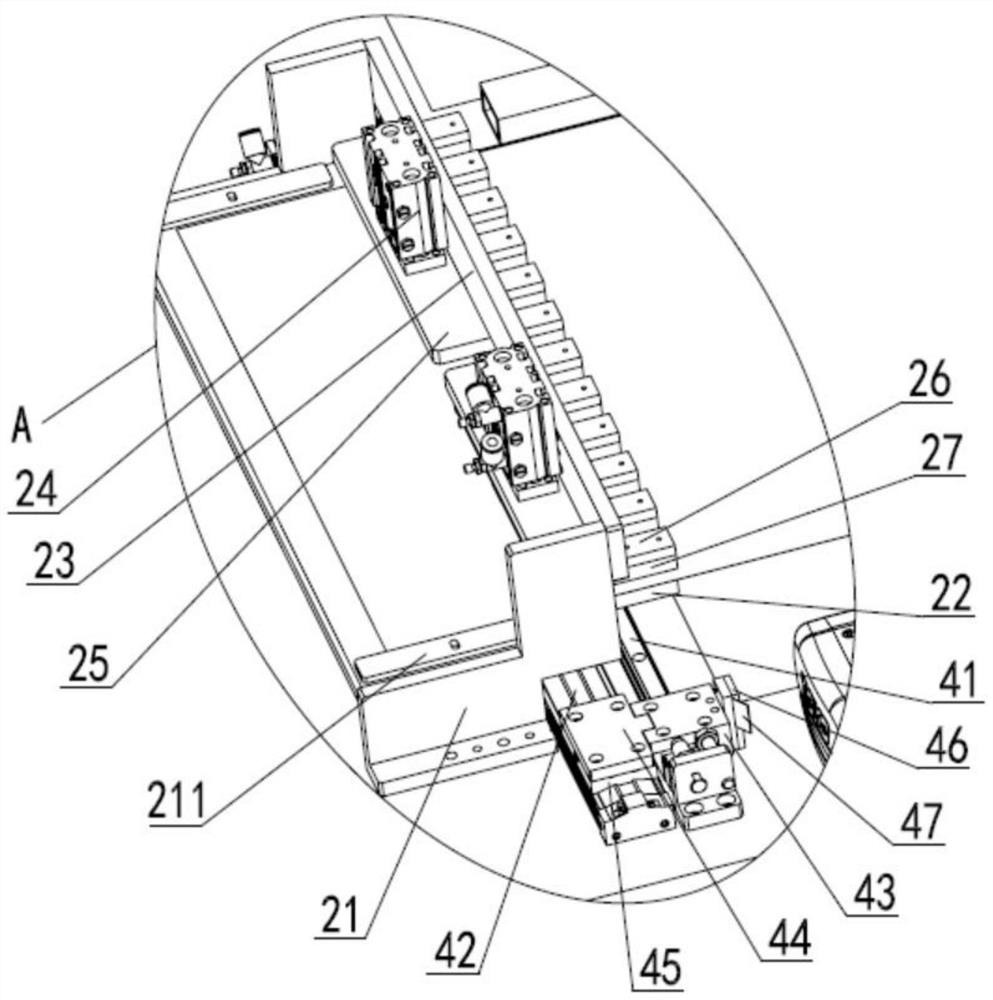

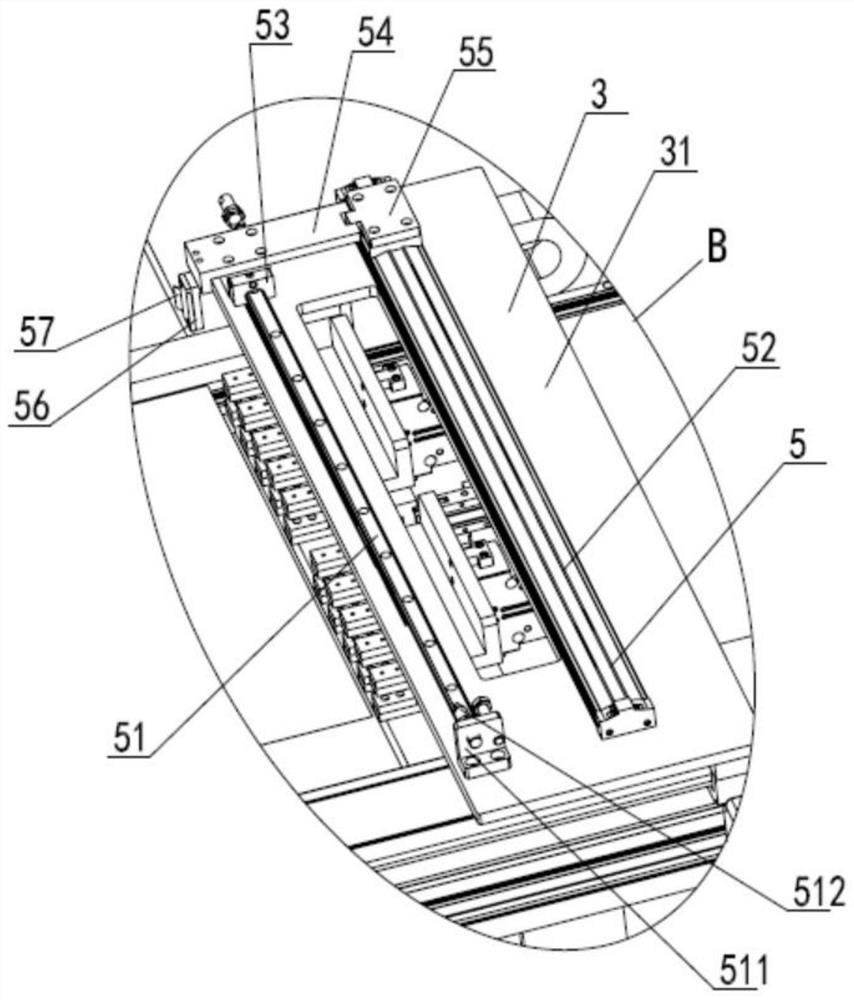

Flexible stacking clamp capable of automatically clamping and classifying products

PendingCN109502356AAchieve the purpose of clampingControl gripping forceStacking articlesDe-stacking articlesProduction lineLaser

The invention discloses a flexible stacking clamp capable of automatically clamping and classifying products. The flexible stacking clamp comprises a fixing plate, wherein driving devices for drivingthe fixing plate to move up and down are arranged on the two sides of the top of the fixing plate respectively, fixing parts are arranged on the two sides of the bottom of the fixing plate respectively, servo electric cylinder modules are installed on the outer sides of the fixing parts, the directions of the moving ends of the servo electric cylinder modules on the two sides are opposite, the moving ends of the servo electric cylinder modules are provided with servo motors and gear end covers through connecting plates, wire rails are arranged at the bottoms of the fixing parts, sliding blocksare arranged on the wire rails, the gear end covers are opposite to the sliding blocks on the other side fixing parts and are rotationally connected with connecting rods respectively, clamping jaw assemblies is fixed on the connecting rods, laser through-beam sensors, travel limiting switches and suckers are arranged on the inner sides of the clamping jaw assemblies, and the laser through-beam sensors and the travel limit switches are used for sending detection signals to a PC end. The flexible stacking clamp is used for clamping products with different heights and easy-to-slide and fragile products such as glass on the same production line and can also be used for classifying and stacking the products, and the application range is wide.

Owner:深圳市智能机器人研究院

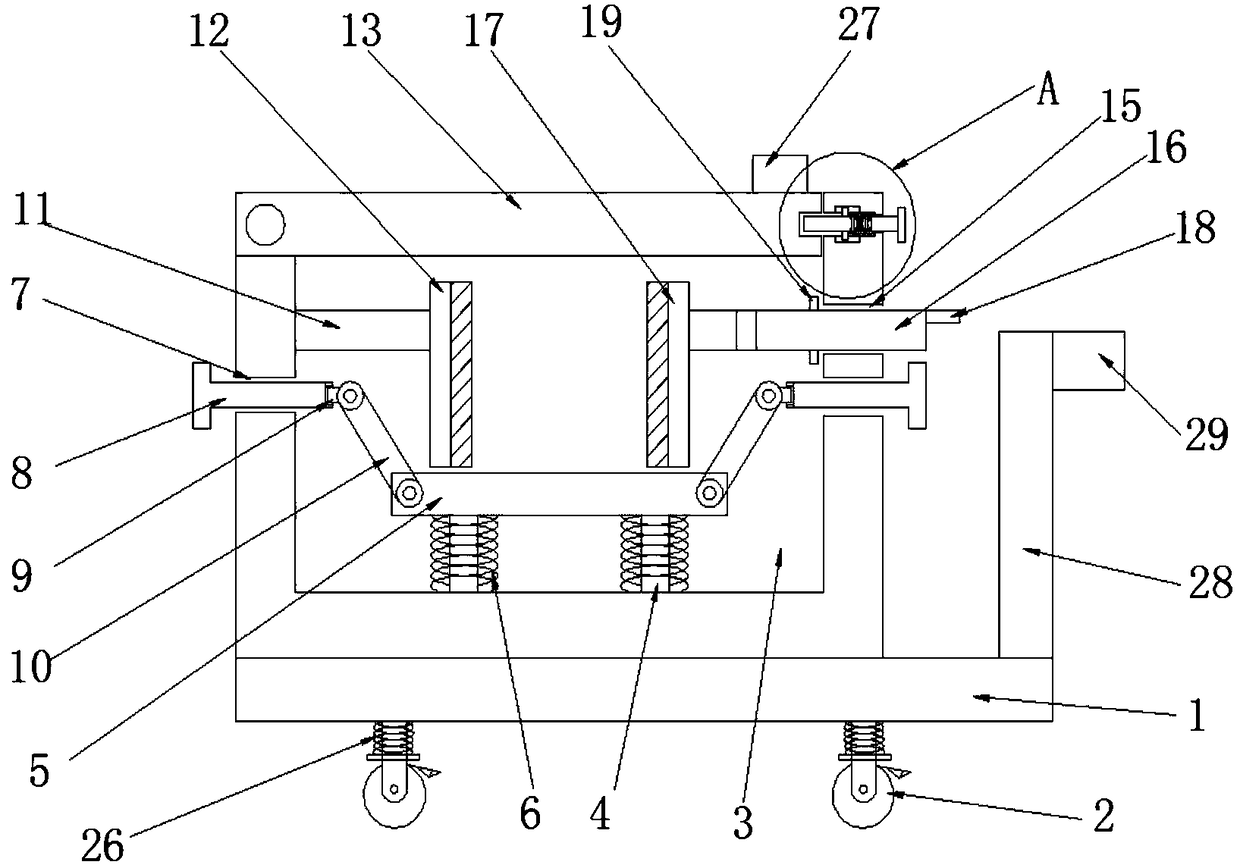

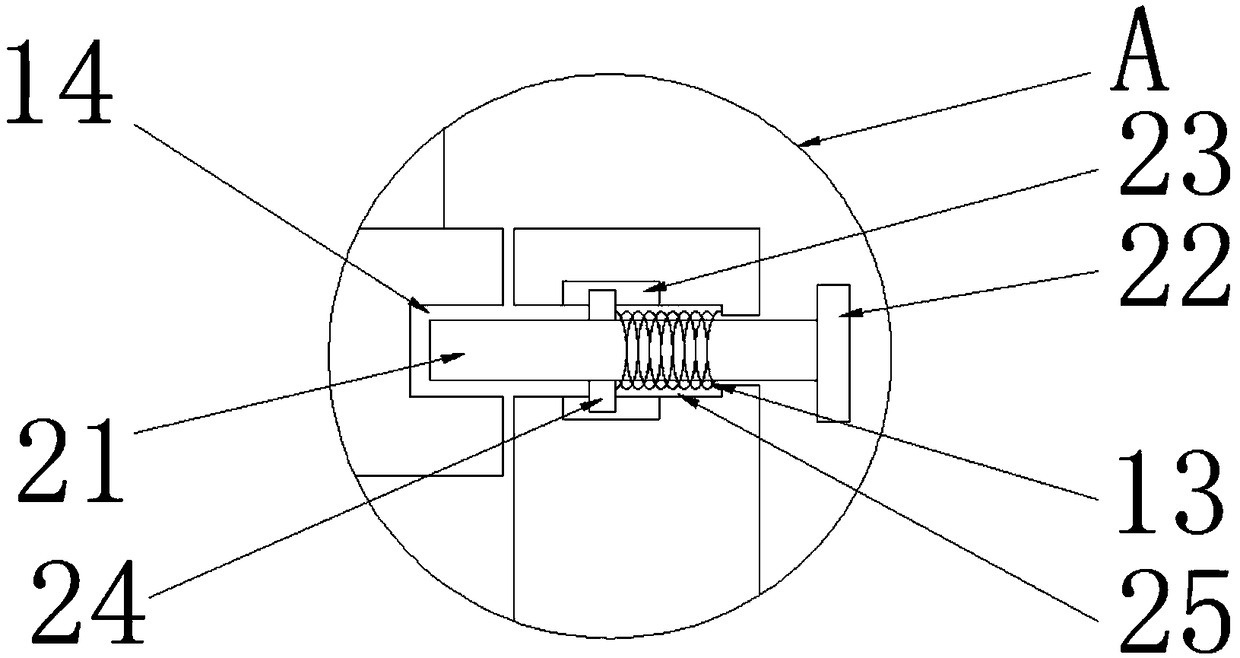

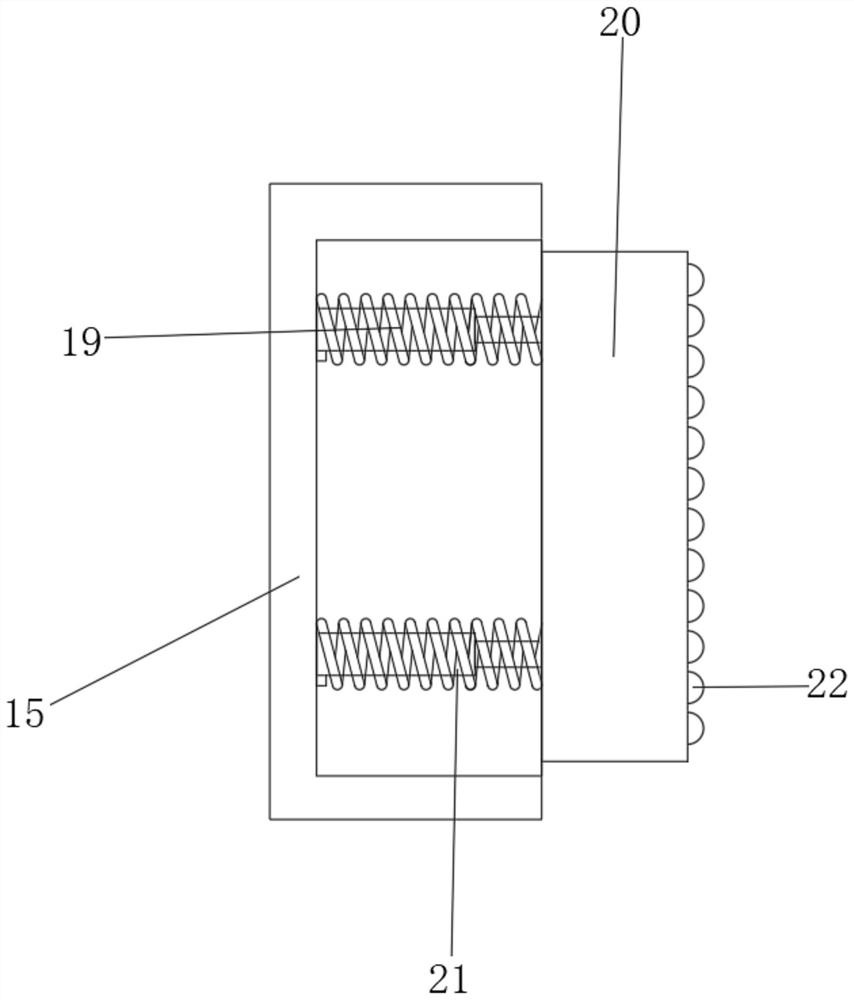

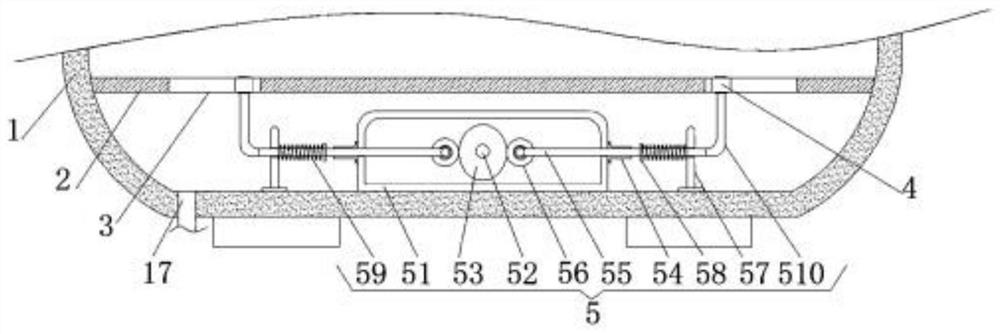

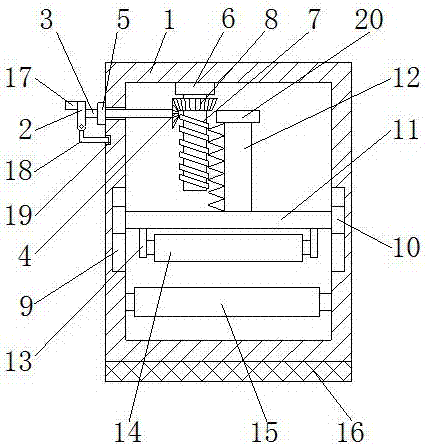

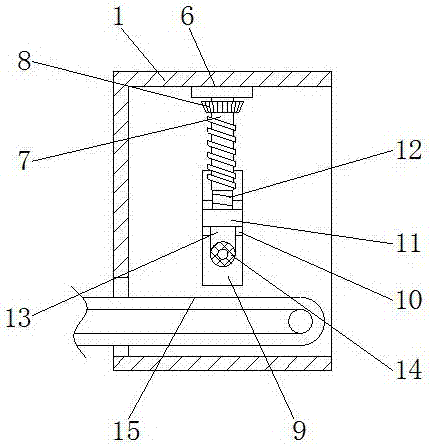

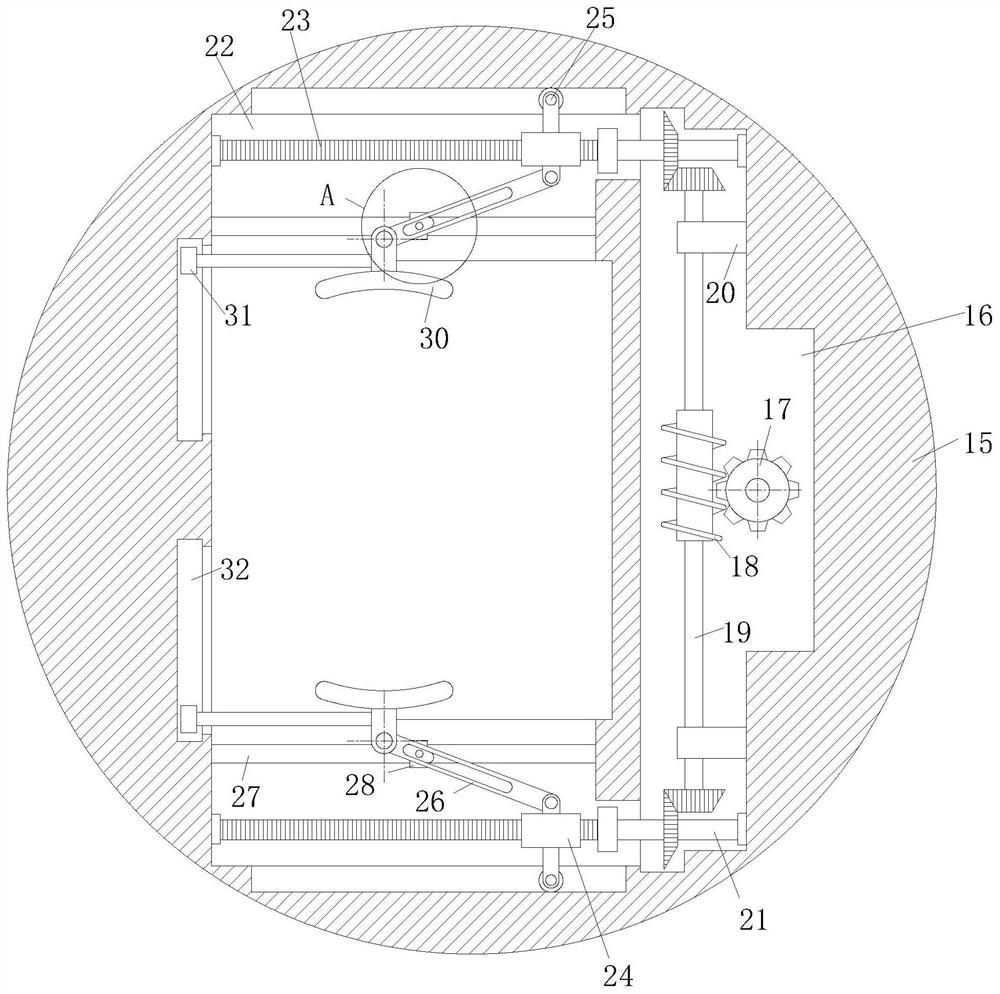

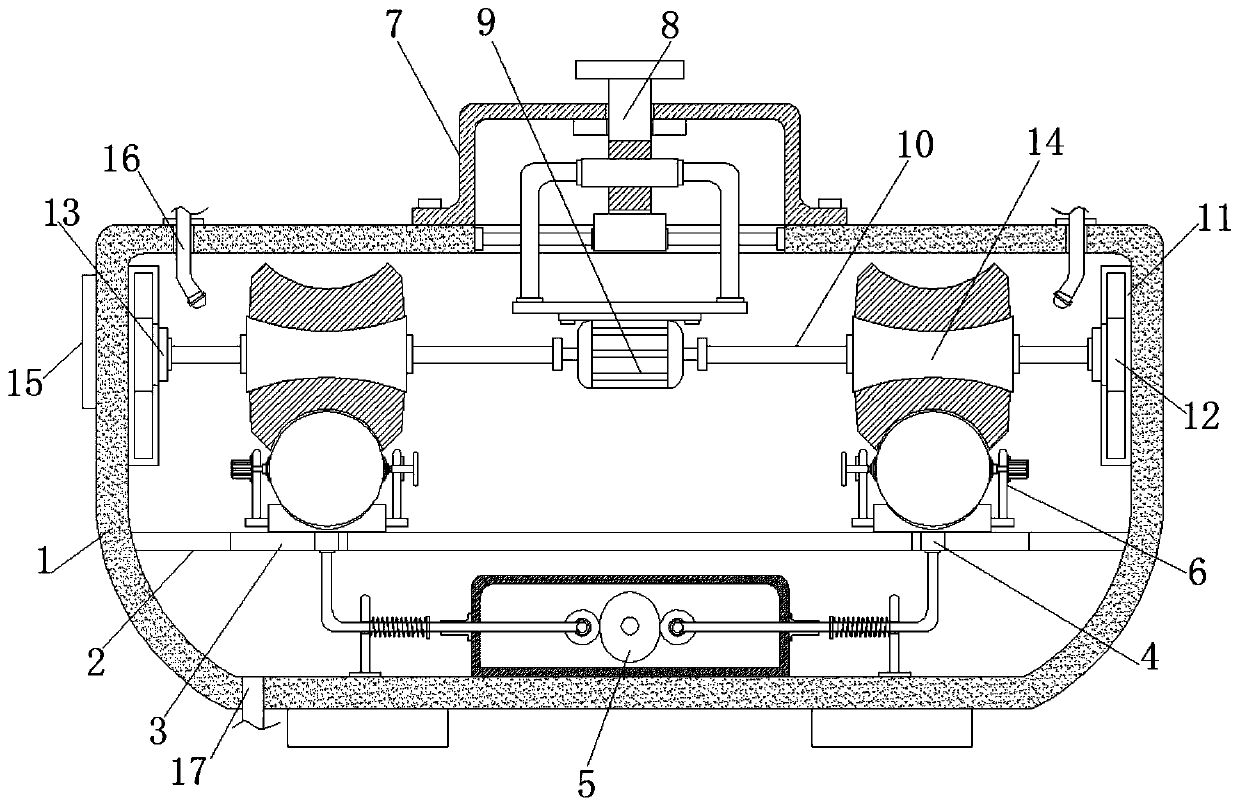

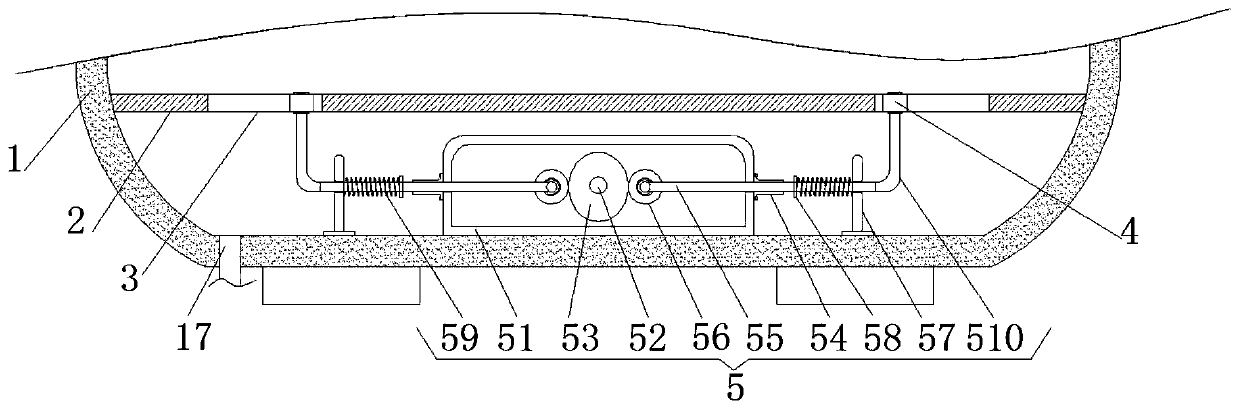

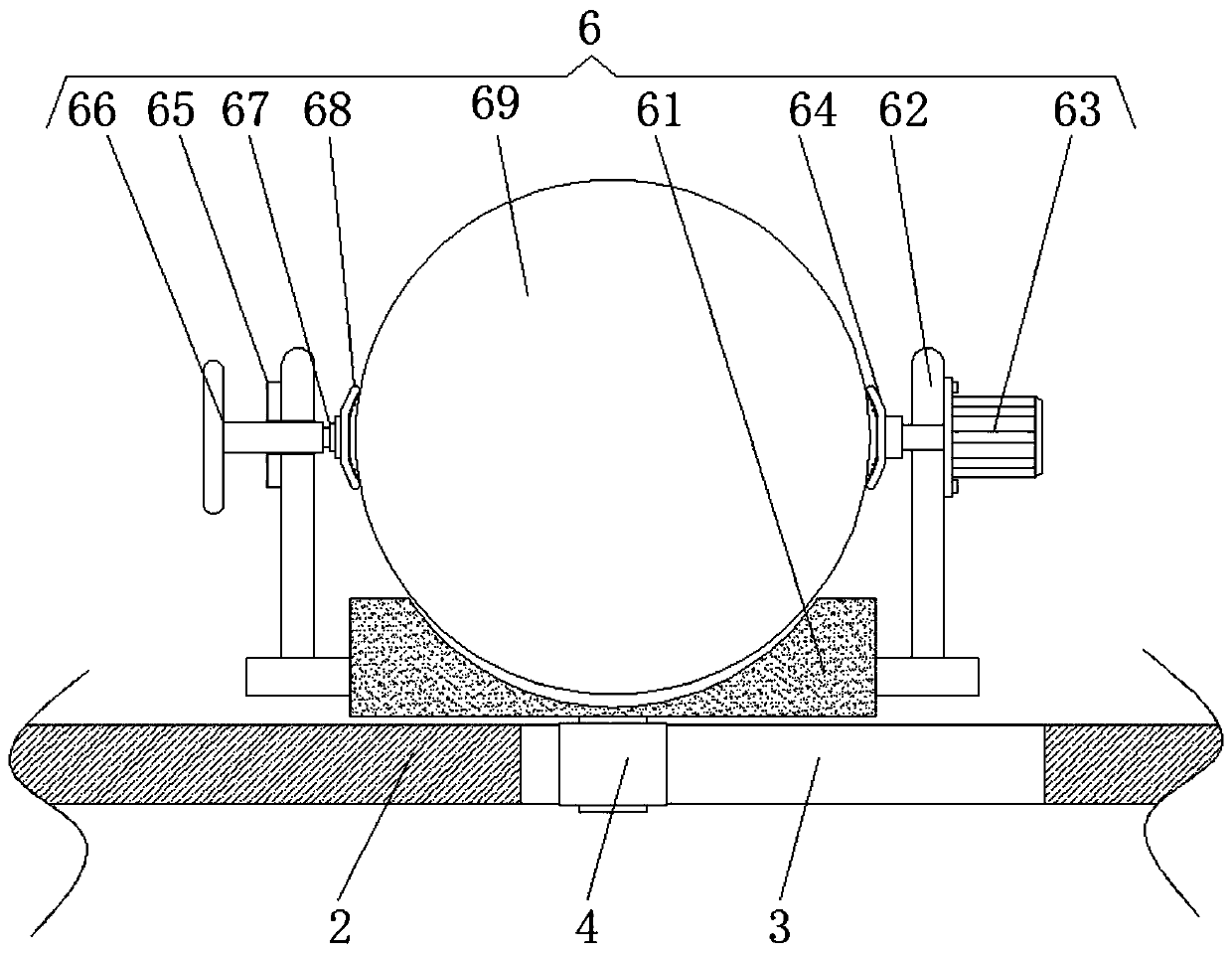

Vibration reduction device for precise instrument transportation

InactiveCN108974646ABuffer intensity adjustmentAchieve the purpose of clampingContainers to prevent mechanical damageDamagable goods packagingEngineeringScrew thread

The invention discloses a vibration reduction device for precise instrument transportation. The vibration reduction device comprises a bottom plate, the upper end of the bottom plate is fixedly connected with a box body with an upper end opening, a telescopic rod is fixedly connected to the bottom of the box body, and a platform is fixedly connected to the upper end of the telescopic rod; first threaded holes are formed in the inner side walls of the two sides of the box body respectively, bolts are connected in the first threaded holes in a threaded mode, connecting rods which are obliquely arranged are hinged to one ends, penetrating through the first threaded holes and extending towards the interior of the box body, of the bolts, and the other ends of the connecting rods are hinged to one end of the corresponding platform, and a clamping device is arranged on the side wall of one side of the interior of the box body, and one side, far away from a box cover hinge joint, of the box body is arranged with a locking device. According to the device, the structure is simple, the design is reasonable, the buffering strength of a precise instrument transportation device can be easily adjusted, and the use limitation of the precise instrument transportation device is reduced.

Owner:SUZHOU NONAK ELECTRONICS TECH CO LTD

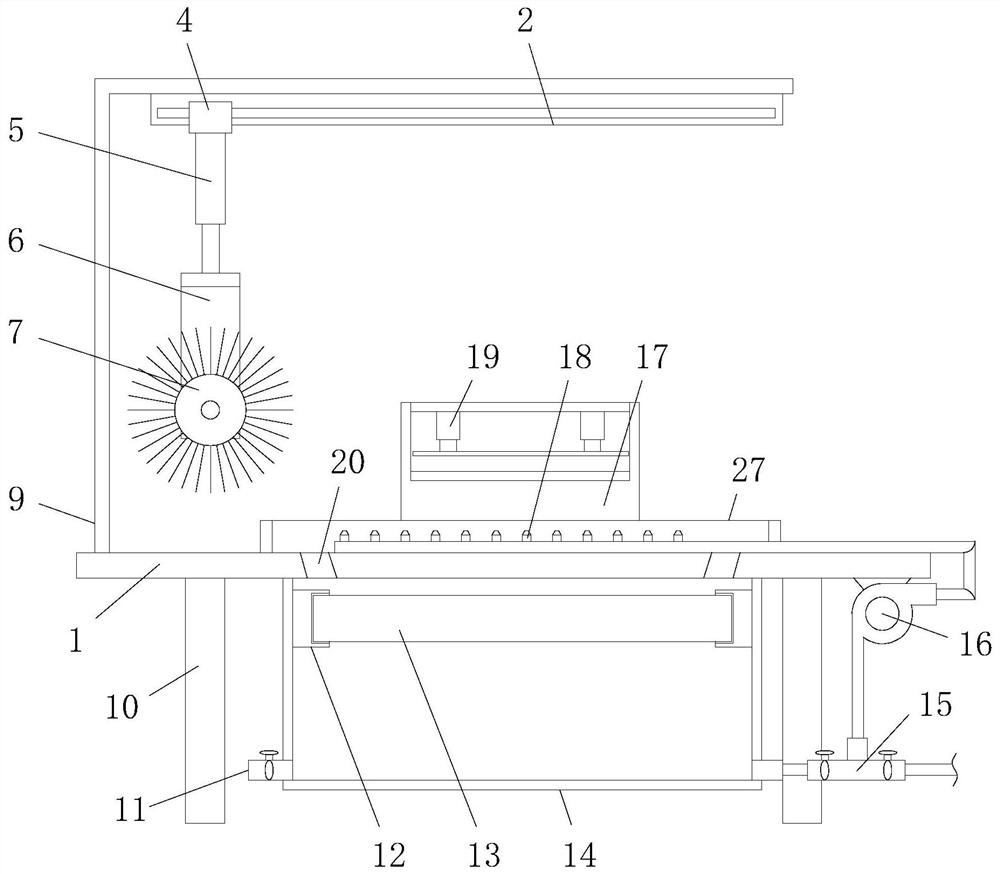

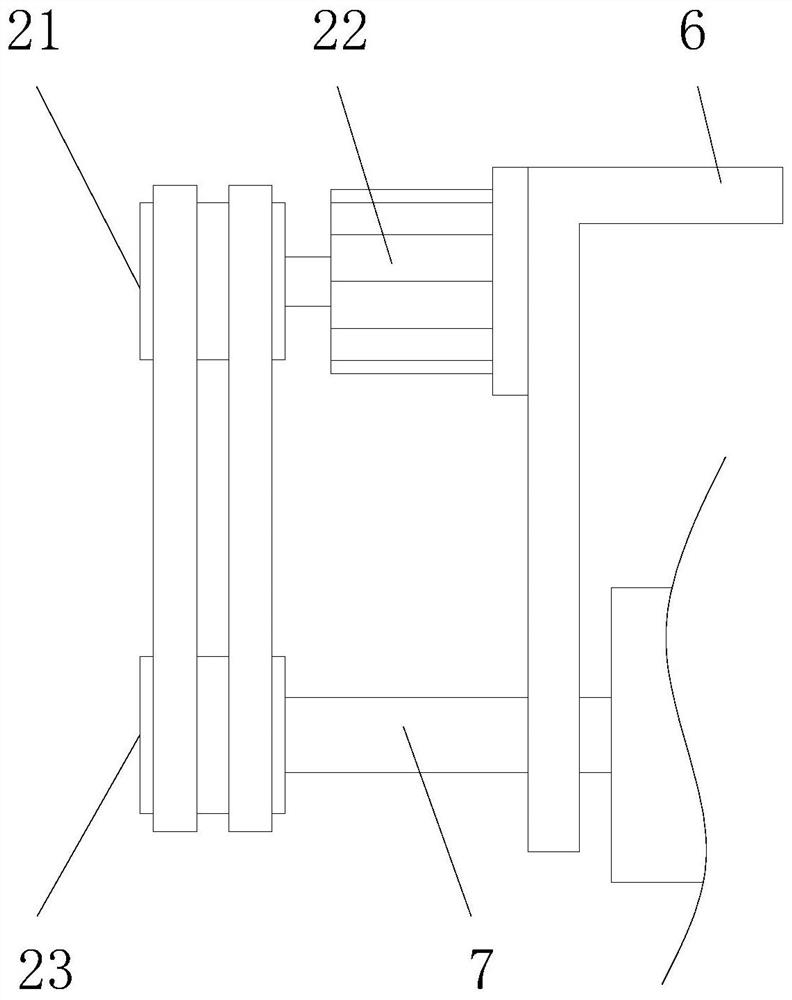

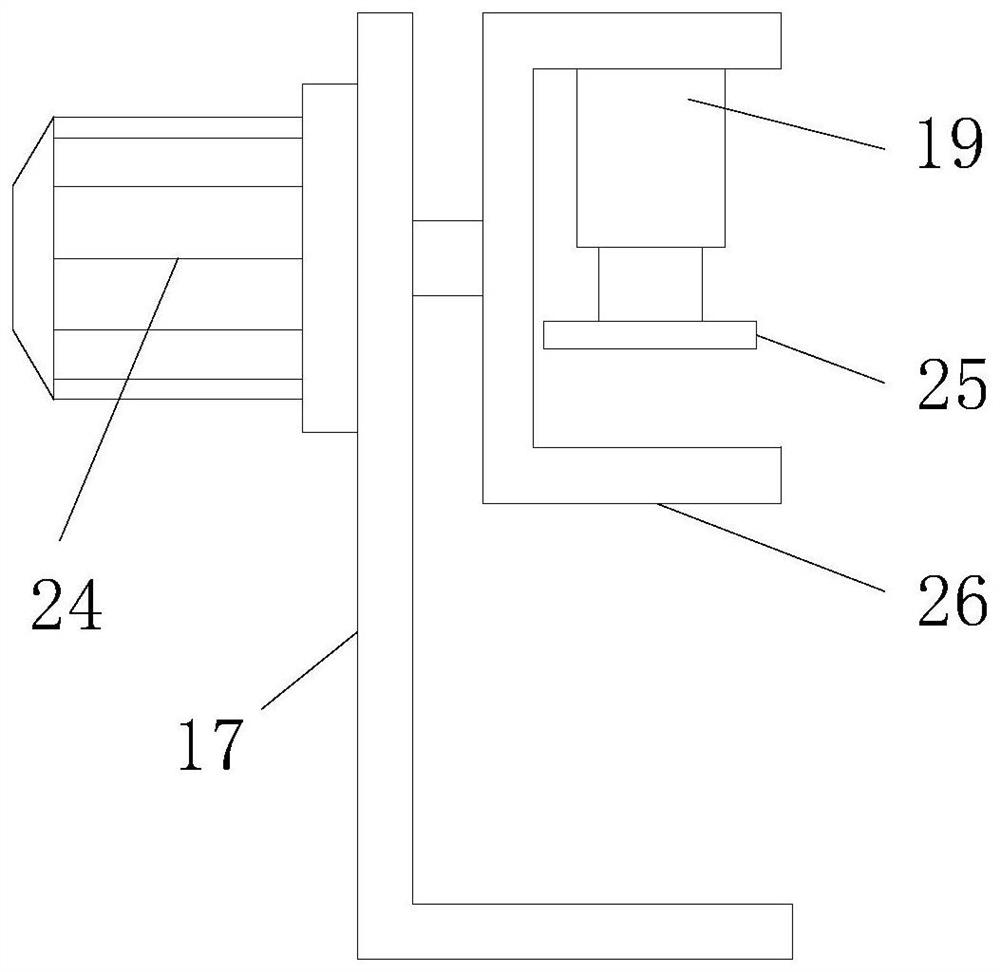

Surface treatment and polishing device for sheet metal processing

PendingCN110788701AAchieve the purpose of clampingImprove applicabilityGrinding drivesGrinding machinesElectric machineryEngineering

The invention discloses a surface treatment and polishing device for sheet metal processing, and relates to the technical field of sheet metal processing. The surface treatment and polishing device for sheet metal processing comprises a grinding table, a workpiece body, a clamping device and a fixed-point grinding device. The clamping device is located on the upper surface of the grinding table. The workpiece body is located in the clamping device. The fixed-point grinding device is located inside the grinding table. According to the surface treatment and polishing device for sheet metal processing, due to the arrangement of the clamping device, a first motor is used for driving two rotating shafts to synchronously rotate, so that two sliding blocks are driven to move face to face or awayfrom each other through cooperation with first electric push rods which drive clamping plates, the surface of the workpiece body is clamped, workpieces with different specifications can be clamped, the workpiece applicability of the device is improved, the workpieces with different specifications can be processed by the device, the situation of purchasing a plurality of sets of grinding devices isavoided, and the working cost is reduced.

Owner:苏州陈泰利金属科技有限公司

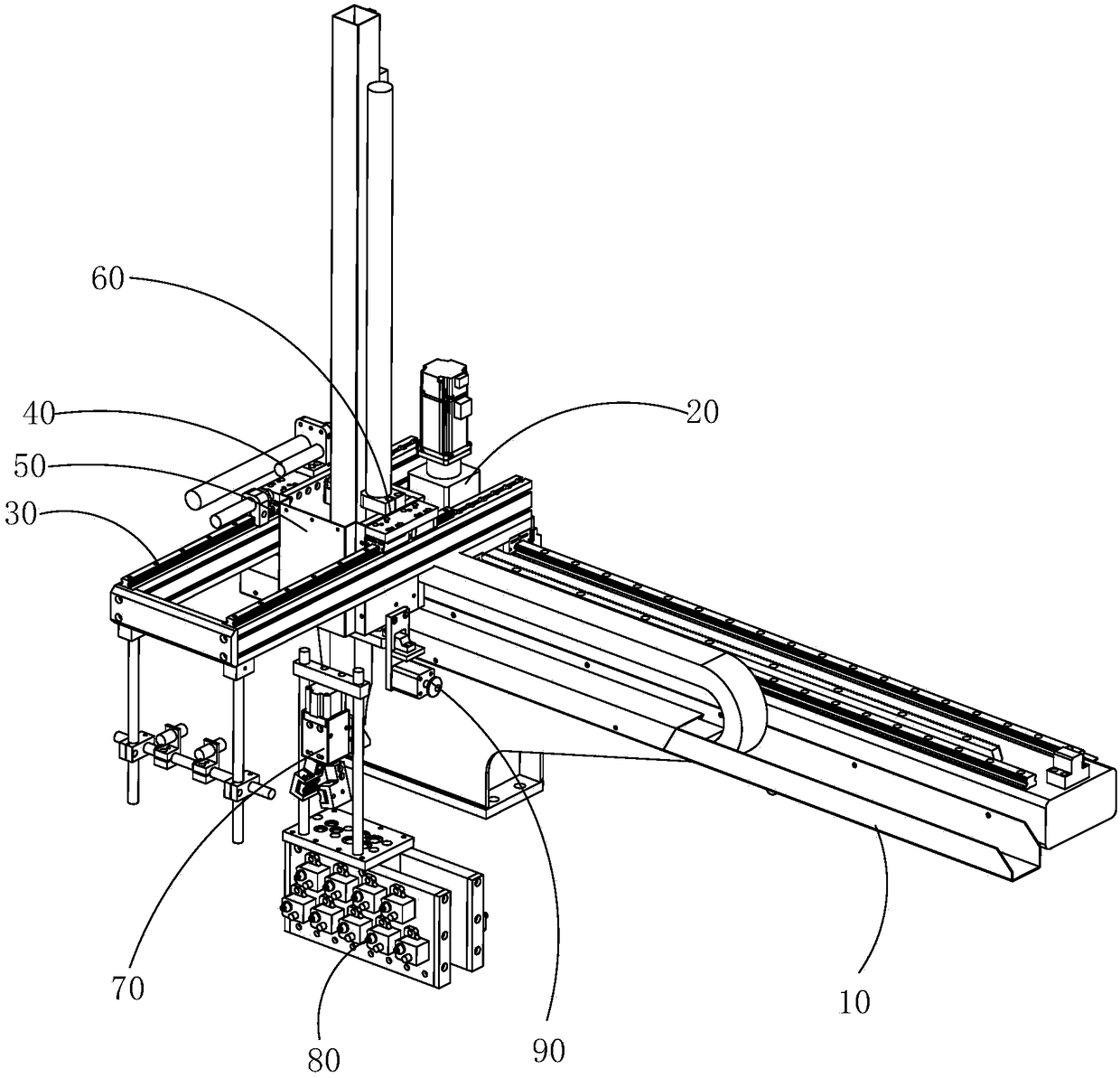

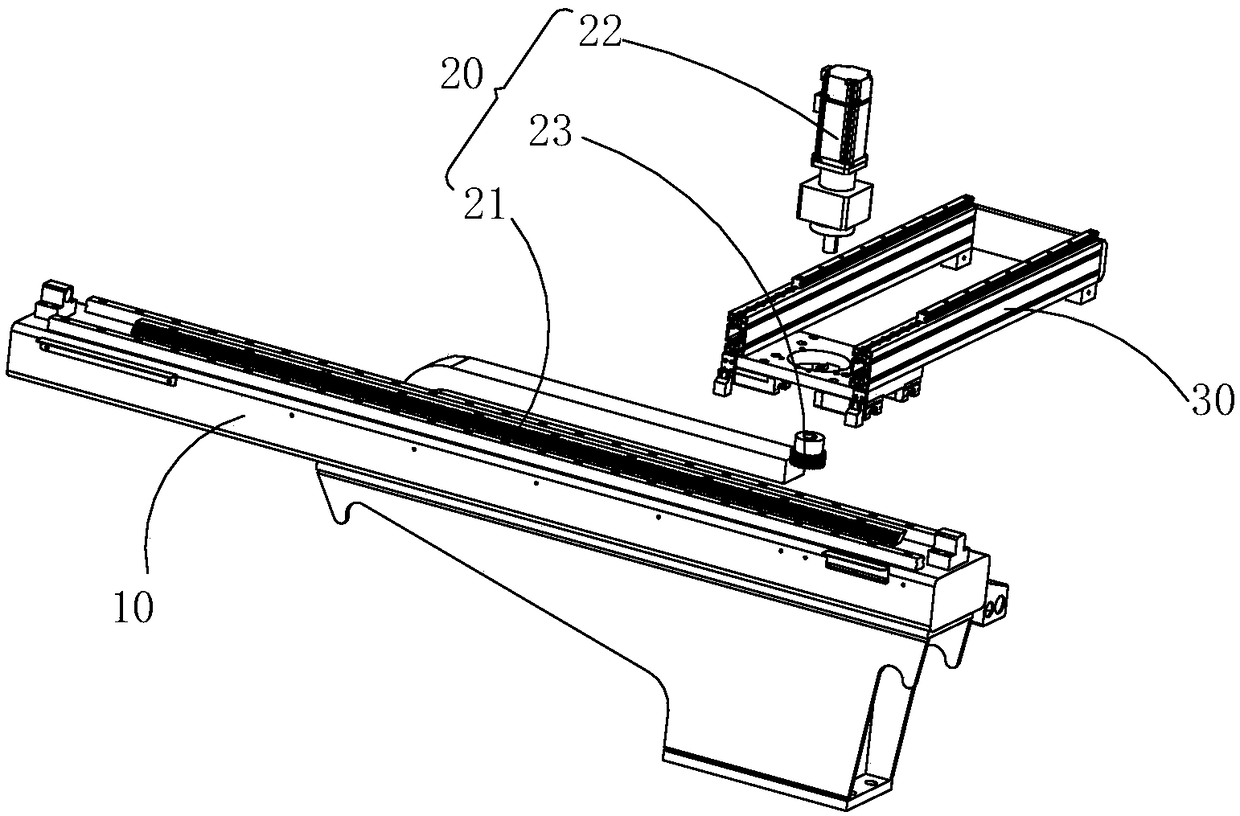

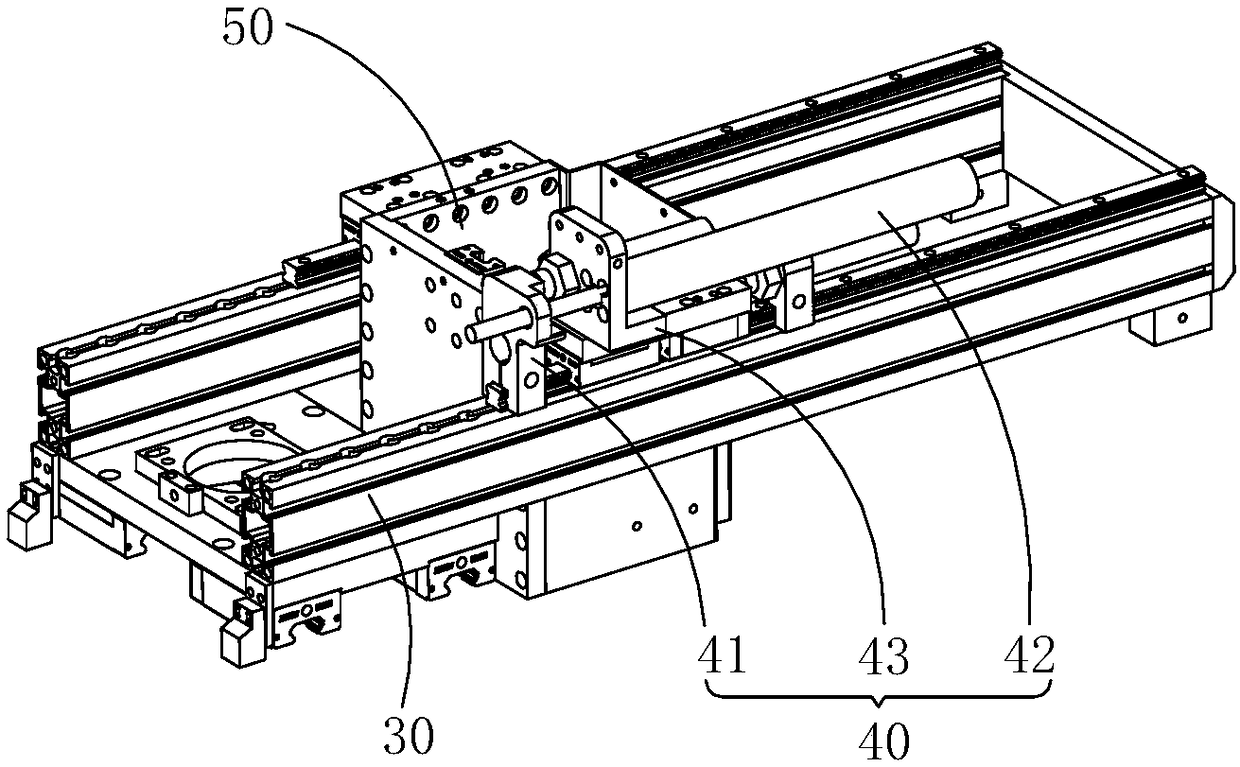

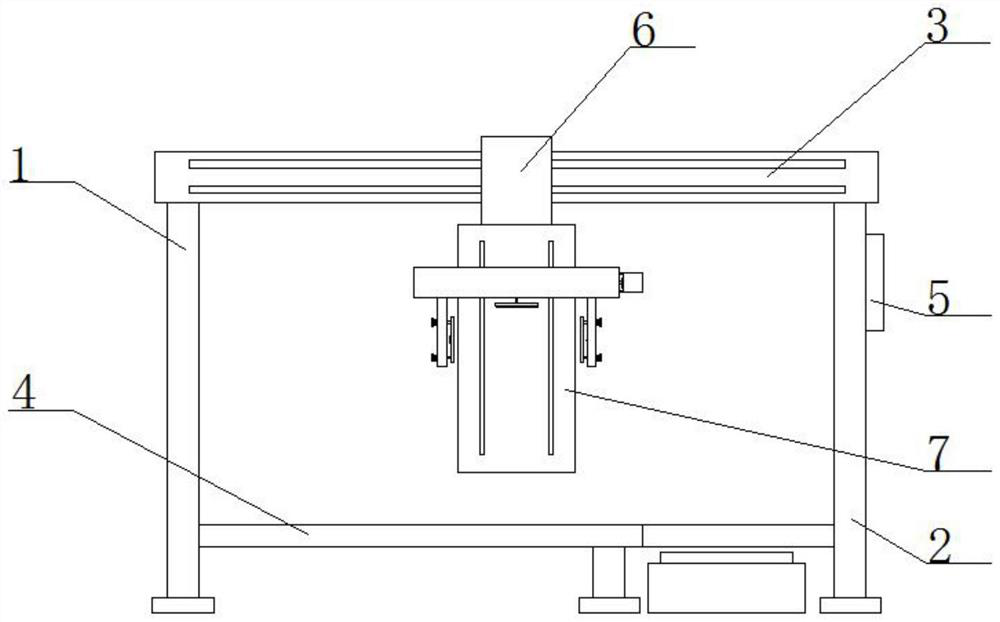

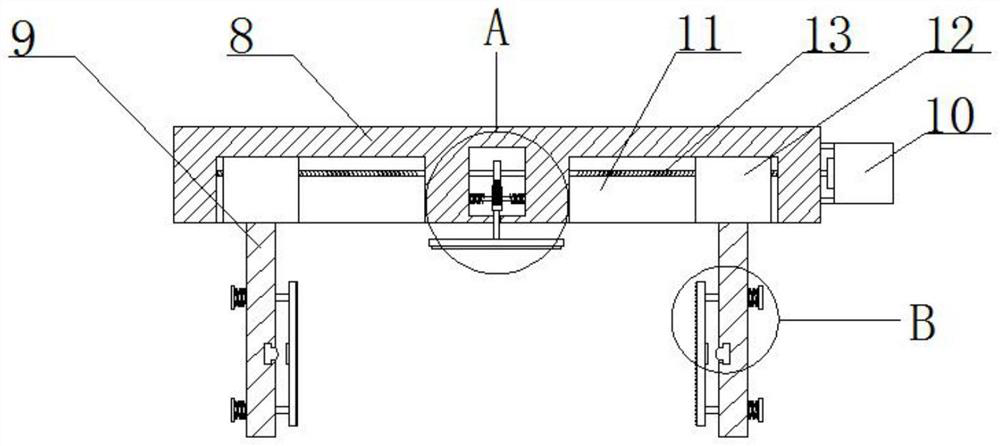

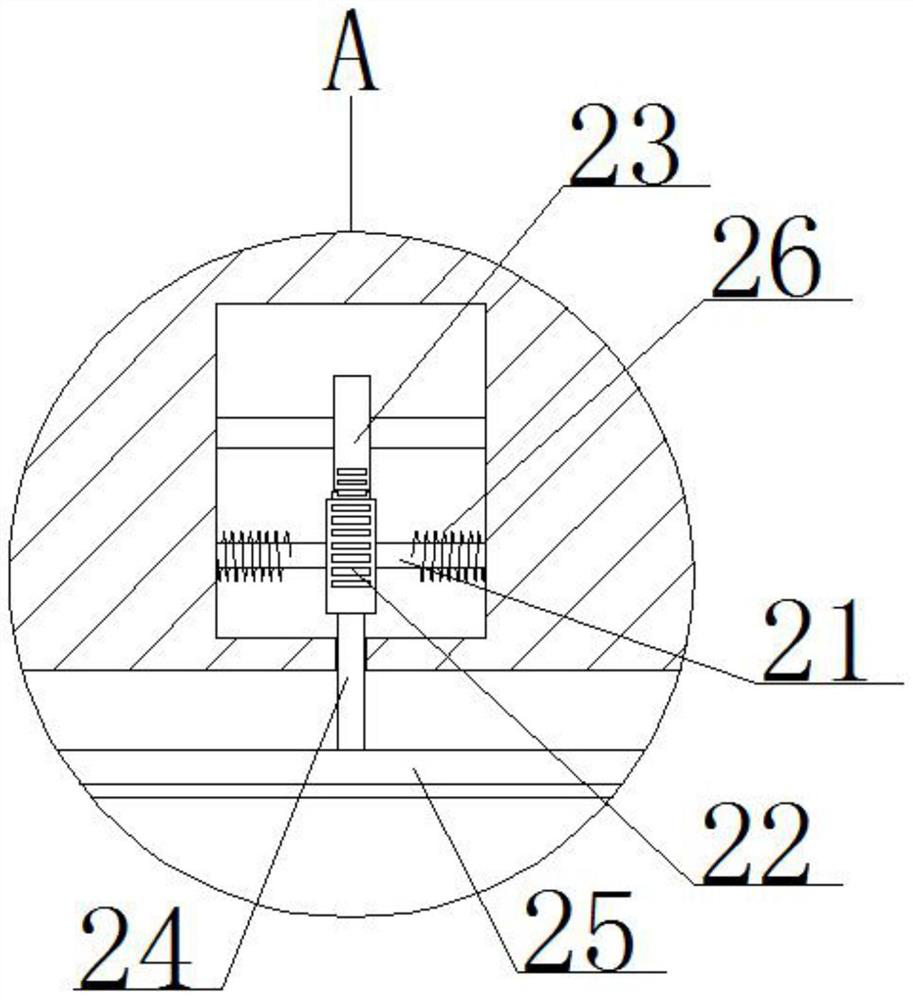

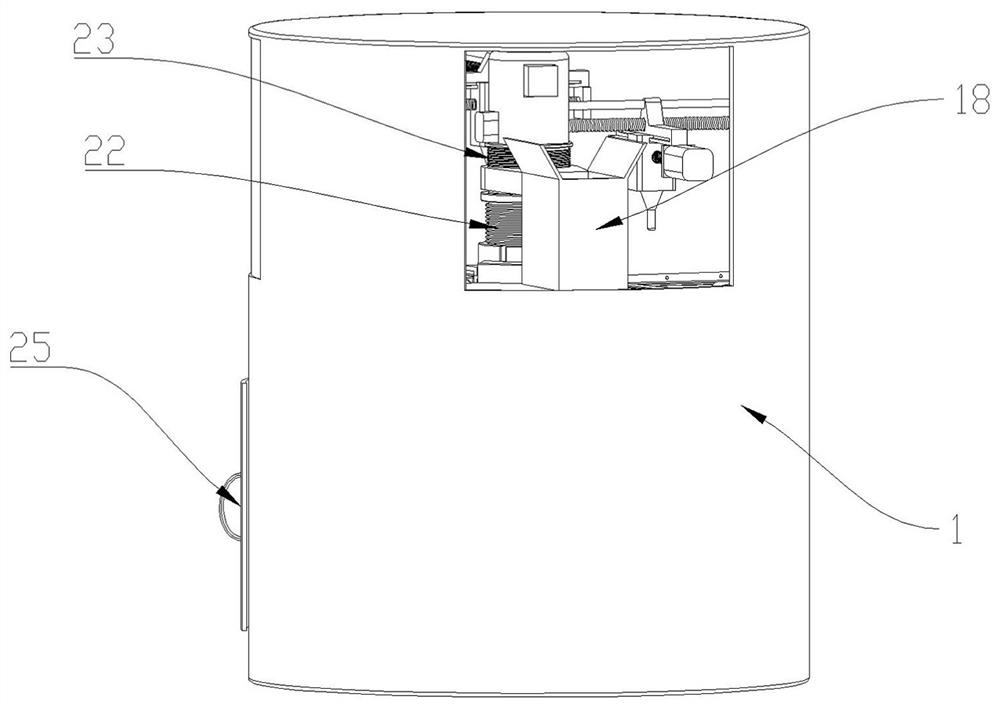

Special linear robot for die casting

The invention discloses a special linear robot for die casting. The special linear robot for die casting comprises an X-axle translation driving device, a transverse moving frame connected with the X-axle translation driving device, a Y-axle translation driving device arranged on the transverse moving frame, a longitudinal moving frame connected with the Y-axle translation driving device, a Z-axletranslation driving device arranged on the longitudinal moving frame, a clamping device connected with the Z-axle translation driving device, and a spraying device connected with the clamping device;the clamping device comprises a mounting base, two connecting modules, two movable clamping blocks and a clamping cylinder; the two connecting modules are connected with the clamping cylinder; the two movable blocks are movably arranged on the two connecting modules; and V-shaped grooves are correspondingly formed in the opposite side surfaces of the two movable clamping blocks. The special linear robot for die casting can realize automatic casting taking and spraying without needing labors, reduces the labor intensity of workers, and protects the health of the workers; and the clamping device can realize clamping of cylindrical castings with different sizes and clamping of conical castings with different tapers, so that the generality is higher.

Owner:东莞国开智能制造有限公司

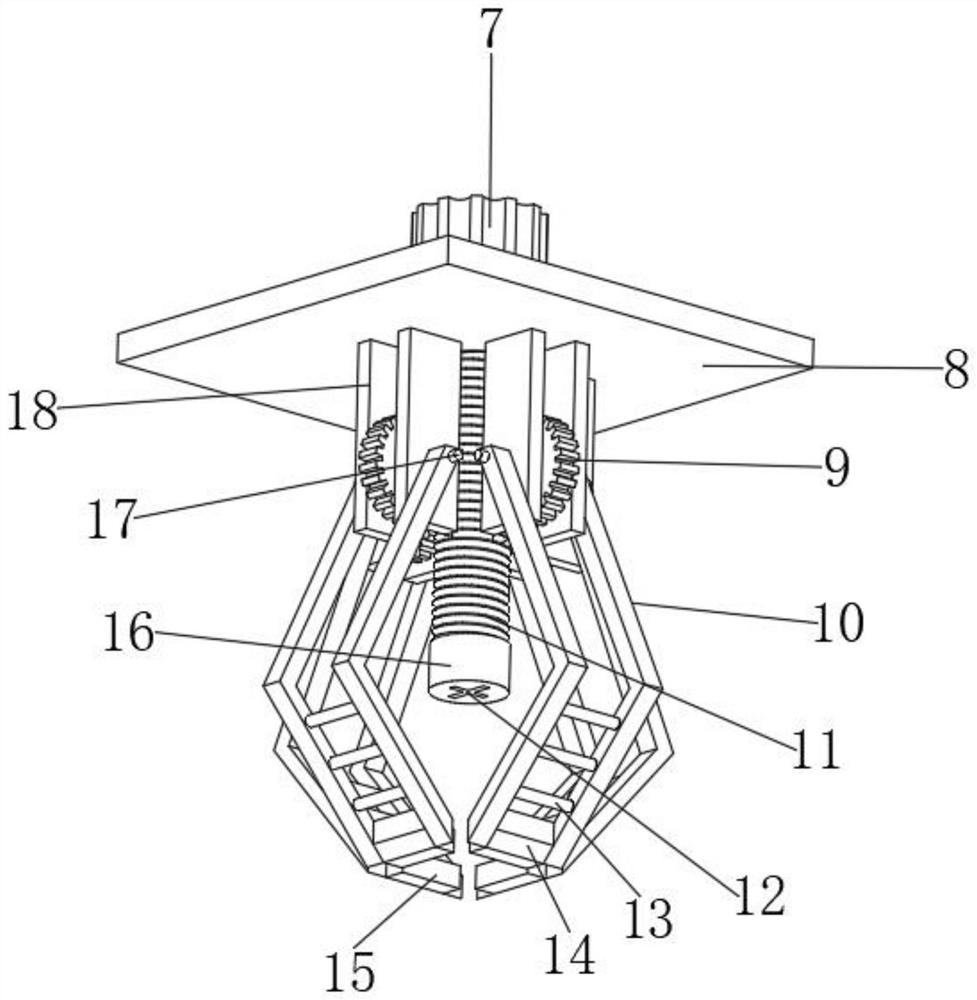

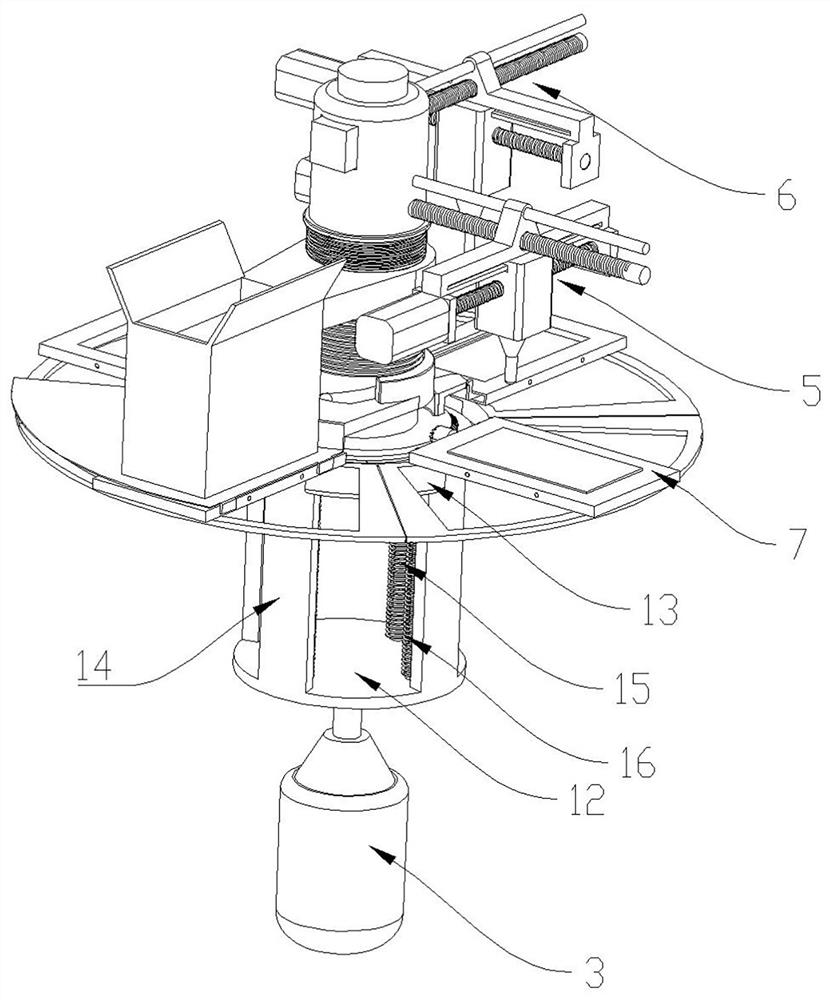

Grabbing device for ultrasonic cleaning equipment

InactiveCN111716336AStable clampingPrevent fallingProgramme-controlled manipulatorGripping headsCouplingMegasonic cleaning

The invention belongs to the technical field of ultrasonic cleaning equipment, and particularly relates to a grabbing device for ultrasonic cleaning equipment. The grabbing device aims to solve the problems that an existing device is unstable in clamping and samples are prone to falling off and damage. The grabbing device for the ultrasonic cleaning equipment comprises a mounting plate and a firstsupporting plate. A second rotating motor is fixed to the outer wall of the top of the mounting plate, and an output shaft, extending to the outer wall of the bottom of the mounting plate, of the second rotating motor is connected with a cross-shaped rotating shaft through a coupler. The outer wall of the cross-shaped rotating shaft is sleeved with a worm, and a first limiting ring is fixed to the outer wall of one end of the cross-shaped rotating shaft. The second rotating motor is used for driving the worm to rotate so as to drive supporting arms to come close, and a sample is clamped through clamping blocks. Through the structure of the worm and a turbine, stable transmission and large transmission are achieved, the sample can be stably clamped, and the situation that the sample fallsoff due to looseness of the supporting arms is prevented. Moreover, the four clamping blocks are used for comprehensively clamping the sample, so that the clamping stability is improved.

Owner:安徽创达超声清洗设备有限公司

Unloading device for motor commutator automatic visual detecting system

The invention relates to the technical field of motor equipment detection, and discloses an unloading device for a motor commutator automatic visual detecting system. The unloading device comprises aslide shaft and a linear servo module; the linear servo module is electrically connected with a PLC; a hydraulic cylinder electrically connected with the PLC is fixed on the linear servo module; a controllable cylinder electrically connected with the PLC is fixed at the bottom of the hydraulic cylinder; a clamping part is arranged at the lower part of the controllable cylinder; the clamping part comprises a clamping block and a rubber plate; the clamping block is provided with a clamping groove; the clamping groove and the rubber plate form an air cavity; the air cavity is provided with a first one-way valve; a spring is arranged in the rubber plate; two clamping plates are arranged at the two ends of the rubber plate, and are fixedly connected with the two ends of the spring; airbags communicating with the air cavity are arranged on the two clamping plates; a second one-way valve is arranged in the communicating place of the air cavity with the airbags; and electromagnetic valves electrically connected with the PLC are arranged in the airbags. Commutators are clamped to prevent damage.

Owner:重庆晓微城企业孵化器有限公司

Cleaning device for rubber ball for pet dog

ActiveCN109482527AAchieve the purpose of scrubbingAchieve clearing effectCleaning using toolsCleaning using liquidsForeign matterEngineering

The invention relates to the technical field of a pet ball cleaning device, and discloses a cleaning device for a rubber ball for a pet dog. The cleaning device comprises a shell, and a transverse bearing plate is fixedly connected between the inner walls of the left and right sides of the shell. Transverse movable through grooves are separately formed in both sides of the upper surface of the transverse bearing plate, and the inner sides of the two transverse movable through grooves are movably connected with transverse connection movable blocks correspondingly. A transverse circulation driving mechanism is fixedly connected to the intermediate position of the inner side bottom of the shell, and the transverse circulation driving mechanism and the two transverse connection movable blocksare connected. According to the cleaning device for the rubber ball for the pet dog, a traditional way of cleaning a rubber ball body by manual use of a brush by manpower is changed through mutual matching of the shell, the transverse bearing plate, the transverse circulation driving mechanism, positioning movable clamp mechanisms, a pressure adjustment mechanism, a small double-axis motor and vertical guide slide rails, and meanwhile, foreign matter in dog mark grooves of the surface of the rubber ball body is effectively removed.

Owner:天长市富宝橡塑制品有限公司

Rubber ball cleaning facility and method for pet dog

InactiveCN111604294AAchieve the purpose of scrubbingAchieve clearing effectCleaning using toolsCleaning using liquidsForeign matterStructural engineering

The invention relates to the technical field of pet ball cleaning facilities, and discloses a rubber ball cleaning facility and method for a pet dog. A shell is included. A transverse bearing plate isfixedly connected between the inner walls of the left side and the right side of the shell. Transverse movable through grooves are formed in the two sides of the upper surface of the transverse bearing plate. The inner sides of the two transverse movable through grooves are movably connected with transverse connecting movable blocks. The middle position of the bottom of the inner side of the shell is fixedly connected with a transverse cyclic drive mechanism. The transverse cyclic drive mechanism is connected with the two transverse connecting movable blocks. Through mutual cooperation of theshell, the transverse bearing plate, the transverse cyclic drive mechanism, a positioning movable clamp mechanism, a pressure adjusting mechanism, a small dual-axis motor and a vertical guiding sliding rail, the manner of rubber ball cleaning through manpower manual usage of a brush is changed, and meanwhile foreign matter in a tooth mark groove in the surface of a rubber ball is effectively removed.

Owner:于宗武

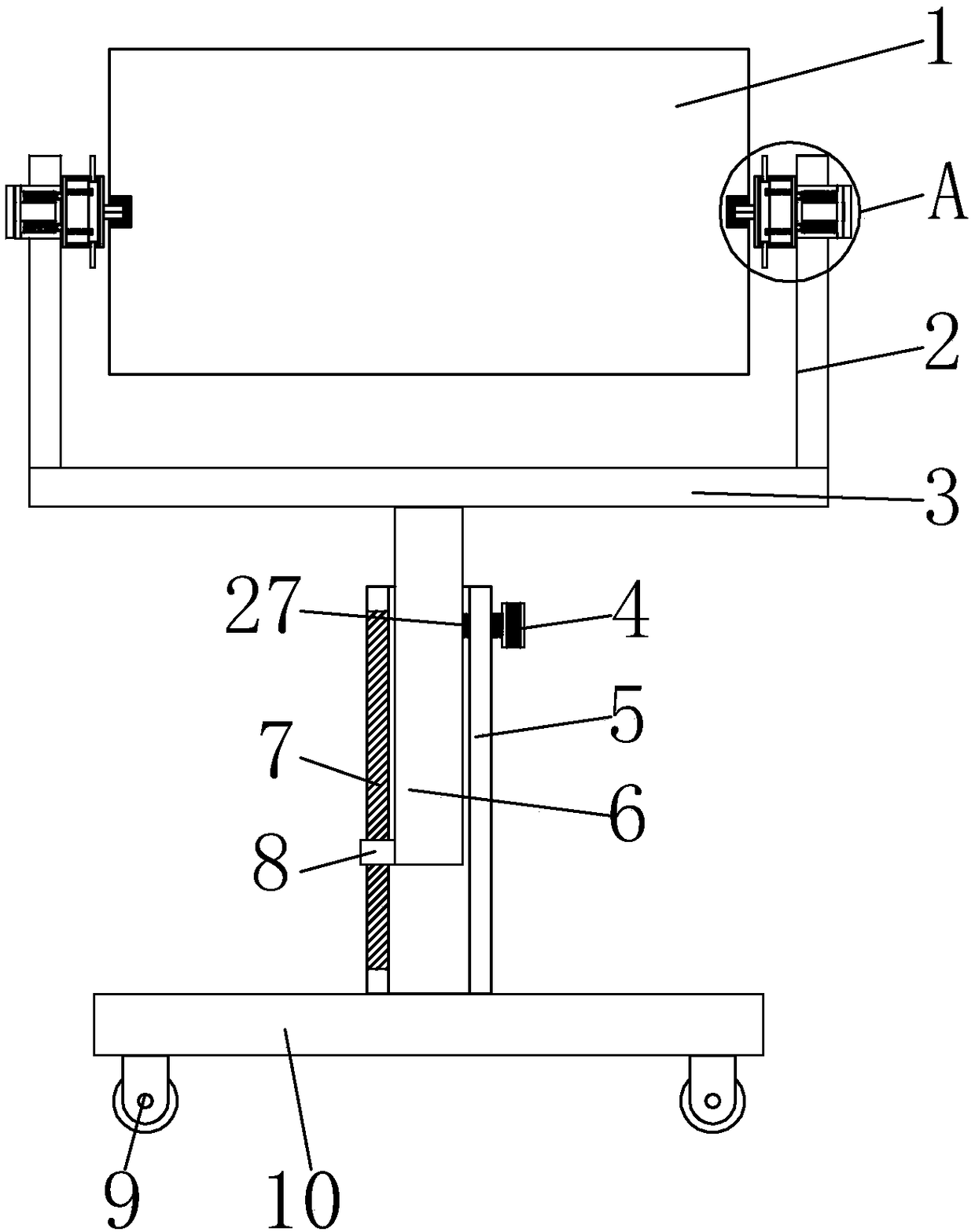

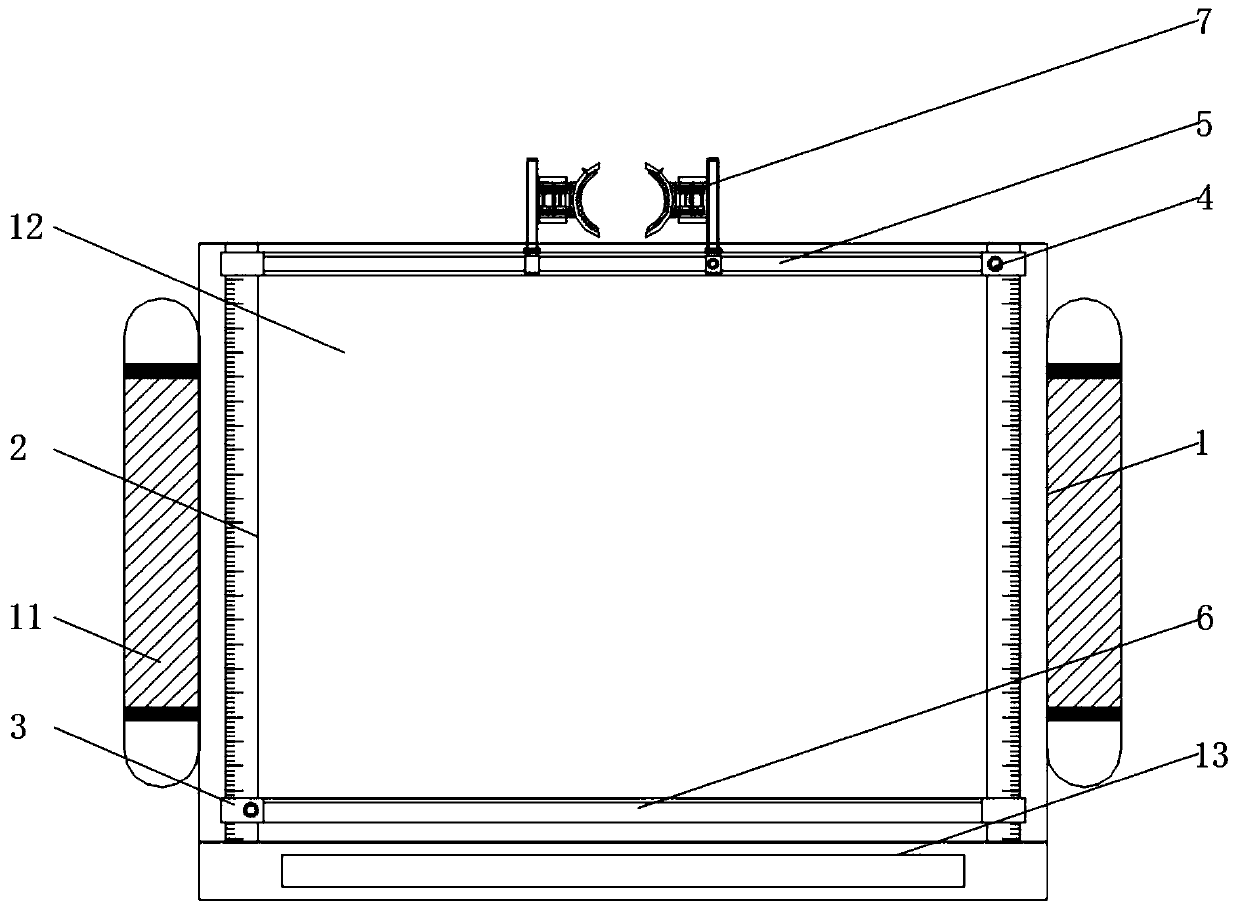

Statistical display board for construction cost

InactiveCN109147555AThe structure of the device is reasonableEasy to operateSignsEngineeringEngineering management

The invention relates to the technical field of building engineering, in particular to a statistical display board for construction cost, including a bottom plate, a lifting mechanism is arranged above the bottom plate, a mounting plate is arranged above the lifting mechanism, a fixing plate is symmetrically arranged above the mounting plate, the fixing plate is embedded with a corresponding movable mechanism, one side of the movable mechanism is connected with a housing, a spring is fixed in the limiting groove, one end of the spring extends out from the limiting groove and abuts against theinner wall of the shell, the other side of the movable plate is provided with a rectangular column, a display plate body is arranged between the fixing plates, mounting blocks are embedded in the middle of the two sides of the display plate body, one side of the mounting block is provided with a rectangular groove, and one end of the rectangular column is arranged in the rectangular groove throughone side of the shell. The device has the advantages of reasonable structure, convenient operation, convenient adjustment of the height and angle of the display board body, convenient viewing, convenient disassembly of the display board body, and the purpose of replacing the contents.

Owner:WENZHOU POLYTECHNIC

Textile machinery yarn guide device convenient in clamping

The invention discloses a textile machinery yarn guide device convenient in clamping. The textile machinery yarn guide device comprise a box and is characterized in that a rotary disc is arranged at the top of the right side of the box, a transmission rod is fixedly connected to the right side of the rotary disc, the right end of the transmission rod penetrates the box, extends into the box and is fixedly connected with a first bevel gear, a first bearing is fixedly connected to the transmission rod and located on the outer surface of the box, and the right side of the first bearing is fixedly connected with the top of the left side of the box. By the coordination of the rotary disc, the transmission rod, the first bevel gear, the first bearing, a second bearing, a worm, a second bevel gear, a slide groove, a slider, a movable plate, a toothed plate, a fixing plate and a rotary rod, the textile machinery yarn guide device has a clamping function, and the problems that an existing textile machinery yarn guide device does not have a clamping function, cloth falling occurs during cloth conveying, a large amount of time of a user is wasted, and production efficiency is lowered are solved.

Owner:SUZHOU COMFORT TEXTILE NEW MATERIALS TECH CO LTD

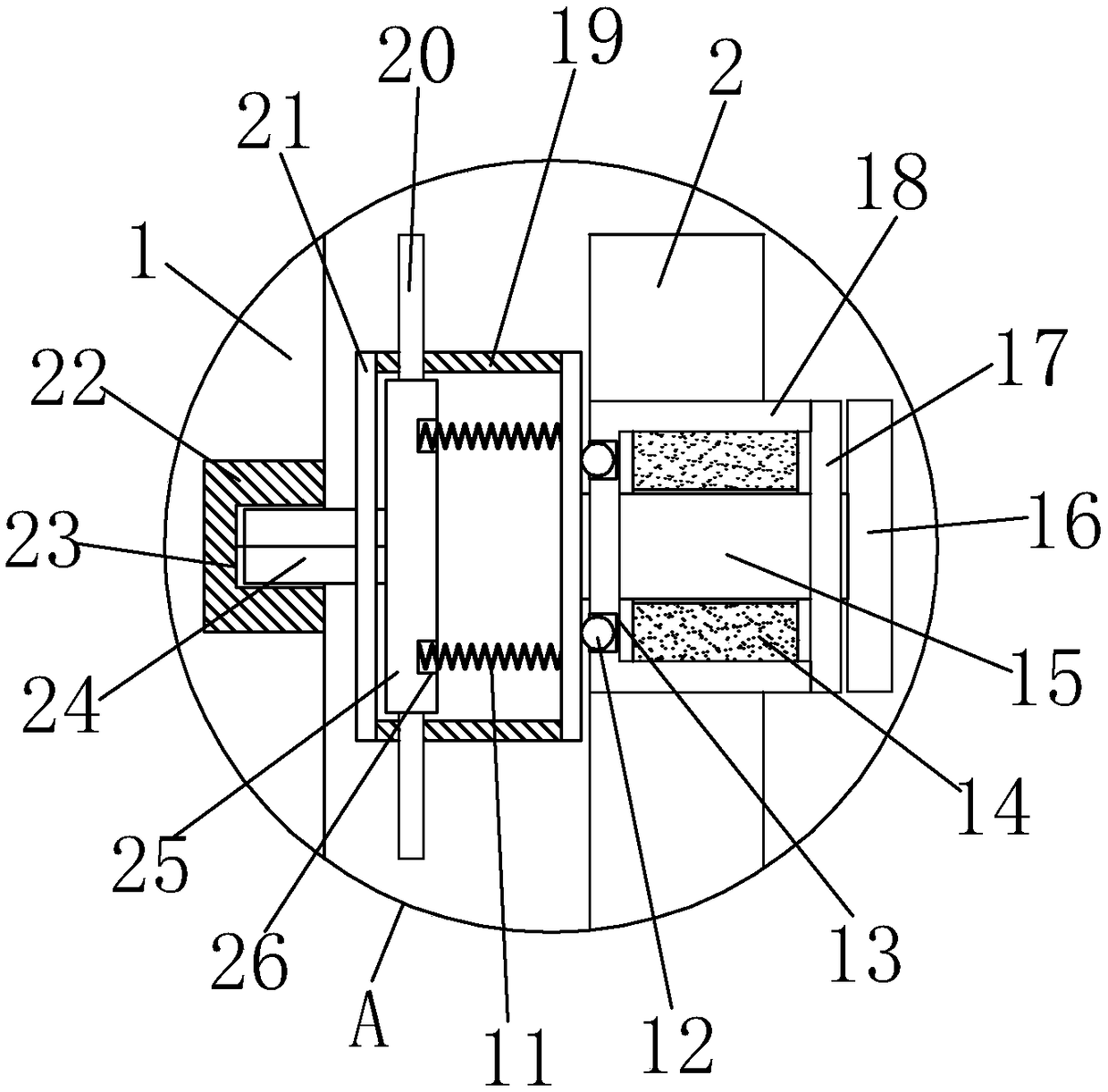

Clamping device for battery of new energy vehicle

ActiveCN111573129AAchieve the purpose of clampingAchieve the purpose of turningConveyorsCell component detailsElectrical batteryAutomotive battery

The invention discloses a clamping device for a battery of a new energy vehicle. The clamping device comprises a first support and a second support, a plurality of first conveying rollers which are distributed at equal distances and are in transmission connection through a first conveying belt are movably mounted on the inner surface of the first support, and a first motor is fixedly mounted at the front left end of the bottom of the first support, wherein an output shaft of the first motor is in transmission connection with the first conveying roller located at the leftmost end of the inner surface of the first support through a belt. A sliding seat and a slider are arranged so that the purpose of driving a clamping mechanism to move left and right can be achieved, a first electric telescopic rod is arranged so that the purpose of driving the clamping mechanism to move up and down can be achieved, the clamping mechanism is arranged so that the purposes of clamping the battery througha first clamping plate and a second clamping plate and steering the clamped battery can be achieved, through cooperation of the structures, the clamping efficiency of the clamping device for batteriesof different types is effectively improved, and great convenience is brought to use by people.

Owner:上海航空发动机制造有限公司

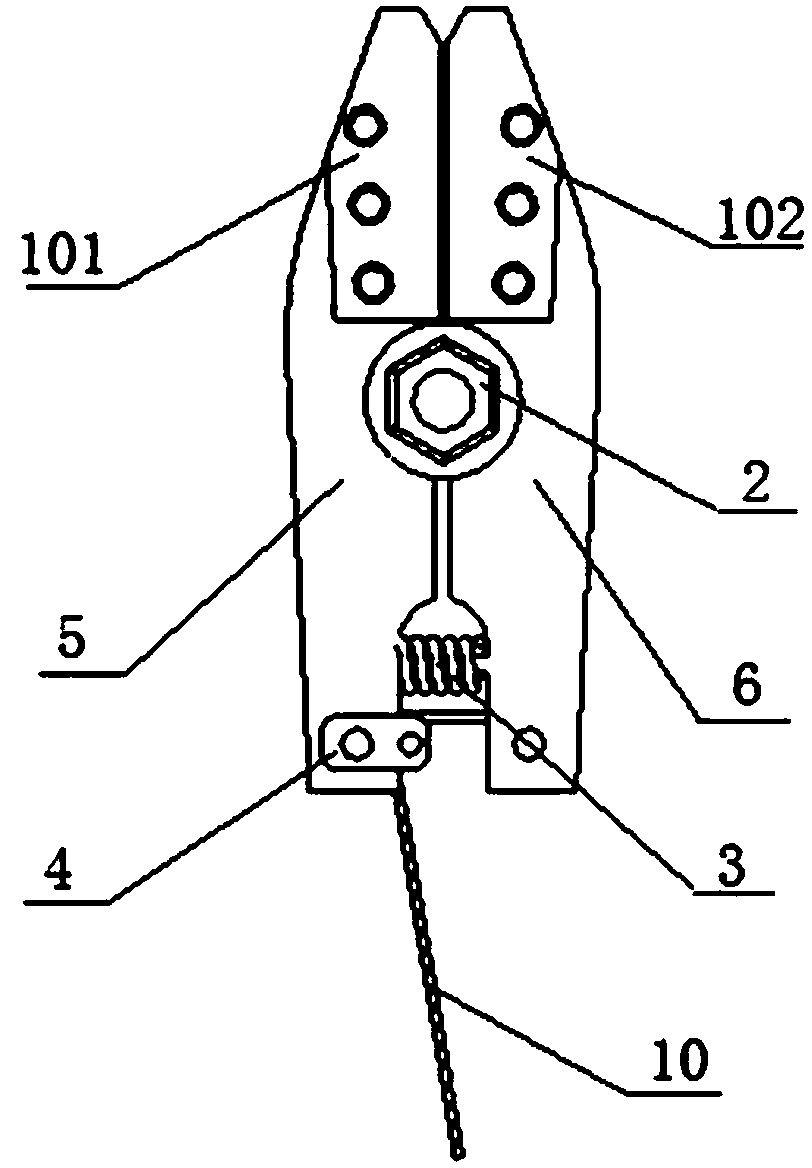

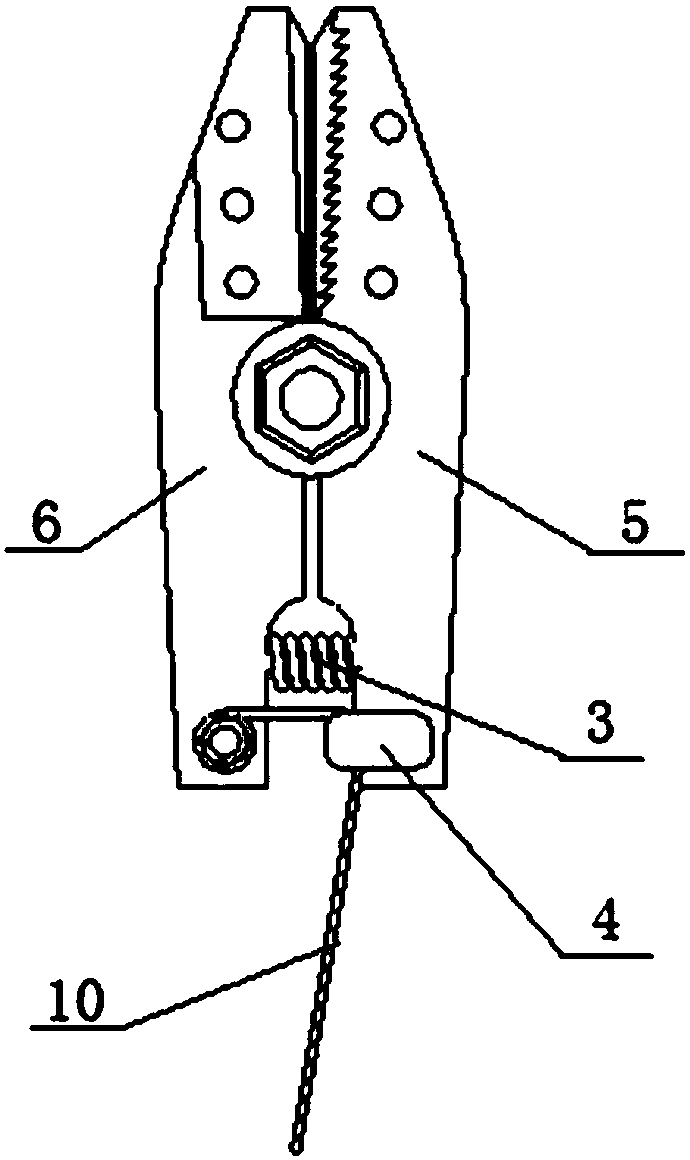

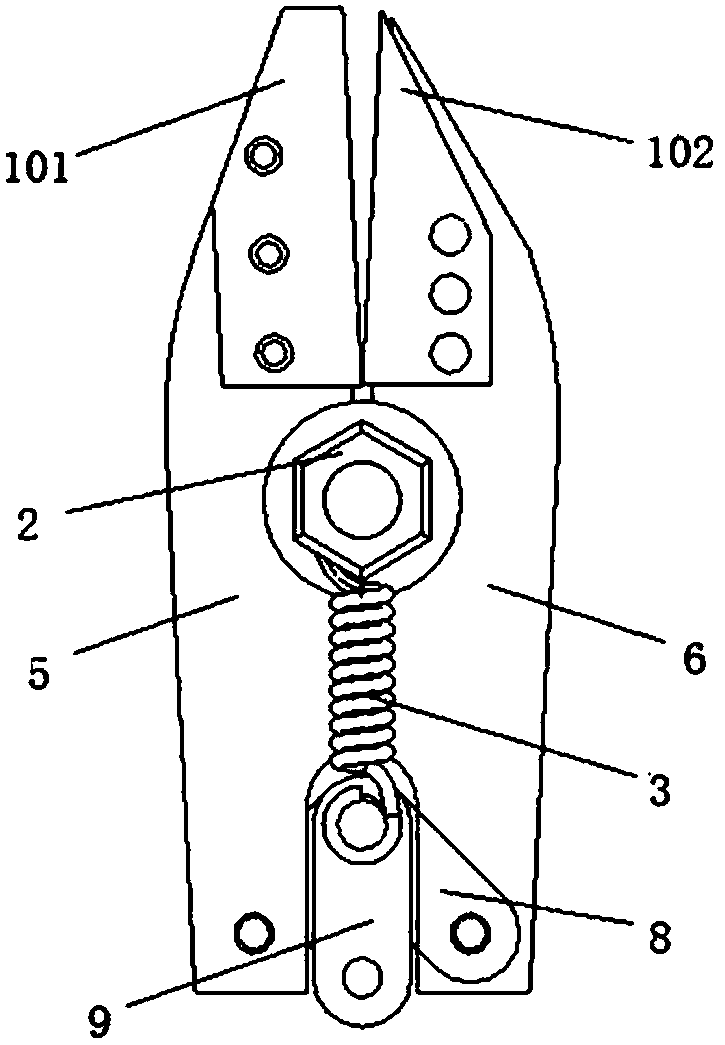

Picking and collecting integrated device and high-altitude picking pliers thereof

PendingCN107926286AAchieve the purpose of clampingControl the clamping forcePicking devicesStructural engineeringKnife blades

The invention discloses a picking and collecting integrated device and high-altitude picking pliers thereof. The picking and collecting integrated device includes two pliers heads of which middle portions are mutually rotated through a hinge shaft, the head portions of the two pliers heads cooperate with each other to form a pliers mouth, detachable blades with cutting edges are arranged inside the pliers mouth, and a reset spring is arranged at the tail portions of the pliers heads; the head portions of the two pliers heads are provided with a first elastic adhesive and a second elastic adhesive respectively, a clamping gap is reserved between the first elastic adhesive and the second elastic adhesive after the first elastic adhesive and the second elastic adhesive are arranged oppositely, and the position of the clamping gap is consistent with the position of the cutting edges of the pliers mouth. The picking and collecting integrated device has a simple structure and high packing efficiency, and is very suitable for batch packaging. The picking and collecting integrated device is characterized in that elastic adhesives are used for achieving the purpose of picking and collectingintegration, and is suitable for small fruits with easily damaged fruit skin. The picking and collecting integrated device can pick up fruits at a high altitude without hands, so that the fruits arenot damaged, and the hands are not hurt. The picking and collecting integrated device is safe in operation, and the cut fruits do not fall off.

Owner:王兴武

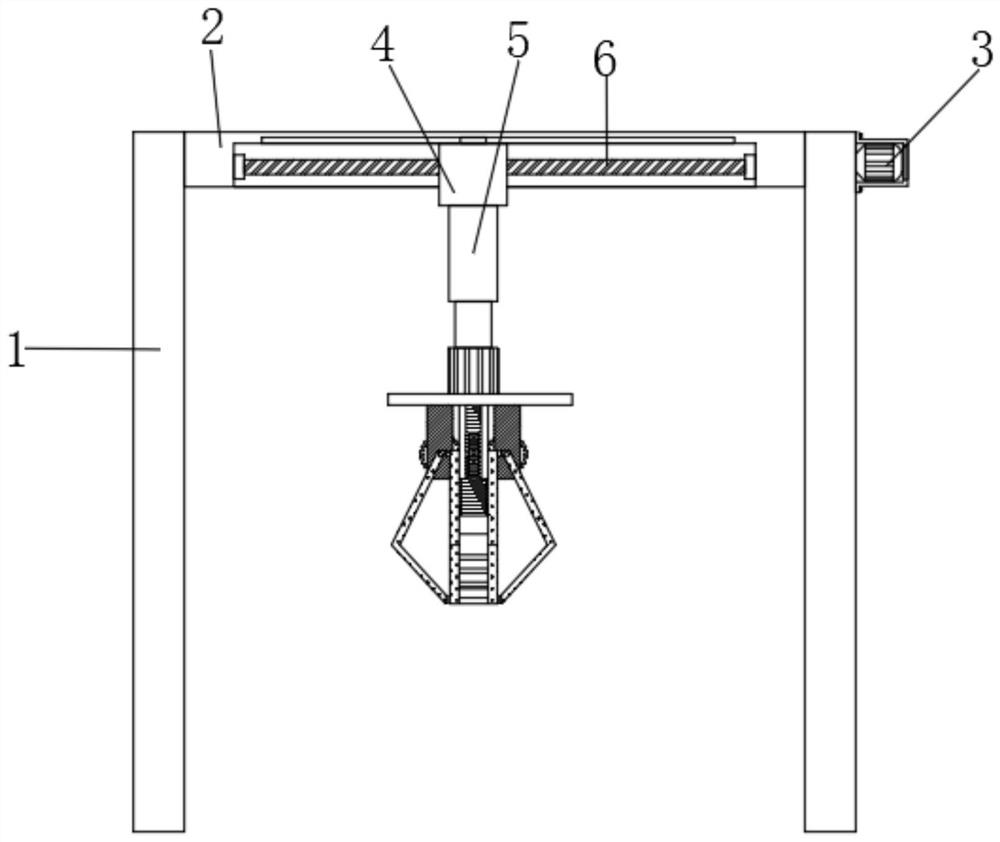

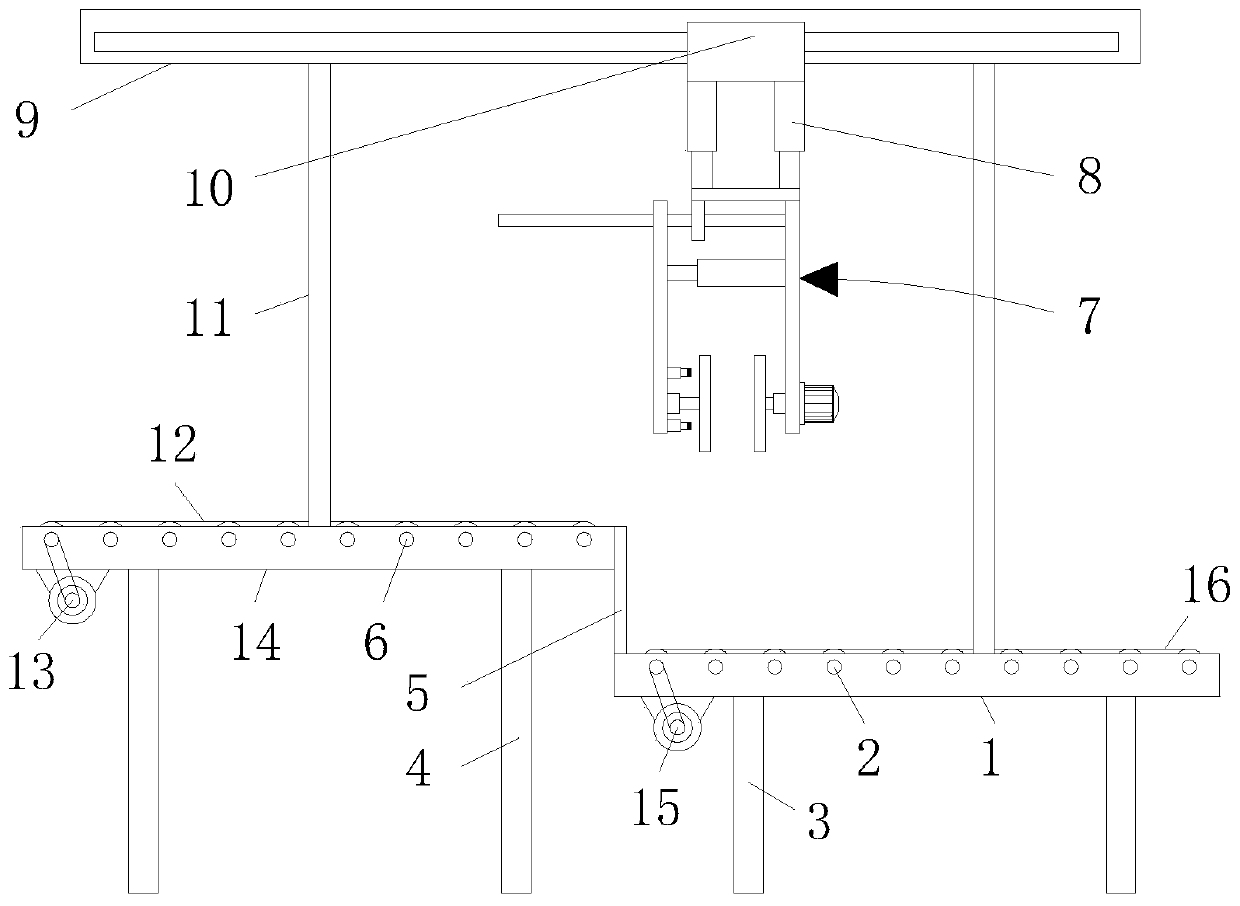

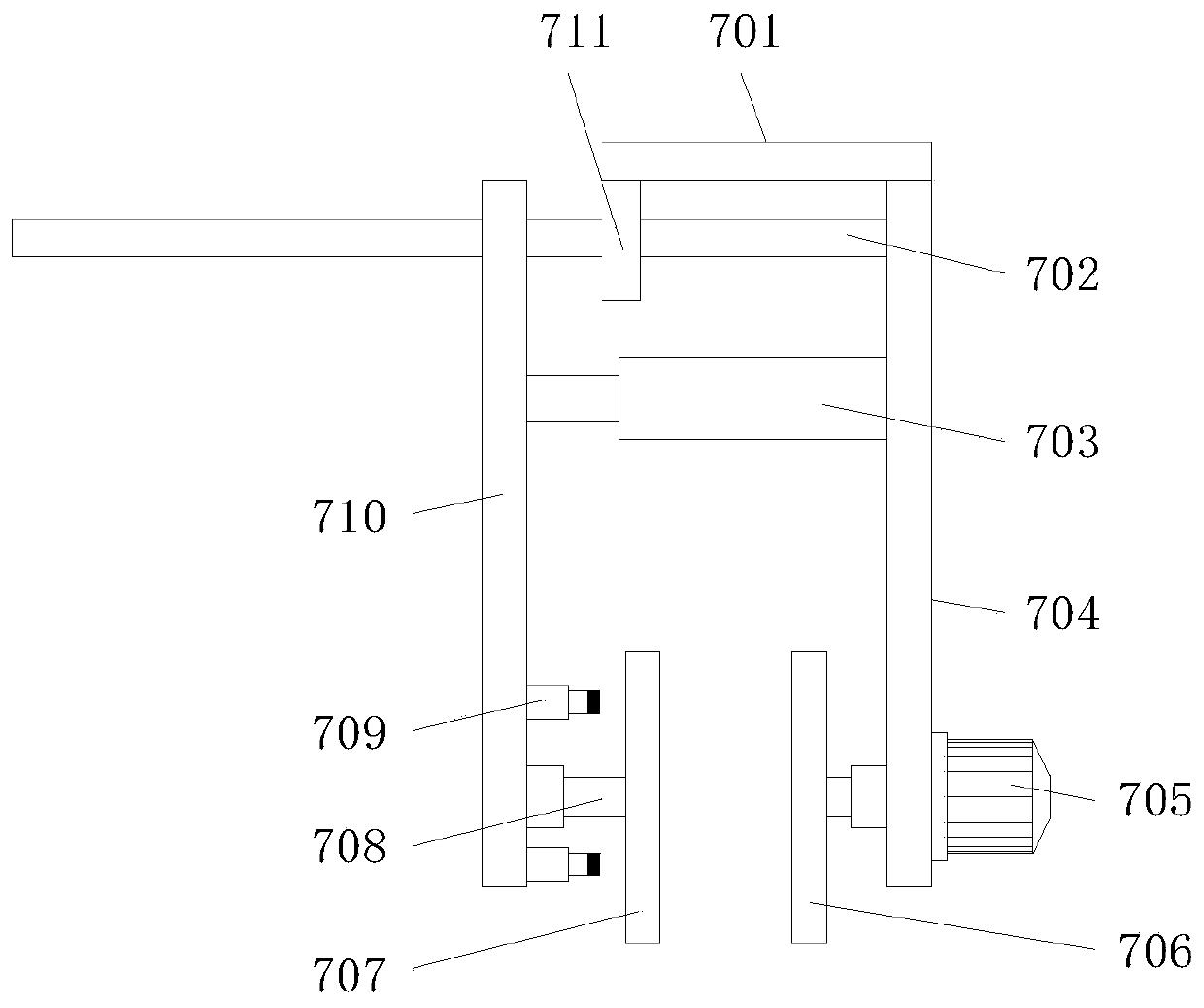

Lifting stacking machine with starting assembly

InactiveCN114572706AAchieve the purpose of clampingEffective squeezeBio-organic fraction processingGripping headsEngineeringMachine

The invention belongs to the field of stacking machines, particularly relates to a lifting stacking machine with a starting assembly, and aims to solve the problems that an existing stacking machine is extremely easy to excessively extrude cargoes, the cargoes are damaged, the stacked cargoes cannot be scanned and registered in time in the stacking process, the position information of the stacked cargoes is lacked, and the stacking efficiency is poor. In order to solve the problems in the prior art, the invention provides the following scheme that the device comprises a first supporting column and a second supporting column, the top ends of the first supporting column and the second supporting column are fixedly connected with the same cross rod, and the first supporting column and the second supporting column are provided with the same stacking plate; when in use, goods extrusion damage caused by too large clamping force can be effectively avoided through the pressure sensor, and the stacked goods can be subjected to comprehensive information scanning, so that the information of the goods is registered to a cloud end for storage, and subsequent operation is facilitated.

Owner:SHENZHEN GUANHAO IND EQUIP

Automatic feeding laser engraving machine

PendingCN114178706ASuitable for small batch processingAchieve the effect of double-sided engravingLaser beam welding apparatusLaser engravingElectric machinery

The automatic feeding laser engraving machine comprises a machine shell, a feeding opening is formed in the machine shell, a fixed shaft is fixedly installed in the machine shell, a cam groove is formed in the fixed shaft, a rotating plate is slidably connected into the cam groove, and a storage box is slidably connected to the fixed shaft; the rotating plate is tightly attached to the lower surface of the storage box and provided with a second opening allowing the sectional materials to pass through. And a driving motor is further included, an output shaft of the driving motor is connected with a rotating assembly, a plurality of carving frames and a plurality of rotating bottom frames are installed on the rotating assembly, and the carving frames are located below the rotating plate. A clamping piece which is connected with the side wall of an engraving frame is arranged on the side wall of a rotating plate, the engraving frame rotates to drive the rotating plate to rotate and ascend under the action of a cam groove, so that the clamping piece ascends to be separated from the side wall of the engraving frame, and feeding is completed, and then the rotating plate resets under the action of a first spring; and at the moment, the next carving frame enters the position below the rotating plate again, the steps are repeated, and automatic feeding of the multiple profiles is completed.

Owner:孙二辉

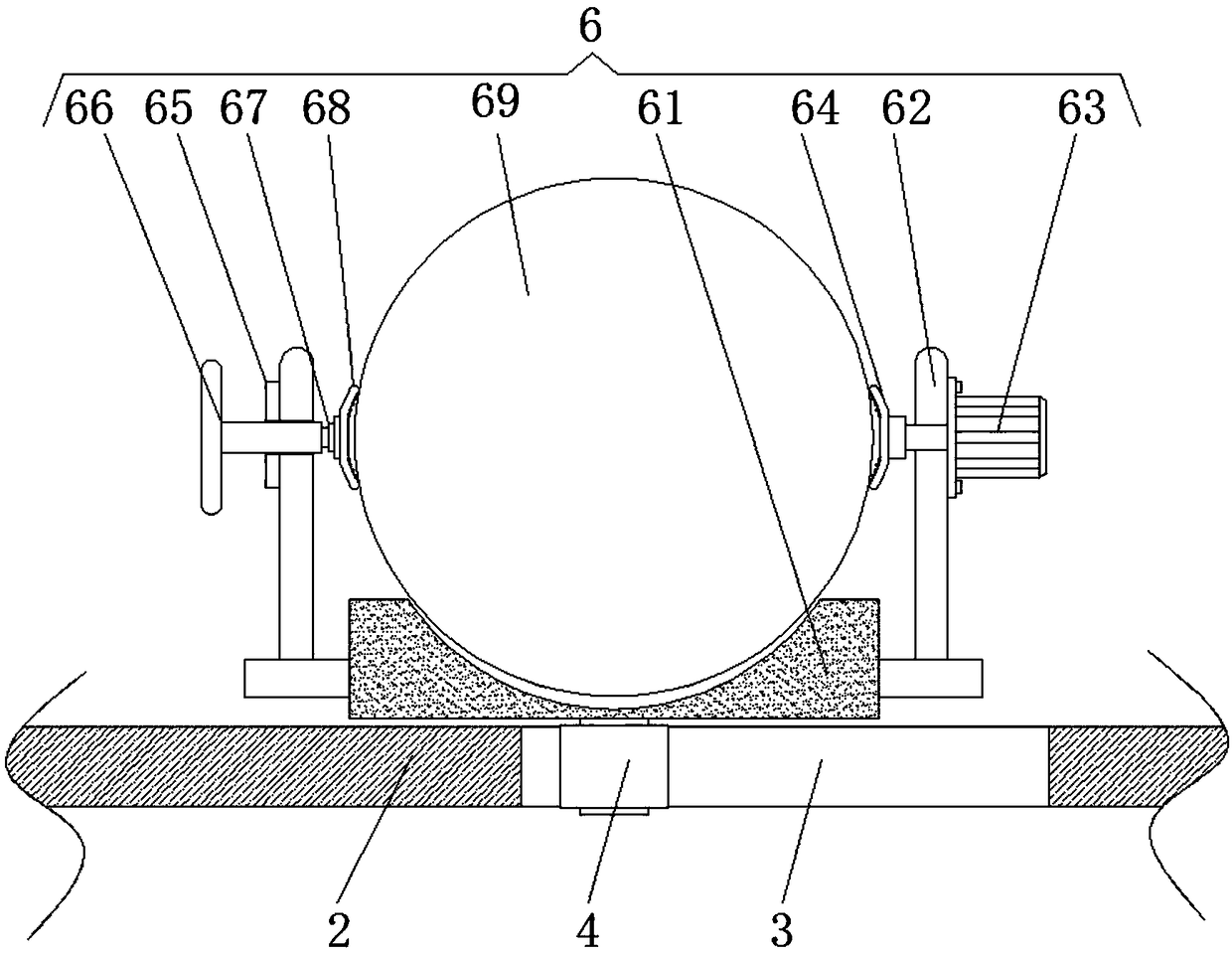

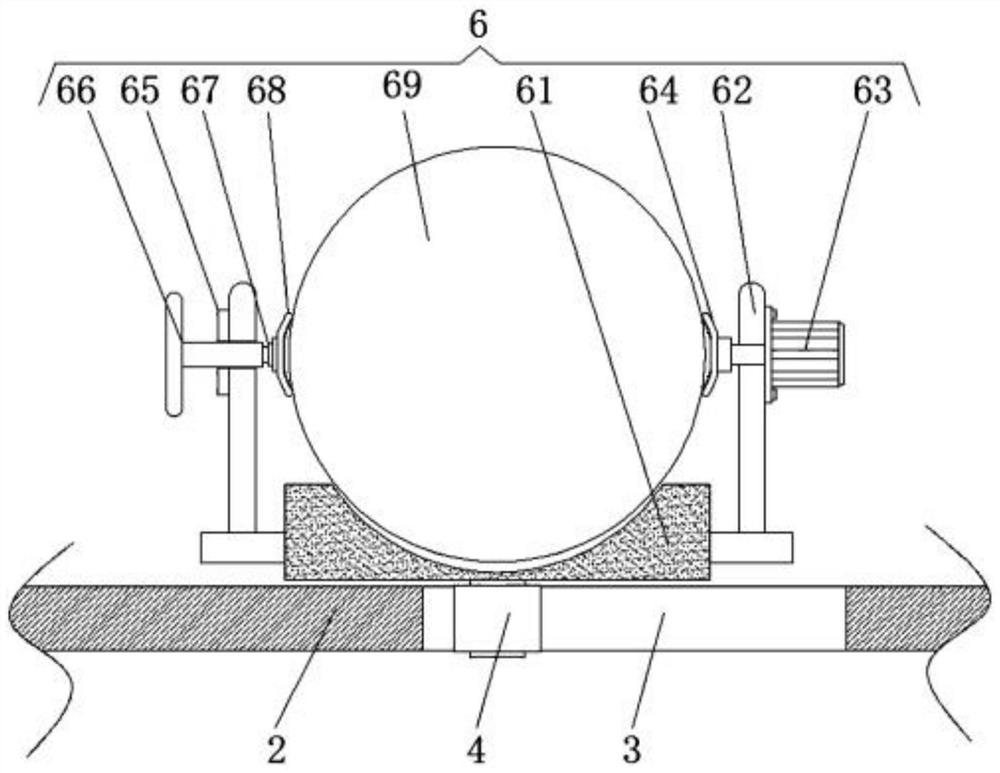

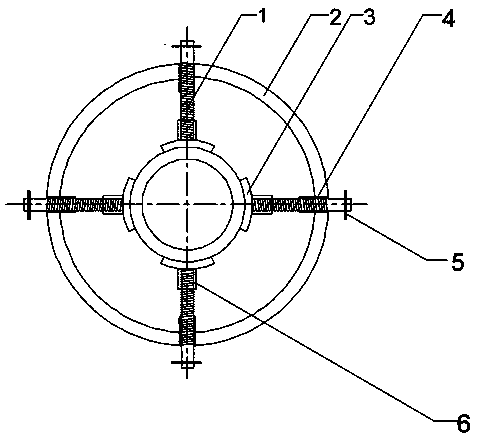

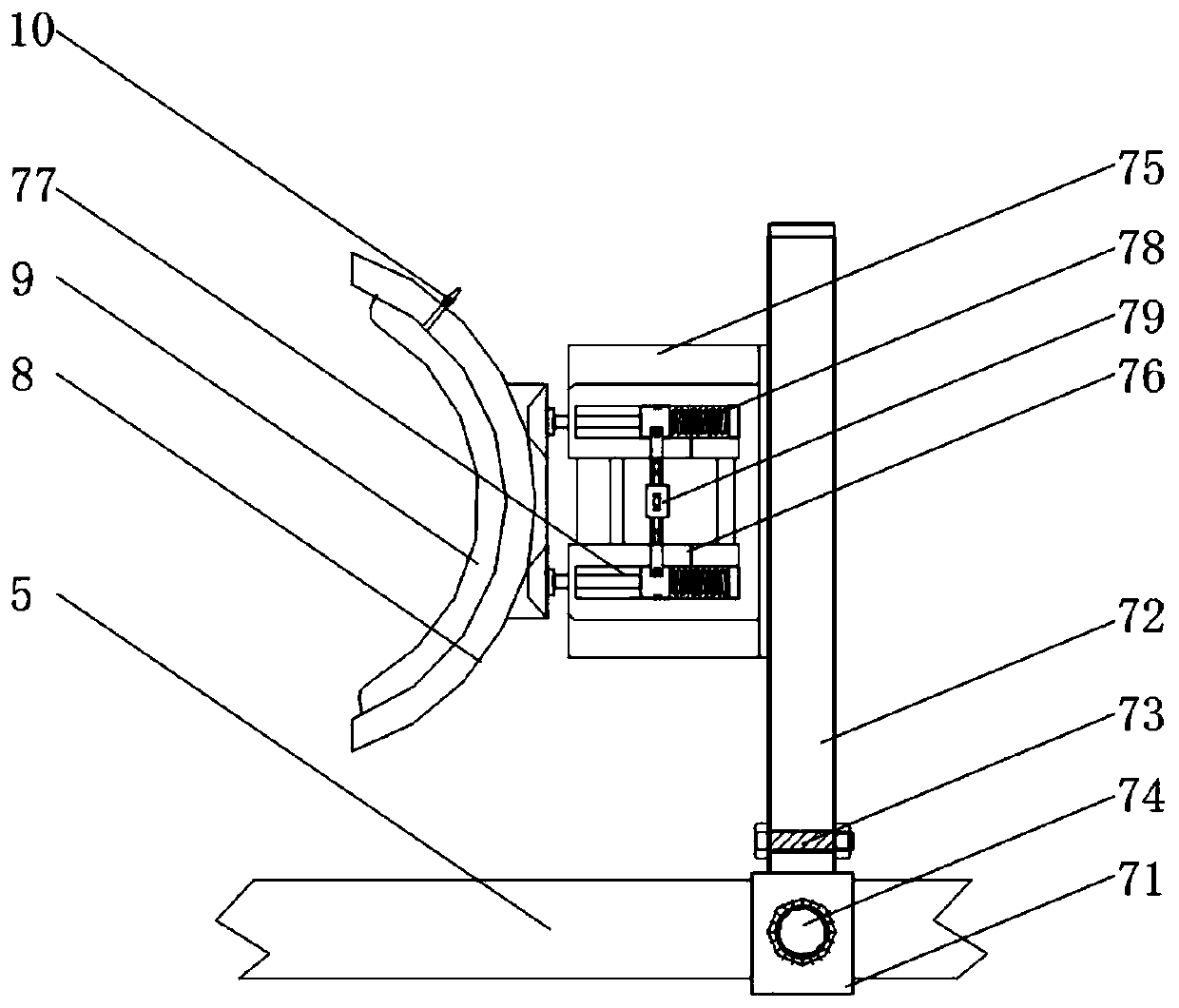

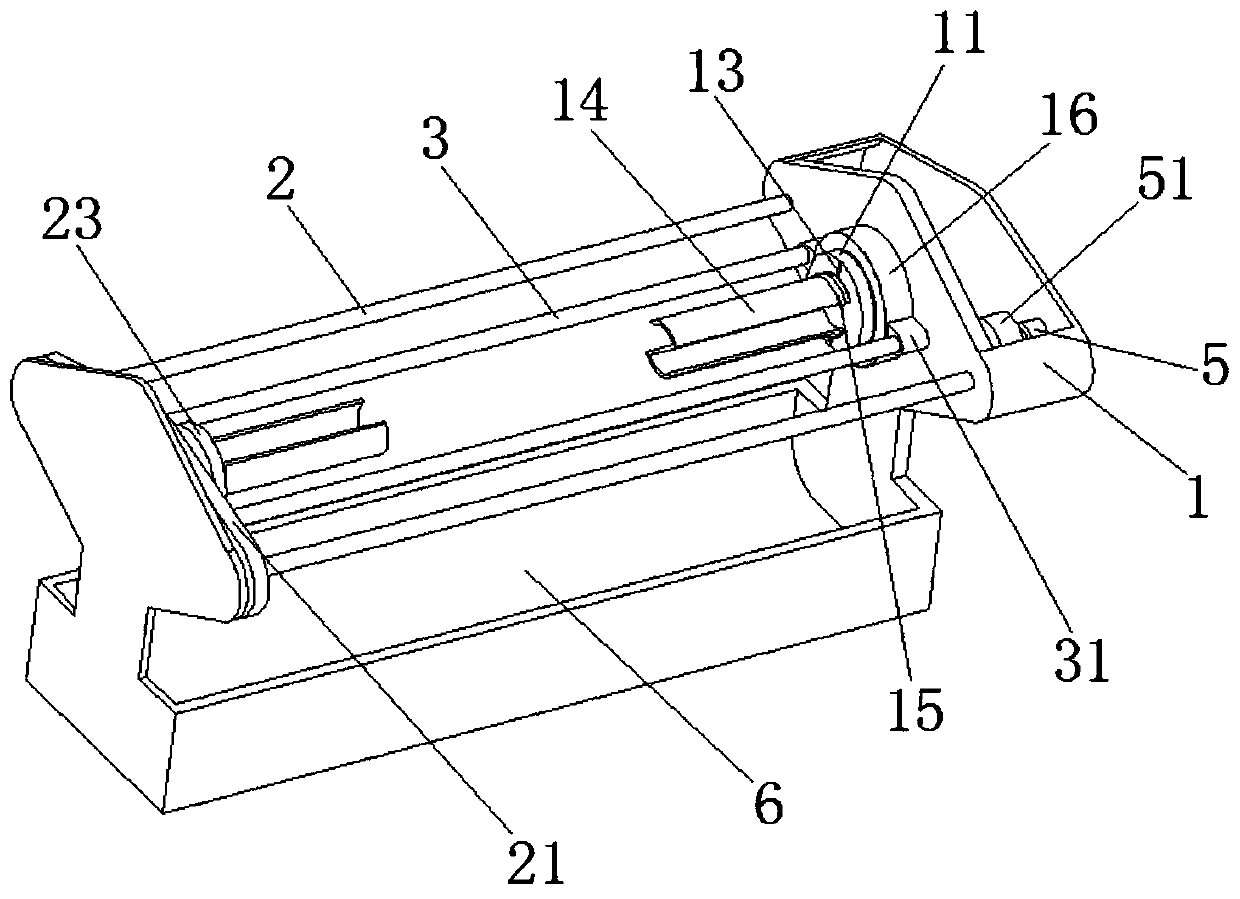

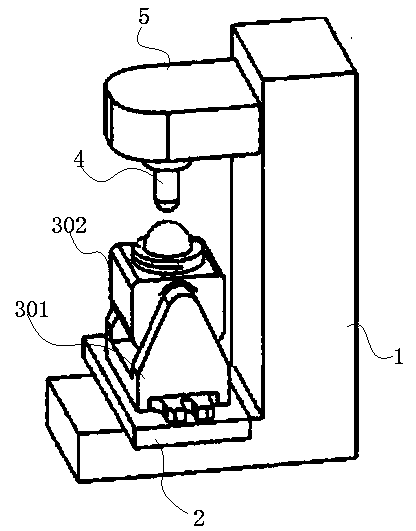

Assistant machining clamping device for bearing inner rings

InactiveCN111482824AAchieve the purpose of clampingPositioning apparatusMetal-working holdersMachiningPhysics

The invention discloses an assistant machining clamping device for bearing inner rings. The assistant machining clamping device for the bearing inner rings comprises lead screws, an annular supportingframe, cushion pads, tracks, rotating handles and connecting blocks, and can be used for controllably clamping the bearing inner rings in different sizes to machine the inner rings. The assistant machining clamping device for the bearing inner rings has the advantages of being simple in structure and easy to operate, can reduce damage to the bearing inner rings in the clamping process, and can clamp the bearing inner rings more stably to facilitate machining of the bearing inner rings.

Owner:NORTHWEST A & F UNIV

Intelligent mechanical clamping device

ActiveCN113580039AAchieve the purpose of clampingAccurate clampingWork holdersEngineeringMechanical engineering

Owner:HUNAN MECHANICAL & ELECTRICAL POLYTECHNIC

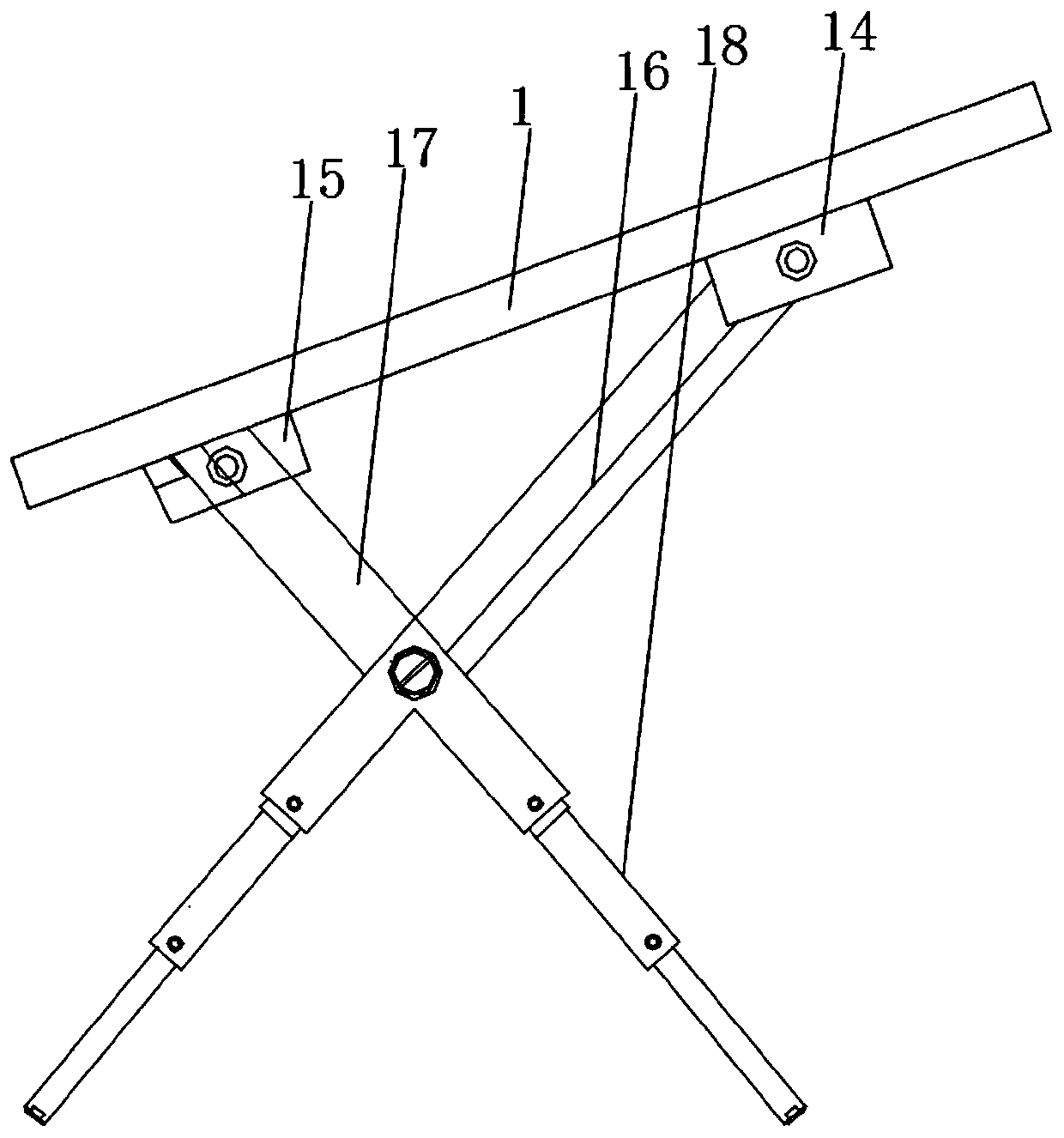

Highway construction test board

The invention discloses a highway construction test board. The highway construction test board comprises a test board, wherein a measurement track ruler is arranged above the test board, locking sliding sleeves are arranged on the outer side of the measurement track ruler, locking knobs are arranged on the outer sides of the locking sliding sleeves, an upper fixing frame and a lower fixing frame are arranged between the locking sliding sleeves, a clamping moving device is arranged at the top of the upper fixing frame, a clamping arc-shaped plate is fixedly connected to the inner side of the clamping moving device, a pressurizing air bag is arranged on the inner side of the clamping arc-shaped plate, a gas adding needle head is arranged on the rear side of the clamping arc-shaped plate, andthe air feeding needle head and the pressurizing air bag are connected through a gas guide pipe. The invention relates to the technical field of highway construction. According to the highway construction test board, the purpose of convenient carrying is achieved, drawing paper is convenient to fix, drawing personnel can be supported when tired, and a surveying and mapping tool is clamped; and asupporting frame can also rotate along a rotating bolt shaft, so that the position of the surveying and mapping tool can be conveniently adjusted.

Owner:何宇

Cleaning device for production and machining of metal protective fences

InactiveCN113967619AReach the purpose of recyclingAchieve the purpose of clampingCleaning using toolsCleaning using liquidsWater storageActivated carbon filtration

The invention discloses a cleaning device for production and machining of metal protective fences. The cleaning device comprises a workbench and a three-way communicating vessel, a water storage tank is fixedly connected to the middle end of the bottom of the workbench, a clamping seat is fixedly connected to the upper end of the inner surface of the water storage tank, meanwhile, an activated carbon filtering layer is clamped to the inner surface of the clamping seat, second connecting plates are fixedly connected to the middle ends of the front side and the rear side of the workbench, a second motor is fixedly mounted on the back side of the second connecting plate located at the rear end of the workbench, and a rotating shaft is movably connected to the upper end of the back surface of the second connecting plate located at the front end of the workbench through a bearing. The device is provided with a first connecting plate, a sliding seat, a sliding device, a first electric telescopic rod, a third connecting plate, a first belt pulley, a first motor, a second belt pulley, a brush roller, the three-way communicating vessel, a pump machine, a spray head, the activated carbon filtering layer, a second electric telescopic rod, a pressing plate, a fourth connecting plate, a second connecting plate and the second motor, the cleaning effect of the device on the metal protective fences is effectively improved.

Owner:赣州市桐鑫金属制品有限公司

Unloading device for automatic visual inspection system of motor commutator

The invention relates to the technical field of motor equipment detection, and discloses an unloading device for a motor commutator automatic visual detecting system. The unloading device comprises aslide shaft and a linear servo module; the linear servo module is electrically connected with a PLC; a hydraulic cylinder electrically connected with the PLC is fixed on the linear servo module; a controllable cylinder electrically connected with the PLC is fixed at the bottom of the hydraulic cylinder; a clamping part is arranged at the lower part of the controllable cylinder; the clamping part comprises a clamping block and a rubber plate; the clamping block is provided with a clamping groove; the clamping groove and the rubber plate form an air cavity; the air cavity is provided with a first one-way valve; a spring is arranged in the rubber plate; two clamping plates are arranged at the two ends of the rubber plate, and are fixedly connected with the two ends of the spring; airbags communicating with the air cavity are arranged on the two clamping plates; a second one-way valve is arranged in the communicating place of the air cavity with the airbags; and electromagnetic valves electrically connected with the PLC are arranged in the airbags. Commutators are clamped to prevent damage.

Owner:重庆晓微城企业孵化器有限公司

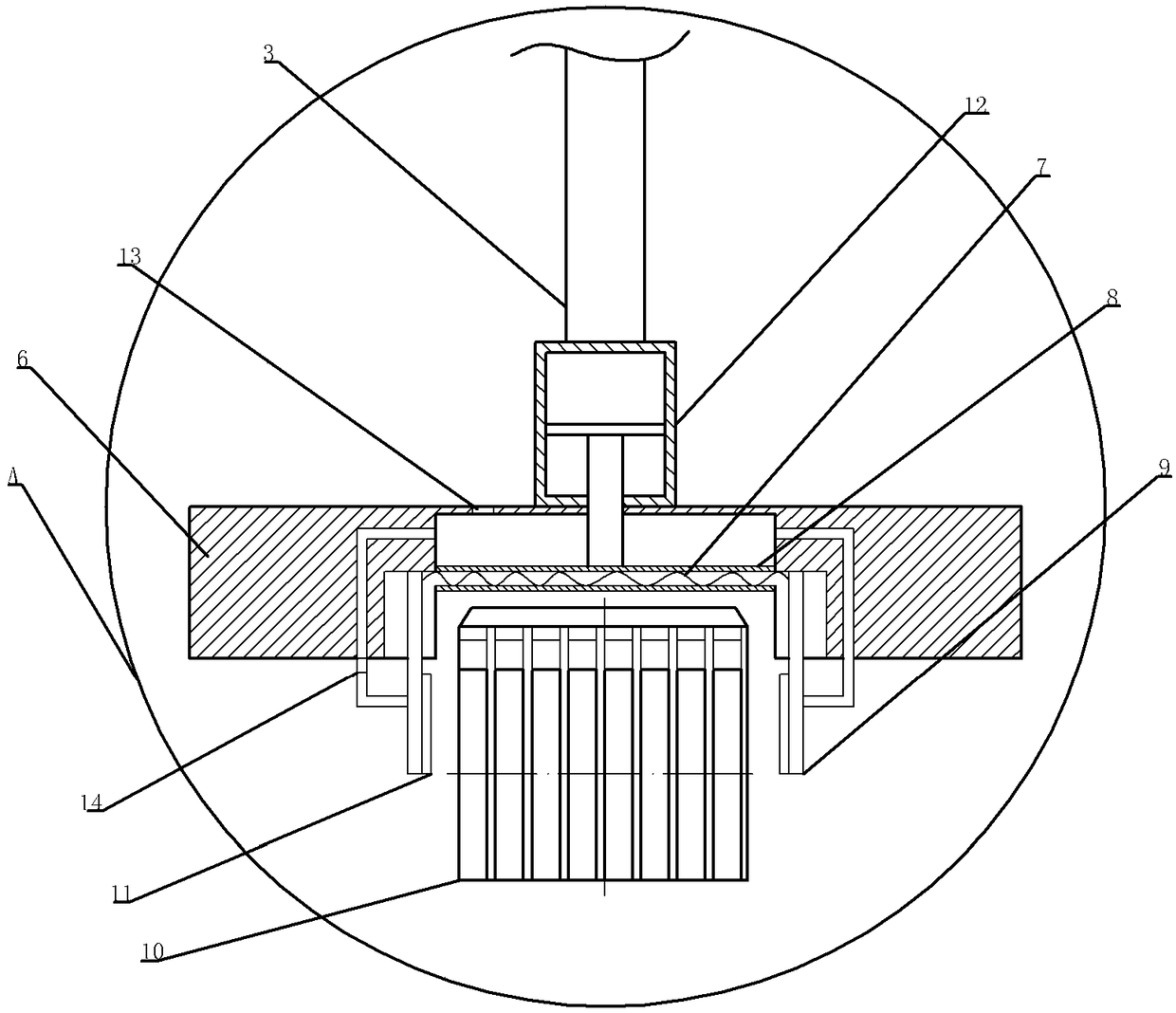

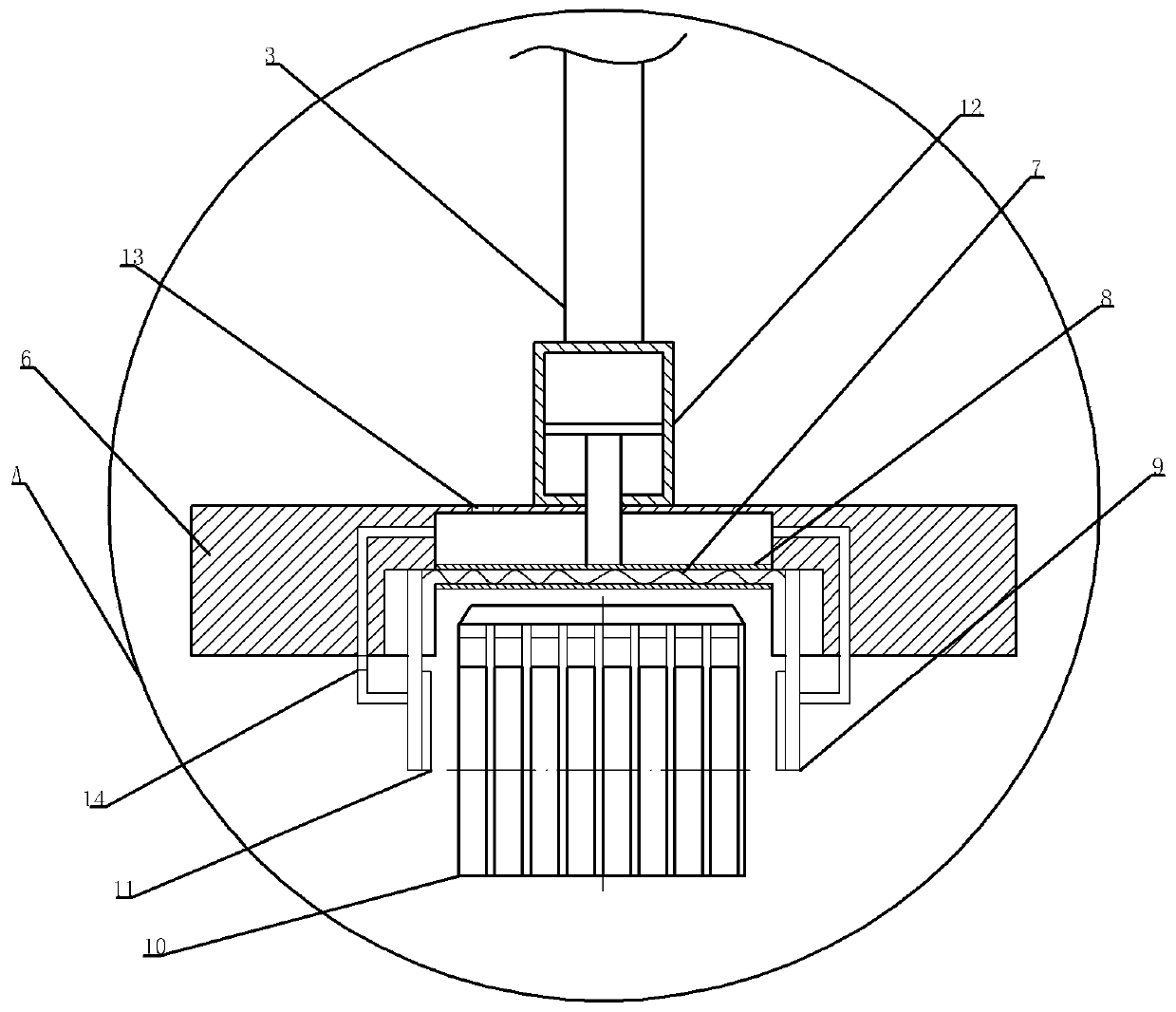

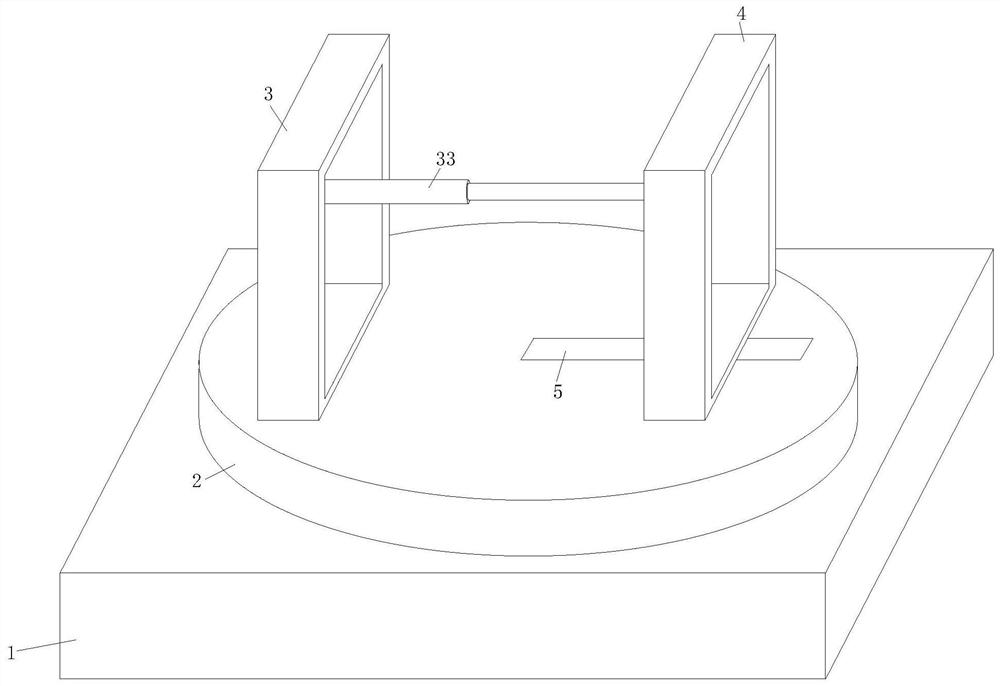

Adjustable clamp structure for steel pipe welding for steel structure buildings

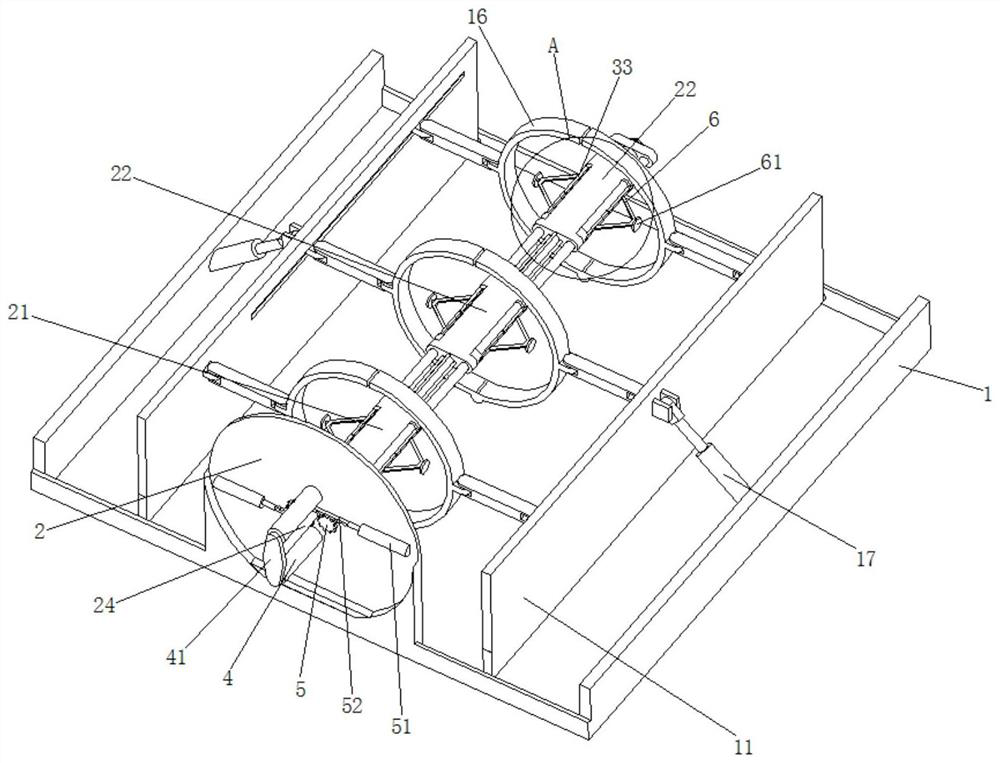

PendingCN112621086AEffective clampingAchieve the purpose of clampingWelding/cutting auxillary devicesAuxillary welding devicesThreaded pipeGear wheel

The invention relates to the field of steel structure buildings, in particular to an adjustable clamp structure for steel pipe welding for steel structure buildings. The adjustable clamp structure comprises a base, a rotary table, a first clamping mechanism, a second clamping mechanism and a sliding mechanism; the top of the base is rotatably connected with the rotary table, and the first clamping mechanism is fixedly mounted at the top of the rotary table; and the top of the rotary table is slidably connected with the second clamping mechanism through the sliding mechanism. According to the adjustable clamp structure for steel pipe welding for the steel structure buildings, by arranging a driving device, a worm wheel motor is used for promoting a gear vertical rod to drive a gear transverse rod to rotate through a worm, so that a threaded pipe drives a deflection rod to drive clamping plates to do lifting motion through a nut sleeve, the two clamping plates clamp a steel pipe, the adjustable clamp structure can effectively clamp steel pipes of different specifications, the purpose that the steel pipes of various different specifications can still be clamped is achieved, and the practicability of the adjustable clamp structure is improved.

Owner:湖南鸿云钢模科技有限公司

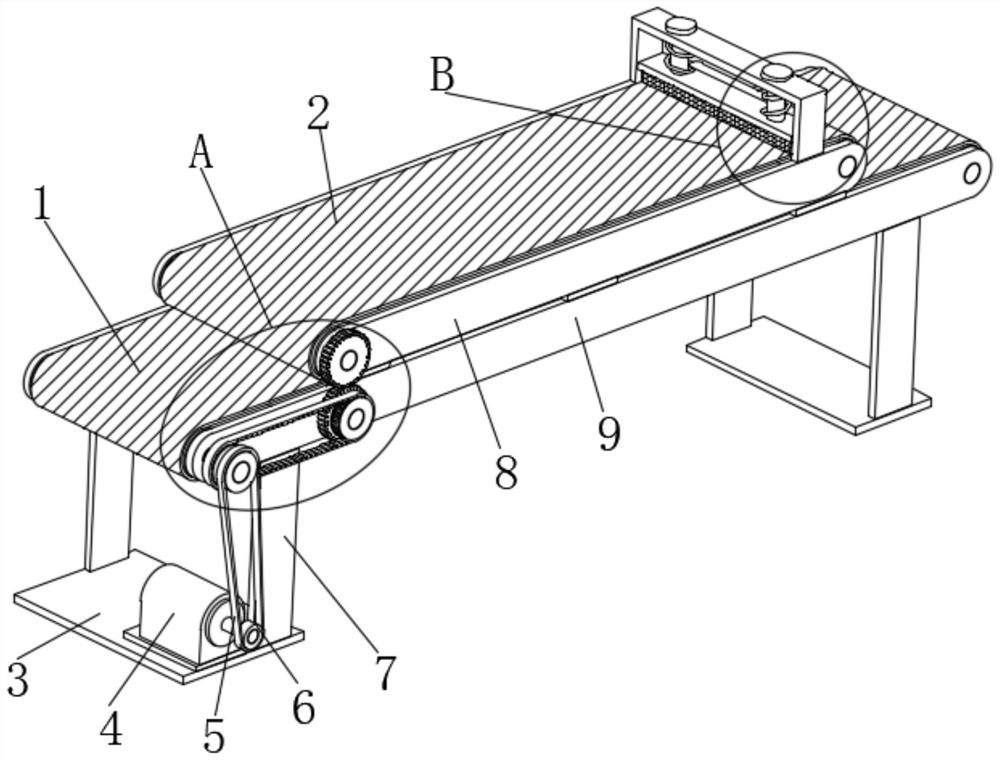

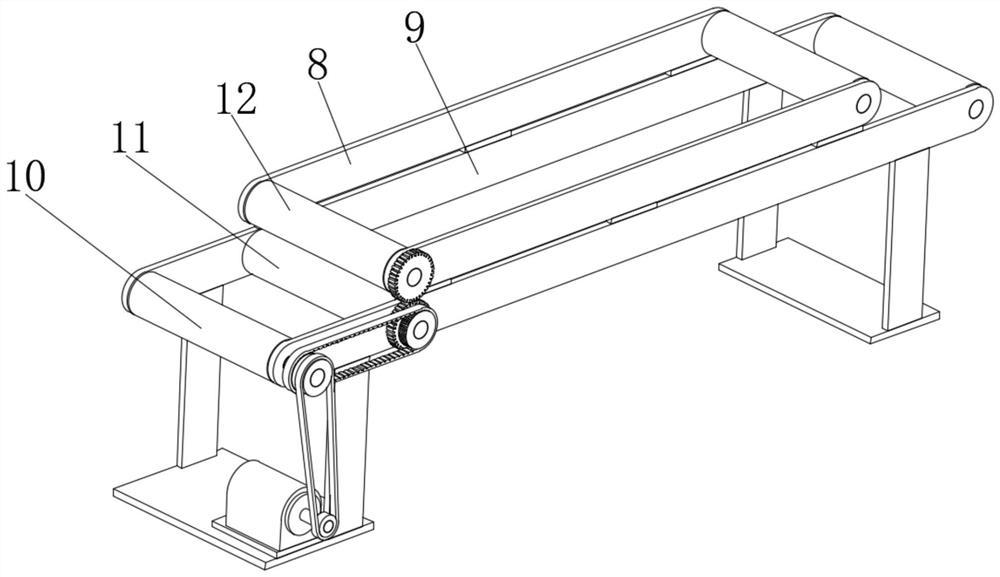

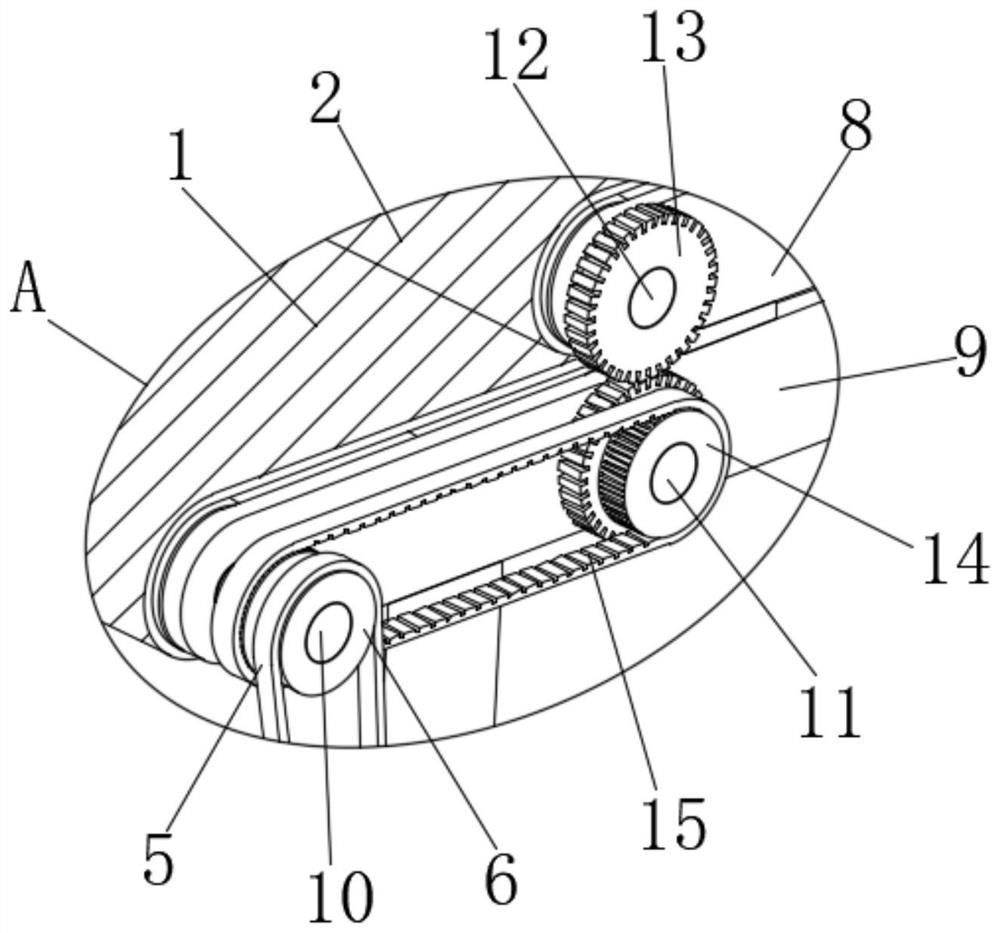

Conveying device for antibacterial mask production

PendingCN113526185APrevent fallingReasonable designCleaningArticle feedersManufacturing engineeringMechanical engineering

The invention relates to the technical field of mask production, in particular to a conveying device for antibacterial mask production. The conveying device comprises two second baffles, supporting parts are arranged at the bottoms of the second baffles, first rolling shafts are movably connected to the two ends of the two second baffles, and a lower conveying belt is connected between the first rolling shafts. A driving component is arranged at one end of the first rolling shaft, a connecting rolling shaft is further movably connected between the second baffles, a linkage component is arranged between the connecting rolling shaft and the first rolling shaft, a sweeping component is arranged above an upper conveying belt, gears are arranged at one end of a second rolling shaft and one end of the connecting rolling shaft, and the two gears are meshed with each other. The device is reasonable in design and convenient to operate, under the cooperation of the gears, a synchronous wheel, the upper conveying belt and the lower conveying belt, the situation that masks fall off under rapid conveying is prevented, and people can conveniently use the mask conveying device.

Owner:天津港保税区有维生物科技有限公司

A kind of rubber ball cleaning equipment for pet dogs

ActiveCN109482527BAchieve the purpose of scrubbingAchieve clearing effectCleaning using toolsCleaning using liquidsForeign matterElectric machinery

The invention relates to the technical field of pet ball cleaning equipment, and discloses a rubber ball cleaning equipment for pet dogs, which includes a casing. A transverse load-bearing plate is fixedly connected between the inner walls of the left and right sides of the casing. There are transverse movable slots on both sides of the surface. The inner sides of the two transverse movable slots are movably connected with transverse connecting movable blocks. The middle position of the inner bottom of the shell is fixedly connected with a transverse circulation drive mechanism. The transverse circulation drive mechanism is connected with two Horizontal connections connect movable blocks to each other. The invention changes the traditional human manual use of brushes to clean rubber balls by arranging a shell, a transverse load-bearing plate, a transverse circulation drive mechanism, a positioning movable clamp mechanism, a pressure adjustment mechanism, a small two-axis motor and a vertical guide slide rail to cooperate with each other. method, and at the same time effectively remove foreign matter in the tooth mark grooves on the surface of the rubber ball.

Owner:天长市富宝橡塑制品有限公司

Machine for machining pipeline compensating component

InactiveCN111545380AImprove efficiency and yieldImprove smudge effectSpraying apparatusEngineeringClassical mechanics

The invention relates to the field of pipe fitting machining, in particular to a machine for machining a pipeline compensating component. The machine comprises a base. A first clamp is inserted in thebase. A slot of an inclined structure is formed in one end of the first clamp. Slide grooves are formed in the first clamp symmetrically. Clamping plates are inserted in the slide grooves correspondingly. First hydraulic cylinders are fixedly connected into the first clamp symmetrically. Output ends of the first hydraulic cylinders are fixedly connected with one ends of the symmetrical clamping plates correspondingly. First lead screws and second lead screws are inserted in the base symmetrically. A movable plate is arranged on the first lead screws in an inserted mode and is in threaded connection with the first lead screws. The movable plate is symmetrically provided with through holes. The second lead screws penetrate through the symmetrical through holes correspondingly. One side of the movable plate is fixedly connected with a second clamp. The second clamp and the first clamp are symmetrically staggered. By means of the machine, metal corrugated pipes of different specificationscan be clamped, meanwhile the surfaces of the metal corrugated pipes are evenly smeared, and the yield of the metal corrugated pipes is improved.

Owner:HANGZHOU YAOYAO PHOTOVOLTAIC TECH CO LTD

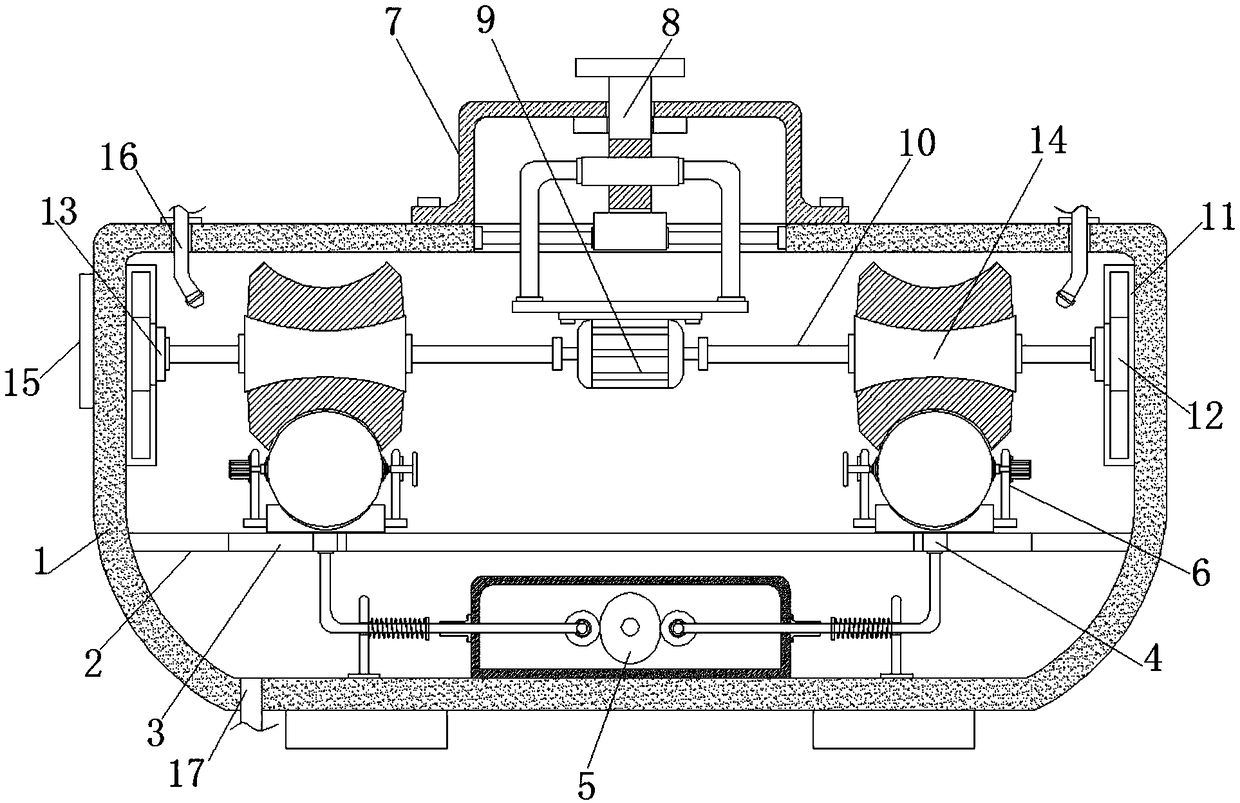

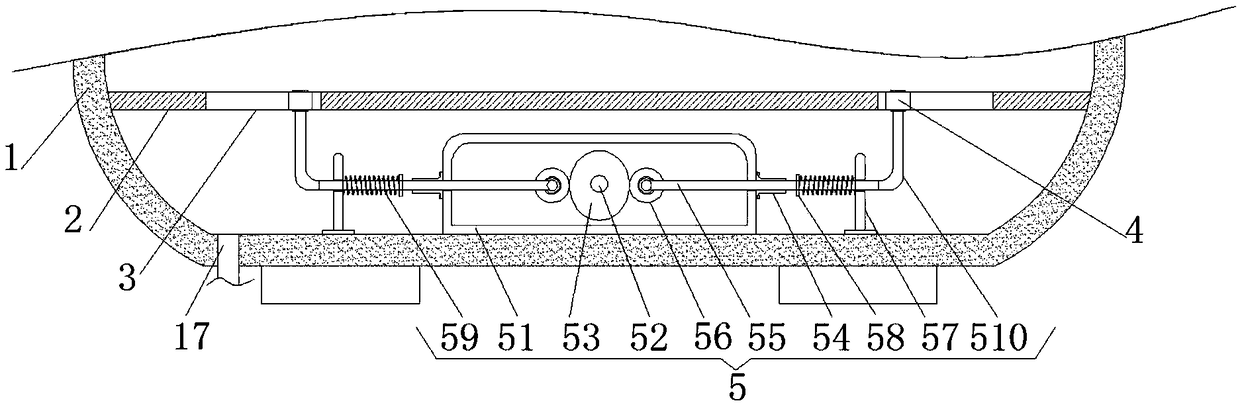

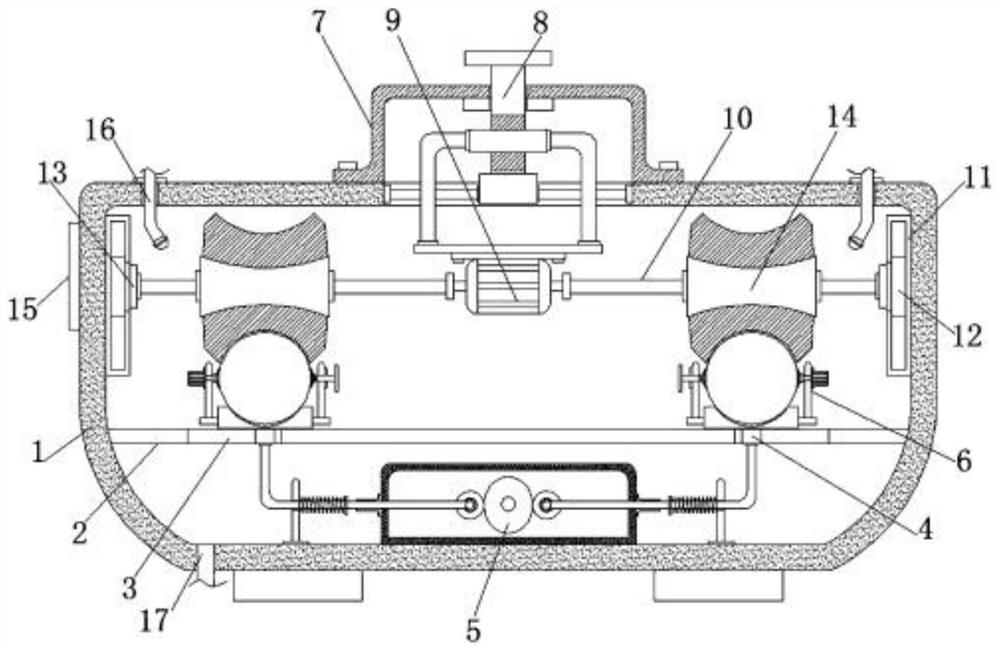

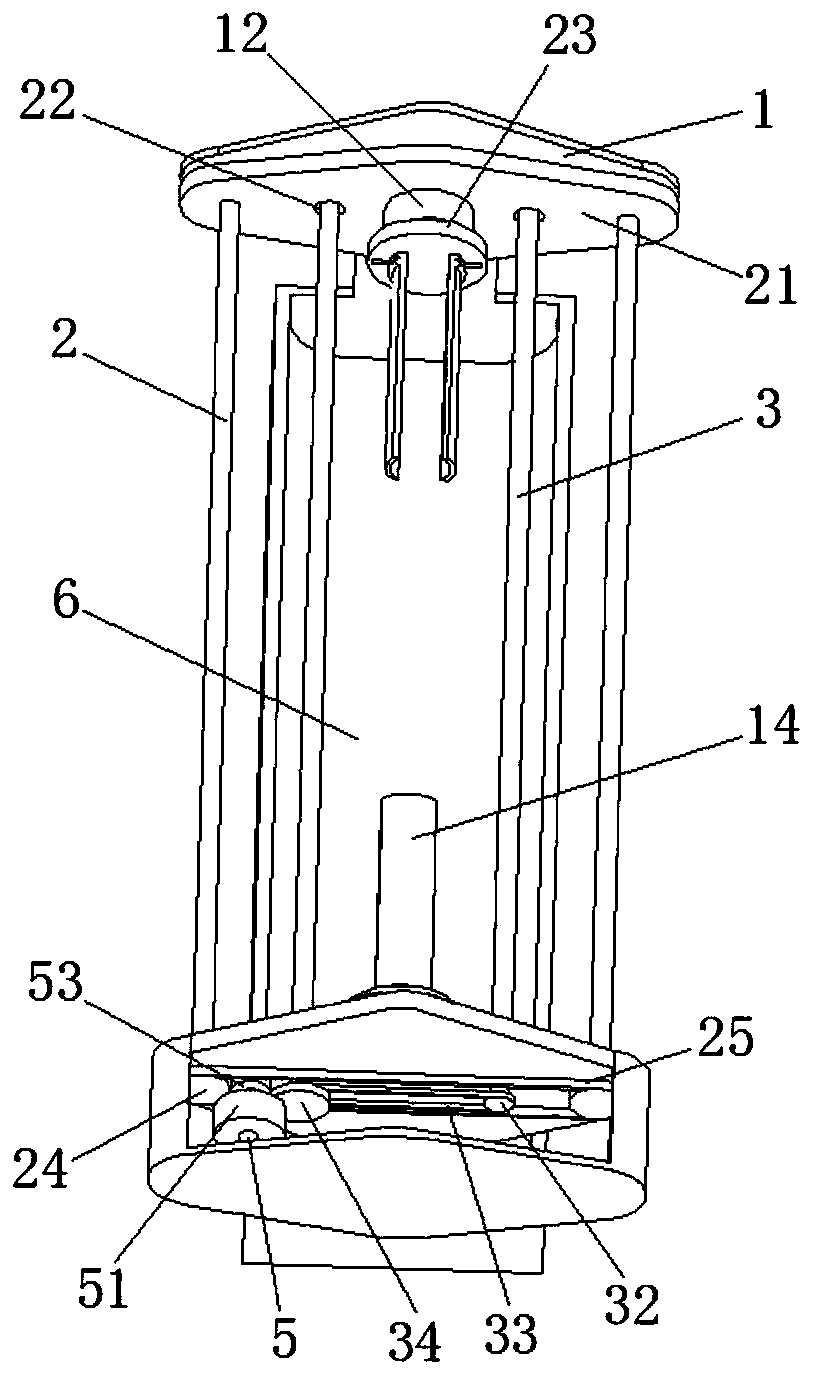

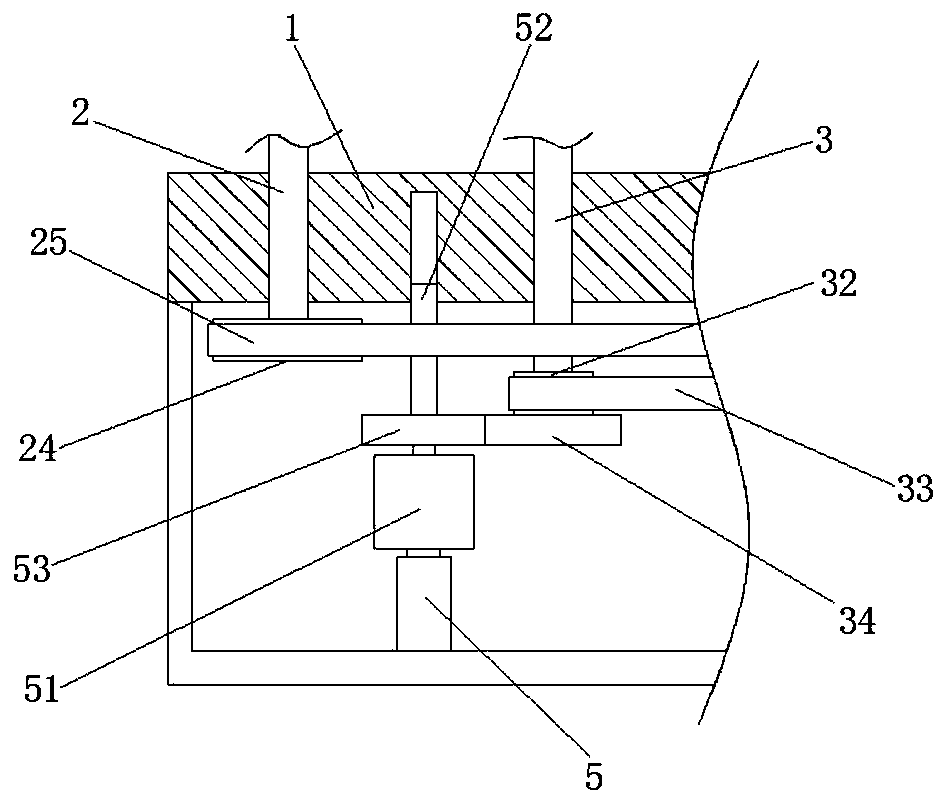

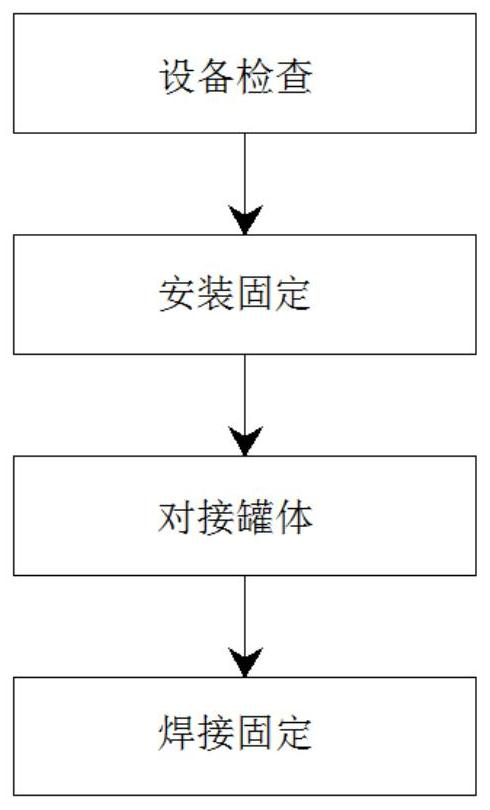

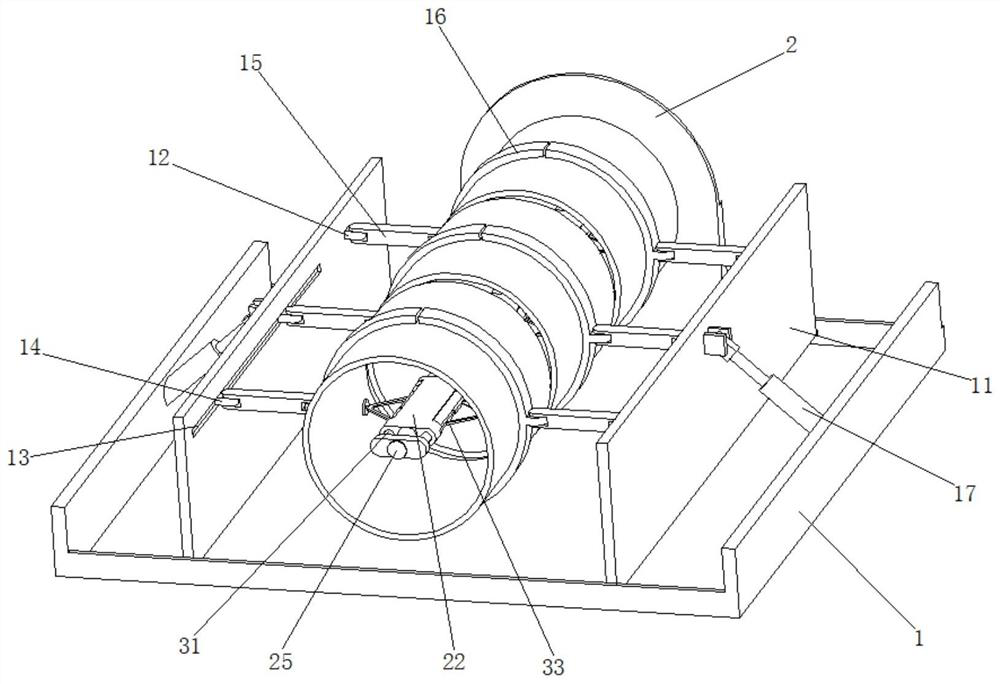

A manufacturing process for chemical storage tanks

ActiveCN111515572BGuaranteed accuracyEnsure stabilityWelding/cutting auxillary devicesAuxillary welding devicesChemical storageIndustrial engineering

The invention relates to a chemical storage tank manufacturing process, which uses a tank body assembly device, the tank body assembly device includes a fixed frame and a support frame, one side of the support frame is fixedly connected to a No. 1 module, and one end of the No. 1 module There is a No. 2 module, one end of the No. 2 module is symmetrically inserted with a number of spring telescopic rods, and inserting rods are inserted into the support frame. Both sides of the No. 1 module and the No. 2 module are symmetrically provided with movable slots, and the support frame is symmetrical. The screw nuts are inserted, and the screw nuts run through the support frame, the No. 1 module and the No. 2 module are inserted in the movable groove, and the sliders are set on the screw nuts and located in the movable groove, and the sliders are hinged. There is a telescopic frame, and one end of the telescopic frame is hinged on the No. 1 module and the No. 2 module. The invention can simultaneously clamp and dock a plurality of tank body parts, guarantee the precision of the docking at the same time, and is suitable for popularization.

Owner:惠州忠信化工有限公司

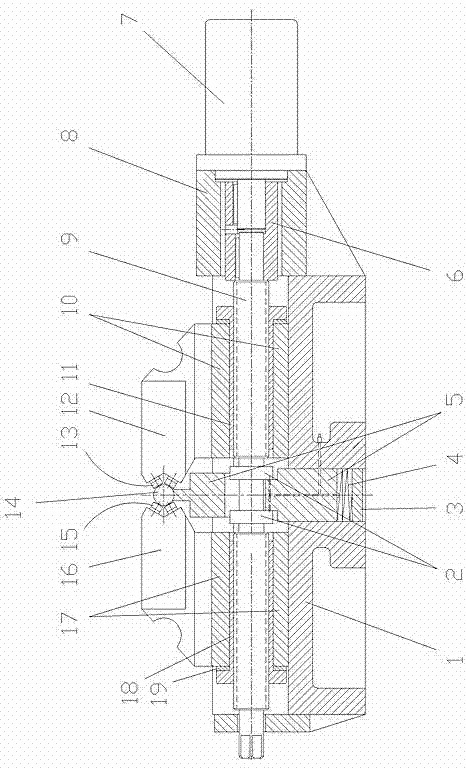

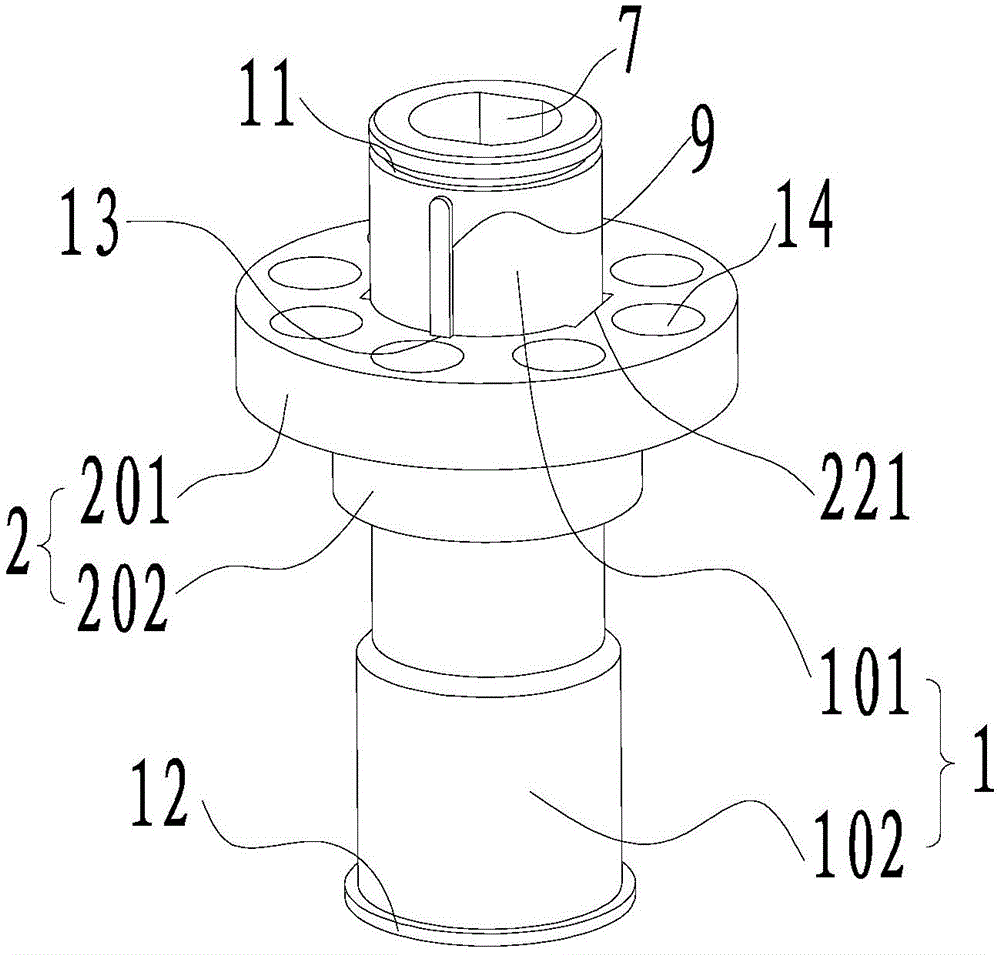

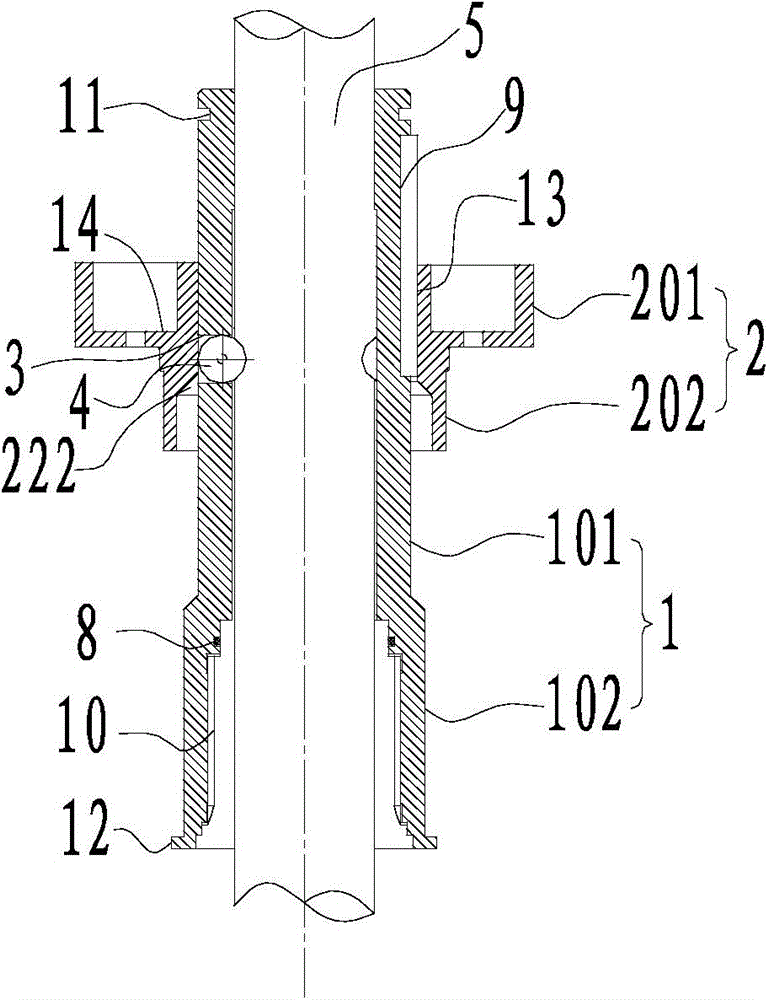

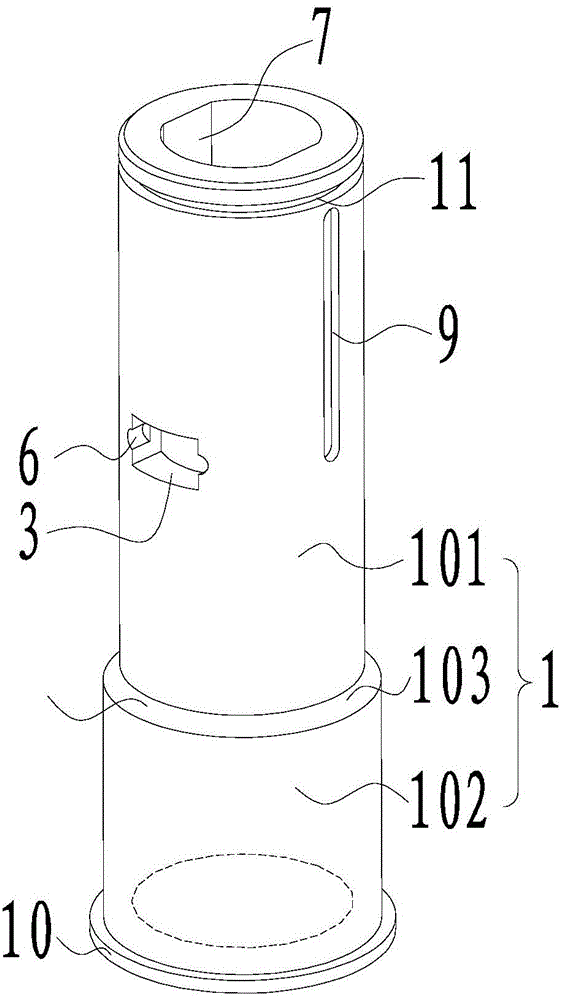

A clamping structure for a core drilling machine

InactiveCN103556958BGuaranteed verticalityBurying smoothlyDrilling rodsDirectional drillingEngineeringDrill pipe

A clamping structure for a core drilling rig, including a guide sleeve, the ring sleeve is outside the drill pipe of the drilling rig, used to transmit torque and ensure the straightness of the drill pipe; a collar, the ring sleeve is outside the guide sleeve and slides axially along the collar The drill pipe is clamped or released by pushing the moving parts or rolling parts; the rolling groove is opened on the guide sleeve to accommodate the moving parts or rolling parts and to position the moving parts or rolling parts, and the moving parts or The rolling part enters to clamp the drill pipe in the guide sleeve or withdraws to release the clamping of the drill pipe in the guide sleeve; the moving part or rolling part is set at the rolling groove between the guide sleeve and the collar, and is moved by the moving part or The way the rolling element rolls applies a clamping force to the drill rod of the drilling rig to clamp the drill rod, or moves in the opposite direction to release the clamping of the drill rod. The clamping structure clamps and releases the clamping of the drill pipe, and the effect of clamping and releasing the clamping of the drill pipe is better, the clamping is more reliable, and the operation is more timely.

Owner:CHANGSHA EXPLORATION MACHINERY FACTORY

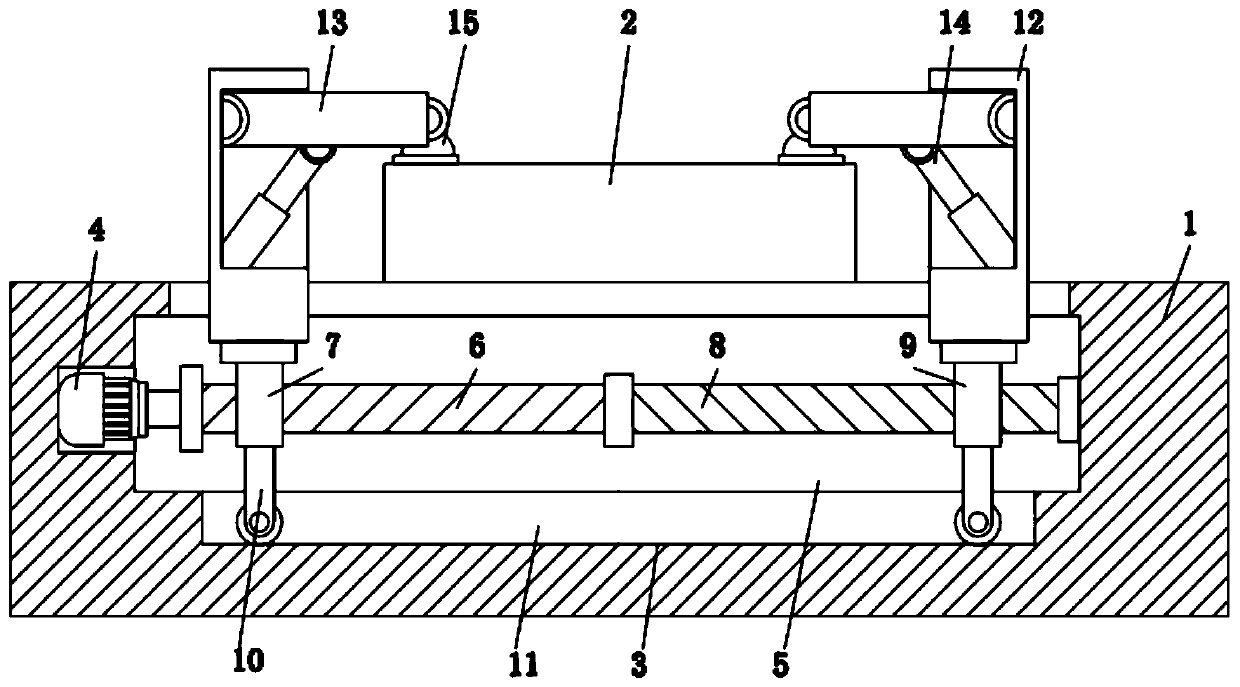

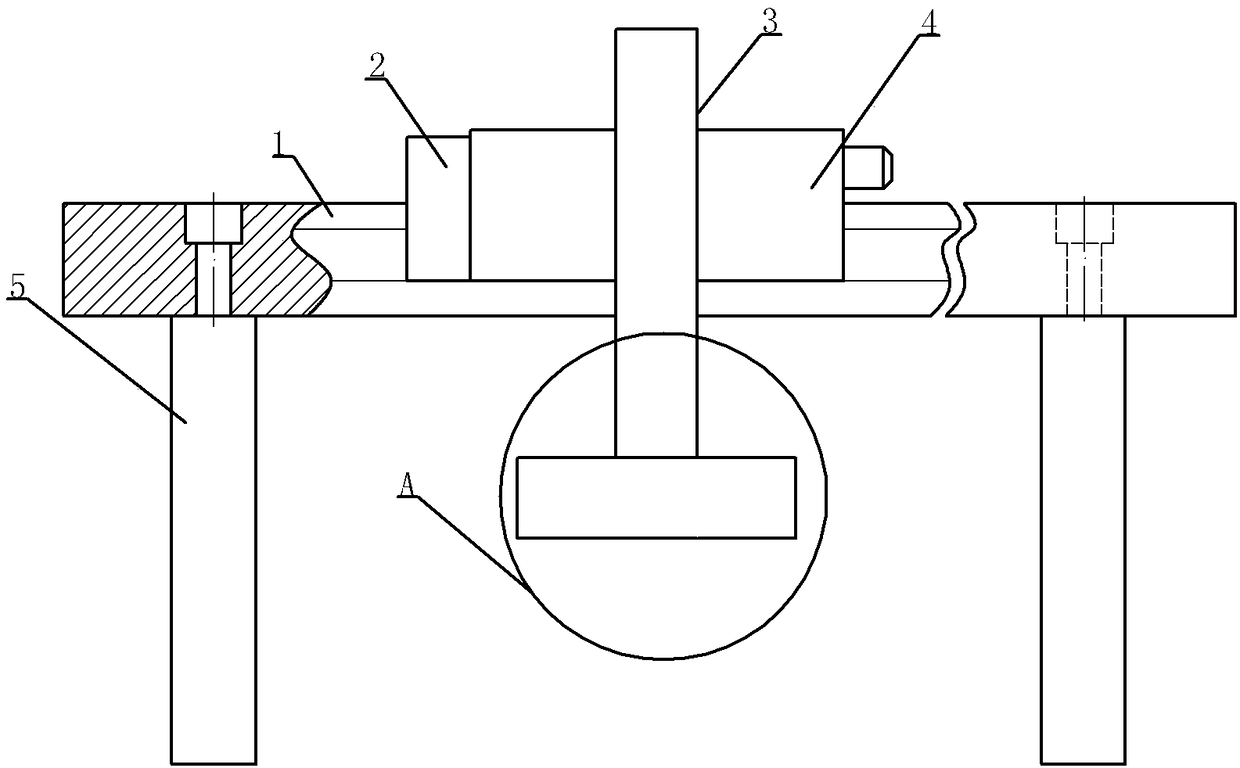

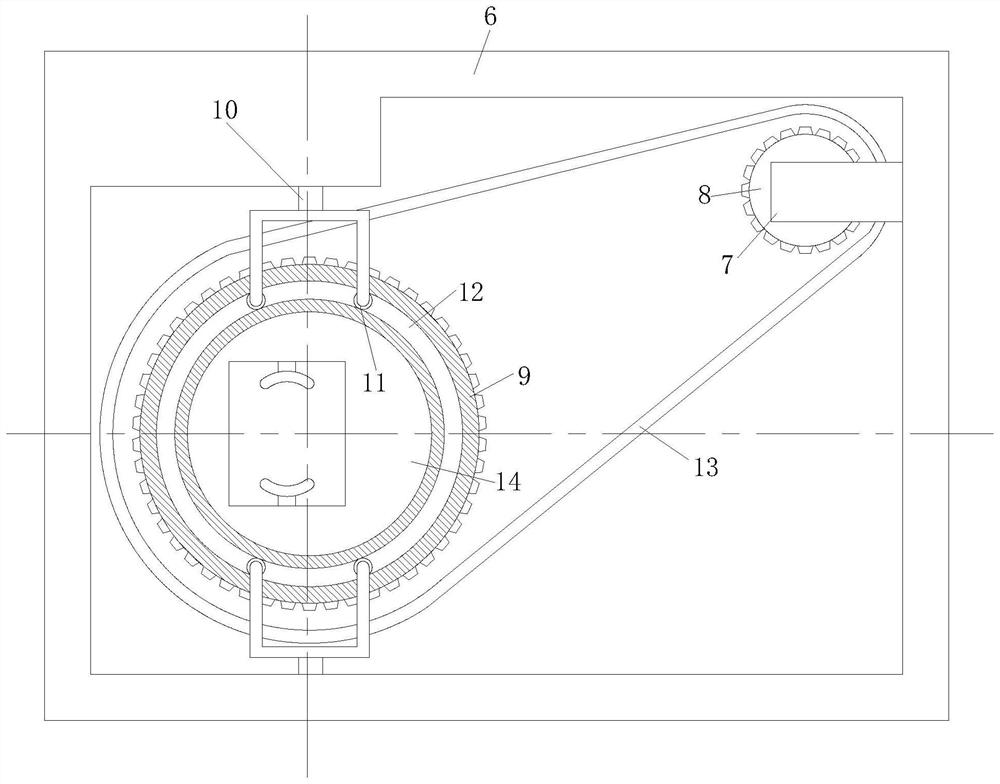

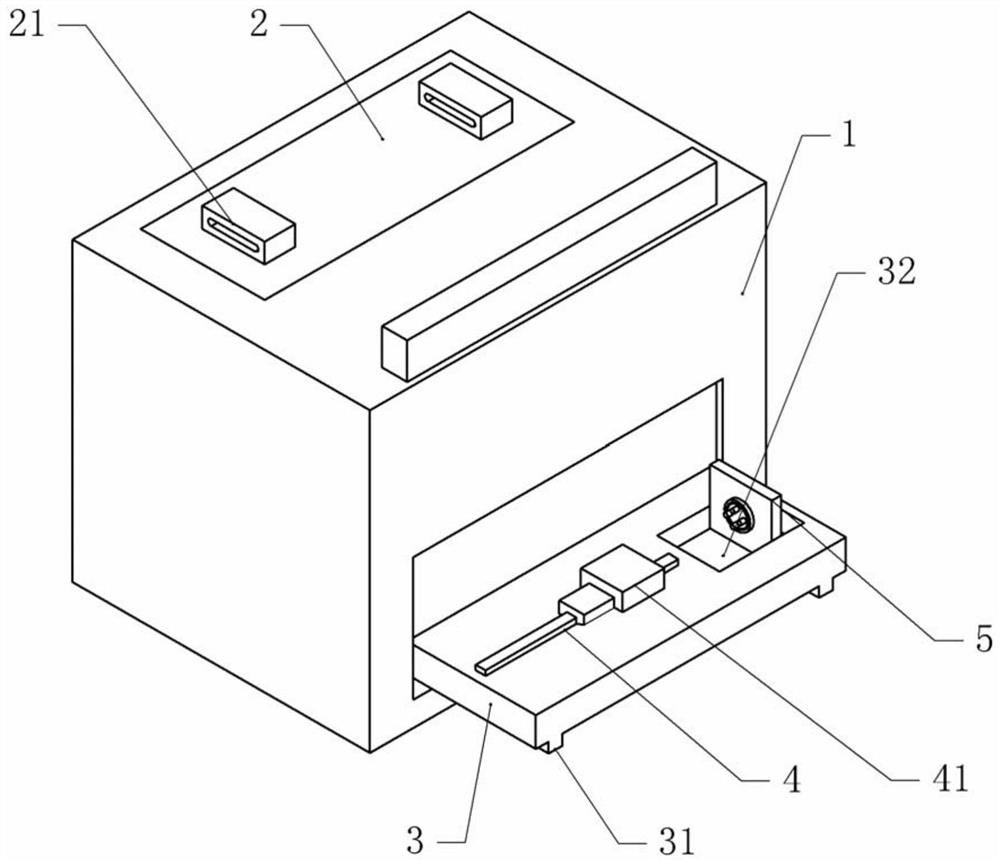

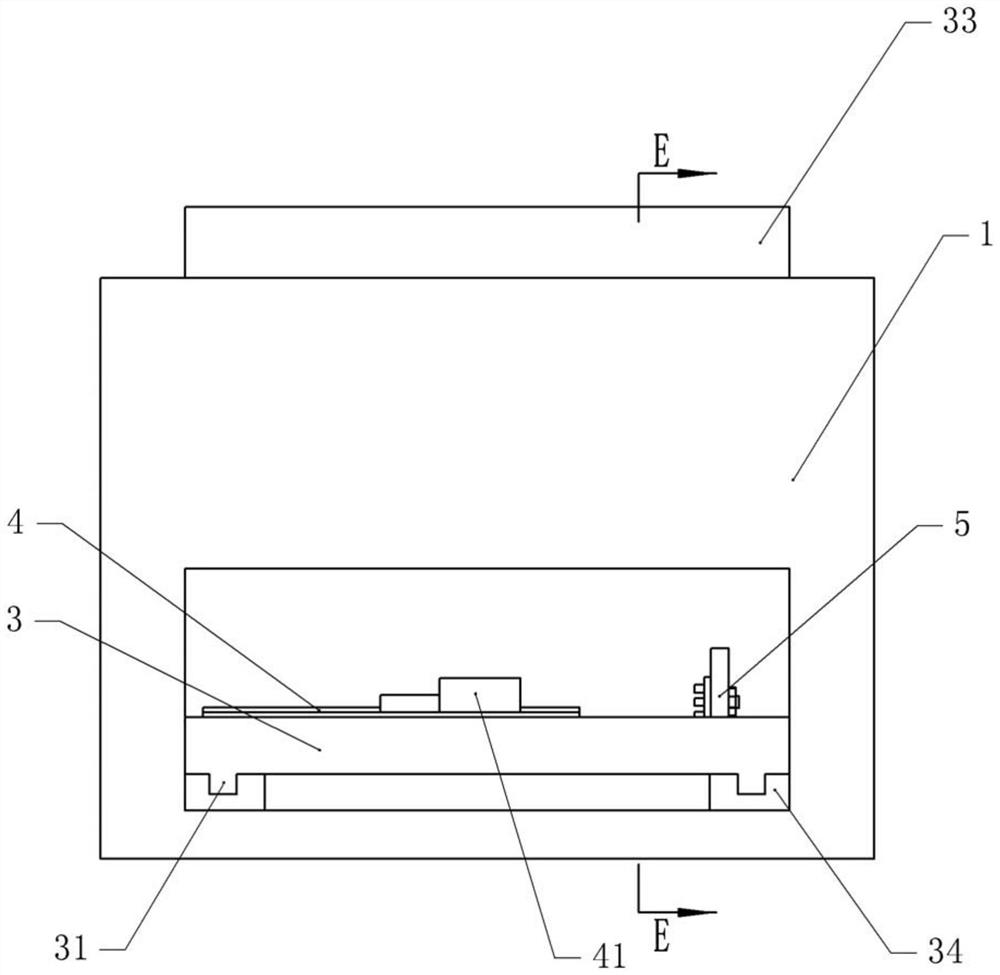

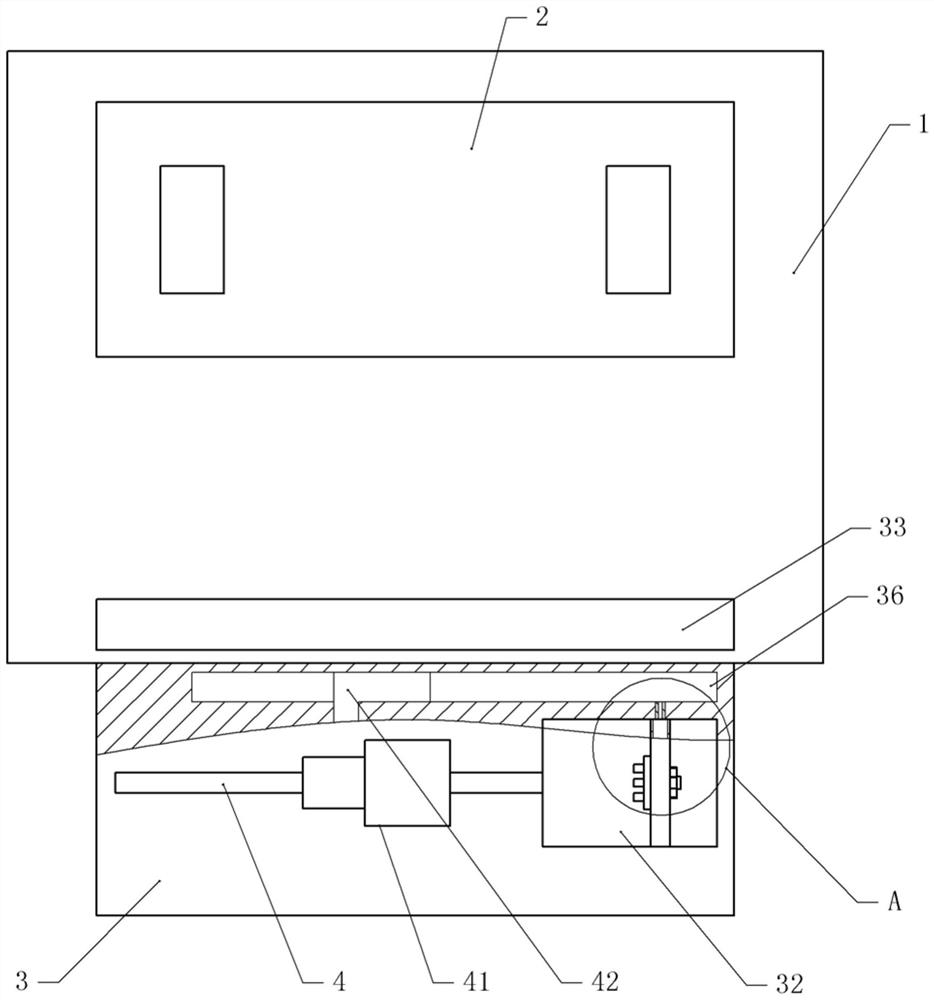

Clamp for machine tool

InactiveCN110948251ASimple structural designAchieve the purpose of clampingLarge fixed membersPositioning apparatusWorkcellMachine tool

The invention discloses a clamp for a machine tool. The clamp comprises an L-shaped supporting base (1), a workbench (2), a reference circle working unit arranged on the workbench (2) and a cutter (4)matched with the reference circle working unit; the workbench (2) is arranged on the L-shaped supporting base (1); an extension cutter rest (5) is arranged on the L-shaped supporting base (1); the extension cutter rest (5) is arranged above the reference circle working unit; and the cutter (4) is fixed to the extension cutter rest (5). The whole structural design of the clamp is simple and reasonable; all the components of the clamp are matched with one another; the use requirements of the machine tool can be met; and cutting or trimming is achieved.

Owner:黄光明

Portable LIBS component analyzer

PendingCN112198149AReduce tanglingImprove detection efficiencyAnalysis by thermal excitationInformation controlEngineering

The invention belongs to the technical field of material analysis and discloses a portable LIBS component analyzer. The portable LIBS component analyzer comprises a body; a first cavity, a second cavity and a third cavity are formed in the body; a storage battery pack is installed in the third cavity; a support is vertically connected into the first cavity in a sliding mode; a computer is fixed tothe support; a supporting plate is horizontally connected into the second cavity in a sliding mode; a linear module is arranged on one side of the supporting plate; an LIBS analyzer is arranged at the output end of the linear module; a distance sensor is fixed to the LIBS analyzer; a clamping assembly is arranged on the other side of the supporting plate. The portable LIBS component analyzer further comprises a controller electrically connected with the linear module and the distance sensor; the distance sensor acquires distance information between the clamping assembly and the LIBS analyzer;the controller acquires the distance information and judges the distance between the LIBS analyzer and the clamping assembly; the controller controls the linear module to adjust the distance betweenthe LIBS analyzer and the clamping assembly. The portable LIBS component analyzer is simple in structure; the computer and the LIBS analyzer are integrated, so that the portable LIBS component analyzer is convenient for an operator to use.

Owner:WENZHOU UNIVERSITY

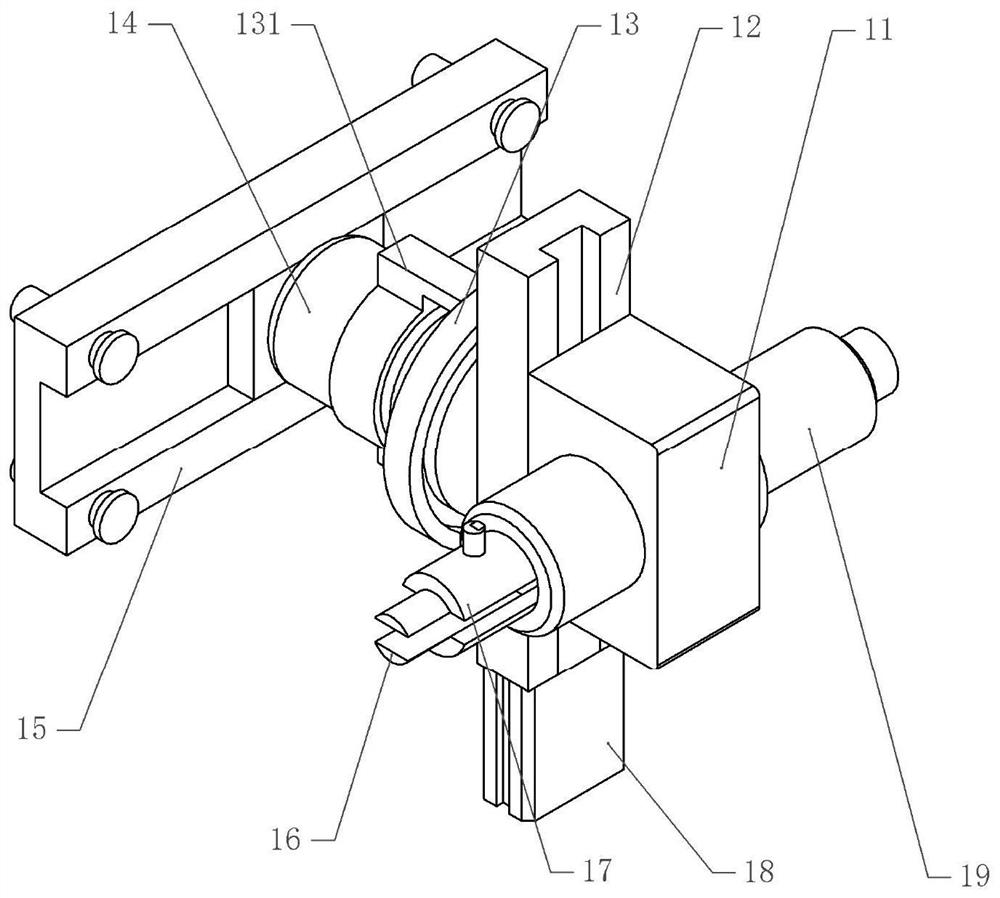

Dielectric film clamping and cutting device and method thereof

ActiveCN111941493BExquisite structureEasy to operateMetal working apparatusEngineeringMechanical engineering

The invention discloses a dielectric film clamping and cutting device and its method, comprising a substrate and an opening provided thereon, a fixed clamping assembly is fixed on the substrate, and the other end of the opening is provided with a The fixed clamping component slides and can clamp the sliding clamping component of the dielectric film, and the dielectric film clamped by the sliding clamping component and the fixed clamping component is parallel to the upper surface of the lower cover ; The substrate is also provided with a fixed cutting assembly located below the fixed clamping assembly for cutting the dielectric film clamped by the fixed clamping assembly, and the sliding clamping assembly is provided with There is a sliding cutting assembly for cutting the medium film clamped by the sliding clamping assembly. The beneficial effects of the present invention are mainly reflected in: realizing fully automatic tightening and fixed cutting of the dielectric film, simple and convenient operation, no need for manual operation, greatly improving work efficiency and reducing cost.

Owner:SUZHOU JEE INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com