Extrusion molding preparation method of polytrifluorochloroethylene bar

A polychlorotrifluoroethylene, extrusion molding technology, applied in the field of extrusion molding, can solve the problems of difficult molding operation control, many secondary processing waste, low product qualification rate, etc., to ensure product quality, overcome bending deformation, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

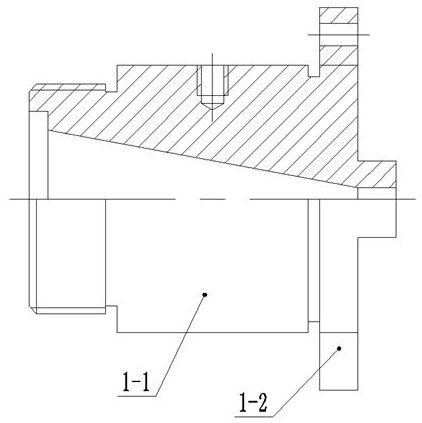

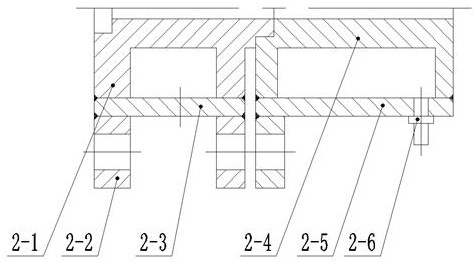

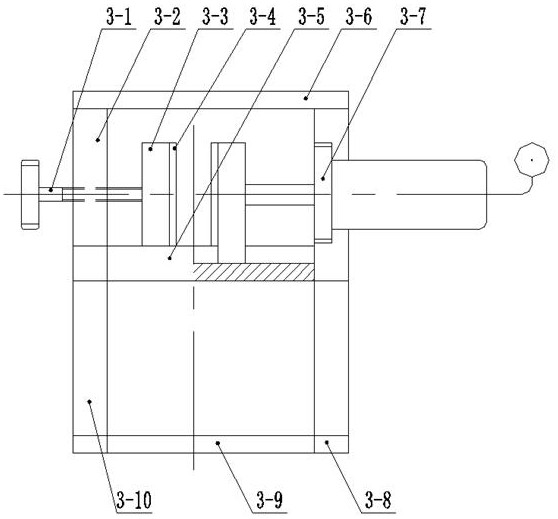

Image

Examples

Embodiment 1

[0063] Take the rod with a diameter of 10mm as an example, check the intact of 45#extruded molding machine equipment, do a good job of site and equipment hygiene, check whether the heating element and melt pump heating element are normal, prepare a diameter of 10mm product mold mold , Cooling set and supporting heating elements, cleaning molds, installation molds and supporting heating elements.

[0064] The requirements of the squeeze, melt pump and mold temperature setting are as follows:

[0065] 1 section of the extrusion machine: 160 ℃;

[0066] Extruder 2 Section Temperature: 200 ° C;

[0067] 3 sections of the extrusion machine: 260 ℃;

[0068] Squeeze out 4 -stage temperature: 280 ° C;

[0069] Flange temperature before the melt pump: 280 ° C;

[0070] The temperature of the melt pump pump: 280 ° C;

[0071] The temperature of the melt pump door panel: 280 ° C;

[0072] Mold mold temperature: 280 ° C;

[0073] The host temperature is divided into:

[0074] Paragraph 1: 180...

Embodiment 2

[0083] Take a rod with a diameter of 5mm as an example. Check the intact of 45#extruded molding machine equipment, do a good job of site and equipment hygiene, check whether the heating element and melt pump heating element are normal, prepare 5mm product mold mold mold mold molds , Cooling set and supporting heating elements, cleaning molds, installation molds and supporting heating elements.

[0084] The requirements of the squeeze, melt pump and mold temperature setting are as follows:

[0085] 1 section of the extrusion machine: 150 ° C;

[0086] Extruder 2 Section Temperature: 190 ° C;

[0087] 3 sections of the extrusion machine: 250 ℃;

[0088] Squeeze out 4 -stage temperature: 270 ° C;

[0089] Flange temperature before the melt pump: 240 ° C;

[0090] Followed pump body temperature: 240 ° C;

[0091] The temperature of the melt pump door panel: 240 ° C;

[0092] Mold mold temperature: 240 ° C;

[0093] The host temperature is divided into:

[0094] Paragraph 1: 180 ° C;

...

Embodiment 3

[0103] Take the rod with a diameter of 20mm as an example. Check the intact of 45#extruded molding machine equipment, do a good job of site and equipment hygiene, check whether the heating element and melt pump heating element are normal, and prepare a diameter of 20mm product mold mold , Cooling set and supporting heating elements, cleaning molds, installation molds and supporting heating elements.

[0104] The requirements of the squeeze, melt pump and mold temperature setting are as follows:

[0105] 1 section of the extrusion machine: 170 ℃;

[0106] Extruder 2 Section Temperature: 210 ° C;

[0107] 3 sections of the extrusion machine: 270 ° C;

[0108] Squeeze out 4 -stage temperature: 290 ° C;

[0109] Flange temperature before the melt pump: 280 ° C;

[0110] The temperature of the melt pump pump: 280 ° C;

[0111] The temperature of the melt pump door panel: 280 ° C;

[0112] Mold mold temperature: 300 ° C;

[0113] The host temperature is divided into:

[0114] Paragraph 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com