Patents

Literature

38results about How to "Control the clamping force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

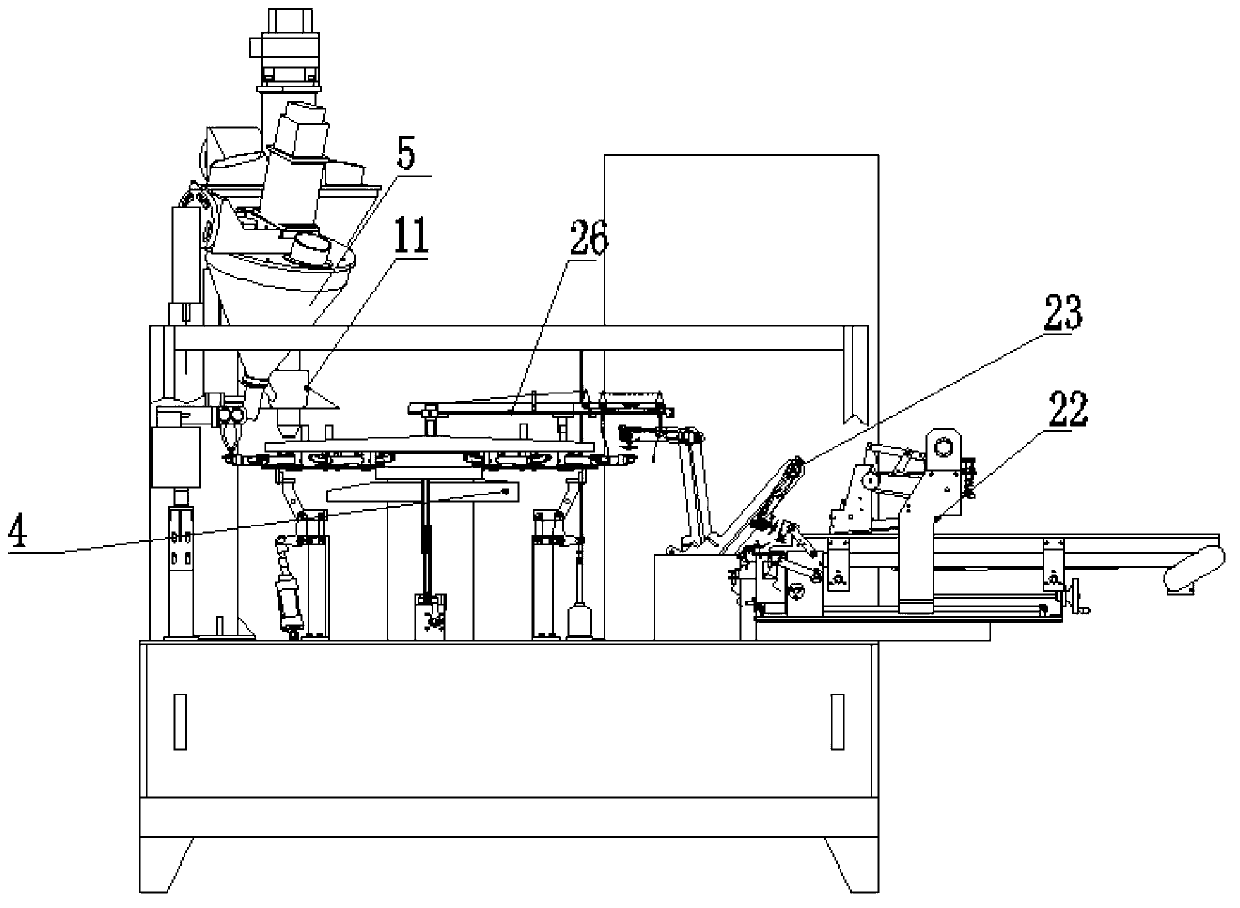

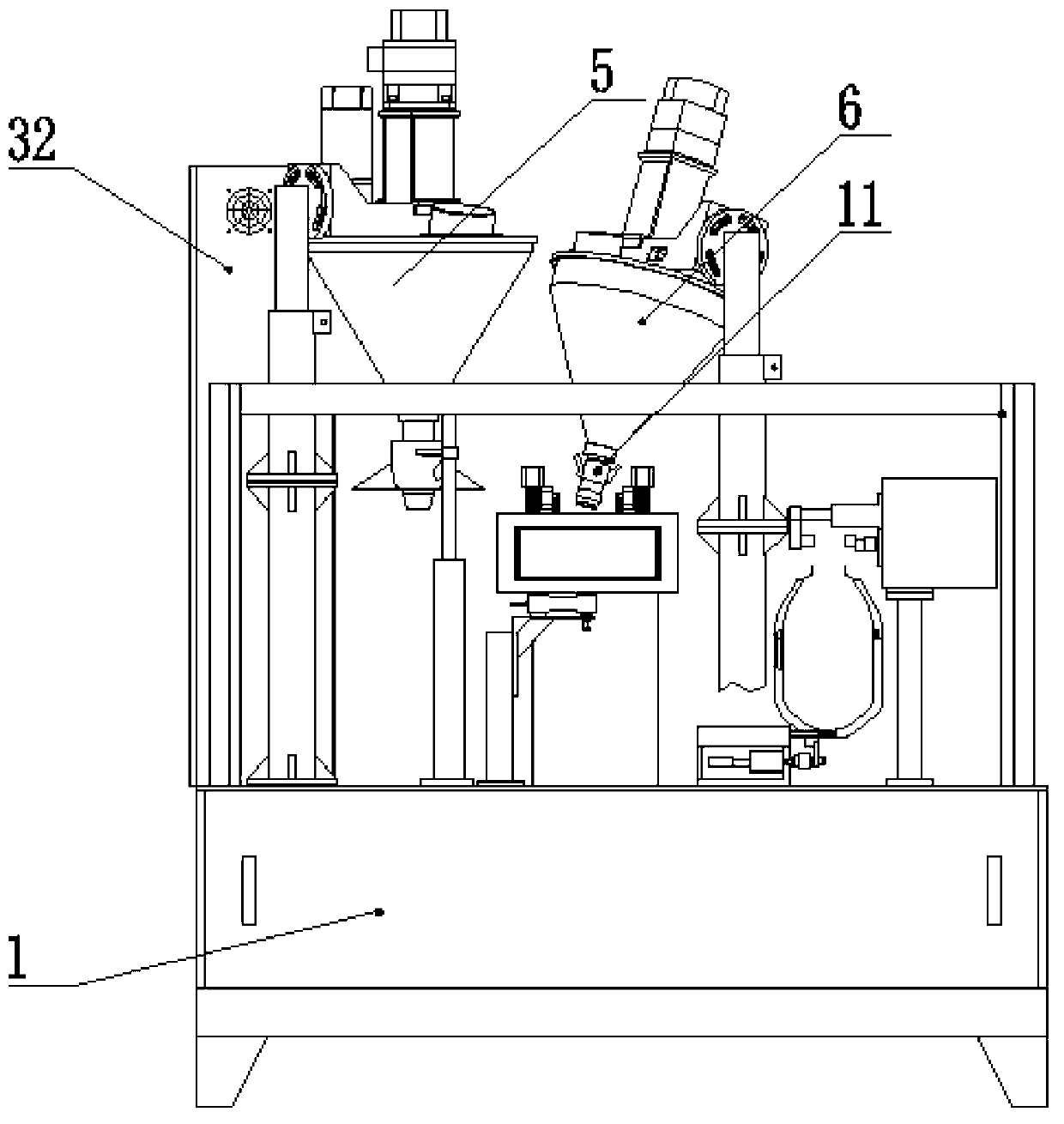

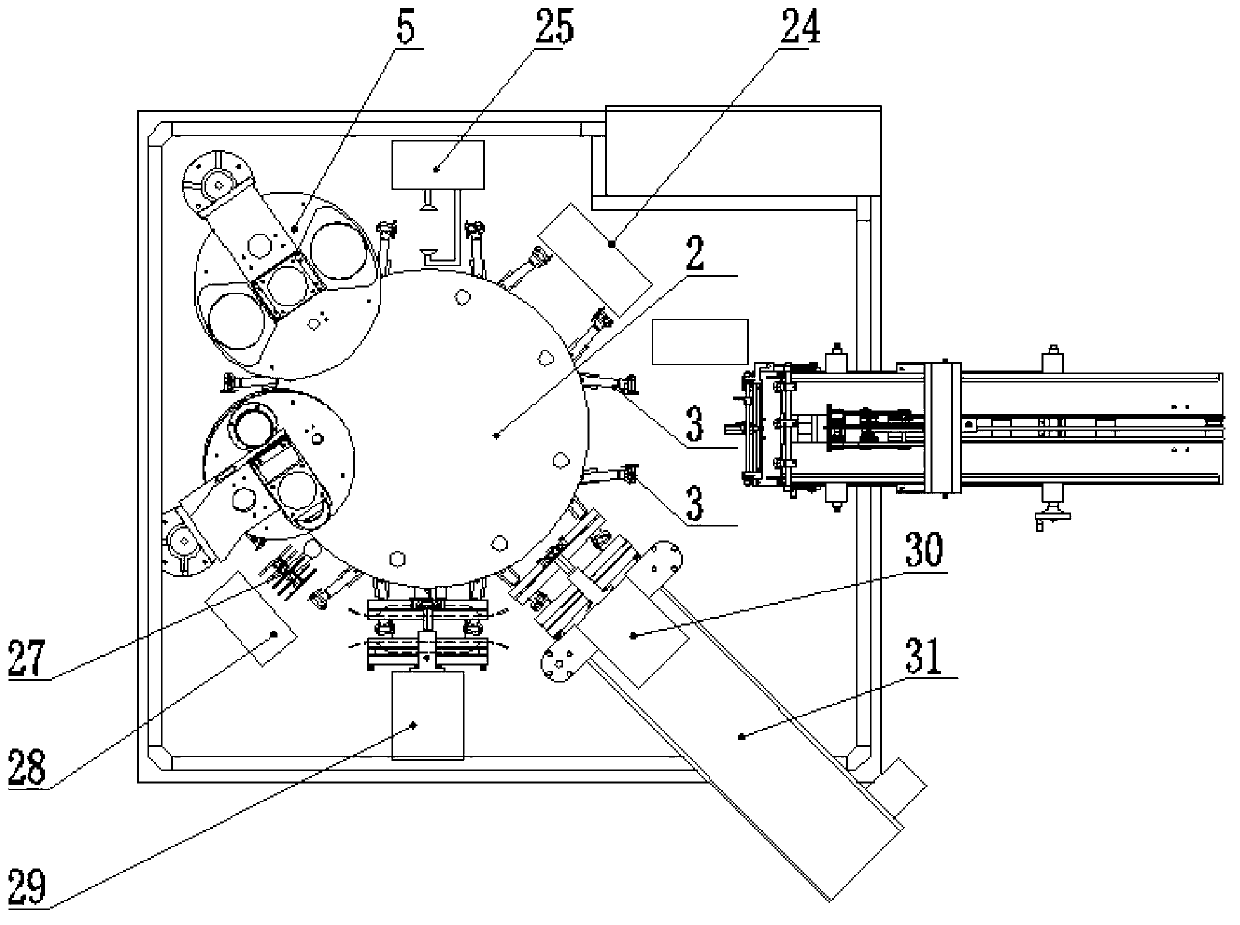

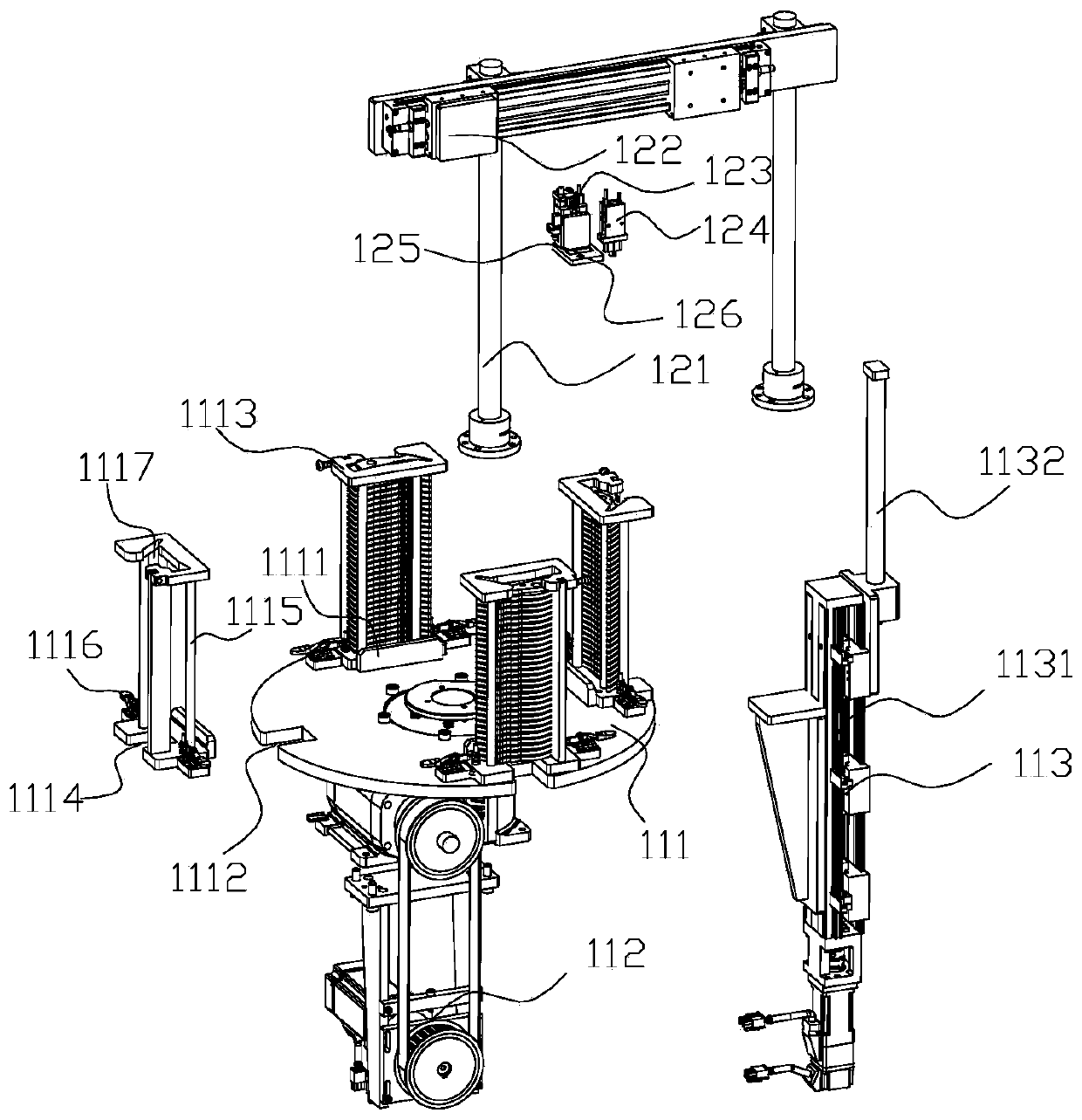

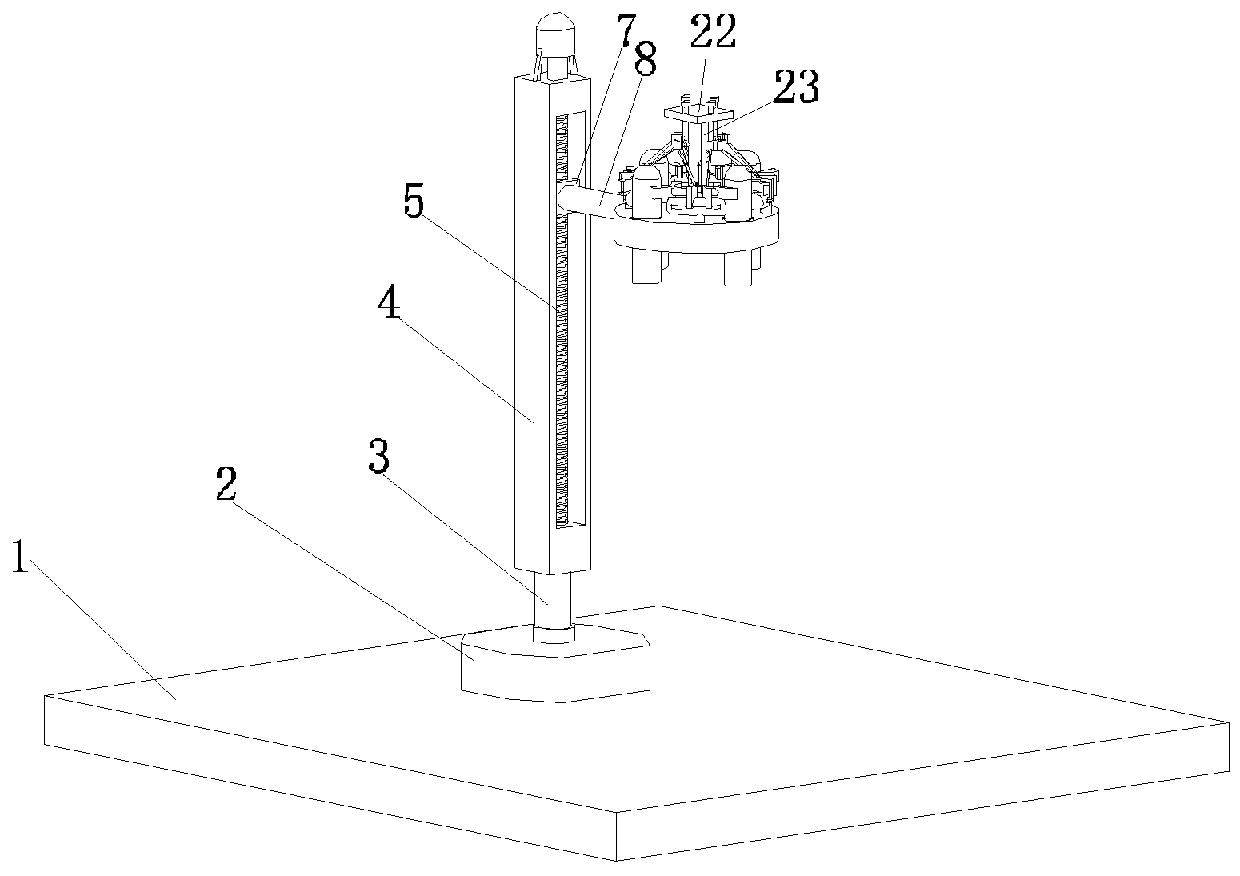

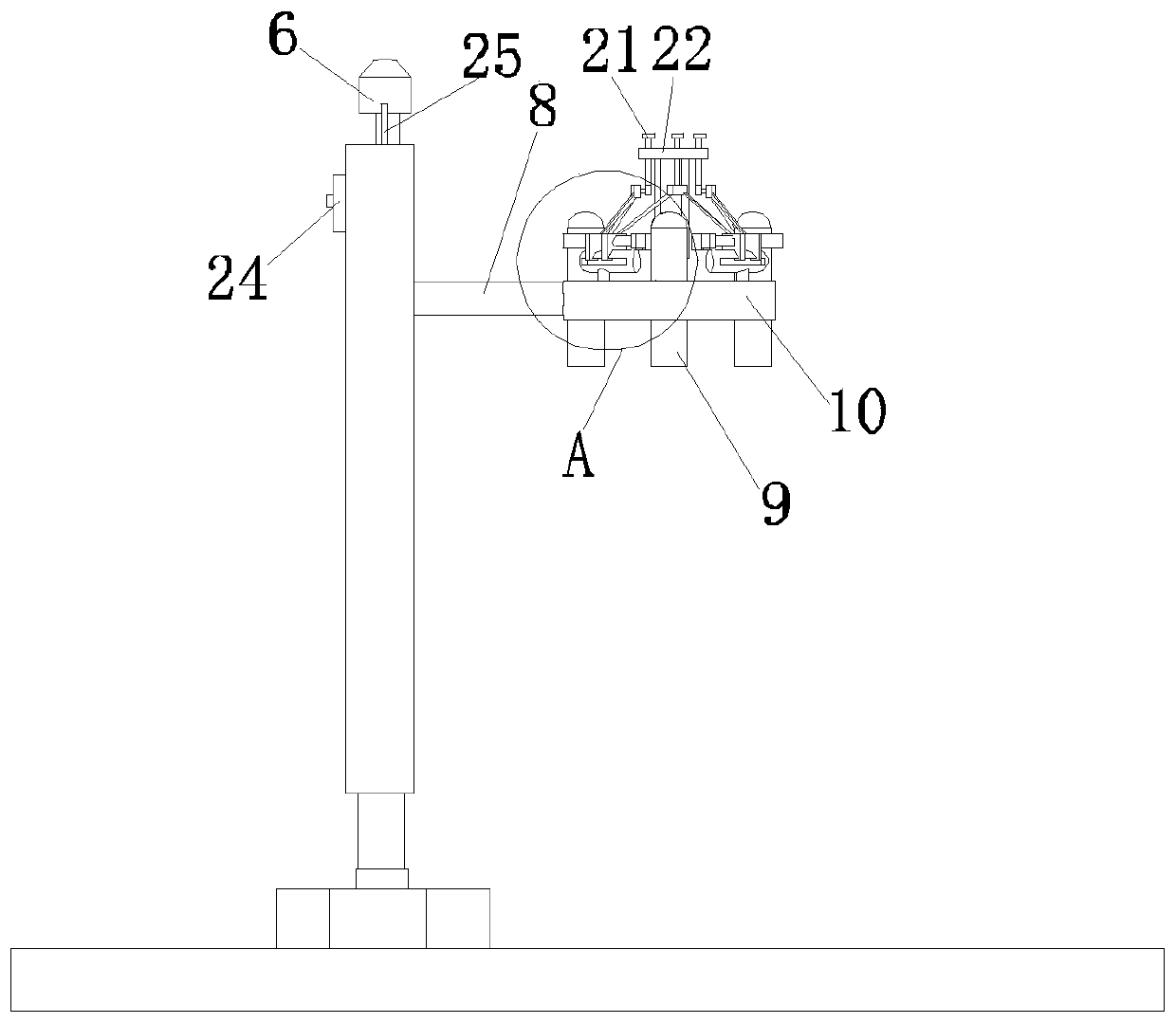

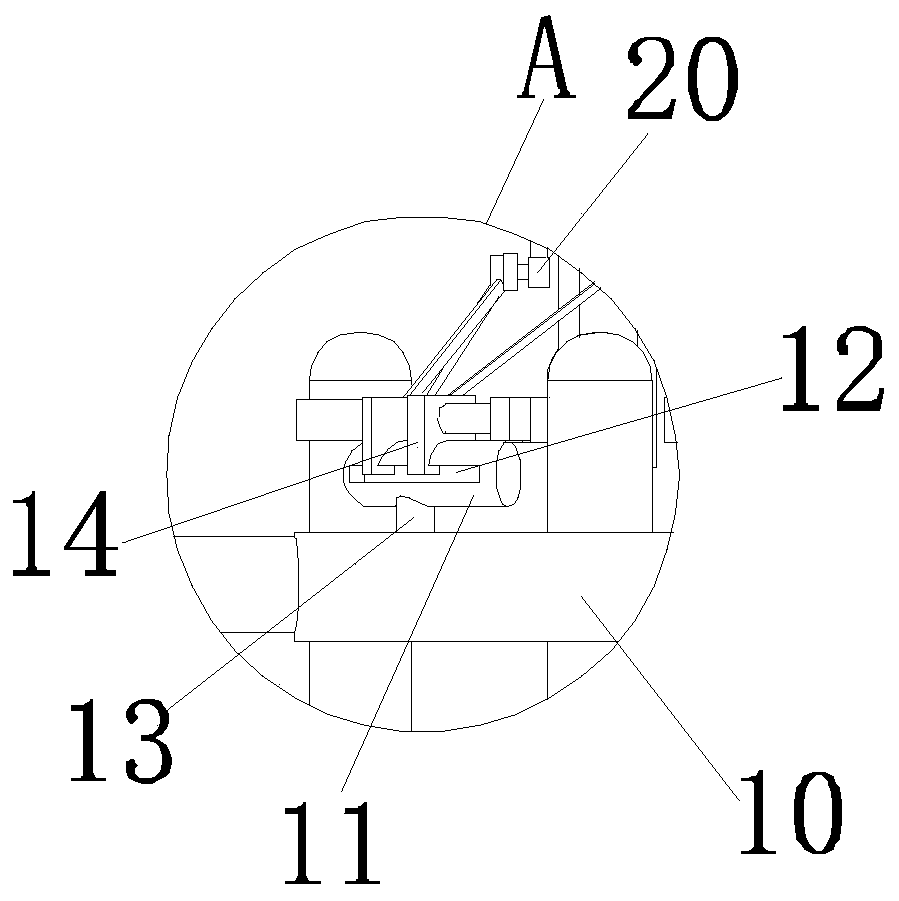

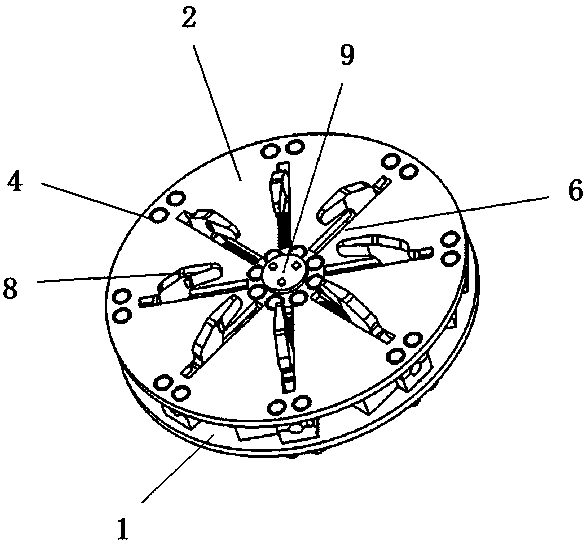

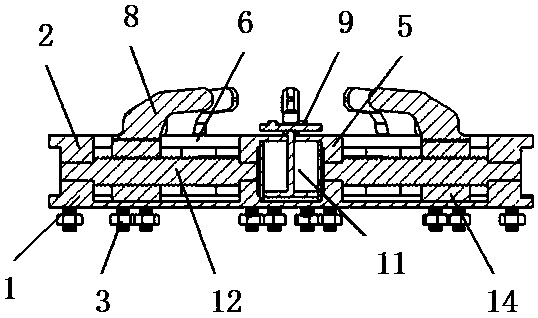

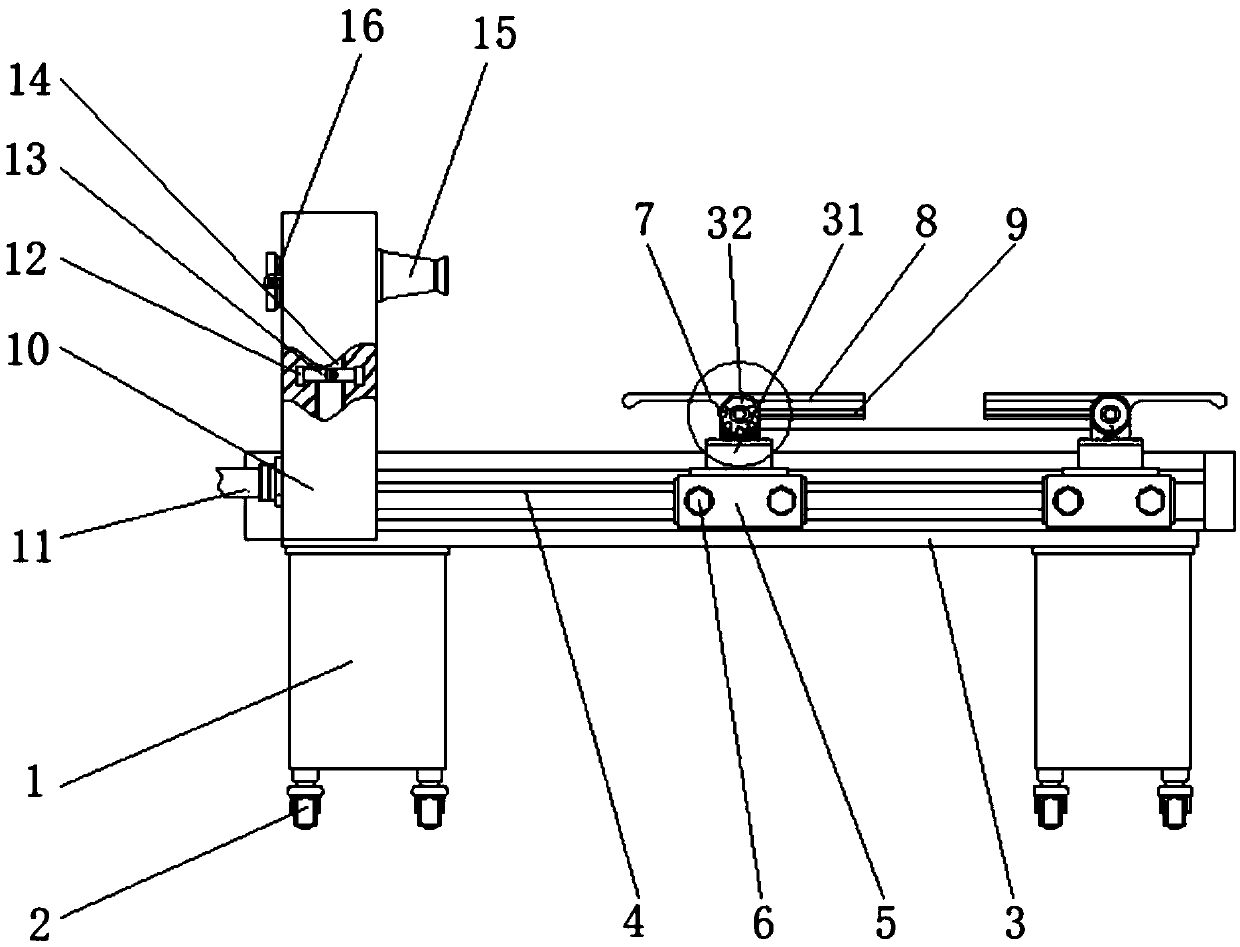

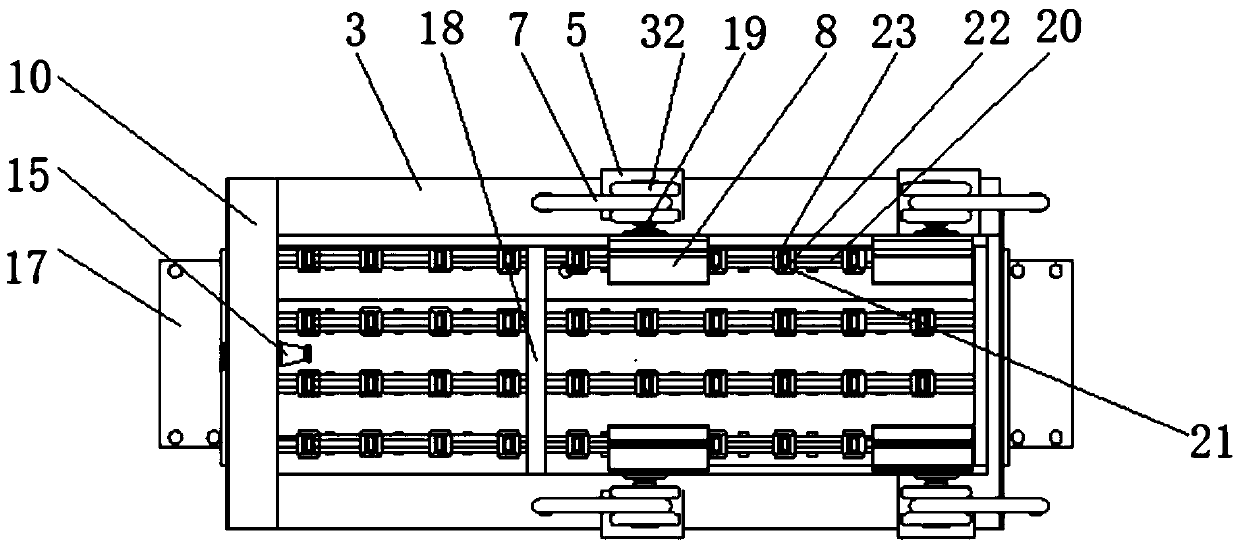

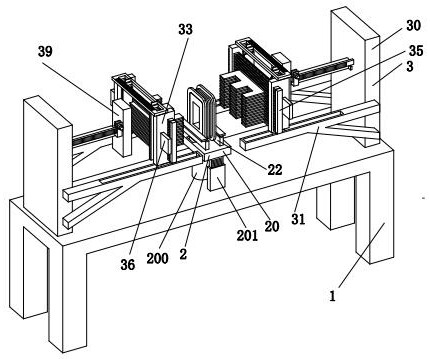

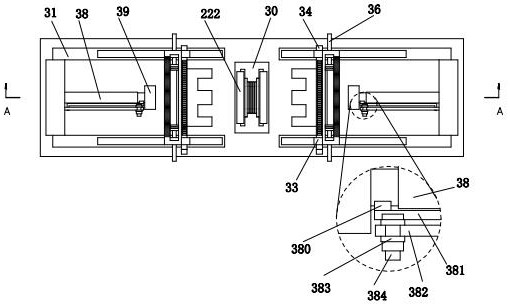

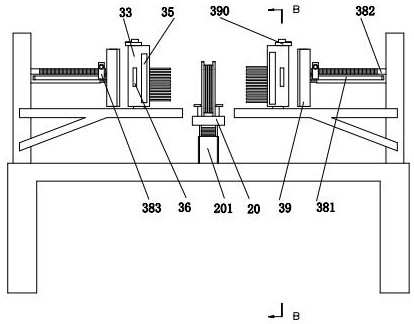

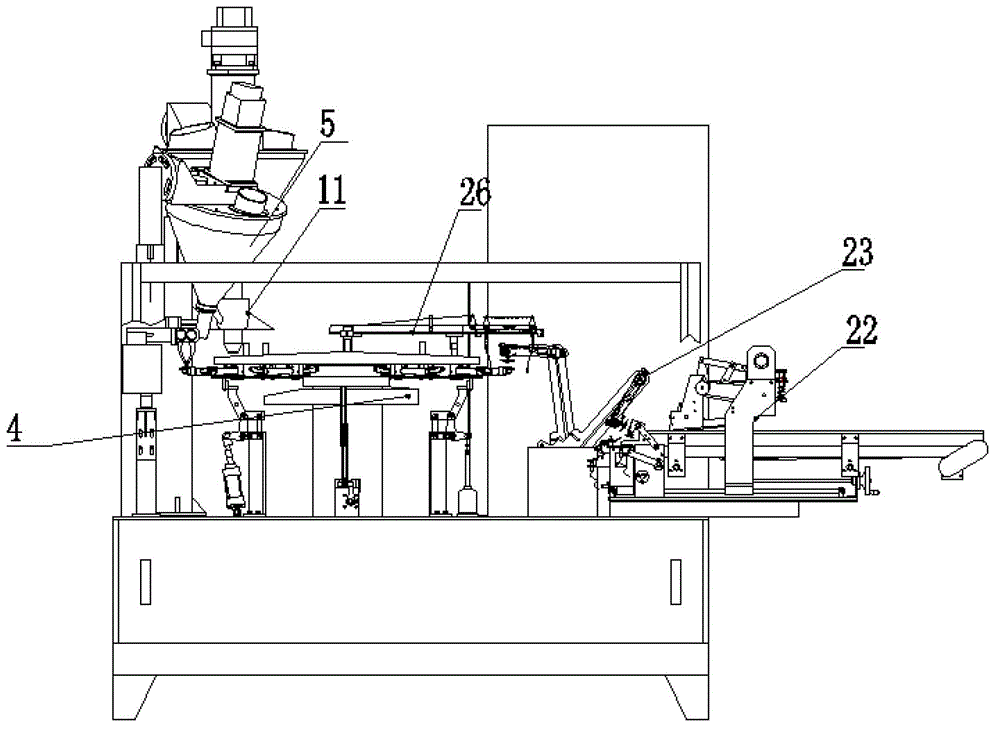

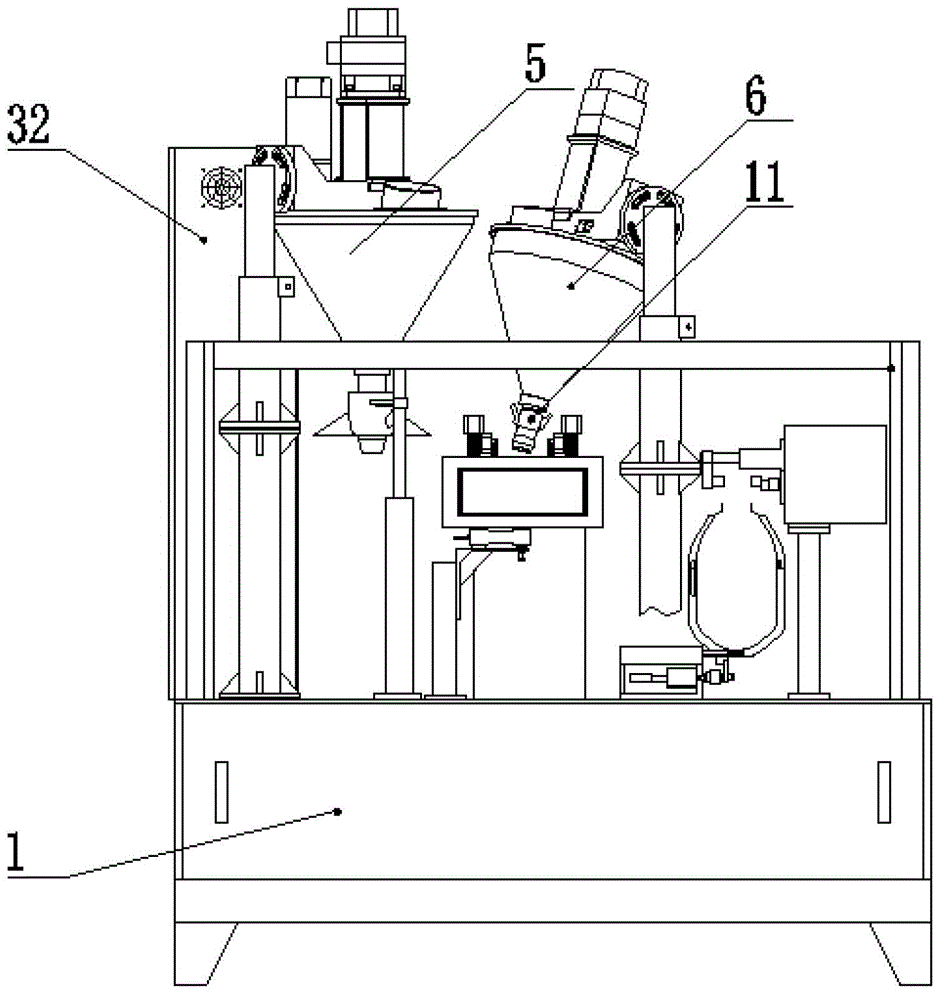

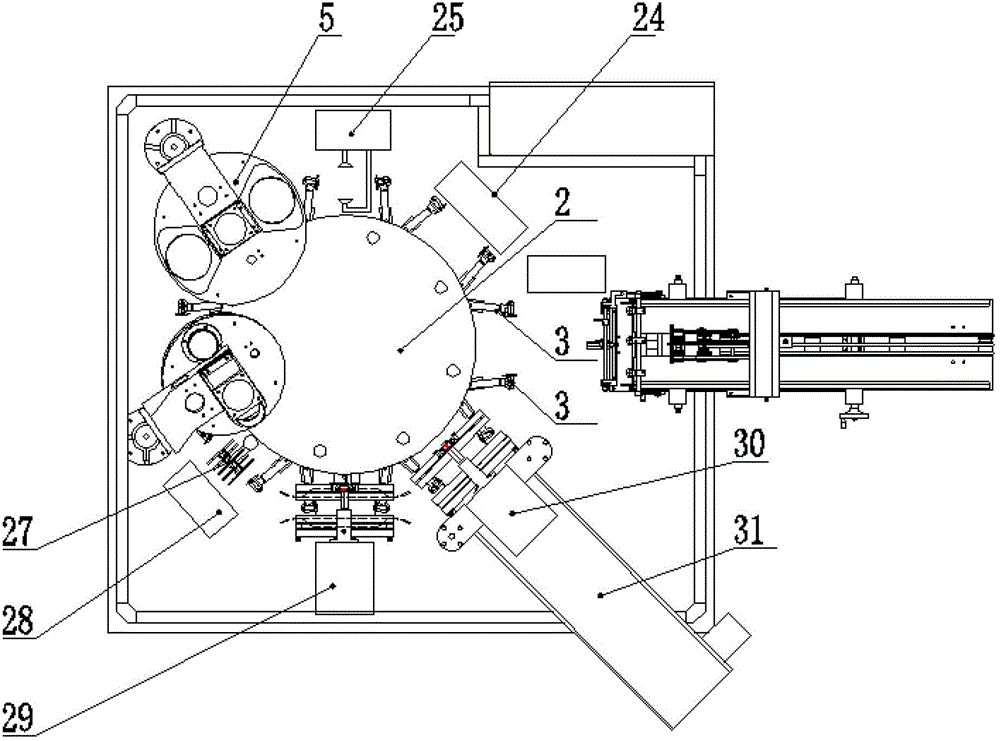

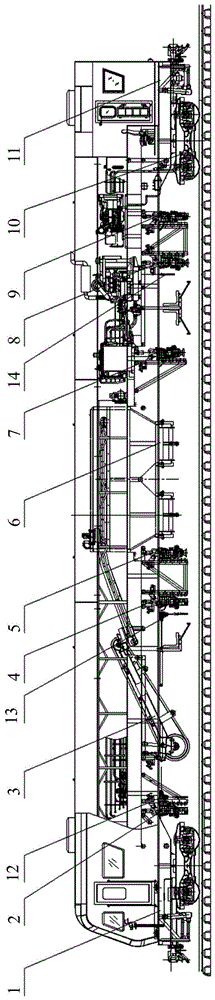

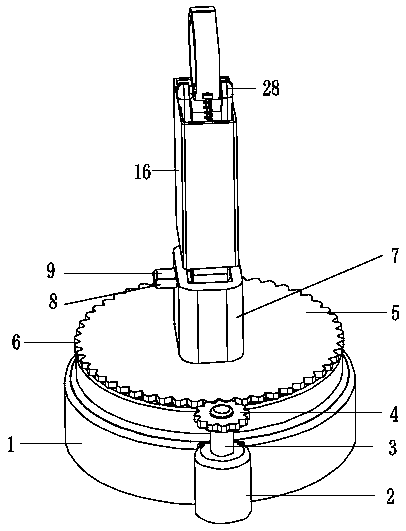

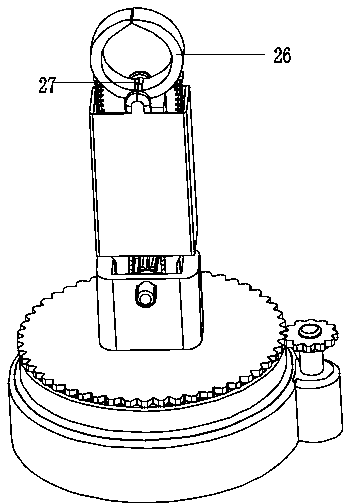

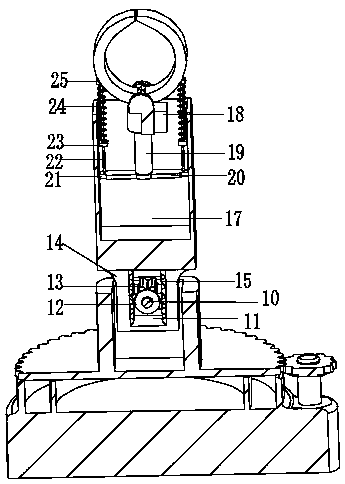

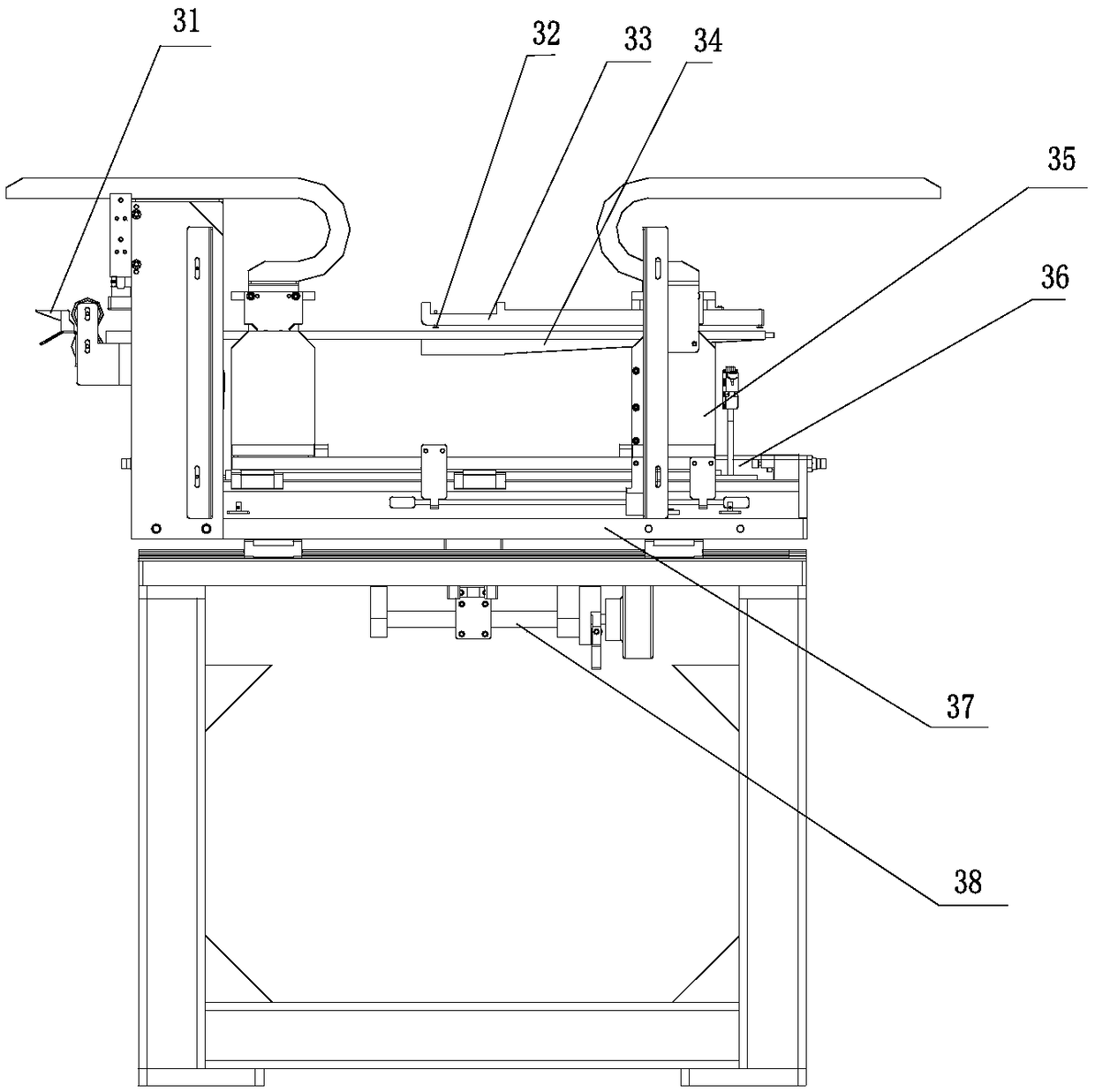

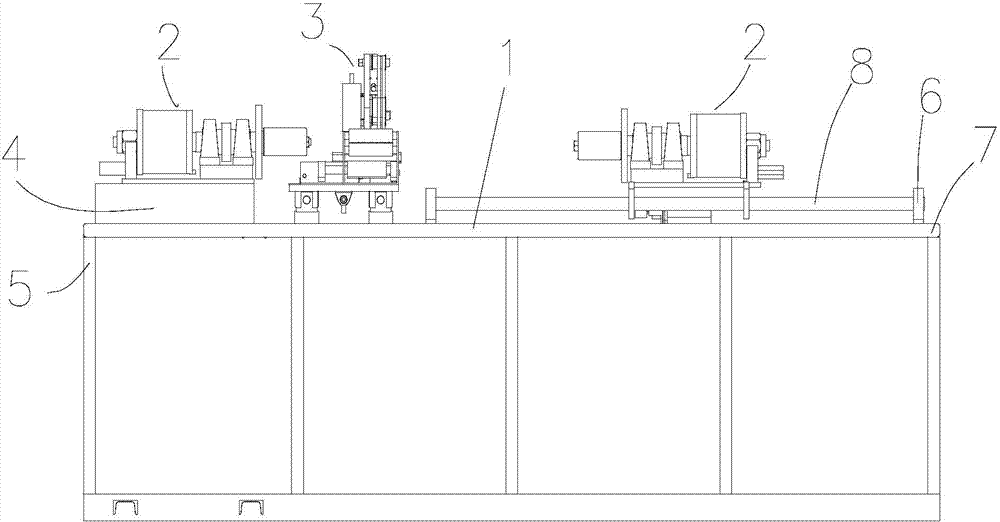

Full-automatic packaging machine

ActiveCN102991734AGuaranteed accuracyIngenious structureWrapper twisting/gatheringSolid materialEngineeringDrive shaft

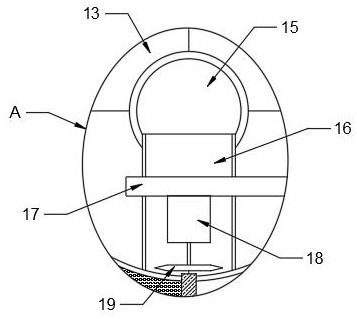

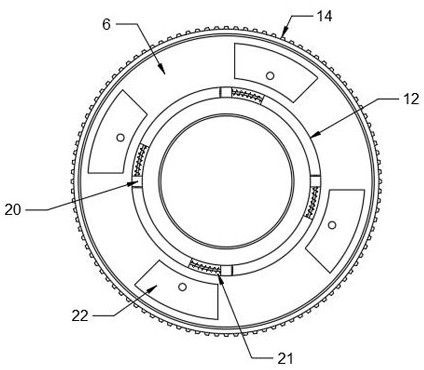

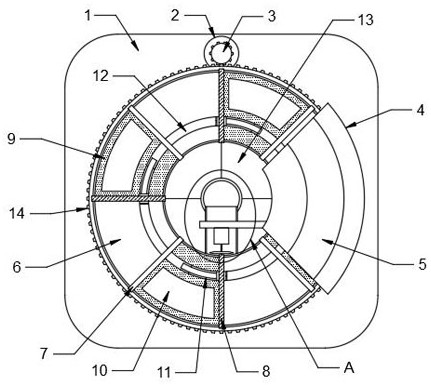

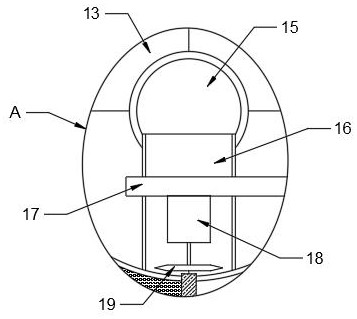

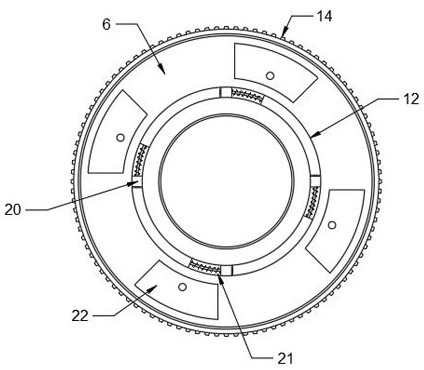

The invention discloses a full-automatic packaging machine. The full-automatic packaging machine comprises a stander, a driving device and a packaging executing device, wherein the driving device is arranged at the lower part of the stander, and the packaging executing device is arranged at the upper part of the stander; the packaging executing device comprises a driving disc, anchor arms, an anchor arm guide rail, stations and a transmission shaft; the number of the anchor arms is eight pairs, and the anchor arms are arranged at eight equal diversion positions of the driving disc in pairs; the anchor arms are glidingly connected with the anchor arm guide rail; the driving device drives the driving disc to rotate by the transmission shaft and drives the anchor arms arranged on the driving disc to slide on the anchor arm guide rail; and the number of the stations is eight, each station corresponds to a pair of the anchor arms, and the stations sequentially include a bagging station, a code printing station, a bag opening station, a rough filling station, a fine material supplementing station, a dust extraction station, an exhausting and heat-seal station and a cold-compacting reshaping station according to an anticlockwise sequence. According to the full-automatic packaging machine, the filling manner is simple and flexible, powders in different forms can be automatically adjusted, the dose precision and the filling speed of various materials are guaranteed, and the full-automatic packaging machine is simultaneously suitable for liquids, particles and irregular materials.

Owner:JIANGSU TOM PACKAGING MACHINERY

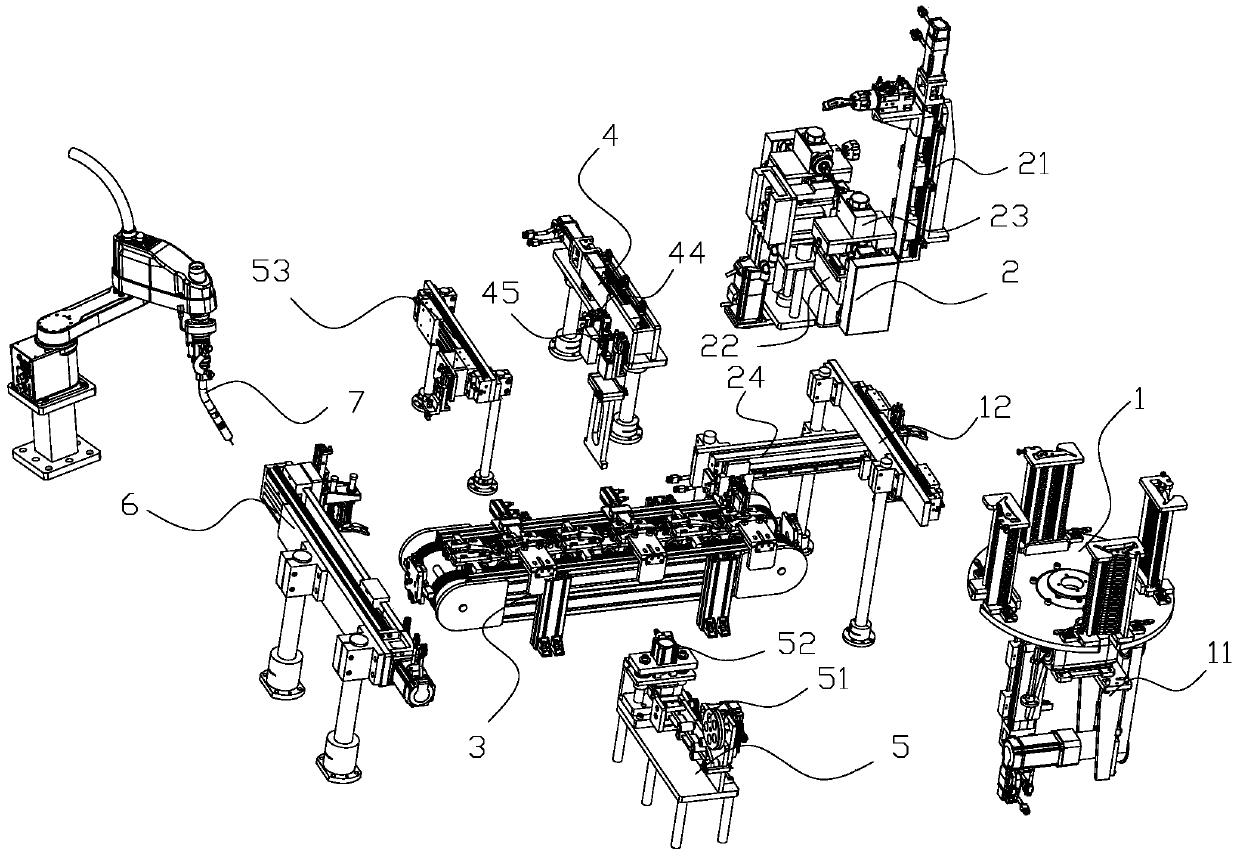

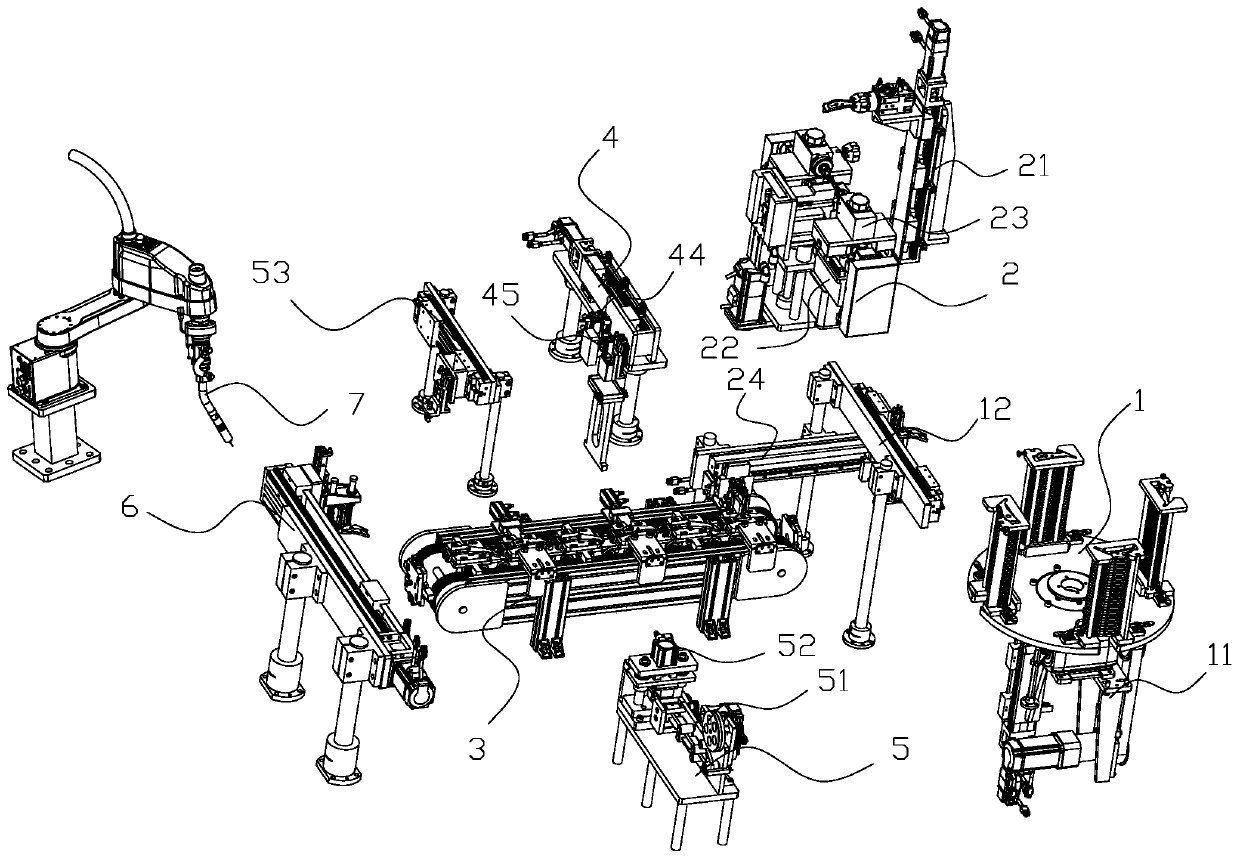

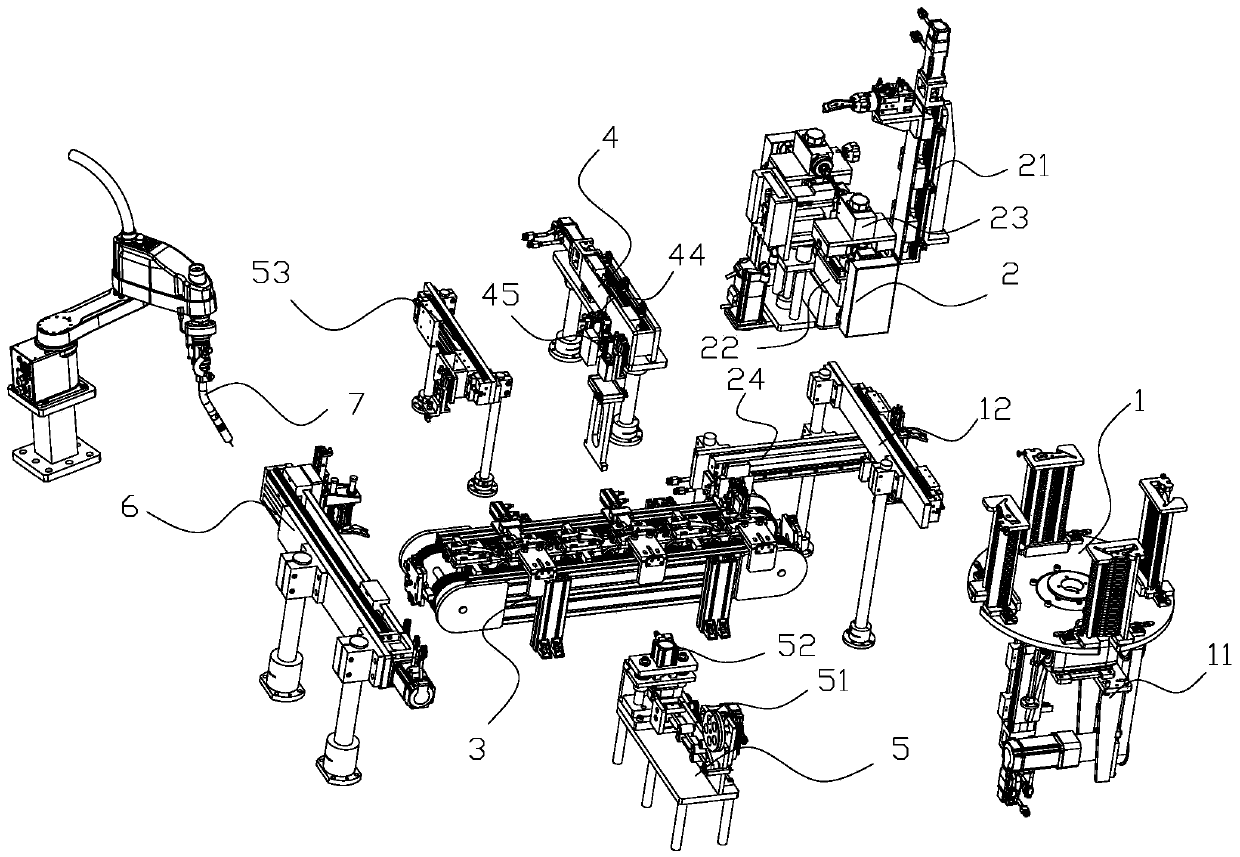

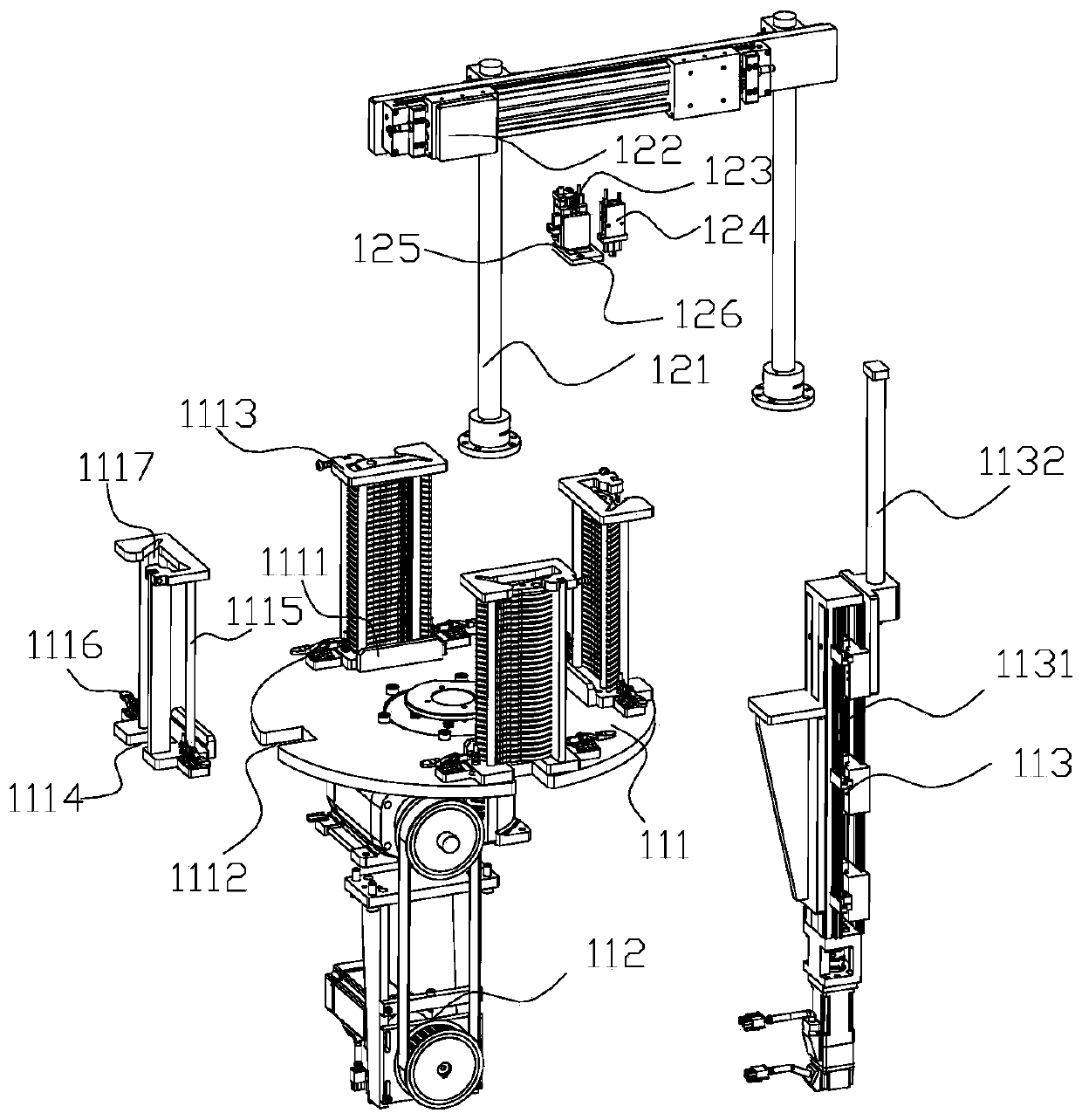

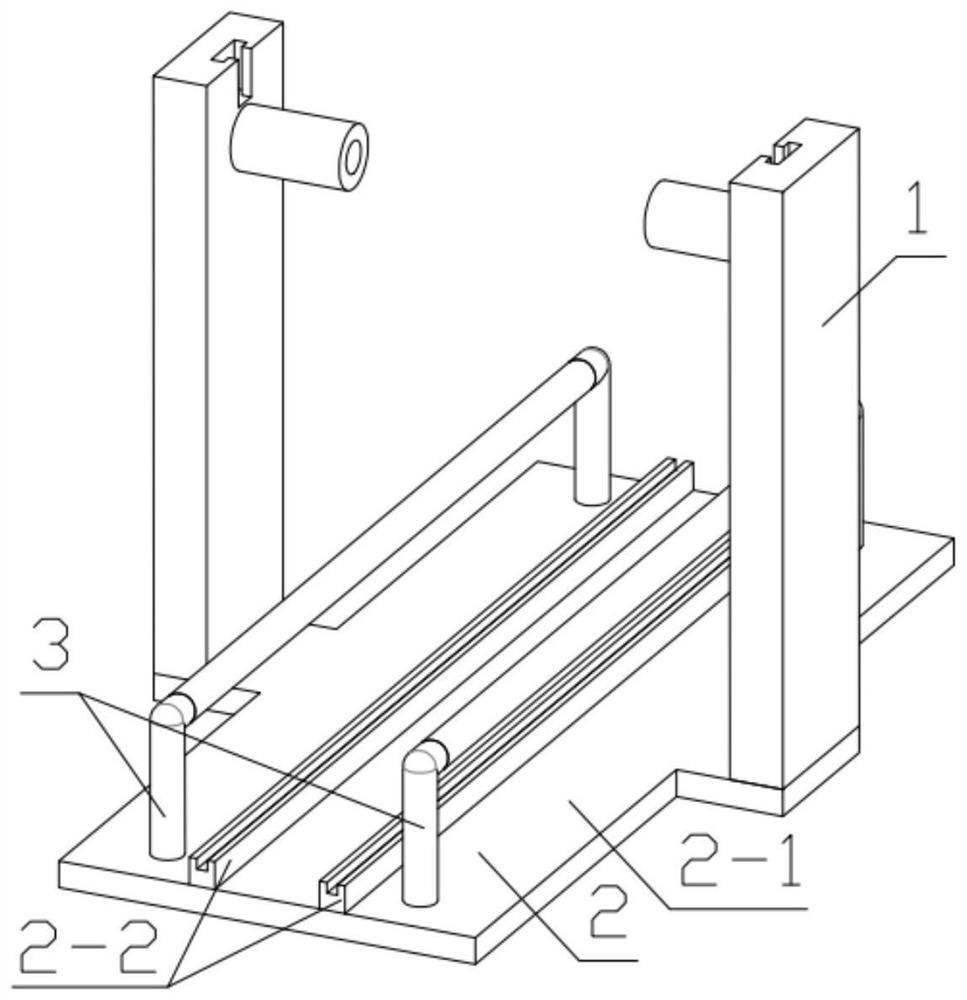

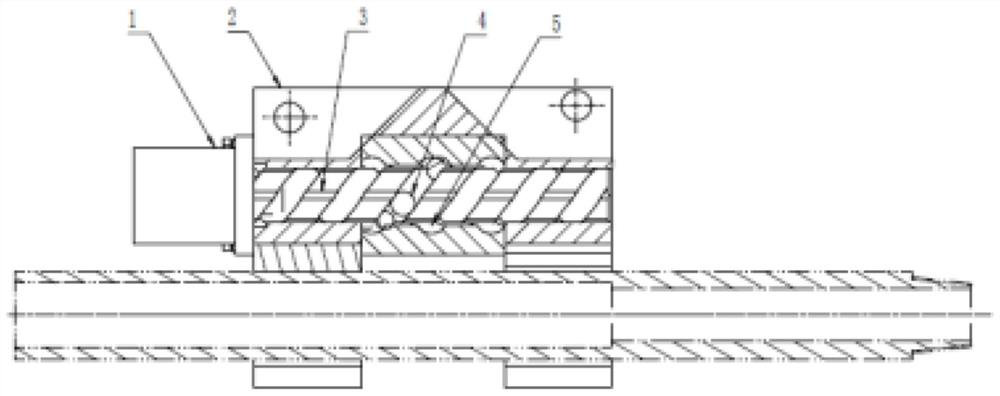

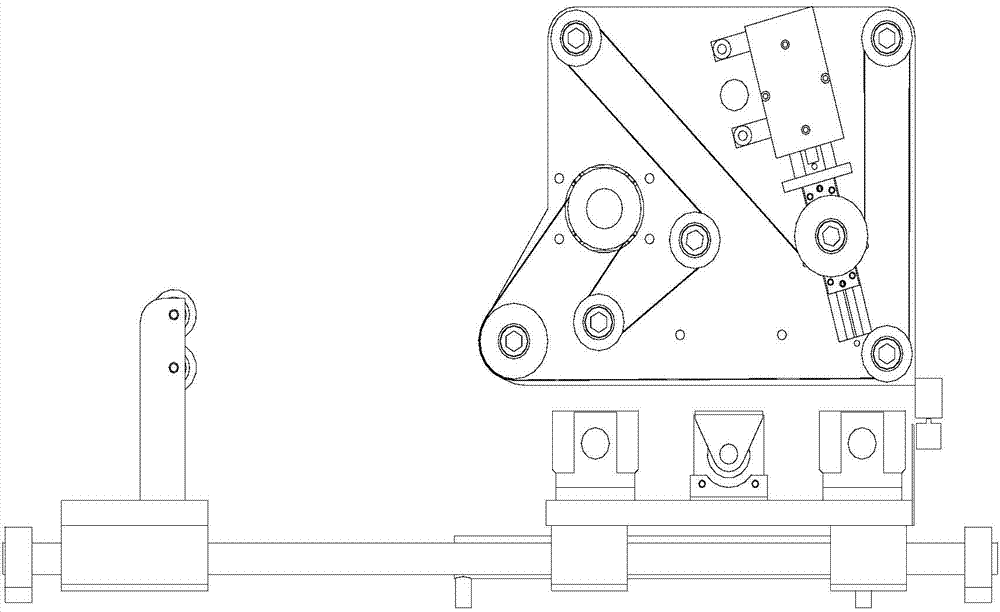

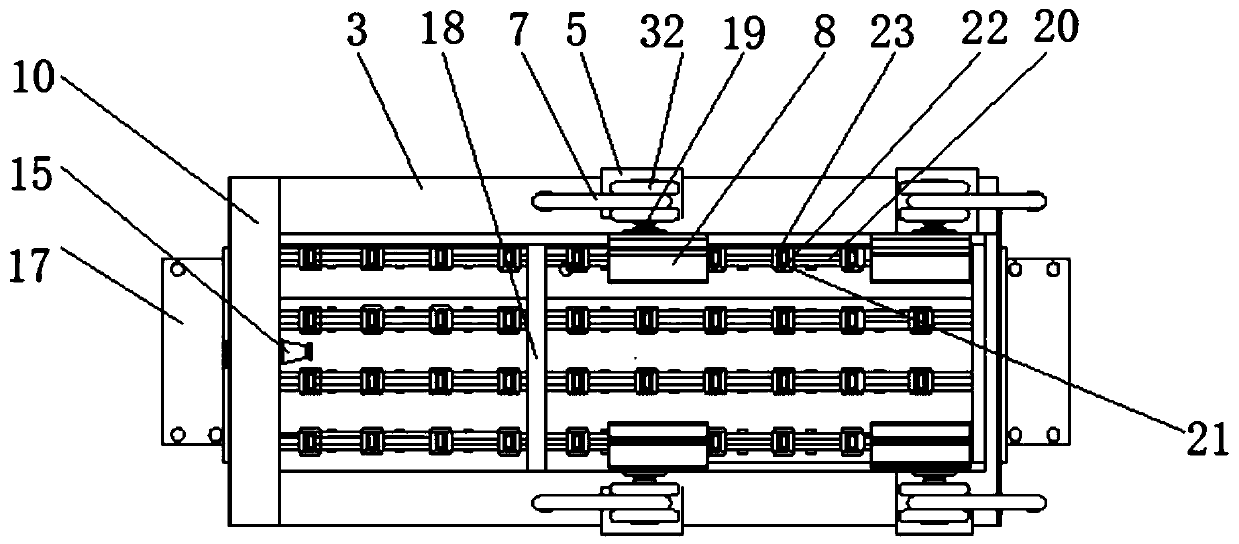

Contact synchronous belt conveying device of circuit breaker assembling equipment and method

InactiveCN111360311AEasy to fixSave spaceShearing machinesCleaning using toolsDrive shaftElectric machinery

The present invention relates to the technical field of circuit breaker production, and discloses a contact synchronous belt conveying device of circuit breaker assembling equipment and a method. Thecontact synchronous belt conveying device of the circuit breaker assembling equipment comprises a synchronous belt support, a synchronous belt motor, a synchronous belt driving shaft and a synchronousbelt driven shaft. The contact synchronous belt conveying device of the circuit breaker assembling equipment and the method have the advantages of improving the conveying efficiency of the synchronous belt, saving equipment space and improving the overall processing efficiency.

Owner:丁水珍

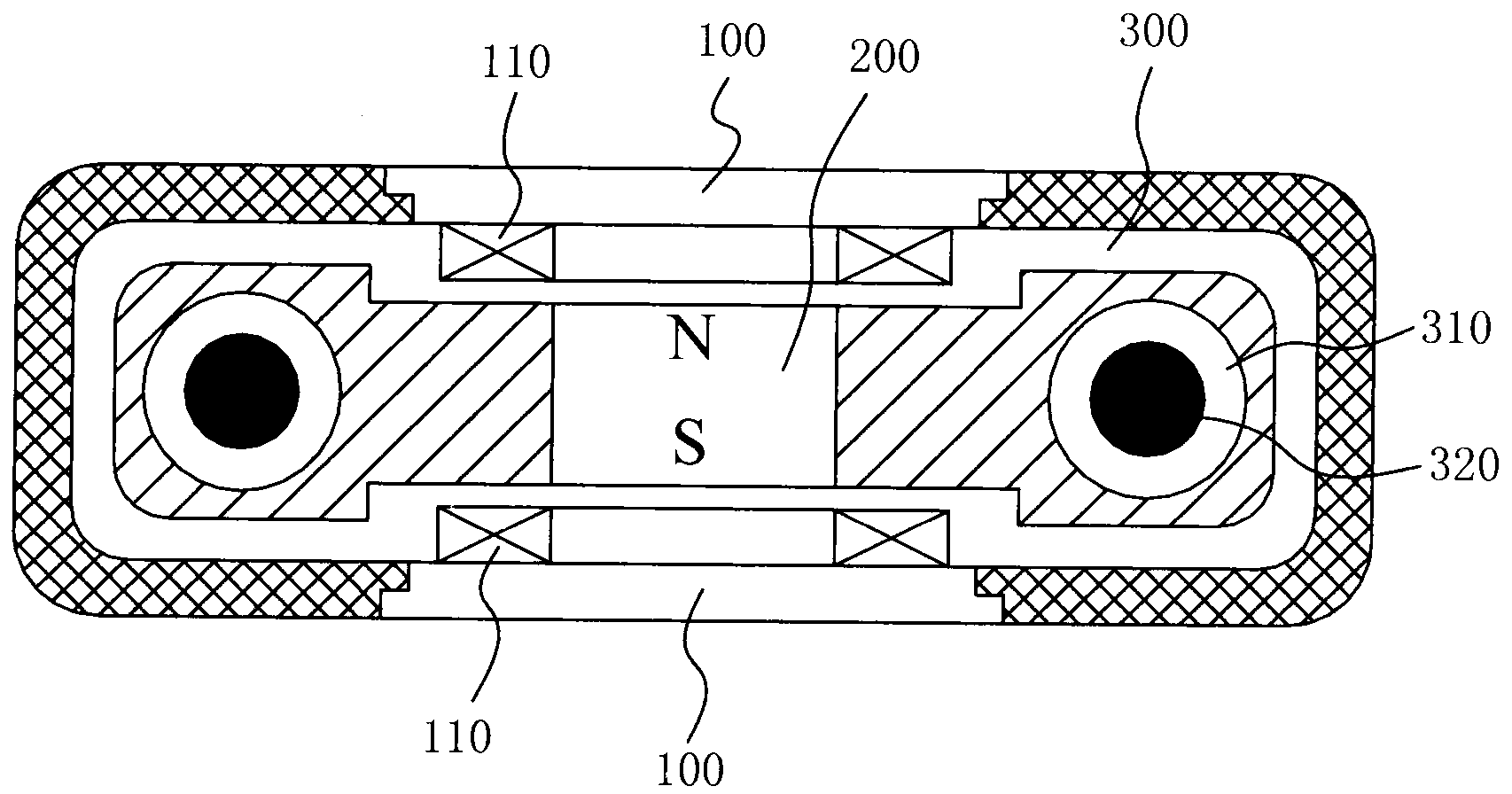

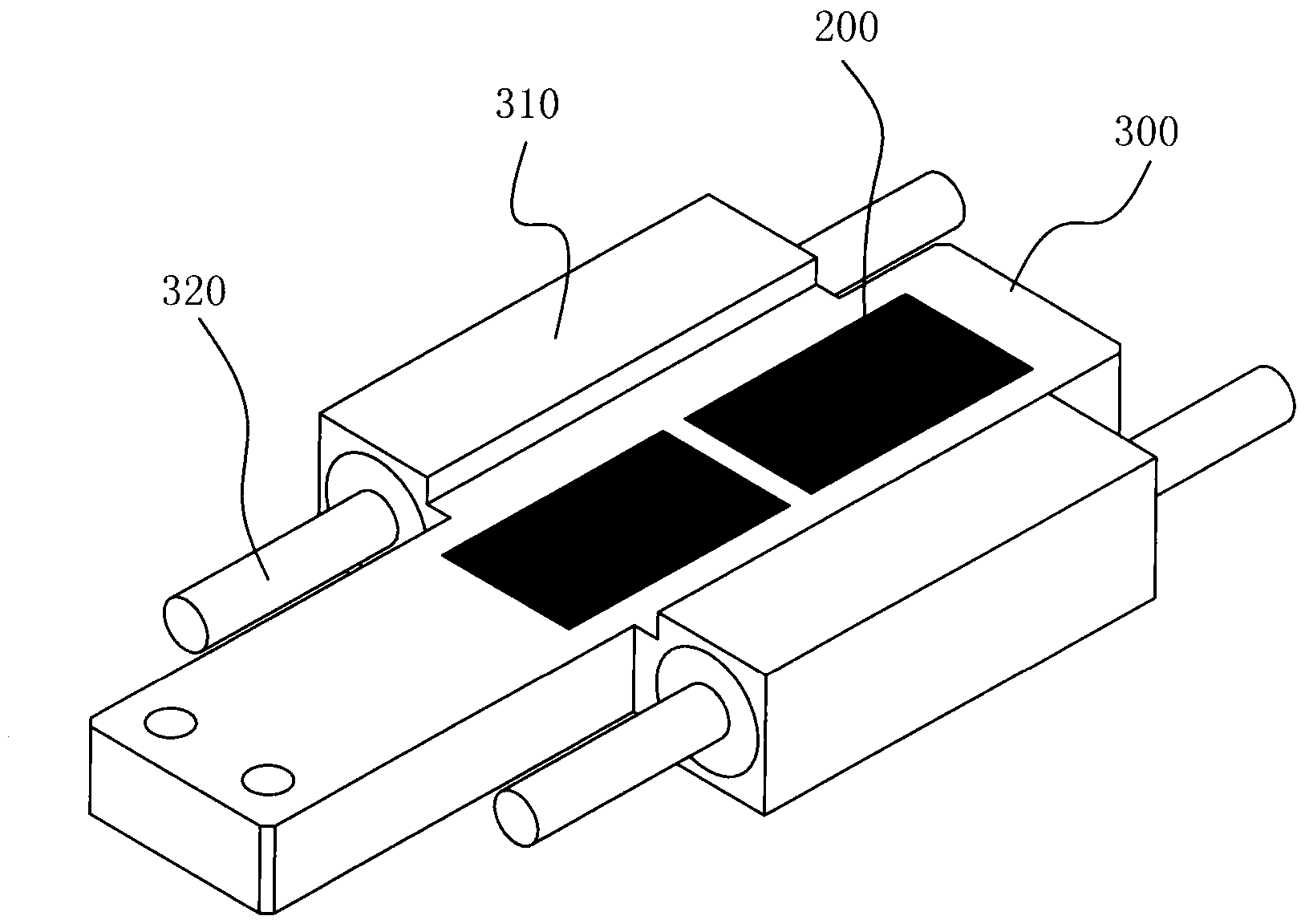

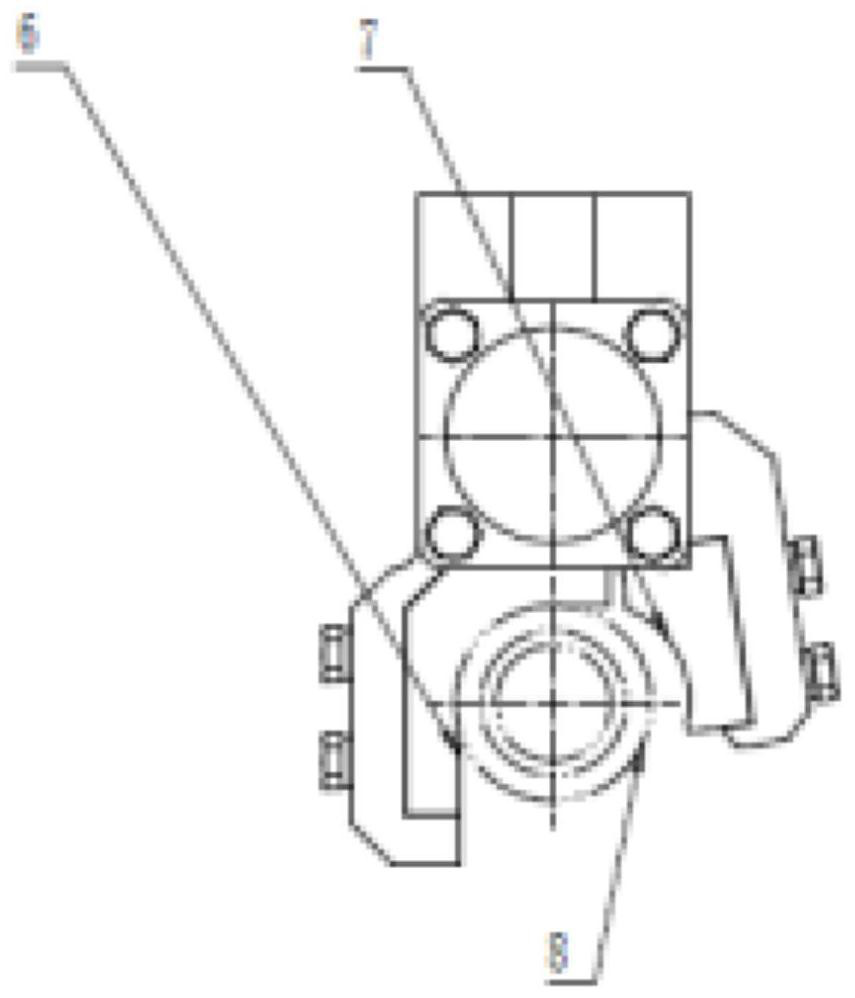

Linear actuator

InactiveCN103187848AControl the clamping forceShort response timeDynamo-electric machinesEngineeringLinear actuator

The invention relates to a linear actuator which comprises coil back iron and magnetic iron. The coil back iron is arranged at one end of the magnetic iron, a coil is wound on the coil back iron, the number of the coil back iron is two, the two coil iron bodies are arranged at the upper end and the lower end of the magnetic iron, distances from each of the two coil iron bodies to the magnetic iron are identical, and the linear actuator further comprises a magnetic iron supporting structure. The magnetic iron supporting structure comprises two bushes connected on the two sides of the magnetic iron, and the two bushes are connected on two fixed shafts and slide along the two fixed shafts. The linear actuator has the advantages of being stable in structure, good in transmission effect, prone to heat dissipation and easy to control.

Owner:AKRIBIS SYST SHANGHAI

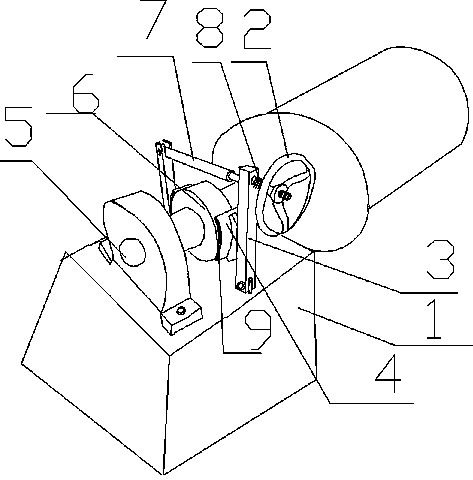

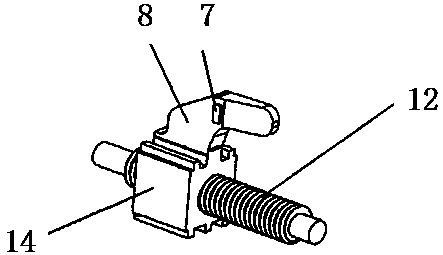

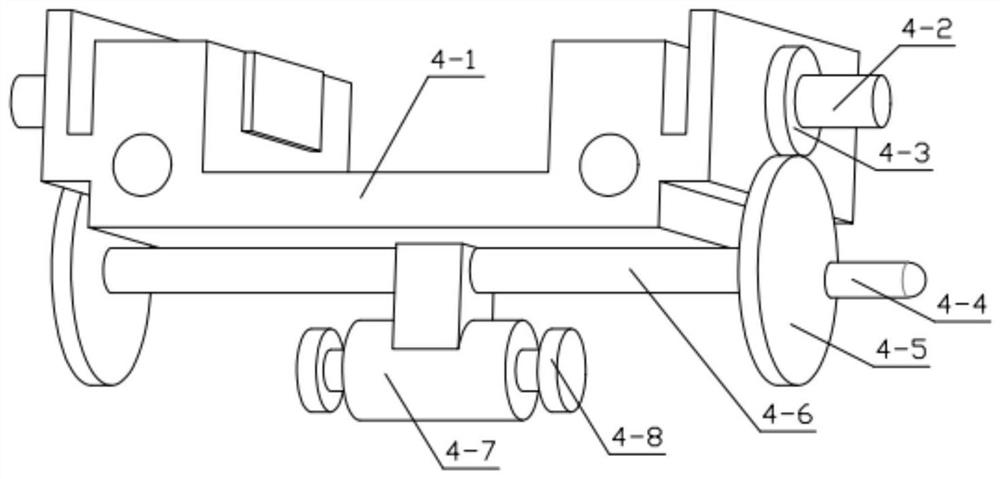

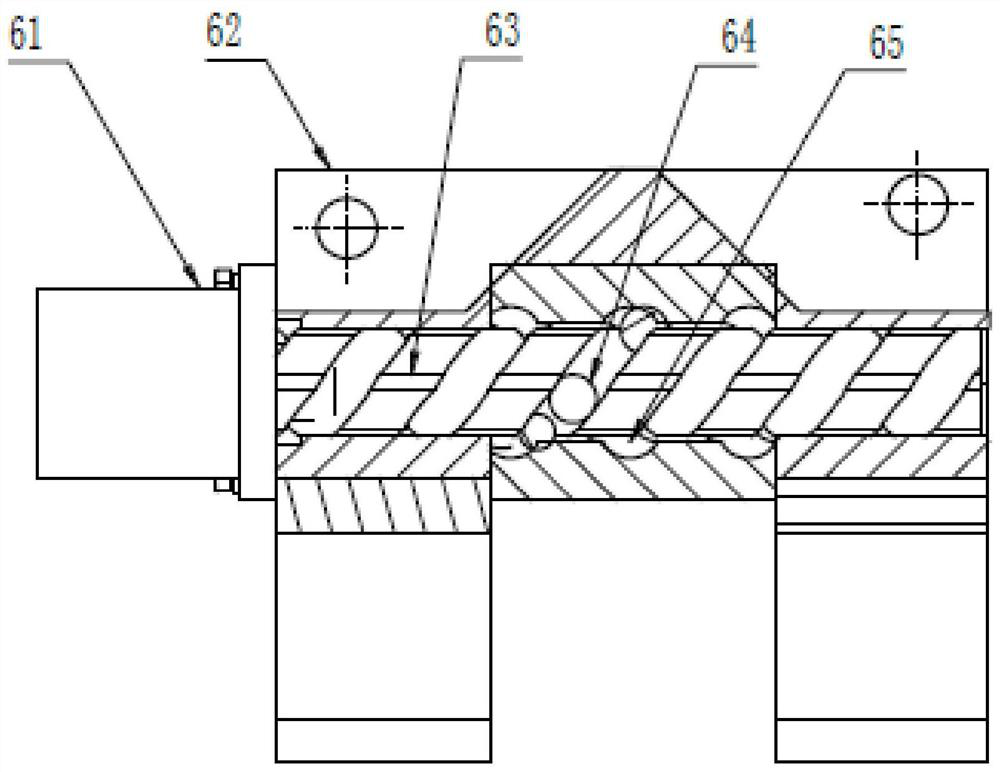

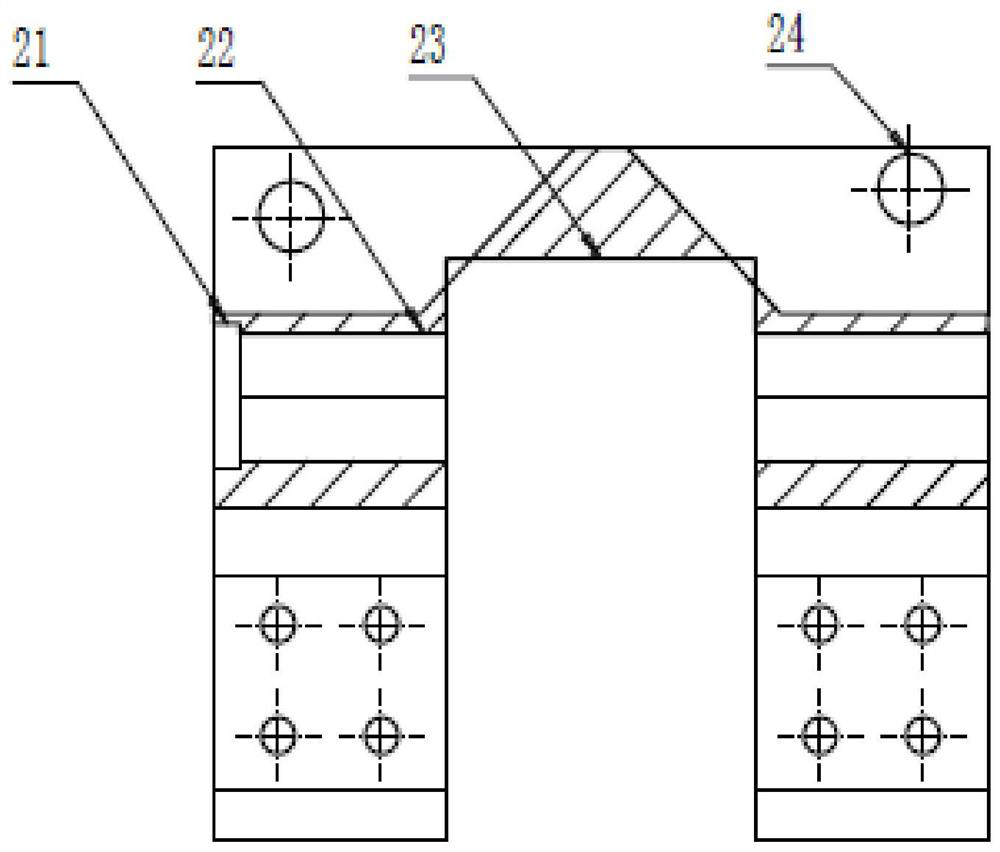

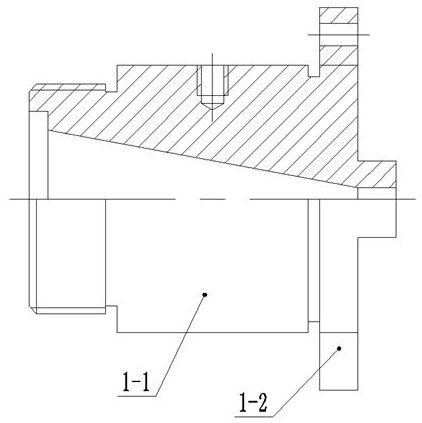

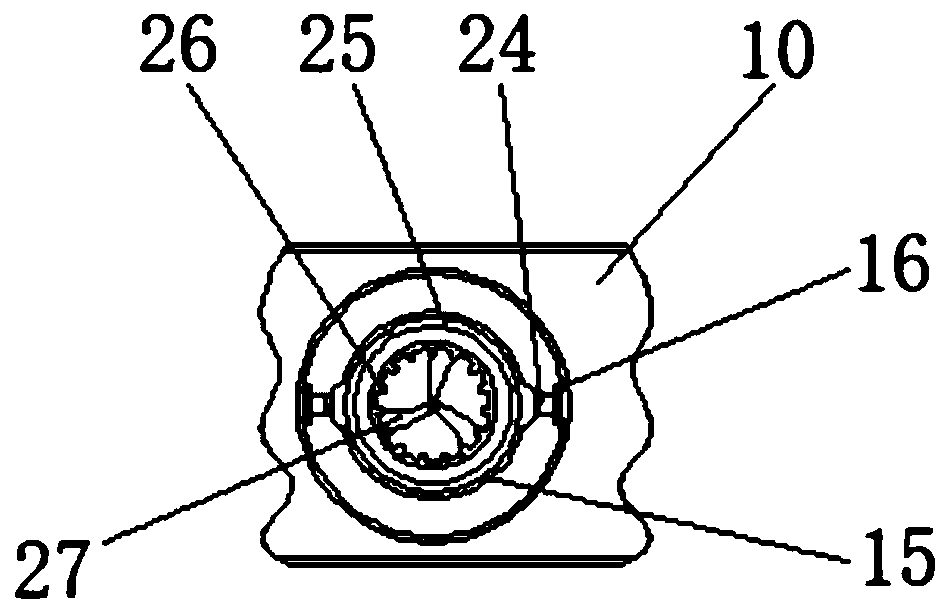

Clamping device of steel belt discharging support

InactiveCN103447609AControl the clamping forceControl the feeding forceShearing machine accessoriesScrew threadSteel belt

The invention discloses a clamping device of a steel belt discharging support. The clamping device comprises the discharging support, and the clamping device is arranged on the discharging support. The clamping device comprises an adjusting disc, support rods, semicircular clamping blocks, a bearing and a connection rod. The bearing is fixedly welded on a rotating shaft of the discharging support, the semicircular clamping blocks are arranged at the left end and the right end of the bearing, each semicircular clamping block is fixed on a corresponding support rod, the bottom of each support rod is fixedly connected onto a support table of the discharging support, the two support rods are fixedly connected through the connection rod, threads are arranged at one end of the connection rod, and the adjusting disc is fixed on the connection rod through the threads. The clamping device has the advantages of effectively controlling discharging speed, facilitating shearing of a steel belt through a shearing machine, being reasonable in design and convenient to manufacture, reducing labor intensity of workers and improving working efficiency.

Owner:TAIZHOU HUINENG STAINLESS STEEL PROD

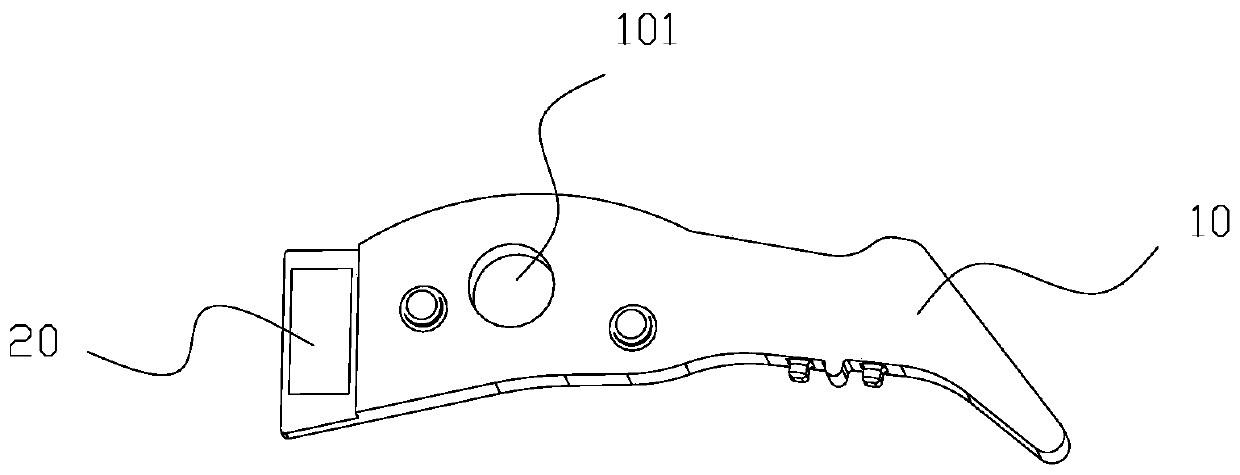

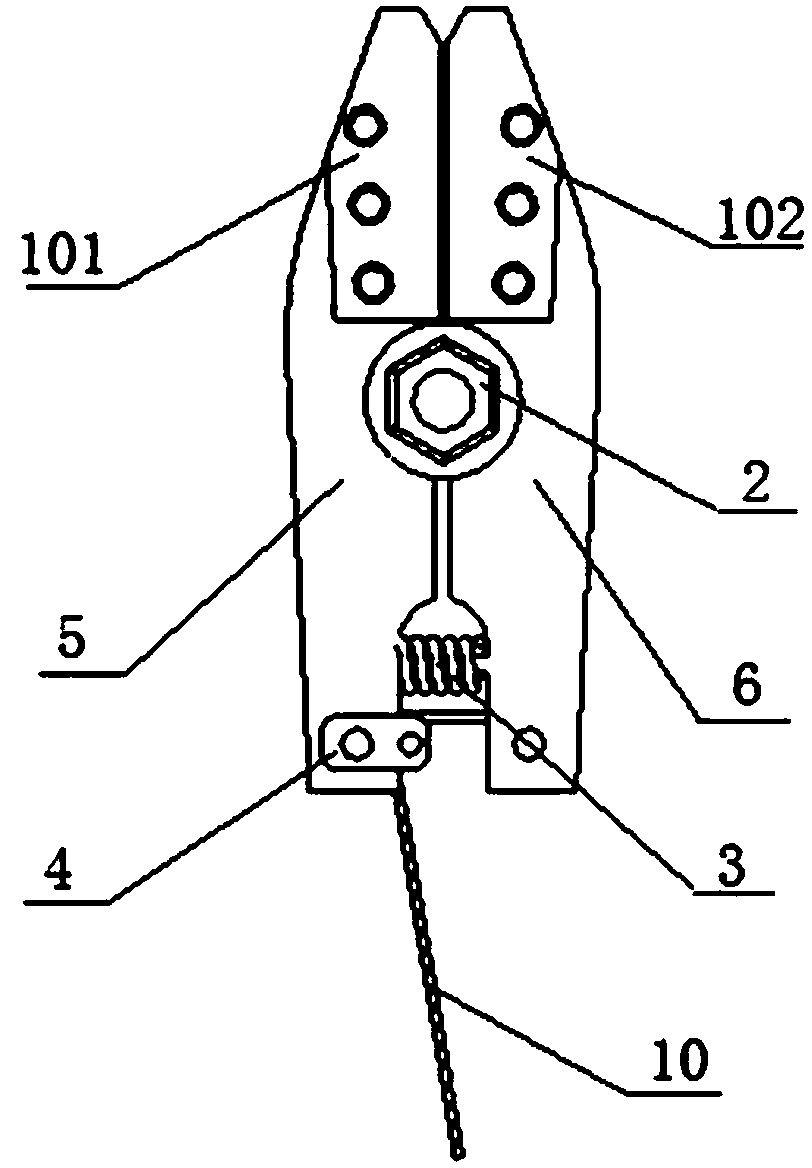

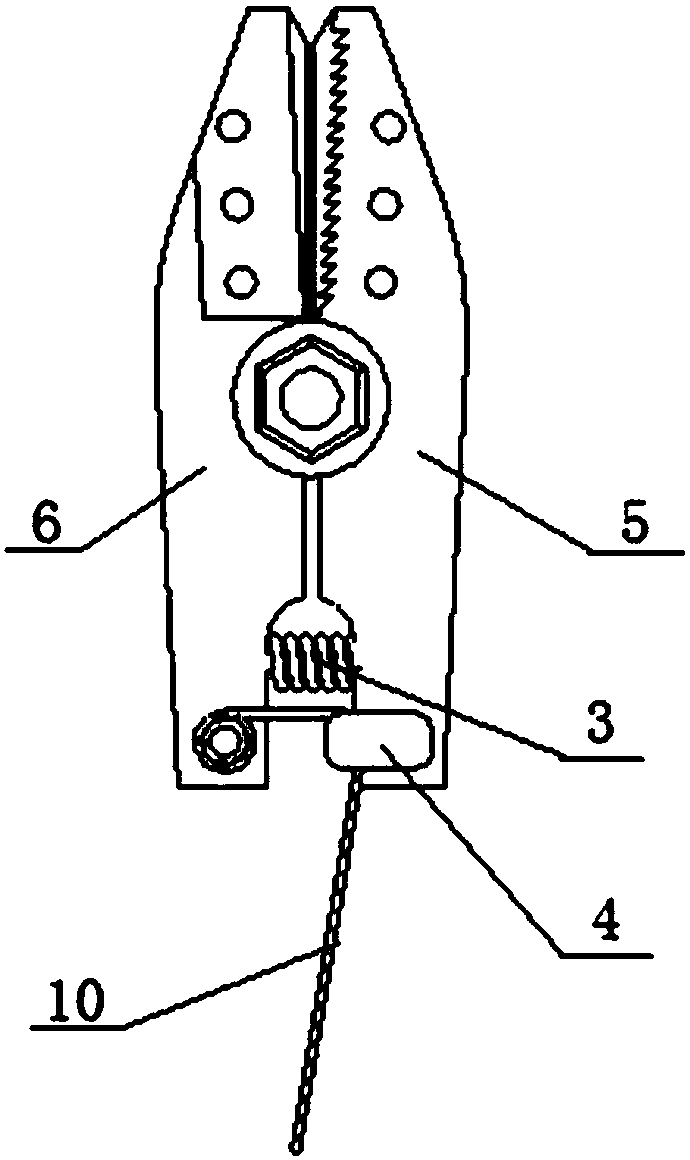

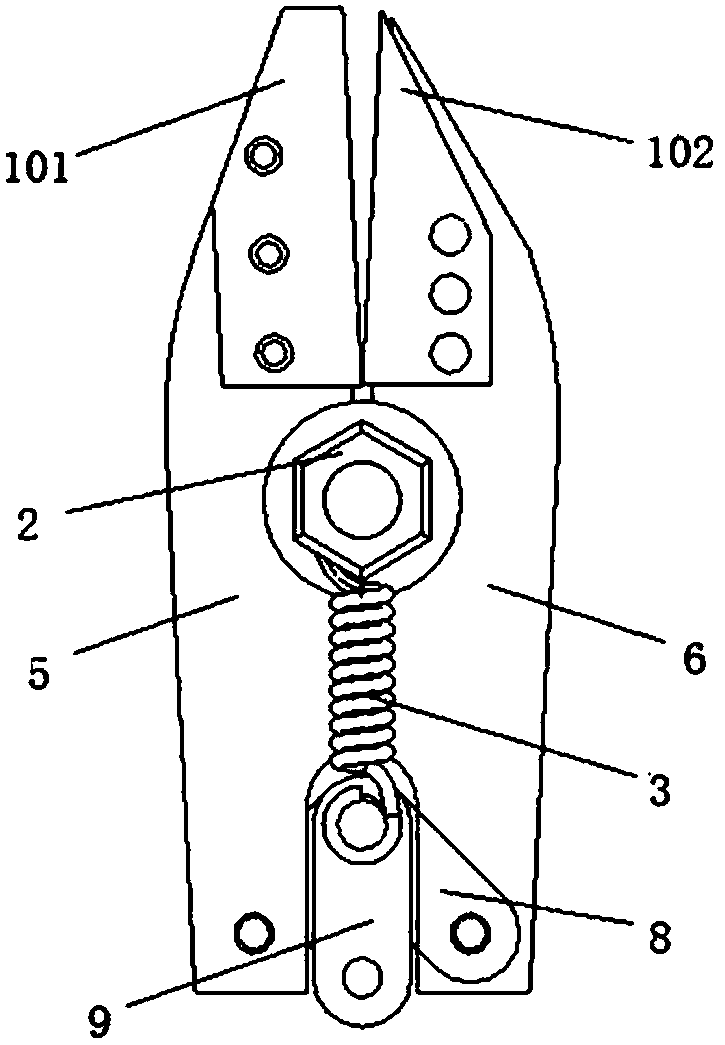

Picking and collecting integrated device and high-altitude picking pliers thereof

PendingCN107926286AAchieve the purpose of clampingControl the clamping forcePicking devicesStructural engineeringKnife blades

The invention discloses a picking and collecting integrated device and high-altitude picking pliers thereof. The picking and collecting integrated device includes two pliers heads of which middle portions are mutually rotated through a hinge shaft, the head portions of the two pliers heads cooperate with each other to form a pliers mouth, detachable blades with cutting edges are arranged inside the pliers mouth, and a reset spring is arranged at the tail portions of the pliers heads; the head portions of the two pliers heads are provided with a first elastic adhesive and a second elastic adhesive respectively, a clamping gap is reserved between the first elastic adhesive and the second elastic adhesive after the first elastic adhesive and the second elastic adhesive are arranged oppositely, and the position of the clamping gap is consistent with the position of the cutting edges of the pliers mouth. The picking and collecting integrated device has a simple structure and high packing efficiency, and is very suitable for batch packaging. The picking and collecting integrated device is characterized in that elastic adhesives are used for achieving the purpose of picking and collectingintegration, and is suitable for small fruits with easily damaged fruit skin. The picking and collecting integrated device can pick up fruits at a high altitude without hands, so that the fruits arenot damaged, and the hands are not hurt. The picking and collecting integrated device is safe in operation, and the cut fruits do not fall off.

Owner:王兴武

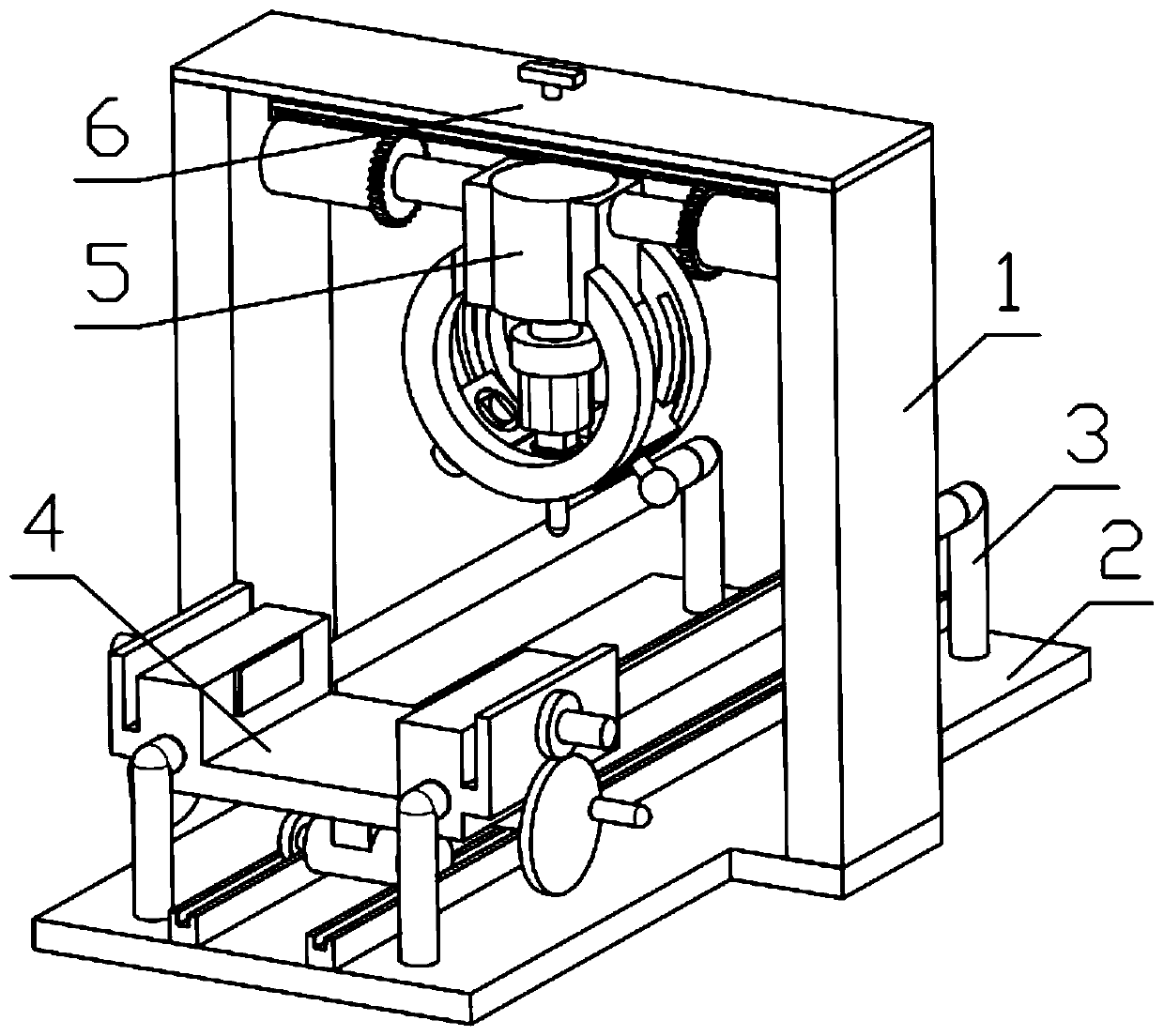

Plastic product processing device

InactiveCN111421421AControl the clamping forceAvoid being too light or too heavyEdge grinding machinesGrinding carriagesPhysicsSupport plane

The invention relates to a plastic processing device, in particular to a plastic product processing device. The plastic product processing device comprises a side support frame, a bottom mounting plate and a track rod, wherein the track rod is fixedly installed on the bottom mounting plate, the side support frame is fixedly installed on the bottom mounting plate, a fixed mechanism is installed onthe track rod in a sliding mode, the fixed mechanism is engaged with the bottom mounting plate, a multifunctional grinding mechanism is fixedly installed on an angle adjusting mechanism, and the angleadjusting mechanism is fixedly installed on the side support frame. The device can be fixed completely according to plastic products of different properties, deformation cannot be generated, the plastic products can be ground at multiple angles by the device, so that the purpose of adaptation to different shapes is achieved, and grinding tools of the device can be freely replaced, so that different grinding requirements are met.

Owner:邵东县乾兴塑料制品有限公司

High school bioexperiment test tube cleaning and clamping device

The invention discloses a high school biological test tube cleaning and clamping device. The device comprises an experimental table top, wherein a fixing shell is arranged above the experimental tabletop; a lifting screw rod is arranged in the fixing shell; the upper end of the lifting screw rod is connected with a motor output end arranged on the upper surface of the fixing shell; a control switch is arranged on one side of the fixing shell; a lifting block is arranged on the outer side surface of the lifting screw rod; one side of the lifting block is fixedly connected with a fixing table through a first connecting rod; test tube holes where test tubes penetrate are formed in the fixing table; arc-shaped clamping plates are symmetrically arranged at the left end and the right end of theouter side surface of the upper end of each test tube; the arc-shaped clamping plates are fixedly connected with sliding blocks through second connecting rods; the sliding blocks are slidably connected in chutes; and the chutes are symmetrically formed in the two sides of an arc-shaped sliding rail. According to the device, the clamping force on the test tubes is controllable, so that the test tubes are protected from being damaged; and the clamping is adjustable according to different outer diameters of the test tubes, so that the clamping is firmer, and the use safety is much higher.

Owner:湛雨心

Assembly device and method of copper sheets for circuit breaker

InactiveCN111376059AEasy to transportStable and accurate transferMaterial gluingCleaning using toolsEngineeringMaterials science

The invention relates to the technical field of production of circuit breakers. An assembly device of copper sheets for a circuit breaker comprises a copper sheet feeding bracket, a copper sheet feeding assembly, a copper sheet cutting assembly and a copper sheet assembling assembly, wherein the copper sheet feeding assembly and the copper sheet cutting assembly are arranged on the copper sheet feeding bracket separately, the copper sheet feeding assembly is located at the feeding end of the copper sheet cutting assembly, and is used for conveying a copper sheet band for feeding, the copper sheet cutting assembly is used for cutting the copper sheet band sheet by sheet, and the copper sheet assembling assembly is located at the discharging end of the copper sheet cutting assembly, and is used for transferring and assembling the cut copper sheets. The assembly device has the advantages of being capable of improving the copper sheet cutting quality and stability as well as the copper sheet assembling efficiency and quality.

Owner:丁水珍

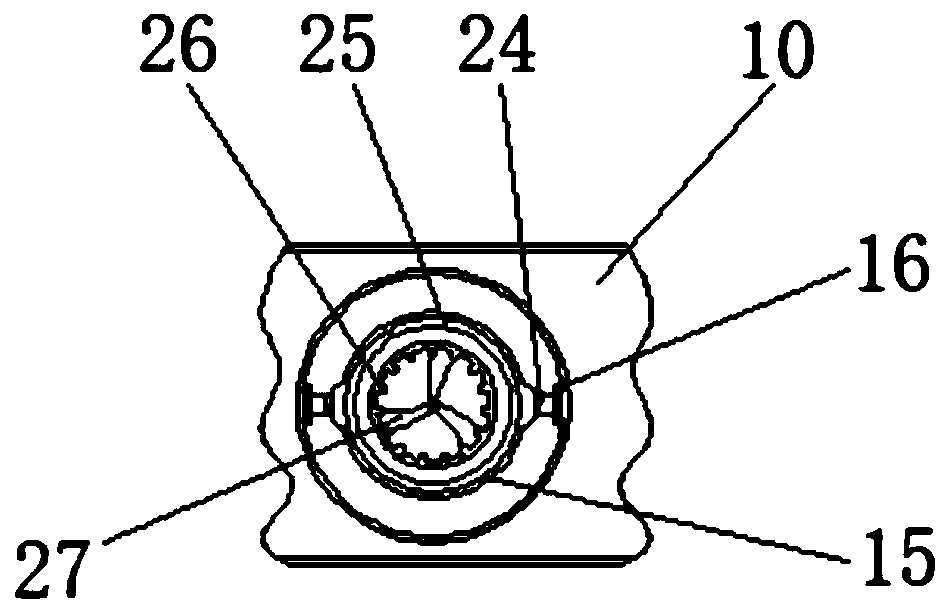

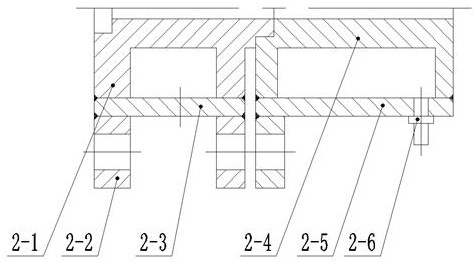

Complex component clamping active control flexible clamp

ActiveCN108296816AAvoid deformationSeriously deformedMeasurement/indication equipmentsPositioning apparatusComputer moduleEngineering

The invention discloses a complex component clamping active control flexible clamp which comprises a clamp body, a data measuring module, a flexible clamping module and a power driving module. The clamp body is composed of a lower clamp body, an upper clamp body and an installing bolt, corresponding displacement of the edges of the lower clamp body and the upper clamp body are provided with roundholes, the installing bolt penetrates the round holes in the lower clamp body and the upper clamp body to fasten the lower clamp body and the upper clamp body together, a through hole is formed in theupper clamp body, a plurality of through holes are formed in the upper clamp body, and the through grooves are distributed in a central symmetry manner with the upper clamp body as the center; and the data measuring module is composed of a force sensor, a data processor and a computer, and the data processor is electrically connected with the force sensor and the computer.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

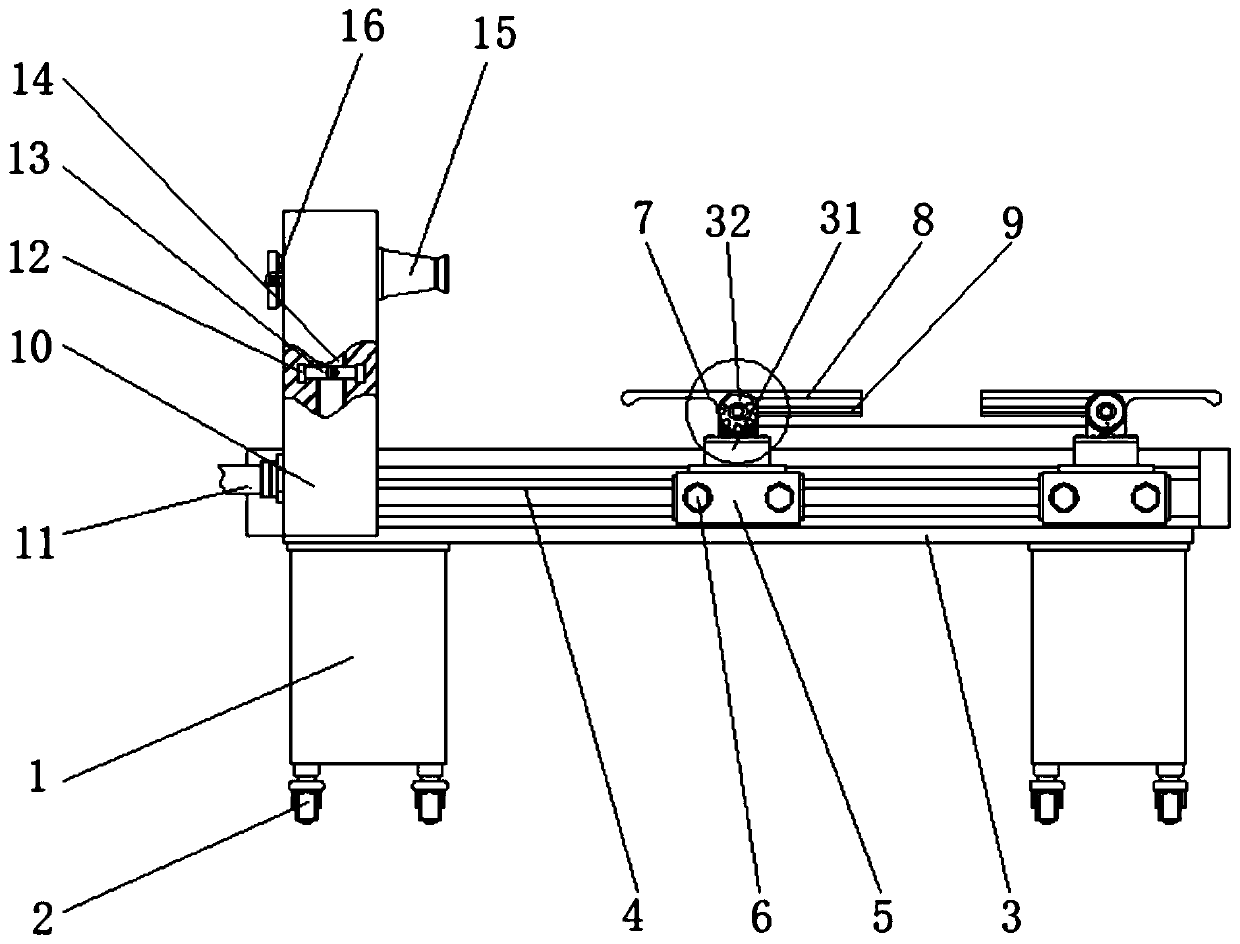

Quick loading and unloading device for mechanical field

InactiveCN109623635AGuaranteed to run horizontallyGuaranteed uptimeDrying gas arrangementsCleaning using liquidsEngineeringMechanical field

The invention relates to a quick loading and unloading device for the mechanical field. The quick loading and unloading device comprises a base, a first sliding rail and a supporting table. Wheels areconnected to two sides of the lower end of the base. A turning lathe is arranged at the upper end of the base. The first sliding rail is embedded in the middle of the outer wall of the turning lathe.A first sliding block is mounted on the outer wall of the first sliding rail. Hex head screws are arranged on two sides of the first sliding block. The supporting table is fixed to the top of the first sliding block. Rotating shafts are arranged at the top of the supporting table. A handle is connected to the left end in each rotating shaft. V-shaped connecting components penetrate through the middles of the rotating shafts. Clamping plates are mounted at the tail ends of the V-shaped connecting components. Soft padding layers are embedded in the bottoms of the clamping plates. The base and the turning lathe are arranged and are welded into an integral structure. The base and the turning lathe are stable, so that the turning lathe can horizontally run during operation, a workpiece plate is prevented from sliding along two sides of the turning lathe during application and causing inconvenient clamping and fixing subsequently.

Owner:江苏博伟自动化设备有限公司

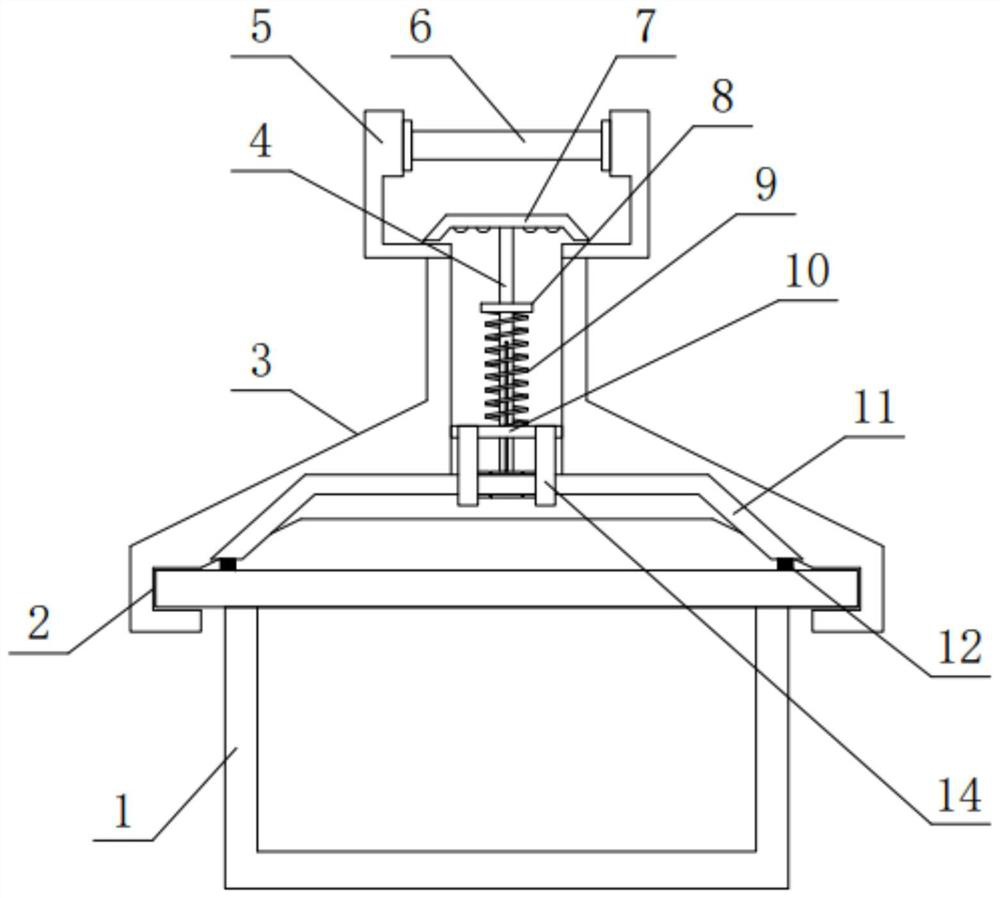

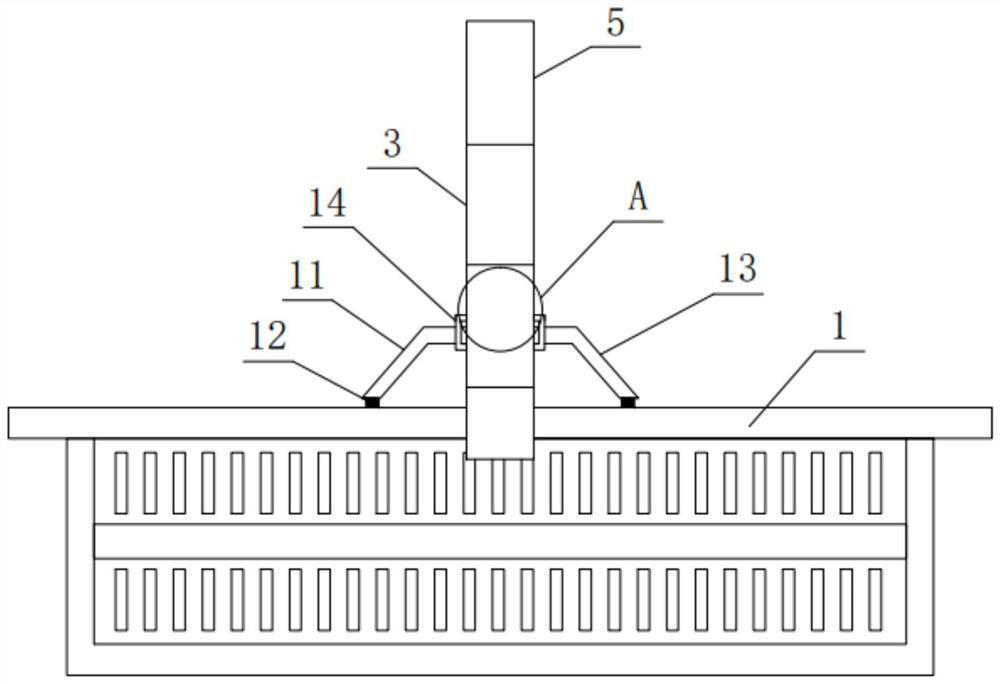

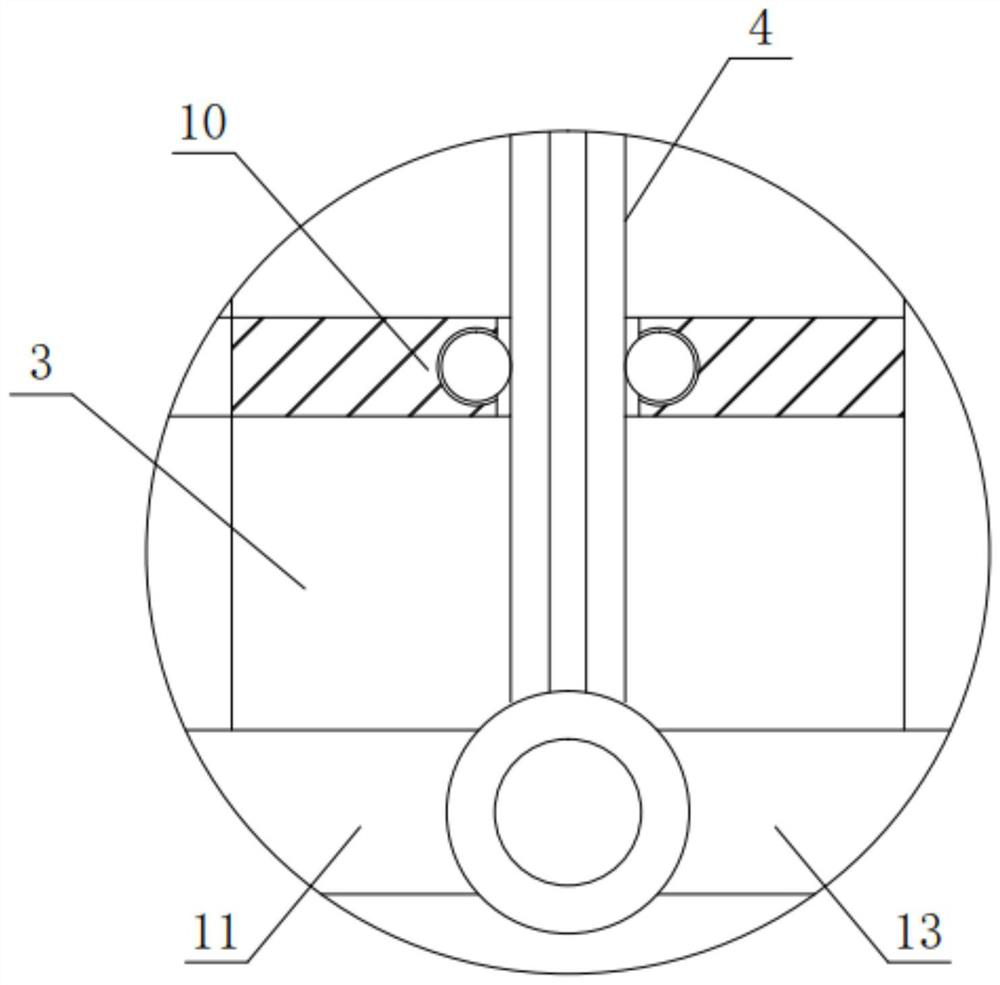

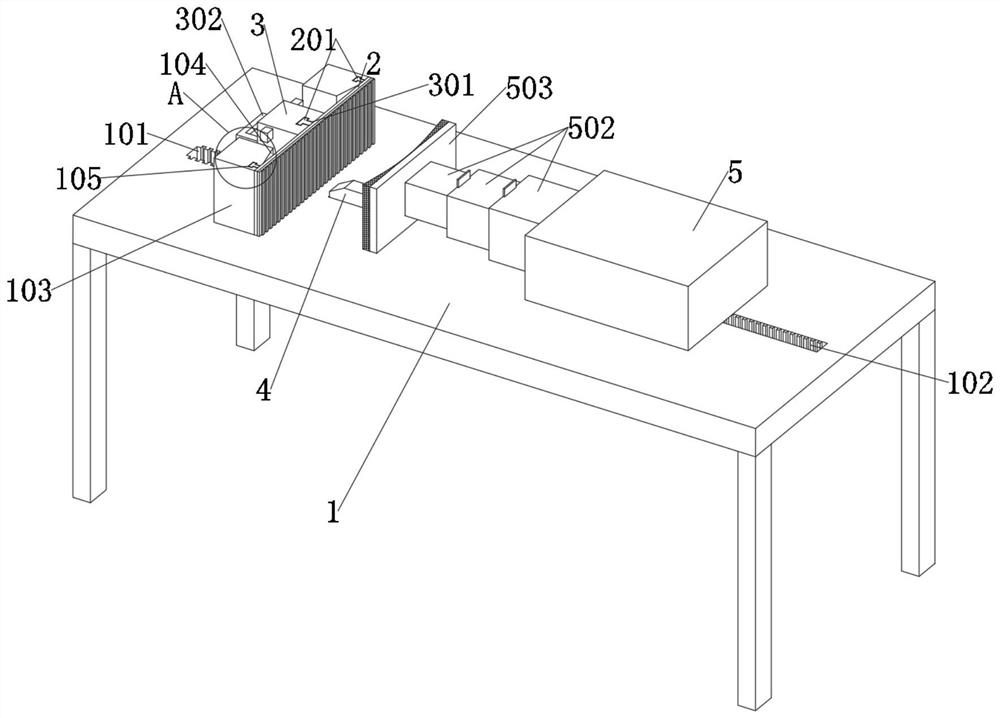

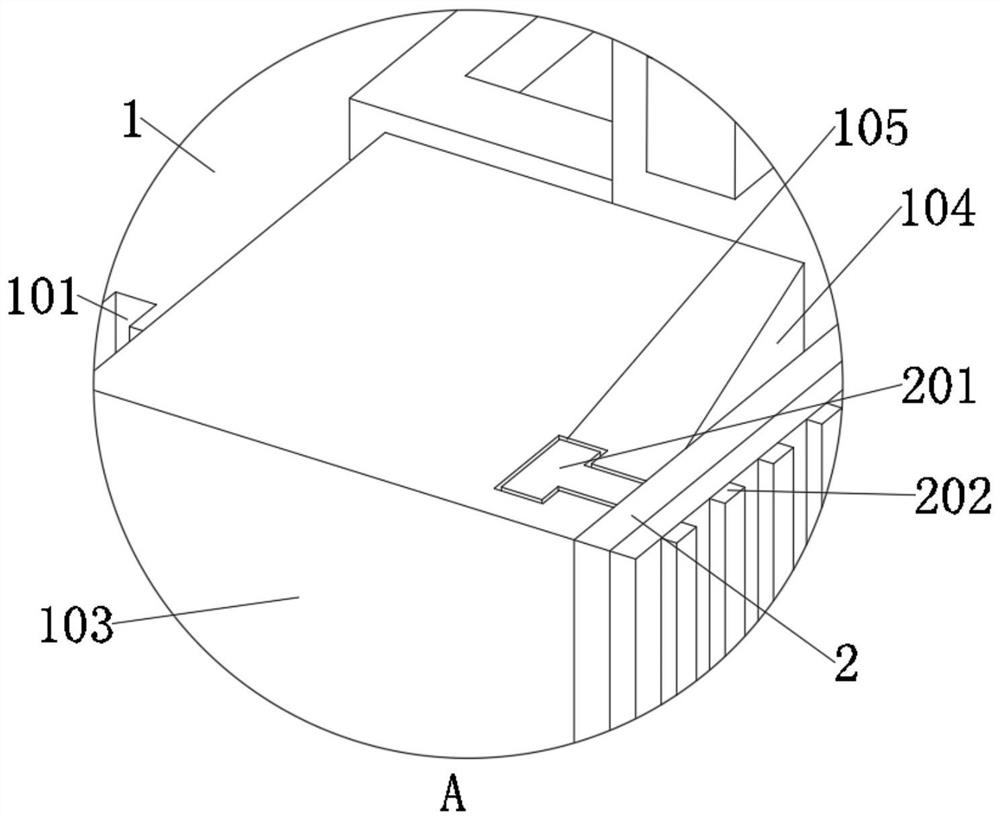

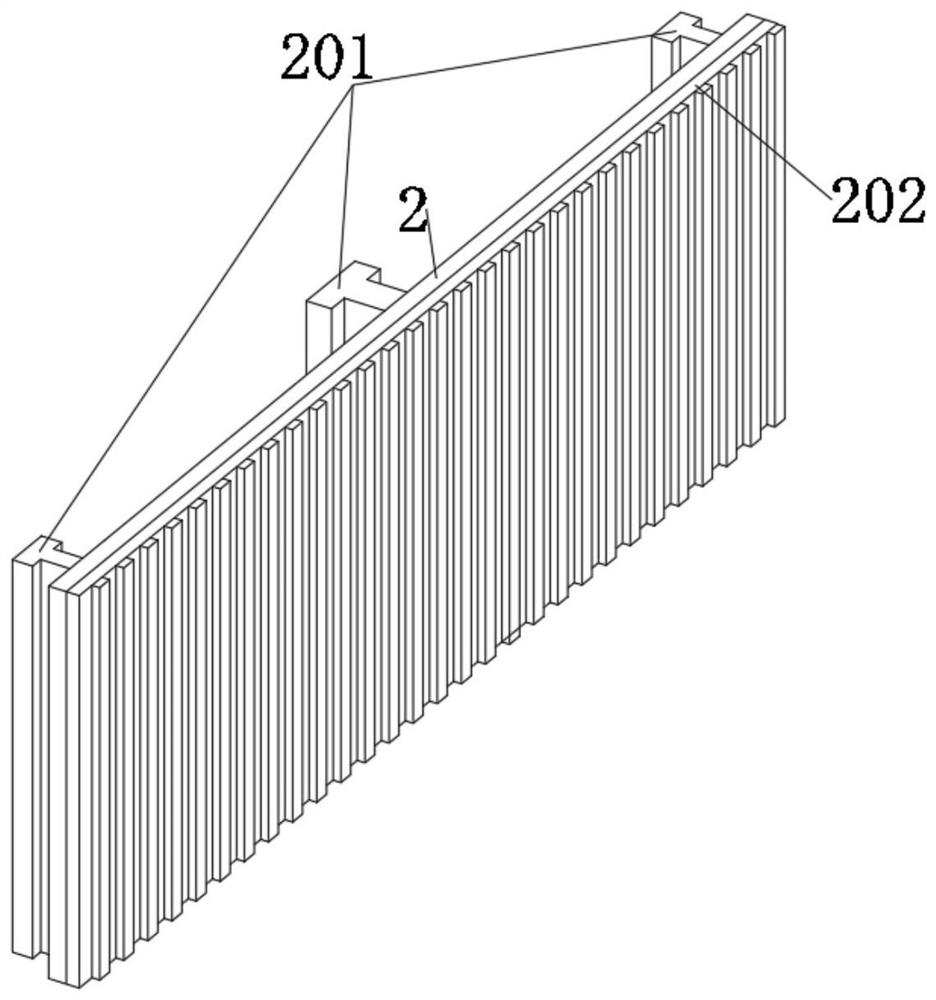

Lamination device for stator iron core of electric motor

ActiveCN113452216BAffect the use effectPlay a role in retainingManufacturing stator/rotor bodiesElectric machineVoltage regulation

The invention relates to the field of stator core processing, in particular to a motor stator core lamination device, comprising a workbench, a fixing mechanism and a lamination mechanism. The workbench is placed on the ground, and a fixing mechanism is arranged in the middle of the upper end surface of the workbench , the left and right sides of the fixing mechanism are symmetrically arranged with a lamination mechanism, which is installed on the upper end surface of the workbench. The present invention adopts the design concept of multiple pressure regulation. Layer superimposition processing, without manually stacking silicon steel sheets one by one, thereby improving the efficiency of stator core forming, and at the same time, the pressure plate set in the lamination mechanism can retain the stacked silicon steel sheets to avoid silicon steel sheets. The deflection of the sheet during the installation of the fastener affects the use effect of the subsequent stator core.

Owner:江苏苏爱尔电力设备有限公司

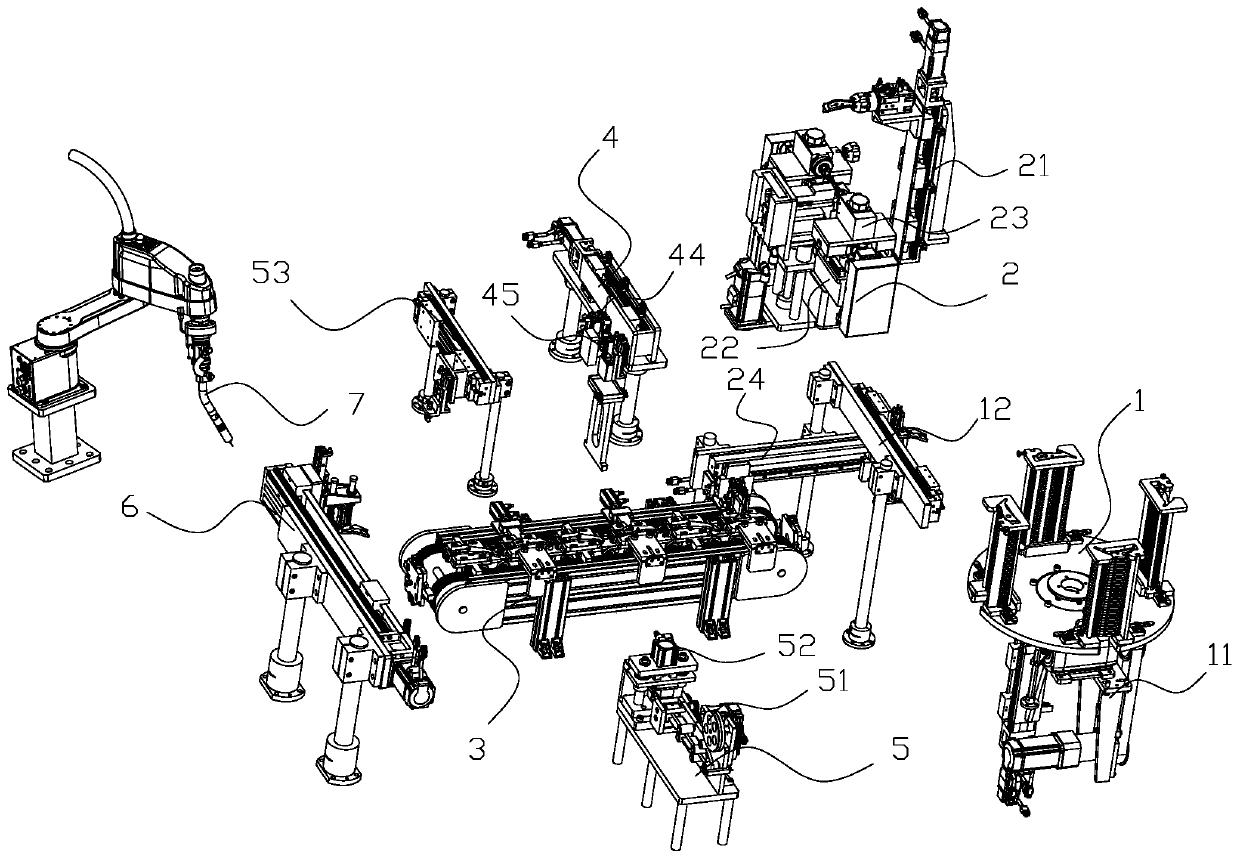

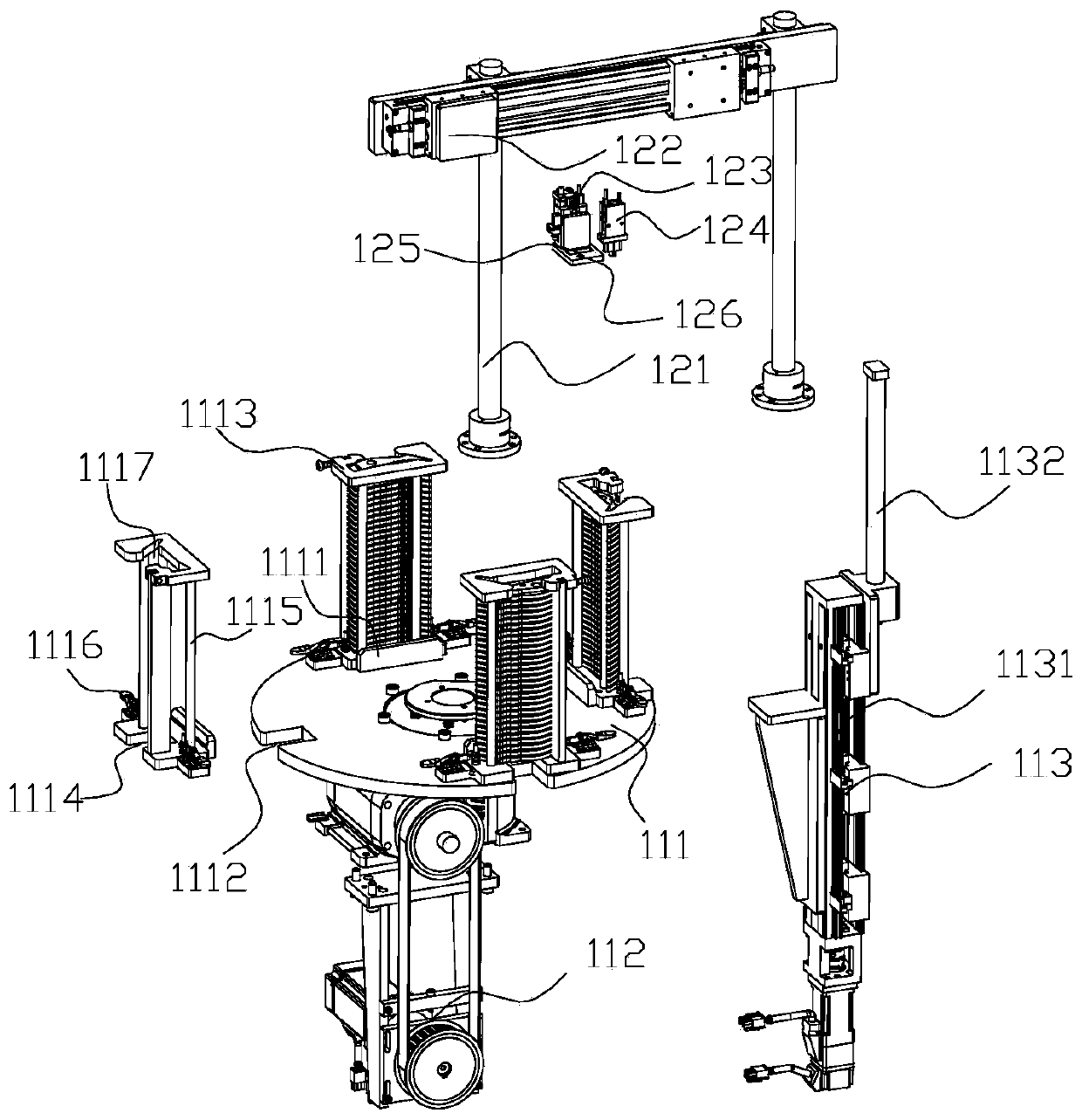

Circuit breaker, and contact and copper sheet automatic assembling method and device thereof

InactiveCN111430189AEasy transferPrevent fallingEmergency protective device manufactureCopperMaterials science

The invention relates to the technical field of circuit breaker production, and discloses a contact and copper sheet automatic assembling device of a circuit breaker. The automatic assembling device comprises a rack, and a contact conveying and transferring device, a contact deburring device, a contact synchronous belt conveying device, a contact cleaning and coating device, a copper sheet assembling device, a discharging device and a welding device which are arranged on the rack. The device has the advantages that the contact clamping quality is improved, the synchronous belt conveying efficiency is improved, and the copper sheet and contact assembling quality is improved.

Owner:丁水珍

A device for processing plastic products

InactiveCN111421421BControl the clamping forceAvoid being too light or too heavyEdge grinding machinesGrinding carriagesEngineeringPhysics

Owner:邵东县乾兴塑料制品有限公司

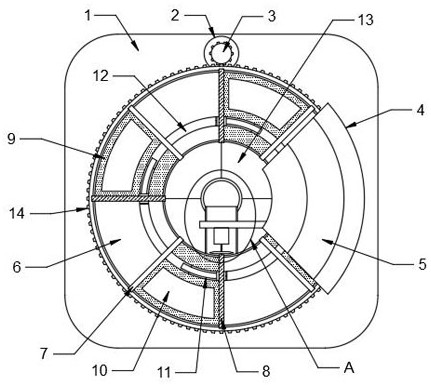

Full-automatic packaging machine

ActiveCN102991734BGuaranteed accuracyEffective clampingWrapper twisting/gatheringSolid materialDrive shaftEngineering

The invention discloses a full-automatic packaging machine. The full-automatic packaging machine comprises a stander, a driving device and a packaging executing device, wherein the driving device is arranged at the lower part of the stander, and the packaging executing device is arranged at the upper part of the stander; the packaging executing device comprises a driving disc, anchor arms, an anchor arm guide rail, stations and a transmission shaft; the number of the anchor arms is eight pairs, and the anchor arms are arranged at eight equal diversion positions of the driving disc in pairs; the anchor arms are glidingly connected with the anchor arm guide rail; the driving device drives the driving disc to rotate by the transmission shaft and drives the anchor arms arranged on the driving disc to slide on the anchor arm guide rail; and the number of the stations is eight, each station corresponds to a pair of the anchor arms, and the stations sequentially include a bagging station, a code printing station, a bag opening station, a rough filling station, a fine material supplementing station, a dust extraction station, an exhausting and heat-seal station and a cold-compacting reshaping station according to an anticlockwise sequence. According to the full-automatic packaging machine, the filling manner is simple and flexible, powders in different forms can be automatically adjusted, the dose precision and the filling speed of various materials are guaranteed, and the full-automatic packaging machine is simultaneously suitable for liquids, particles and irregular materials.

Owner:JIANGSU TOM PACKAGING MACHINERY

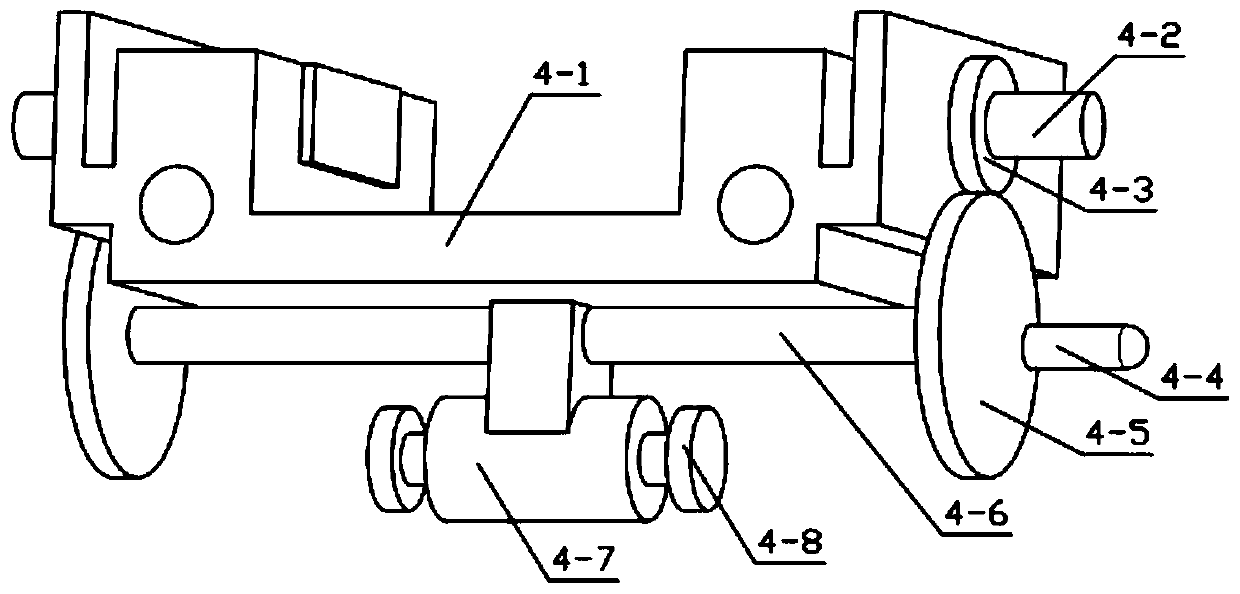

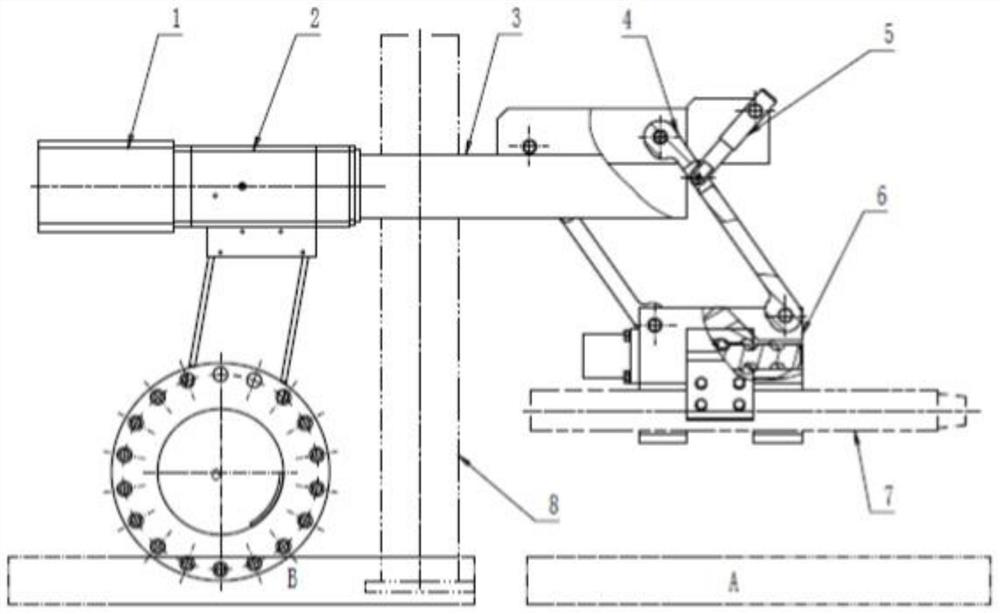

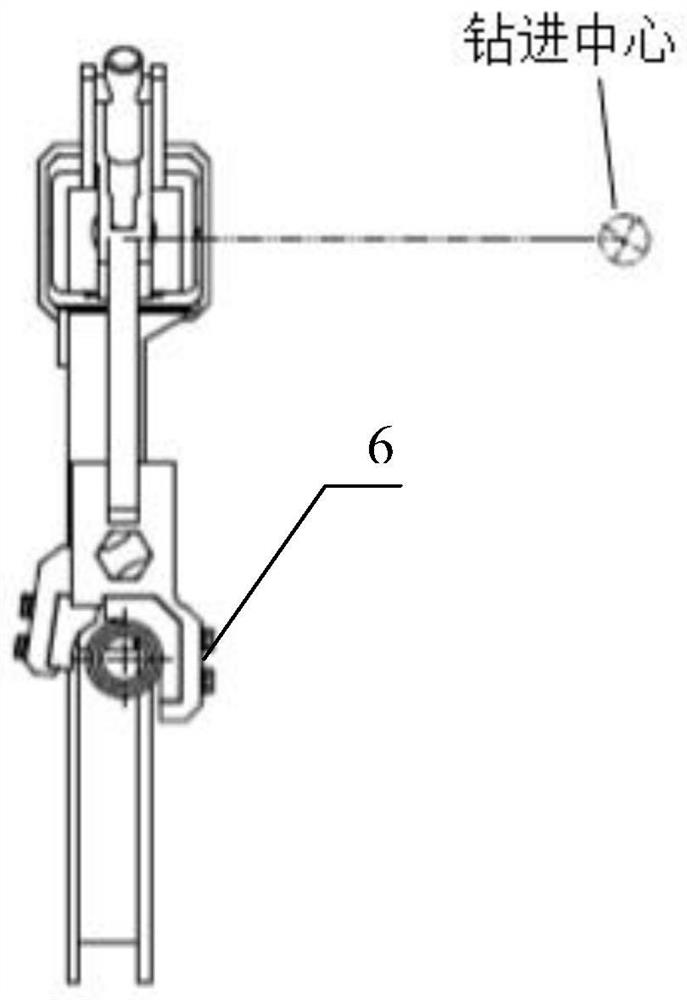

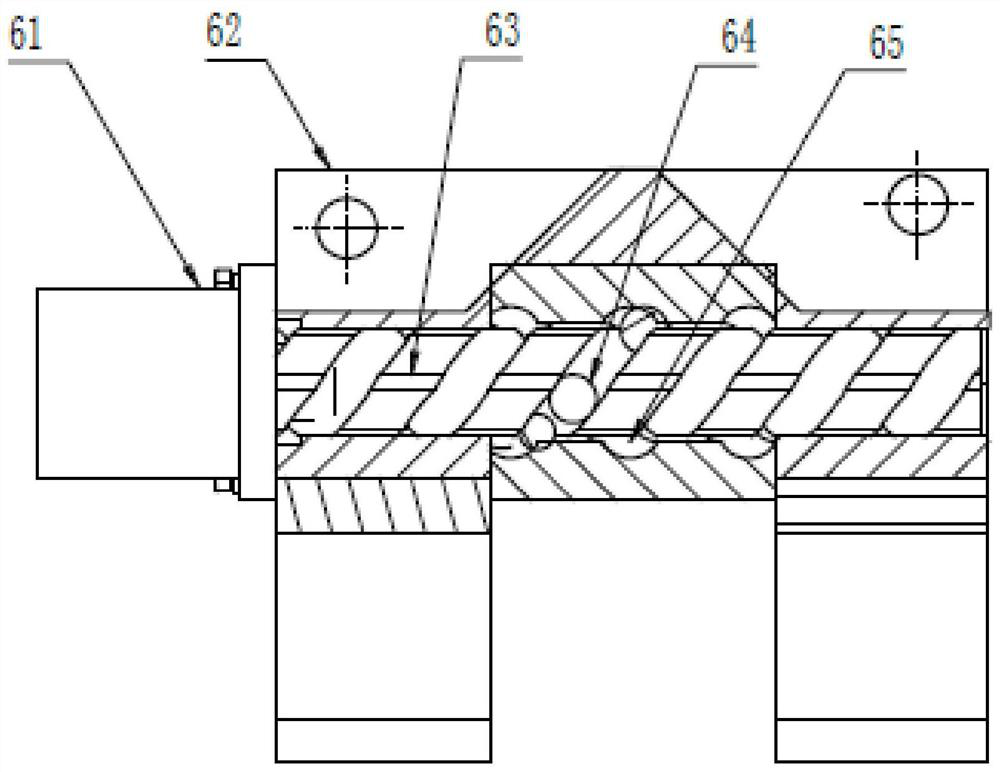

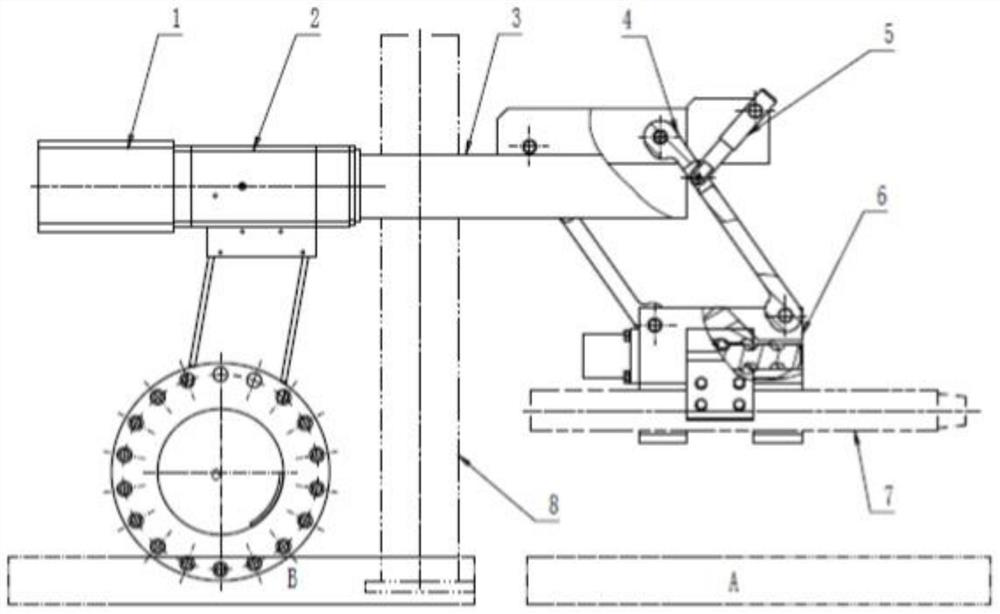

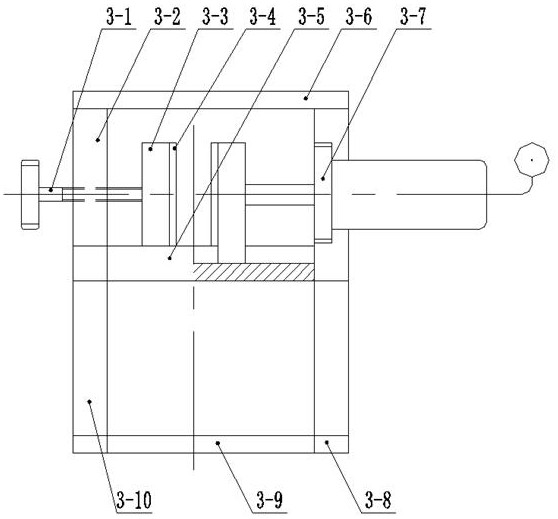

A double-link drill pipe picking manipulator

ActiveCN113006713BEnable mobilityAchieve axial movementDrilling rodsDrilling casingsControl engineeringLinkage (mechanical)

The invention relates to a double-link drilling rod picking manipulator, belonging to the technical field of coal mine drilling machines, comprising a rotating arm capable of rotating in a vertical plane, the other end of the rotating arm is provided with a boom, and one end of the boom is connected with a driving arm The first driving device that rotates the axis, the other end is hinged with two parallel connecting rods, the other end of the two connecting rods is provided with a mechanical claw whose clamping power is parallel to the boom, and is connected with the connecting rod to make the mechanical claw work Translational second drive. The invention adopts a parallel four-bar linkage mechanism to realize the longitudinal movement and parallel movement of the drill pipe, shortens the radius of the drill pipe turning over to the drilling center, improves the turning stability, and at the same time, the double-link swing also realizes the axial movement of the drill pipe. Moving in the direction, combined with the flip function, can effectively avoid the column space.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

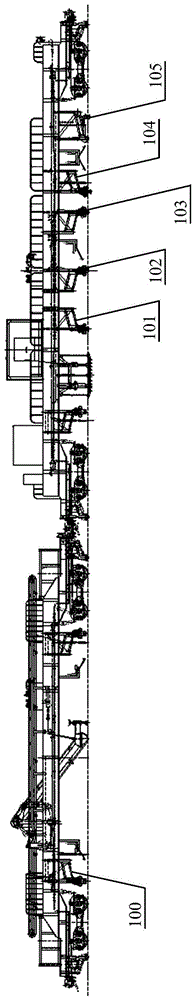

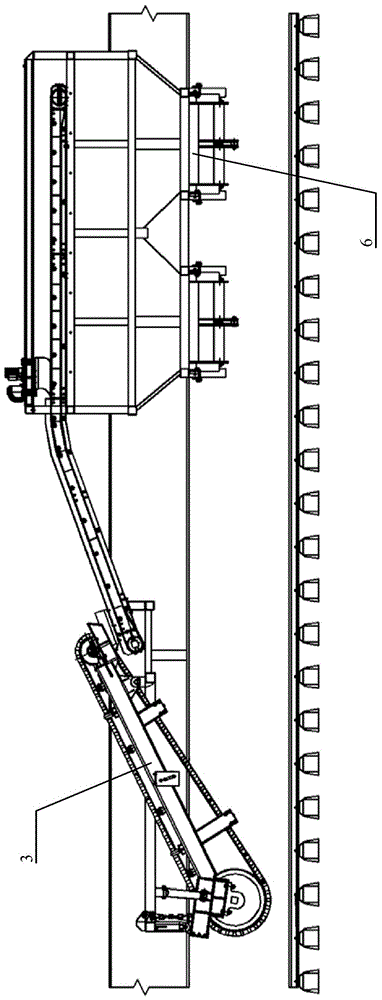

Quick track change operation vehicle and its operation method

ActiveCN104264549BShorten the lengthAdapt to the needs of fast track changeTrack superstructureRailway track constructionBogieFastener

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD +1

Double-connecting-rod drill rod picking manipulator

The invention relates to a double-connecting-rod drill rod picking manipulator, and belongs to the technical field of coal mine drilling rigs. The manipulator comprises a rotating arm capable of rotating in a vertical plane, a big arm is arranged at the other end of the rotating arm, one end of the big arm is connected with a first driving device for driving the big arm to rotate around the axis of the big arm, two parallel connecting rods are hinged to the other end of the big arm, the other ends of the two connecting rods are provided with mechanical claws with clamping power parallel to the big arm, and the manipulator further comprises a second driving device which is connected with the connecting rods and can make the mechanical claws move horizontally. According to the manipulator, a parallel four-connecting-rod mechanism is adopted, longitudinal movement and parallel movement of a drill rod are achieved, the turning radius of the drill rod towards the drilling center is shortened, the turning stability is improved, meanwhile, axial movement of the drill rod is achieved through double-connecting-rod swinging, and by combining the turning function, the space of a stand column can be effectively avoided.

Owner:CHINA COAL TECH ENG GRP CHONGQING RES INST

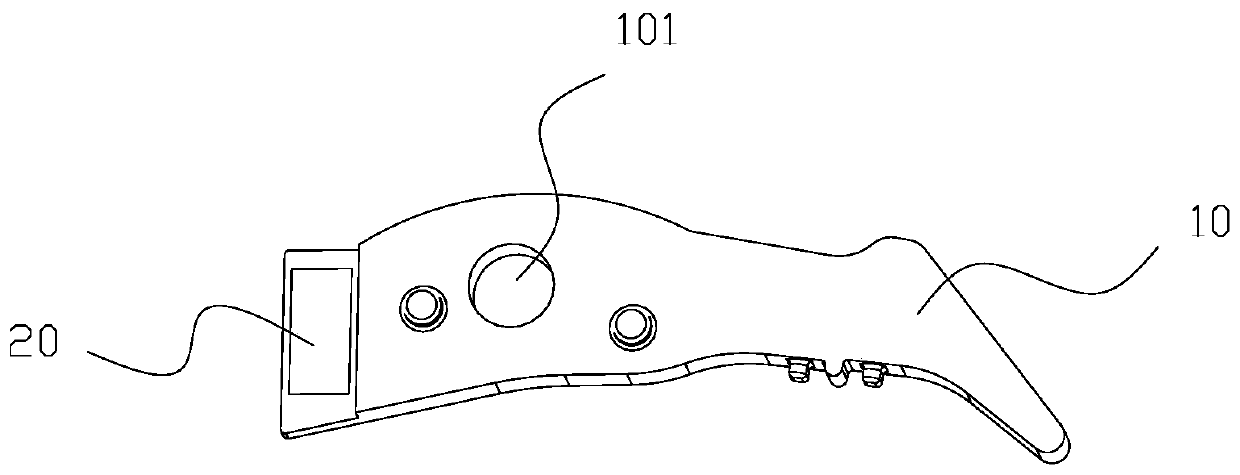

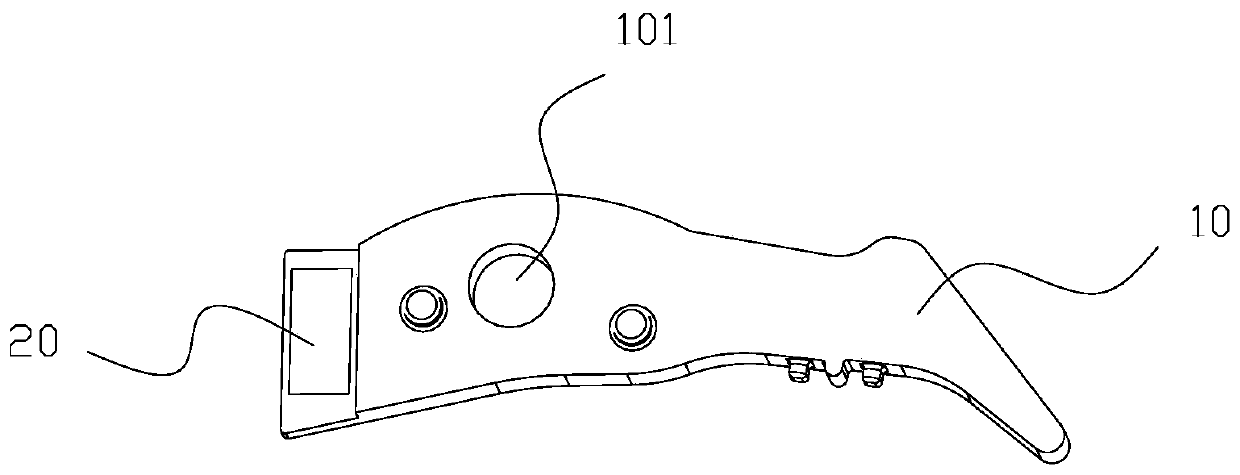

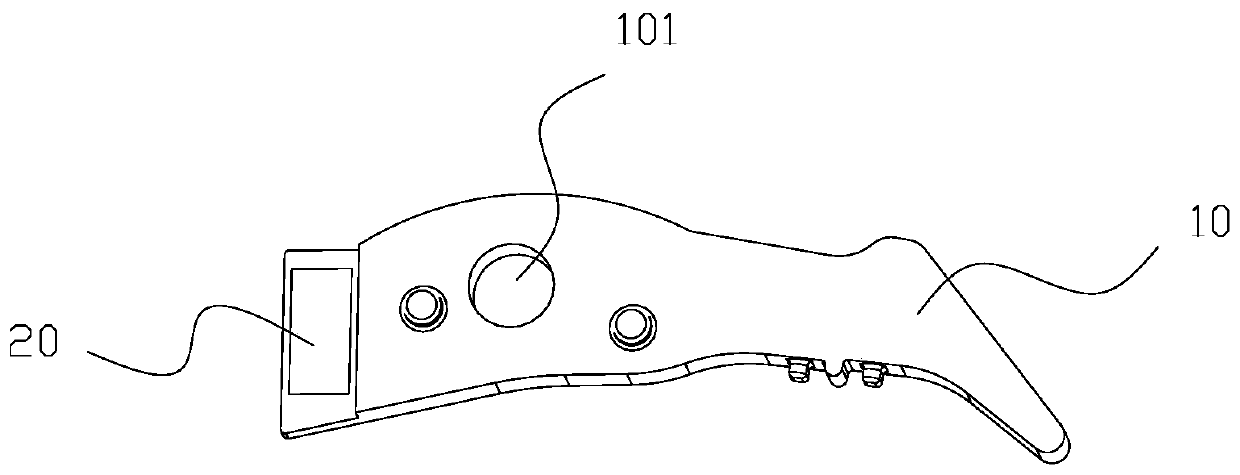

A charging gun clamping seat for a charging robot

ActiveCN111244728BNo damage issuesAvoid resistanceVehicle connectorsCharging stationsSteering wheelGear wheel

The invention discloses a charging gun clamping seat for a charging robot in the technical field of charging gun clamping. There is a top groove on the top, the inner cavity of the top groove is provided with a rectangular plate, the side wall of the rectangular plate is provided with a rectangular groove, the inner walls of both ends of the rectangular groove are evenly equipped with racks, and the side wall of the lifting outer box is fixedly installed with a lifting motor. The output end of the lifting motor is fixedly installed with an inner shaft, which is inserted into the rectangular groove, and the outer wall of the inner shaft is fixedly equipped with a half gear, which meshes with the rack. The top of the rectangular plate is fixedly installed with an upper box, and the top of the upper box is opened There is an inner cavity of the upper box, and a telescopic rod drive motor is fixedly installed in the inner cavity of the upper box. This device can control the clamping force of the charging robot during the clamping process without excessive clamping, and the steering control is precise and can be adjusted. Clamping height.

Owner:CHANGZHOU INST OF DALIAN UNIV OF TECH

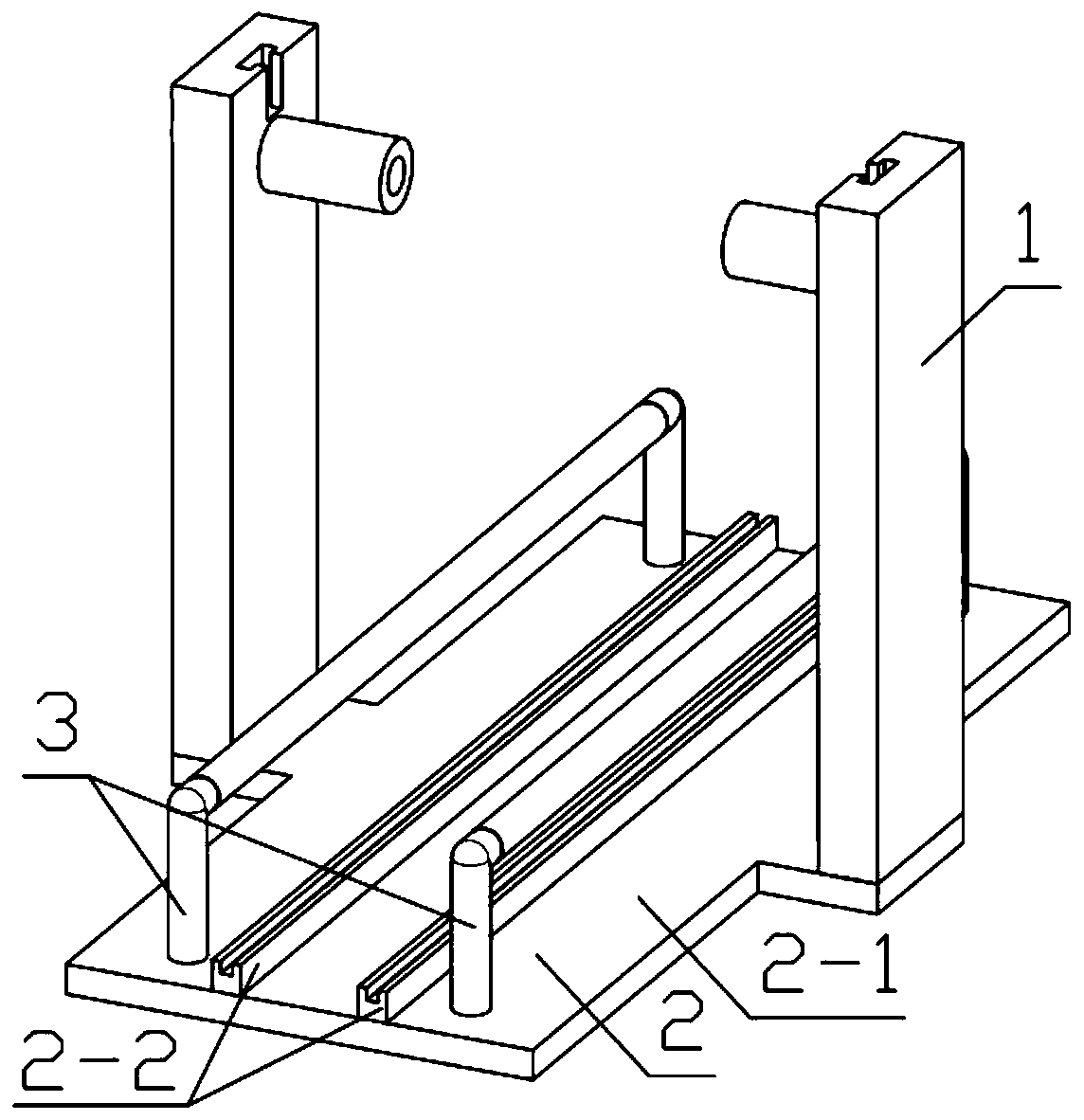

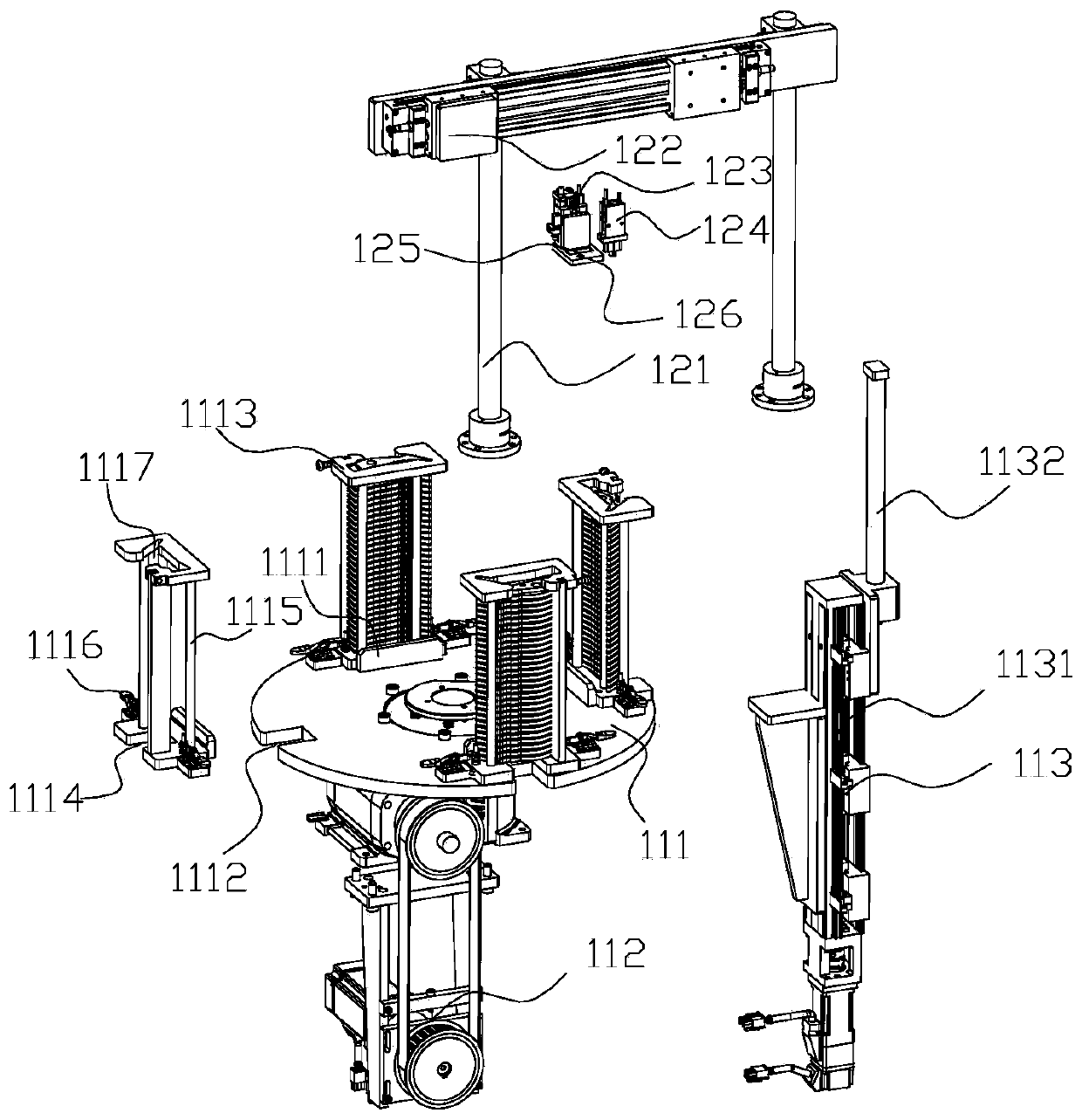

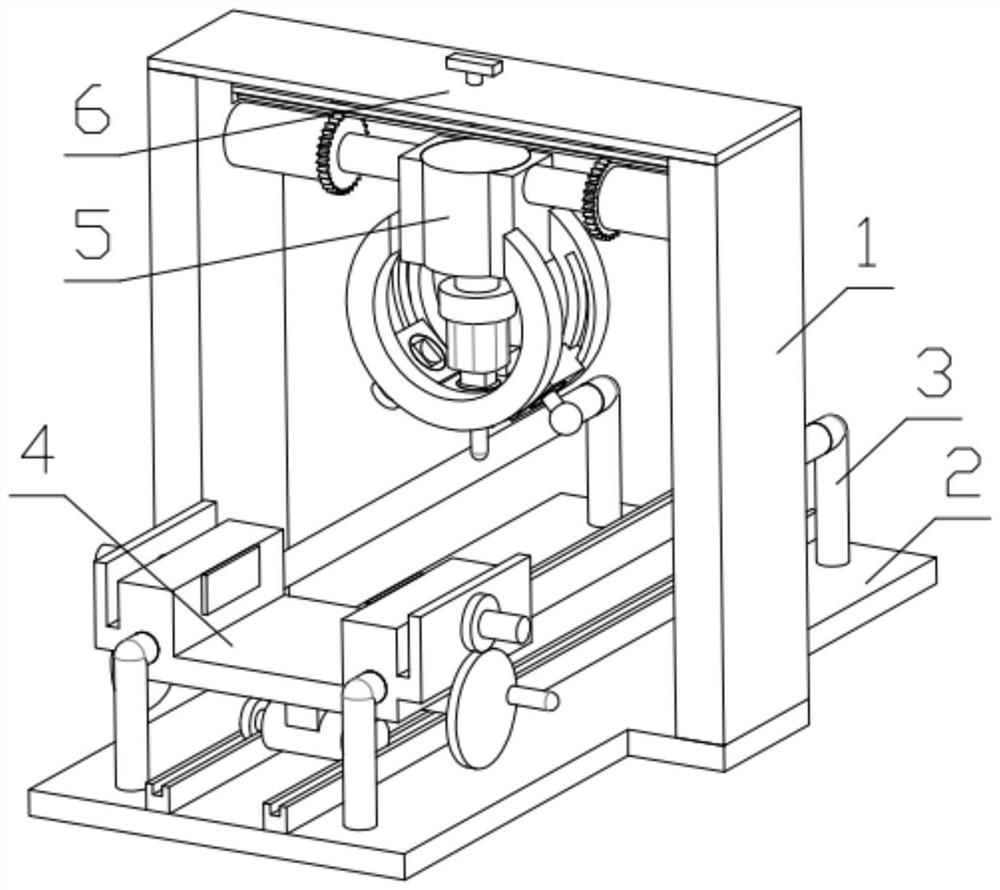

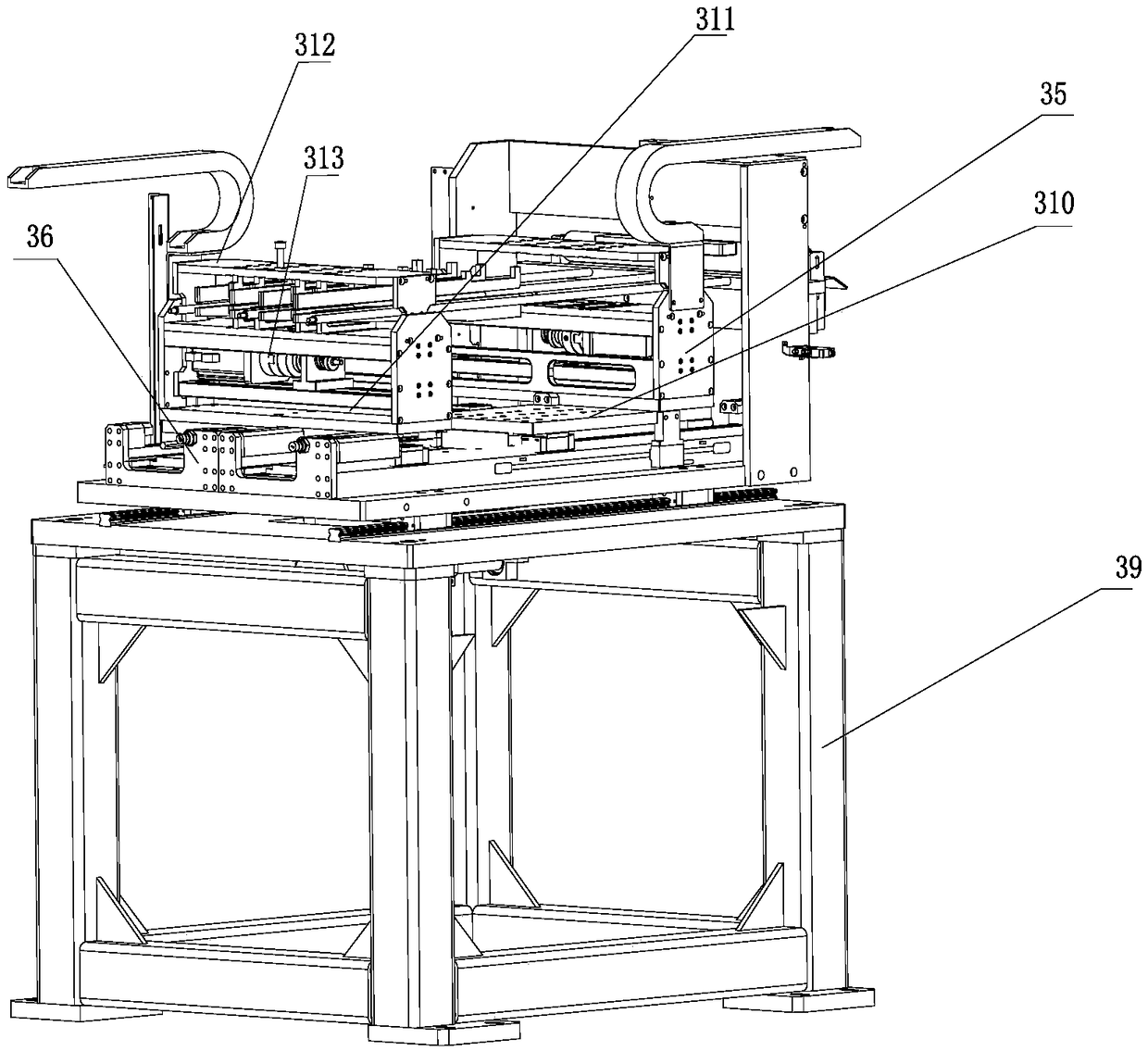

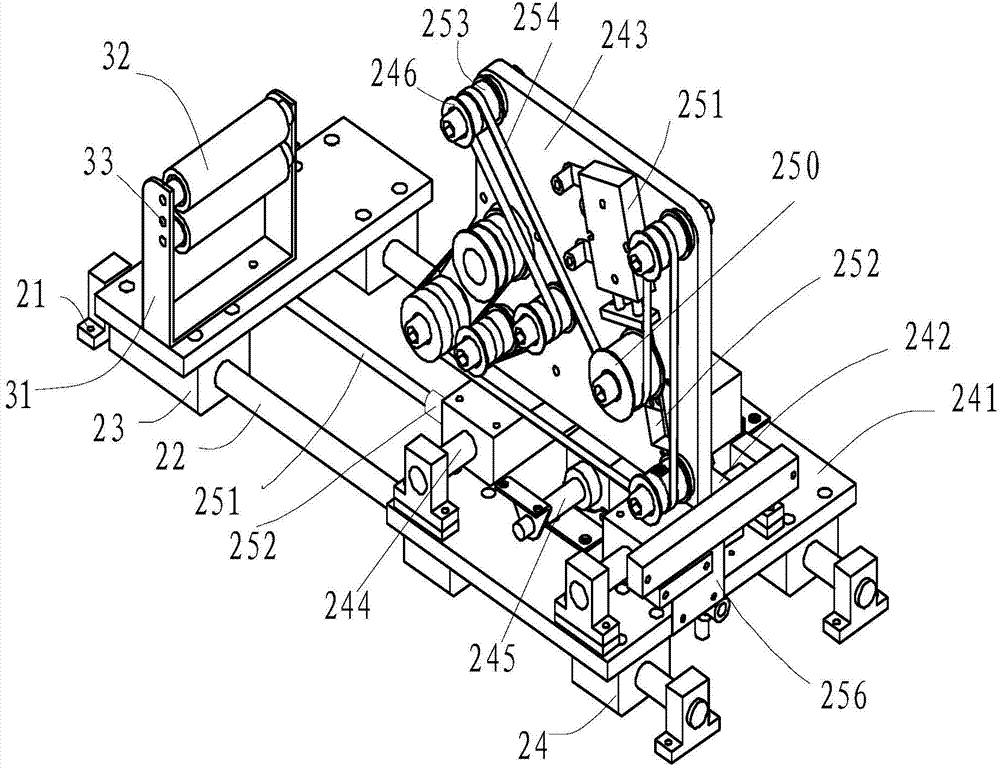

Contact deburring device and method for circuit breaker assembly

InactiveCN111326374AEasy transferHigh precisionPositioning apparatusEmergency protective device manufactureEngineeringCircuit breaker

The invention relates to the technical field of circuit breaker production. The invention discloses a contact deburring device for circuit breaker assembly. The contact deburring device comprises a deburring rotary adjusting assembly, a deburring clamping assembly, a deburring assembly and a deburring transferring assembly. The deburring rotary adjusting assembly is located on the right side of the deburring clamping assembly and used for rotating the contact from the horizontal state to the vertical state. The deburring clamping assembly is used for clamping and fixing the front side and therear side of the contact. The deburring assemblies are located on the front side and the rear side of the deburring clamping assembly and used for conducting deburring treatment on the front portion and the rear portion of the contact. The deburring transferring assembly is located on the left side of the deburring clamping assembly and used for clamping the contact for conveying and transferring.The contact deburring device has the advantages that the contact can be stably clamped, and the deburring quality of the contact and the stability in the deburring process are improved.

Owner:丁水珍

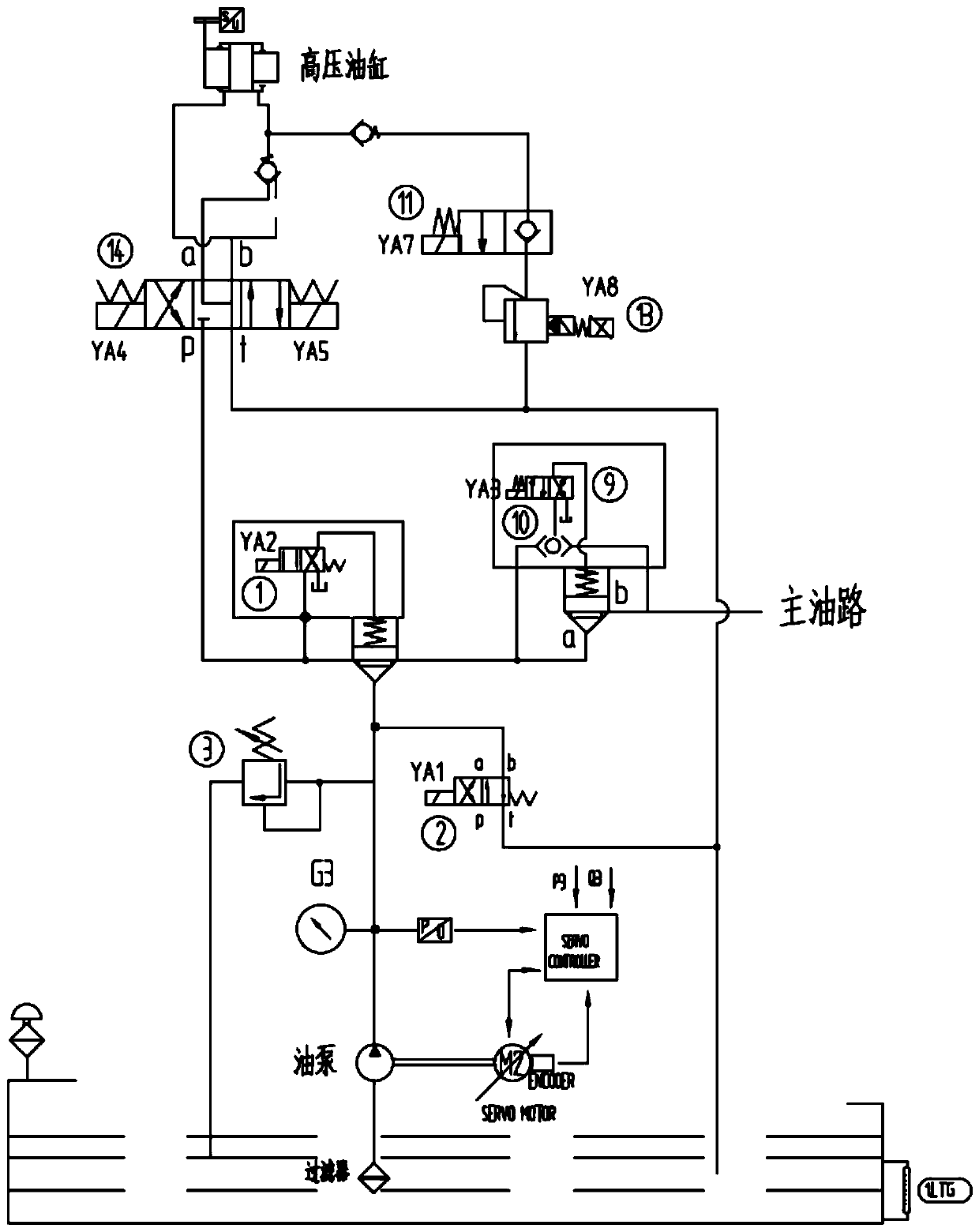

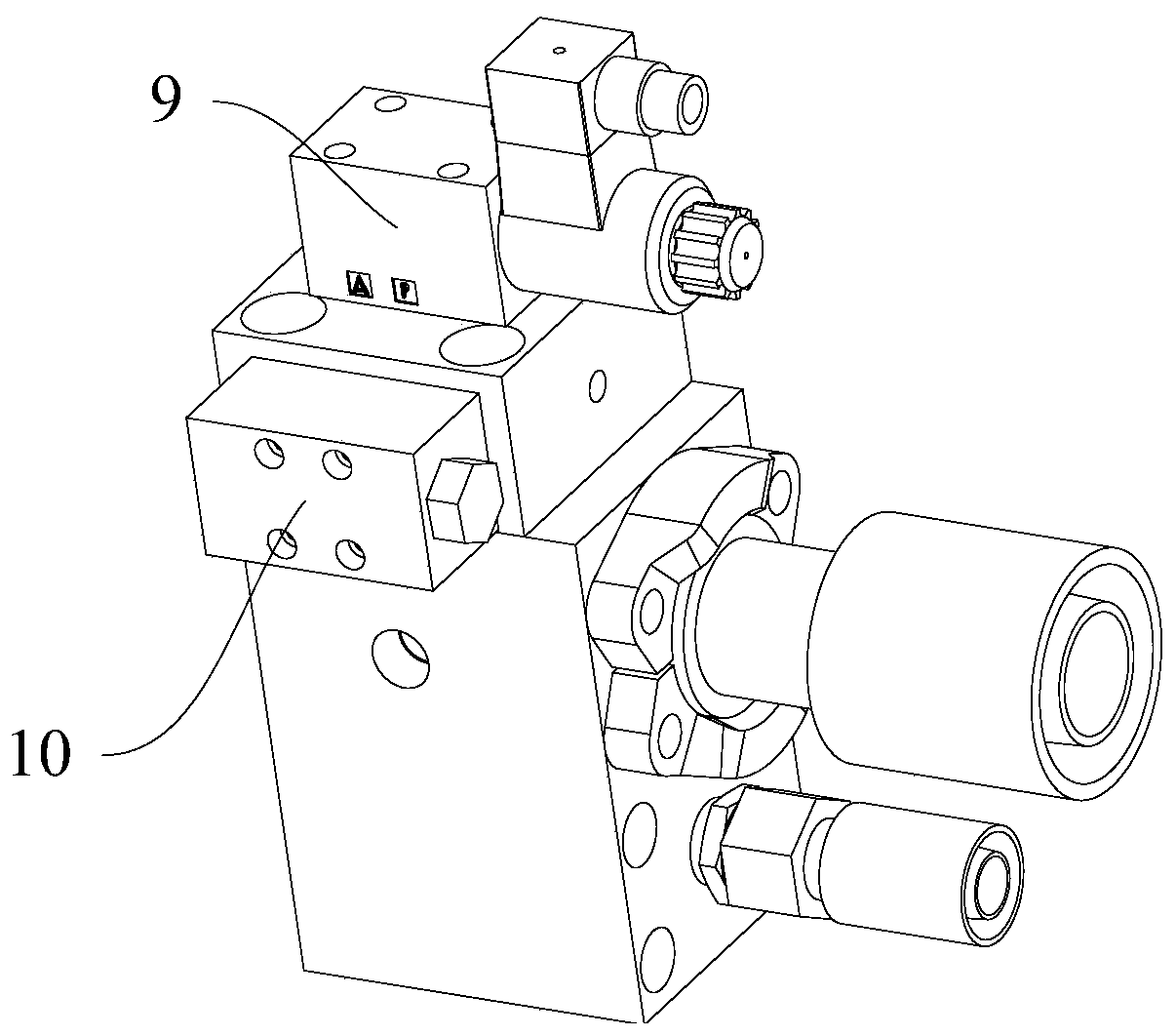

Multi-time mode-locking hydraulic oil path structure of injection molding machine and multi-time mode-locking method thereof

The invention discloses a multi-time mode-locking hydraulic oil path structure of an injection molding machine. The structure comprises an oil tank, a first oil pump, a main oil path oil pump, a servomotor and a mode-locking high-pressure oil cylinder; a first control valve and a second control valve are arranged in a connecting oil path between the oil pump and the mode-locking high-pressure oilcylinder, a third control valve is arranged on a connecting oil path between the main oil path oil pump and the mode-locking high-pressure oil cylinder, the main oil path oil pump sequentially communicates with the third control valve, the first control valve, the second control valve and the mode-locking high-pressure oil cylinder to form a second oil path channel, a first oil return channel isfurther arranged on a connecting oil path between the second control valve and the mode-locking high-pressure oil cylinder, and the first oil return channel comprises a fourth control valve and an adjusting valve and sequentially communicates with the fourth control valve, the adjusting valve and the oil tank. Arrangement of the multiple oil path channels and control of a series of hydraulic oil valves are combined with multi-time mode-locking steps, pressure oil can be effectively conveyed to all mode-locking oil cylinders, and therefore mode-locking force is controlled.

Owner:BORCH MACHINERY

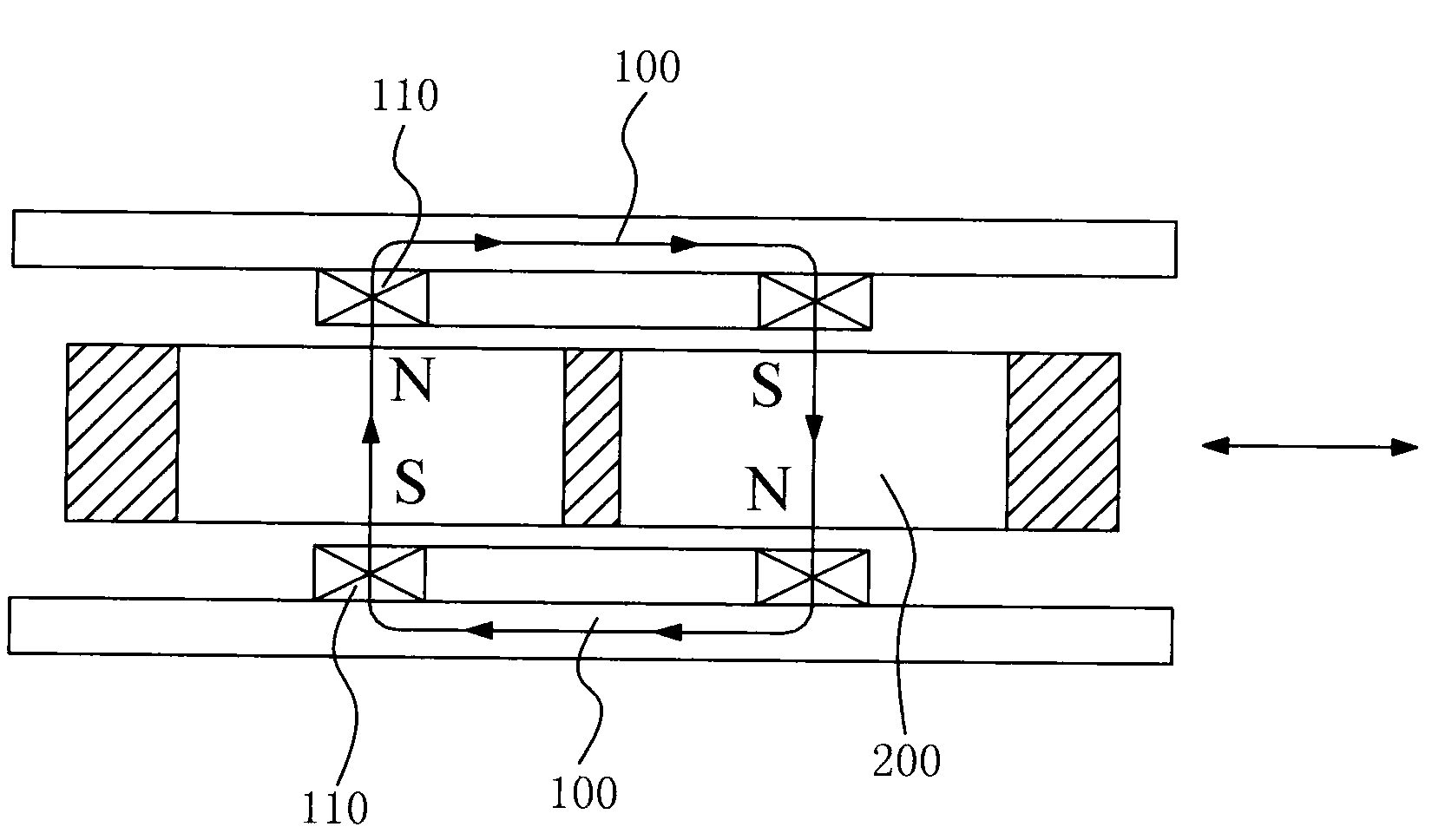

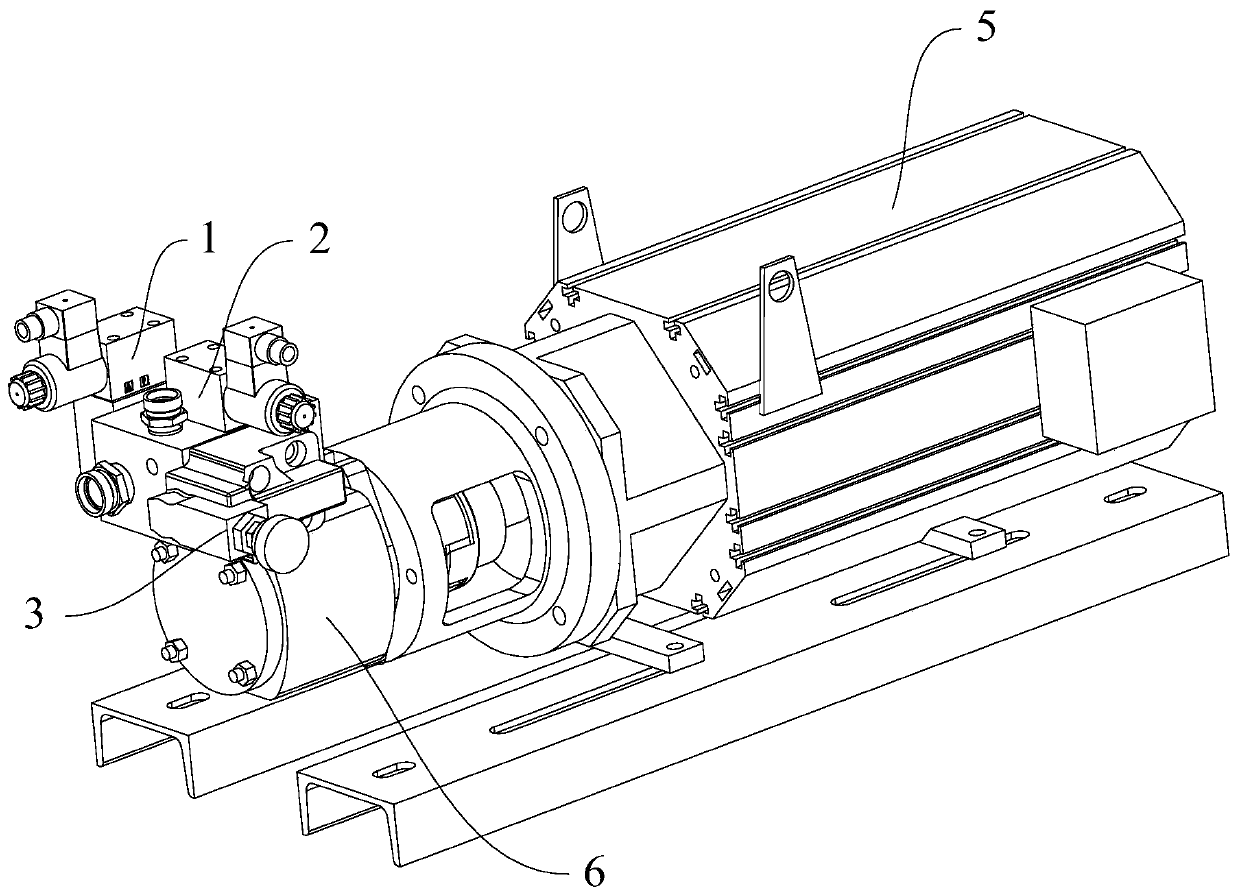

High-frequency start-stop traction system

ActiveCN106865305BControl the clamping forceWon't change trackWebs handlingTraction systemStart stop

The invention discloses a high-frequency start and stop traction system. The high-frequency start and stop traction system comprises a magnetic track and a support mechanism matched with the magnetic track, wherein an iron core coil is arranged in the magnetic track; a material strip clamping mechanism is arranged on the support mechanism; a plurality of upper clamping jaws and a plurality of lower clamping jaws, which work together, are fixedly arranged on the material strip clamping mechanism; a plurality of vacuum suckers are arranged on the upper clamping jaws or the lower clamping jaws; and the upper clamping jaws or the lower clamping jaws can move up and down to clamp a material strip. Owing to the function of the vacuum suckers, the clamping force of the upper and lower clamping jaws and the material strip can be controlled to prevent the material strip from being crushed by an excessively large clamping force and also to prevent the surface of the material strip from being scratched by sliding of the clamping jaws relative to the material strip due to an excessively small clamping force. Besides, by adoption of the structure, the track of the material strip cannot be changed, the material strip is always pulled in the horizontal direction, and therefore, the accuracy is maintained.

Owner:临沂新科绿色建材有限公司

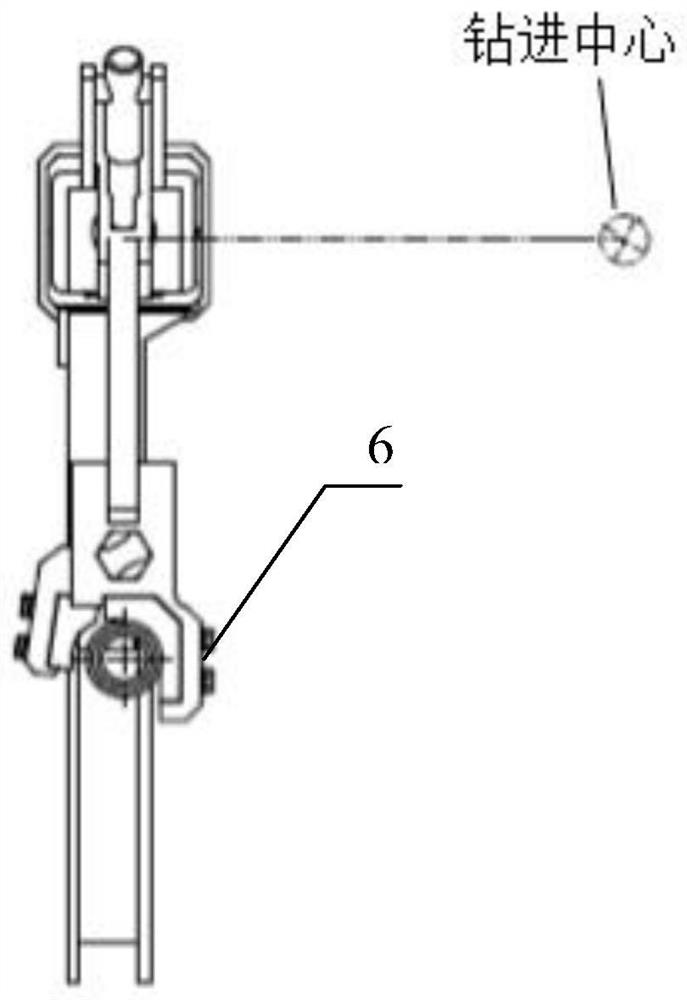

A mine-used built-in piston mechanical claw

ActiveCN113021392BRealize opening and closingRealize the clamping effectGripping headsPilot holeStructural engineering

The invention relates to a mine-used built-in piston-type mechanical claw, which belongs to the technical field of coal mine drilling rigs, and includes a fixed claw, which is provided with a guide hole along its length direction, and a telescopic shaft with only an axial movement degree of freedom is arranged in the guide hole. One end of the telescopic shaft is connected with a driving device capable of driving along its axial movement; the telescopic shaft is also set with a movable claw that can rotate around its axis, and the movable claw and the fixed claw form a clamping center parallel to the telescopic shaft jaws. The clamping power of the mechanical claws of the present invention is parallel to the axis of the drill pipe, which solves the problem of large pick-up space for the drill pipe caused by the clamping power of the mechanical claws being perpendicular to the axis of the drill pipe.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

Vegetable root cutting, weighing and grading device

ActiveCN113370288ACompact structureSmall footprintSortingMetal working apparatusAgricultural engineeringStructural engineering

The invention provides a vegetable root cutting, weighing and grading device. The device comprises a base, a rotatable feeding disc is mounted on the base, the center of the feeding disc is open, a root cutting mechanism is mounted at the opening, a fixing ring is mounted below the feeding disc, a collecting barrel used for collecting vegetable roots is rotationally connected to the position, located below the fixing ring, of the base, a barrel opening is formed in the top of the collecting barrel, a plurality of collecting grooves are fixed to the circumferential side wall of the collecting barrel, weighing assemblies are mounted at the bottoms of the collecting grooves, a top plate is mounted above the feeding disc; and a sorting device is mounted at the bottom of the top plate; a plurality of feeding areas used for placing vegetables are arranged on the feeding disc at intervals, and clamping mechanisms are mounted in the feeding areas. The device adopts a processing mode of an annular production line, is more compact in structure and small in occupied space, and can automatically complete the processes of cutting, sorting and weighing.

Owner:江苏景瑞农业科技发展有限公司

A device for weighing and grading vegetable cut roots

ActiveCN113370288BCompact structureSmall footprintSortingMetal working apparatusAgricultural engineeringMechanical engineering

The invention provides a device for weighing and grading vegetable cut roots, which includes a base, on which a rotatable feeding tray is installed, and the center of the feeding tray is opened, and a cut root is installed at the opening. mechanism, a fixed ring is installed under the feeding tray, and a collection barrel for collecting vegetable roots is connected to the base under the fixed ring. The top of the collection barrel is provided with a barrel mouth, and the circumferential side of the collection barrel is The wall is fixed with a plurality of collection tanks, weighing components are installed at the bottom of the plurality of collection tanks, a top plate is installed above the feeding tray, and a sorting device is installed at the bottom of the top board; the feeding A plurality of feeding areas for placing vegetables is provided in the gap on the plate, and clamping mechanisms are installed in the plurality of feeding areas. The device adopts the processing method of the ring production line, has a more compact structure, takes up less space, and can automatically complete the cutting, sorting and weighing processes.

Owner:江苏景瑞农业科技发展有限公司

Extrusion molding preparation method of polytrifluorochloroethylene bar

The invention provides an extrusion molding preparation method of a polytrifluorochloroethylene bar, and belongs to the technical field of extrusion molding. Comprising the following steps: starting main machine sections 1-3, an extruder and a mold for heating, starting a main machine section 4 and a melt pump for heating after a set temperature is reached, keeping the temperature constant after the set temperature is reached, starting a main machine and adjusting the rotating speed, starting the rotating speed of the melt pump, rotating a screw rod, feeding, and installing a cooling shaping sleeve and connecting a cooling water pipe when a bag plasticized melt is discharged from a mold body opening; plugging one end of the damping rod into the cooling shaping sleeve, adding the other end of the damping rod into the damping clamping plate, starting cooling liquid in a cooling area, starting cold water in the cooling area, adjusting the extruder to a policy working state, adjusting the clamping force of the damping machine, controlling the advancing speed, ensuring that the density of the extruded rod is qualified, and cutting to obtain the polytrifluorochloroethylene rod. Continuous extrusion molding of small-diameter bars is achieved, and the production efficiency of preparing the same product through compression molding is improved.

Owner:ZHUZHOU HONGDA POLYMER MATERIALS

Fire hose testing machine

ActiveCN103487344BReduce work intensityImprove test reliabilityMaterial strength using tensile/compressive forcesInvestigating machinabilityElectricitySynchronous motor

Owner:济南康和消防技术有限公司

Anti-falling anti-slip handle

ActiveCN112720372BControl the clamping forceEffective protectionMetal-working hand toolsControl theoryMechanical engineering

The invention discloses an anti-falling and anti-slip handle, which includes a fixed piece frame and a clamping handle. The clamping handle is clamped on the upper end of the fixed piece frame. An auxiliary pressing handle is connected between the two fixed clip seats, and a lifting and reset mechanism is installed on the clamping handle on the lower side of the auxiliary pressing handle. By setting a lifting and reset mechanism and a supporting mechanism on the clamping handle, the The reset mechanism controls the retraction of the support mechanism, thereby controlling the clamping force on the fixed film holder. When the fixed film holder is lifted, the positioning front bracket and the positioning rear support on the support mechanism are retracted inwardly by the gravity of the fixed film holder , thereby tightly against the fixed film frame, the fixed film frame is fixed, avoiding the relative sliding of the fixed film frame and the clamping handle in the process of moving, and effectively protecting the fixed film frame.

Owner:JIANGSU UNION SEMICON

A quick loading and unloading device for mechanical field

InactiveCN109623635BGuaranteed to run horizontallyGuaranteed uptimeDrying gas arrangementsCleaning using liquidsClassical mechanicsEngineering

Owner:江苏博伟自动化设备有限公司

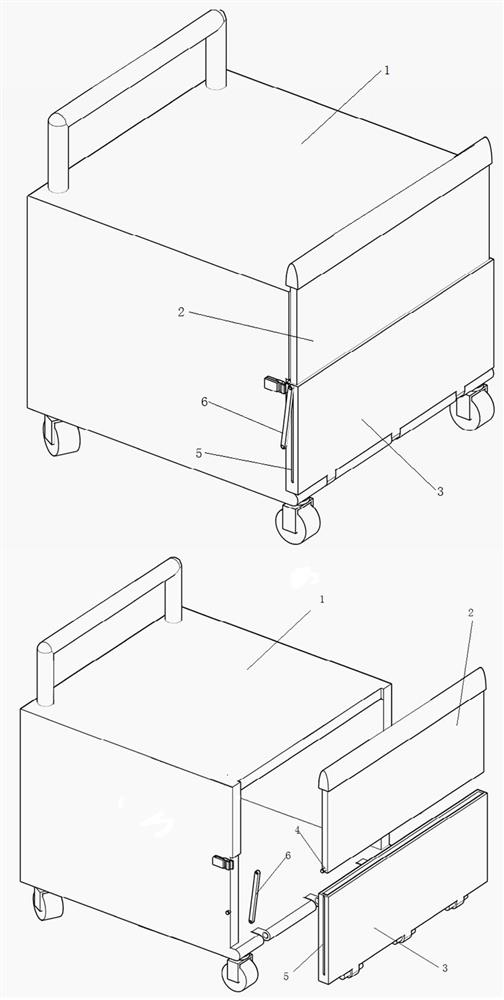

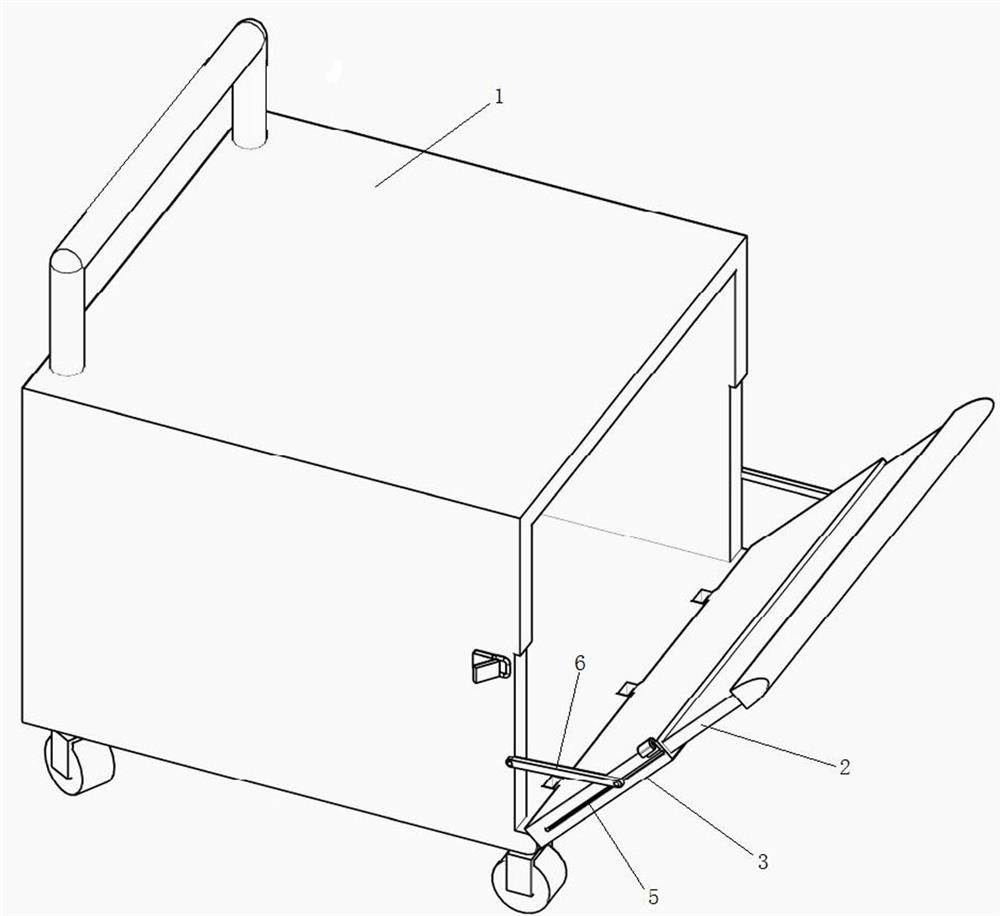

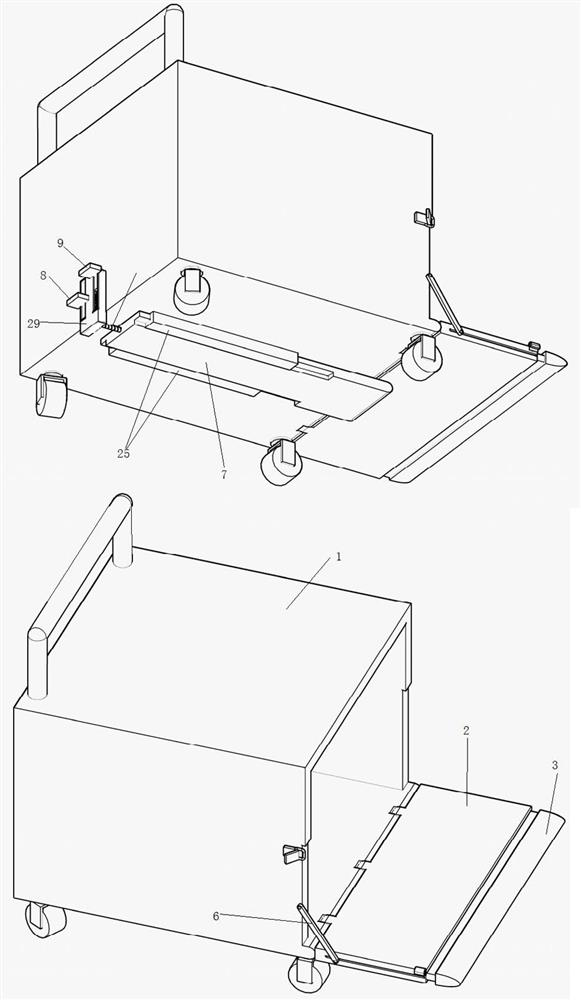

Carrying device for luggage case for containing aviation dangerous goods

ActiveCN113071545AEasy to transportAvoid smashingSupporting partsHand carts with multiple axesTrunk compartmentStructural engineering

The invention discloses a carrying device for a luggage case for containing aviation dangerous goods. The device comprises a containing box with an opening in the side face, universal wheels are arranged at the bottom of the containing box, a closing door is hinged to the opening of the containing box, the length of the closing door is shortened along with increase of the unfolding angle of the closing door, when the closing door is tightly attached to the opening of the containing box, the closing door closes the opening of the containing box, so that the luggage case for accommodating the dangerous goods is convenient to carry.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com