Assistant machining clamping device for bearing inner rings

A technology of auxiliary processing and clamping device, used in positioning devices, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of insufficient processing accuracy of bearing inner ring, affecting the efficiency of processing bearing inner ring, bearing inner ring falling off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] This patent is discussed below according to the examples in the accompanying drawings of this patent.

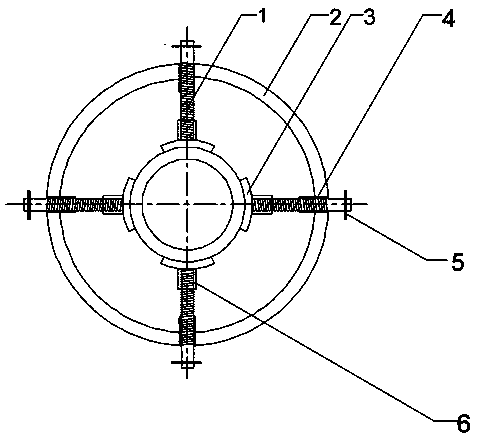

[0007] Referring to the accompanying drawings, this patent has a ring-shaped support frame (2), and four through holes are evenly distributed on the ring-shaped support frame (2), and a track (4) is welded on the through hole, and the track (4) has The screw thread that can fully cooperate with the lead screw (1), the length of the track (4) is greater than the depth of the through hole of the circular support frame (2) but less than 1 / 2 of the length of the lead screw (1). There is a rotating handle (5) on the lead screw (1), and the inside of the connection block (6) has a deep hole whose depth does not exceed three-quarters of the depth of the connection block (6), and there is a hole inside that matches the lead screw (1). The threads, the connecting block (6) and the buffer pad (3) are fixedly connected by glue. When clamping the inner ring of the bearing, place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com