Flexible stacking clamp capable of automatically clamping and classifying products

A flexible and automatic technology, applied in the stacking of objects, destacking of objects, and manufacturing tools, etc., it can solve the problems of limited application scope, inability to hold products in size, and product falling off, so as to achieve a wide range of applications and ensure safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

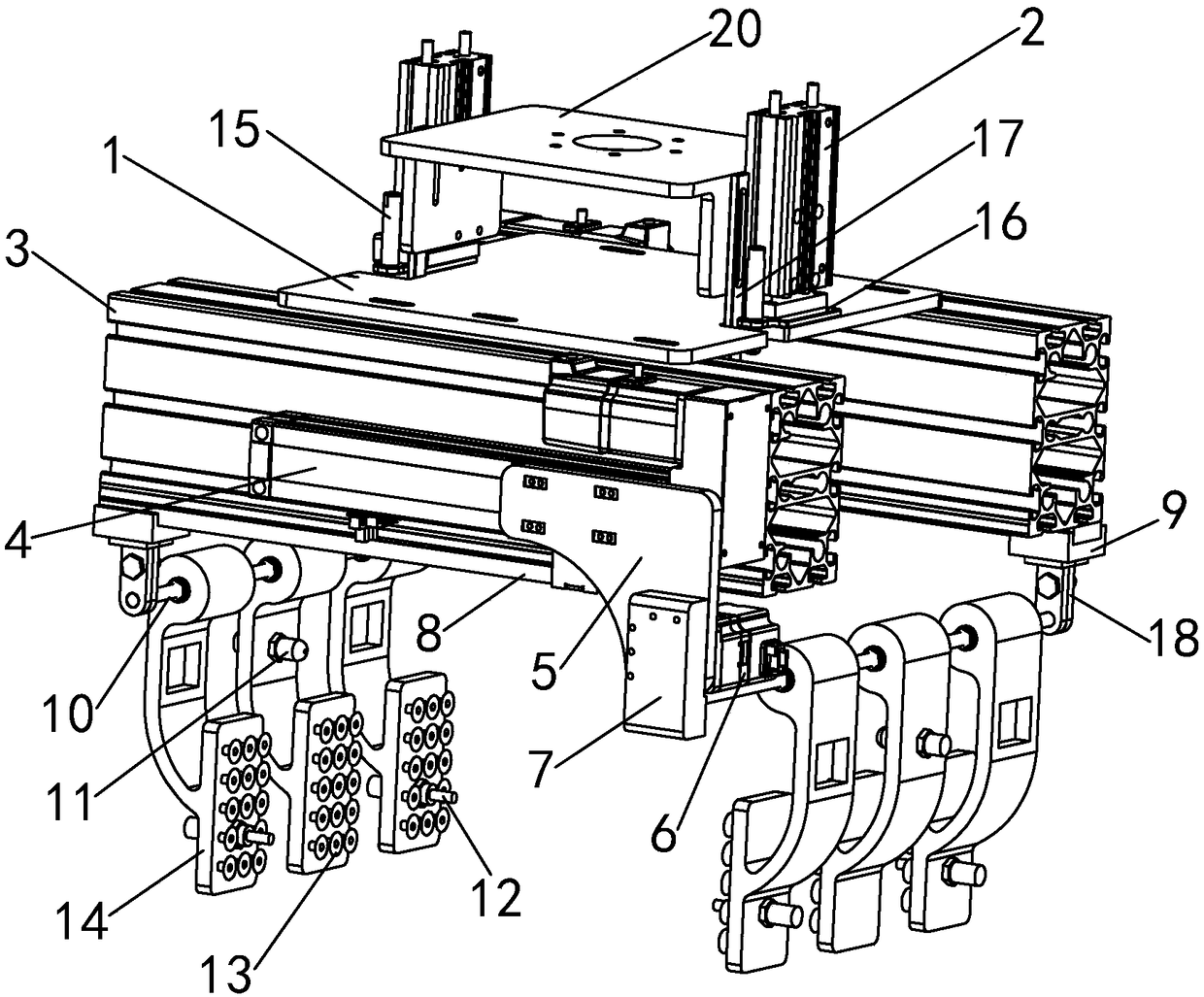

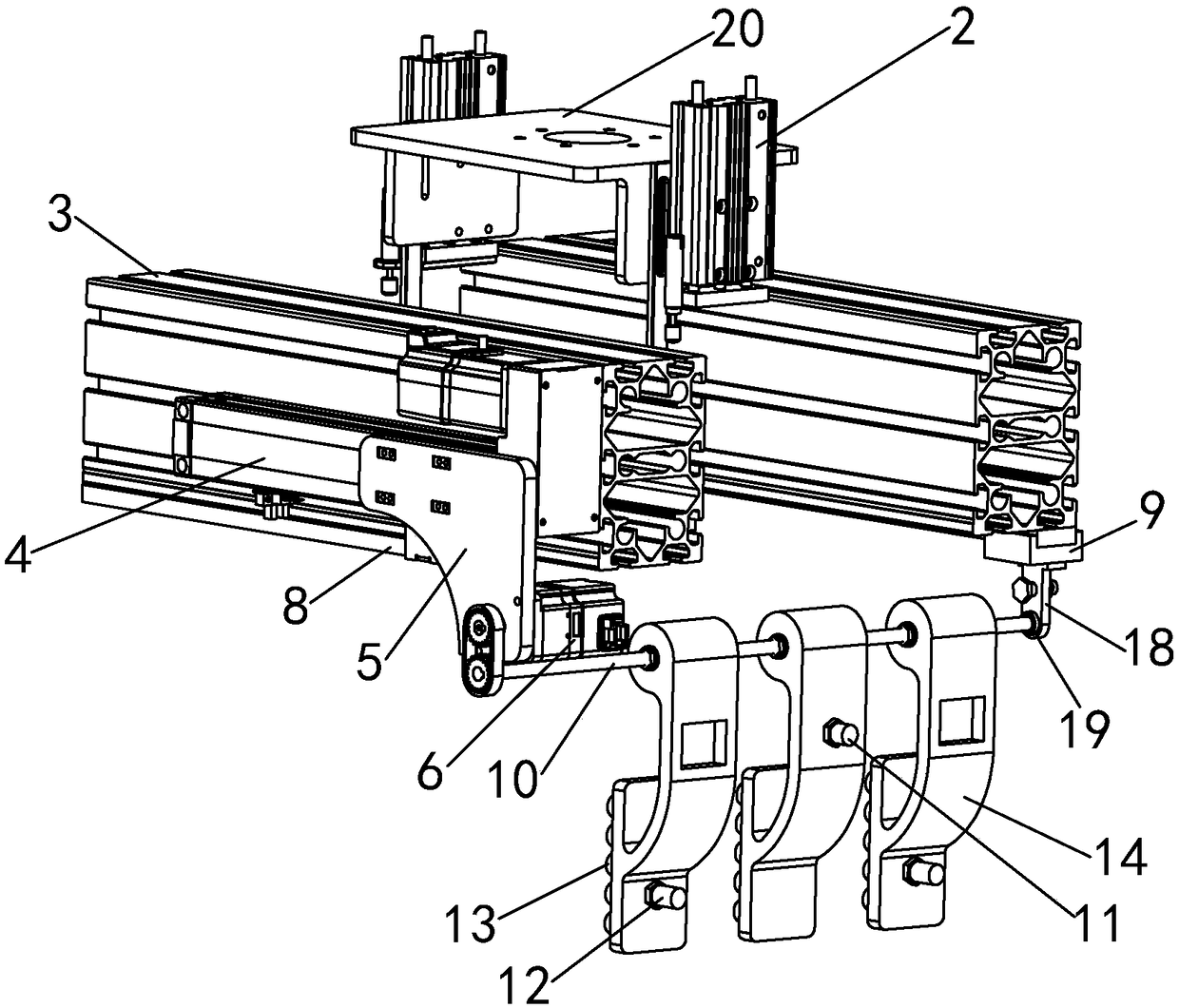

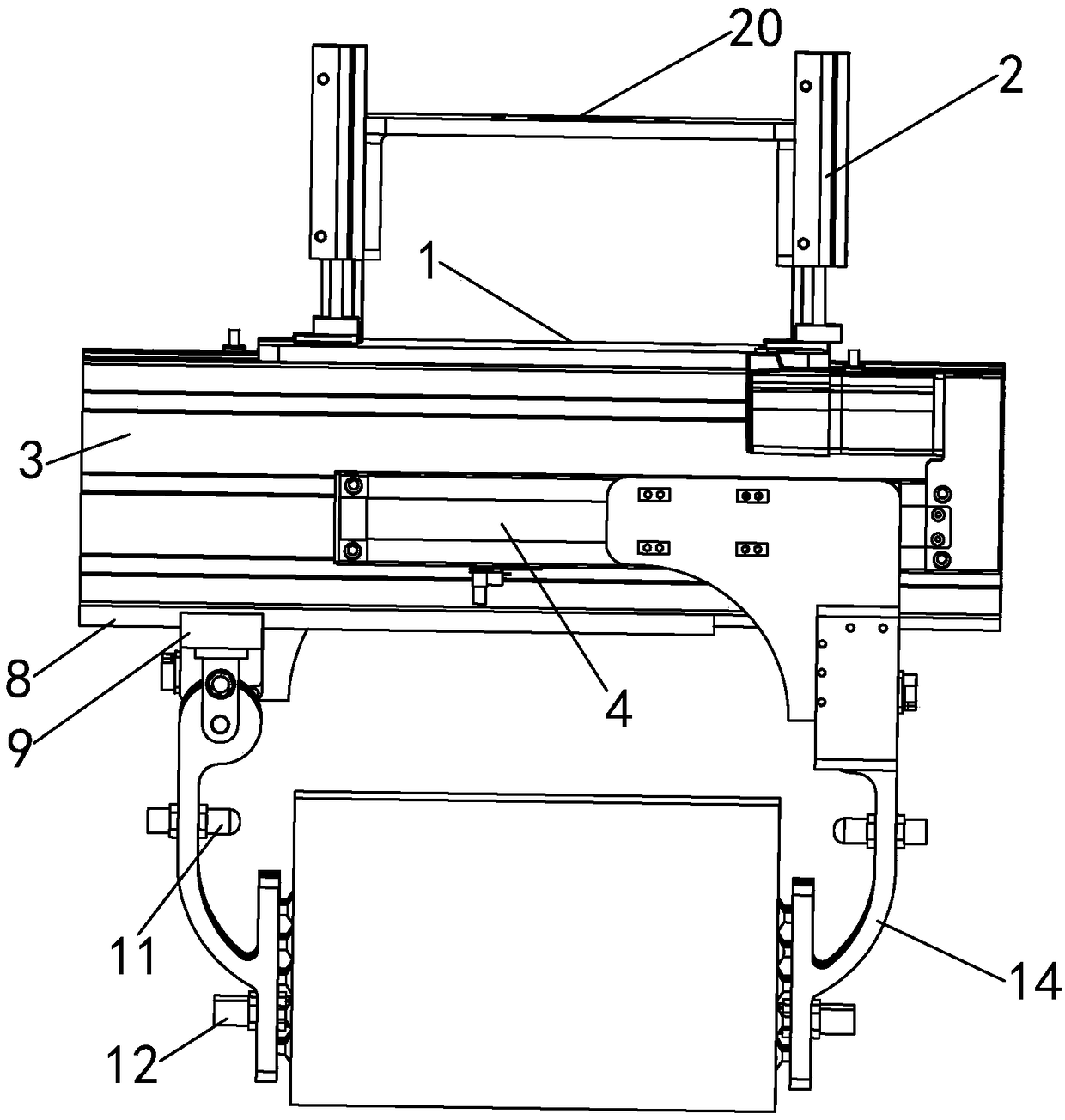

[0026] refer to Figure 1 to Figure 3 , the present invention is a flexible palletizing fixture that can be automatically picked up and classified, which includes a fixed plate 1, and the top and both sides of the fixed plate 1 are respectively provided with a drive device 2 that drives the fixed plate 1 to move up and down. The drive device 2 is preferably Cylinder, fixed part 3 is respectively provided on both sides of the bottom of the fixed plate 1, the fixed part 3 is made of aluminum profile, the fixed part 3 is fixed on the fixed part 1 by the hexagon socket head bolt and the lock nut, and the outer side of the fixed part 3 is installed Servo electric cylinder module 4, the moving ends of servo electric cylinder modules 4 on both sides are opposite in direction, and the moving end of servo electric cylinder module 4 is equipped with servo motor 6 and gear end cover 7 through connecting plate 5, servo motor 6 and The gear end cover 7 is fixed on the connecting plate 5 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com