Plastic product processing device

A technology for processing devices and plastic products, applied in the direction of manufacturing tools, grinding machines, grinding machine parts, etc., can solve the problems of inability to meet the needs of grinding, plastic deformation, etc., to achieve high accuracy, easy operation, and prevent the force from being too light. or overweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

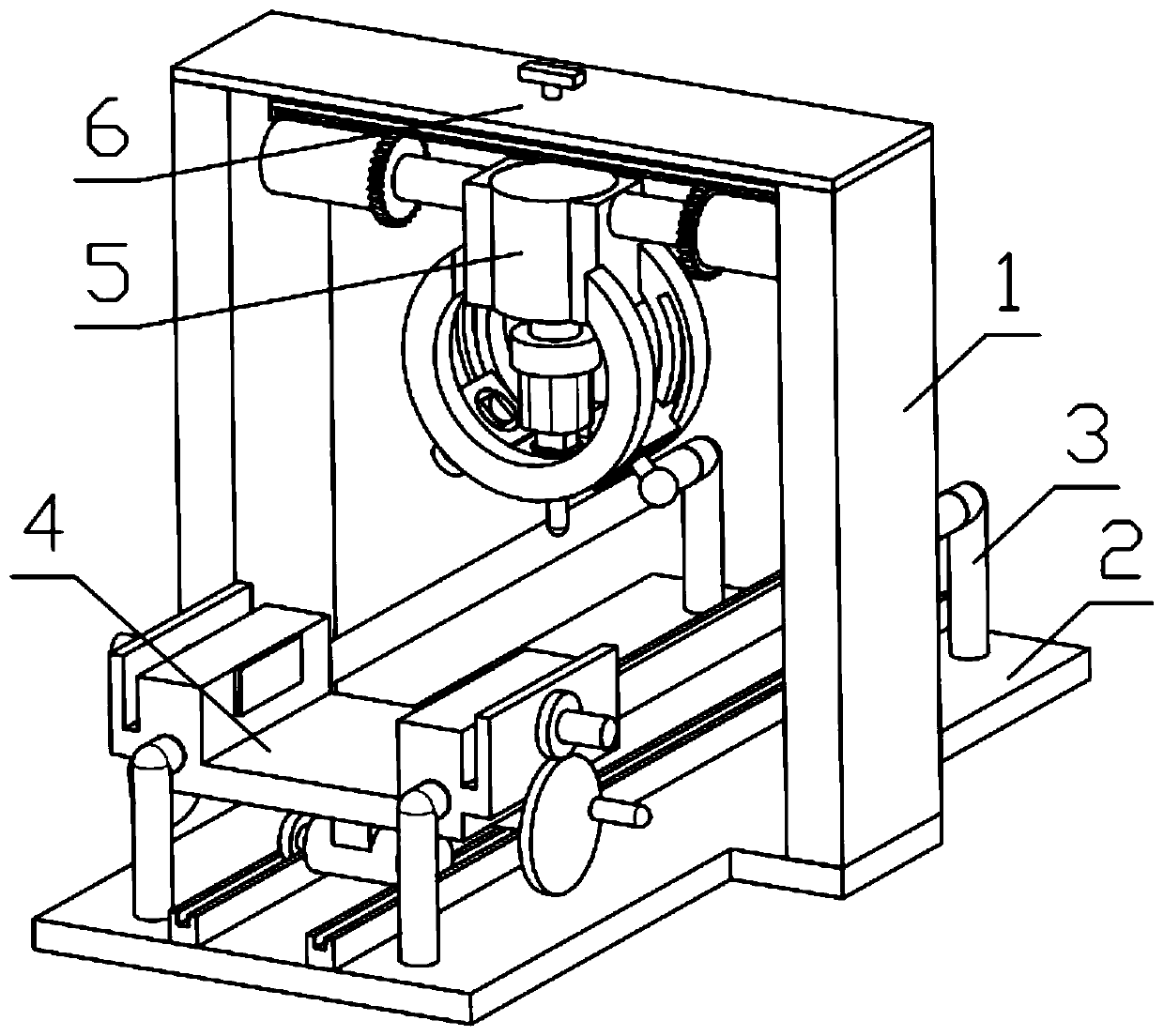

[0038] Combine below Figure 1-13 Describe this embodiment, a plastic product processing device, including a side support frame 1, a bottom mounting plate 2 and a rail rod 3, the rail rod 3 is fixedly installed on the bottom mounting plate 2, and the side support frame 1 is fixedly mounted on the bottom mounting plate 2 Above, the fixed mechanism 4 is slidably installed on the track rod 3, the fixed mechanism 4 is engaged with the bottom mounting plate 2, the multi-functional grinding mechanism 5 is fixedly installed on the angle adjustment mechanism 6, and the angle adjustment mechanism 6 is fixedly installed on the side support Rack 1.

specific Embodiment approach 2

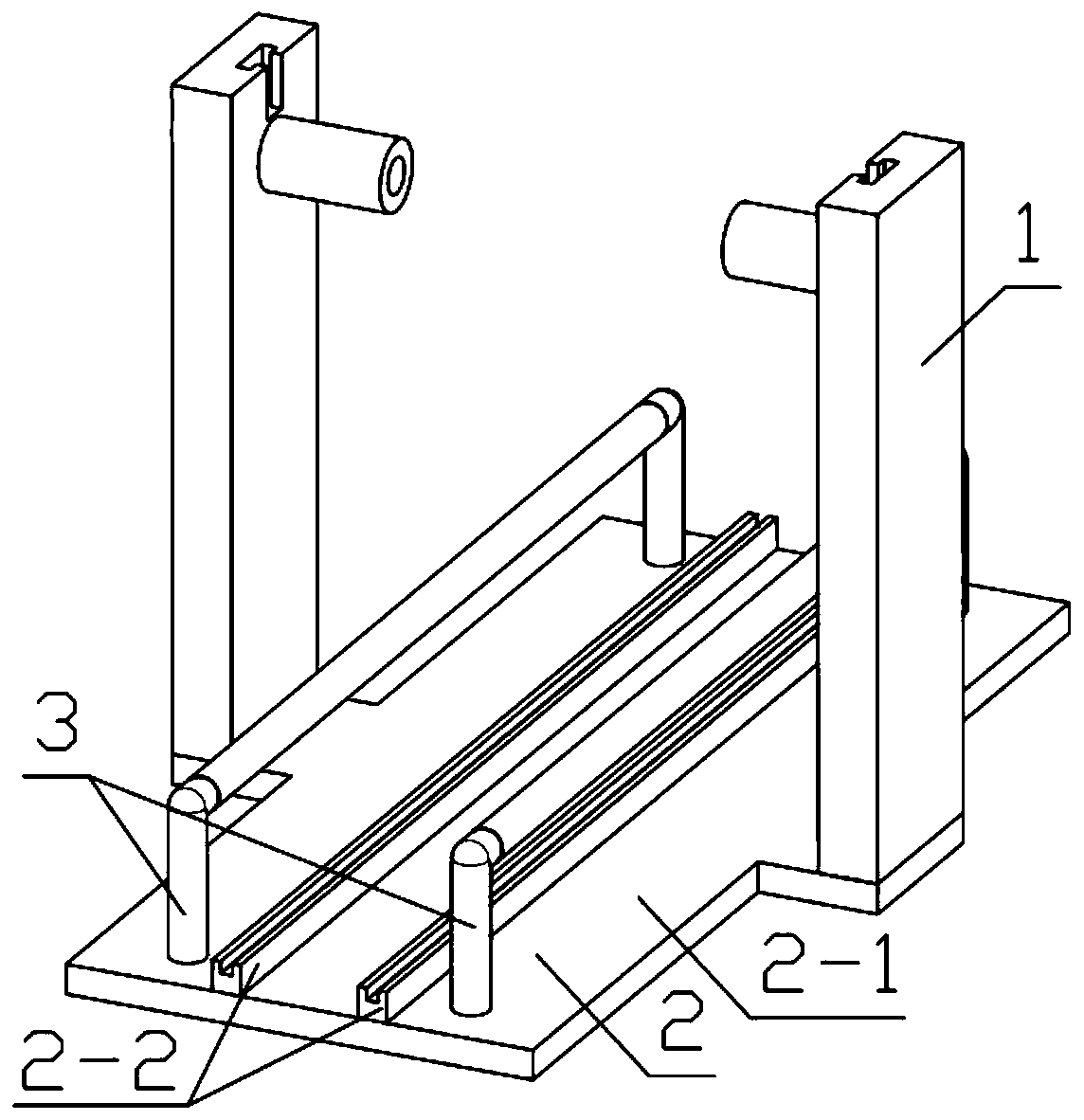

[0040] Combine below Figure 1-13 This embodiment will be described. This embodiment will further describe Embodiment 1. The bottom mounting plate 2 includes a main board 2-1 and a toothed track 2-2, and the main board 2-1 is fixedly connected to the toothed track 2-2.

specific Embodiment approach 3

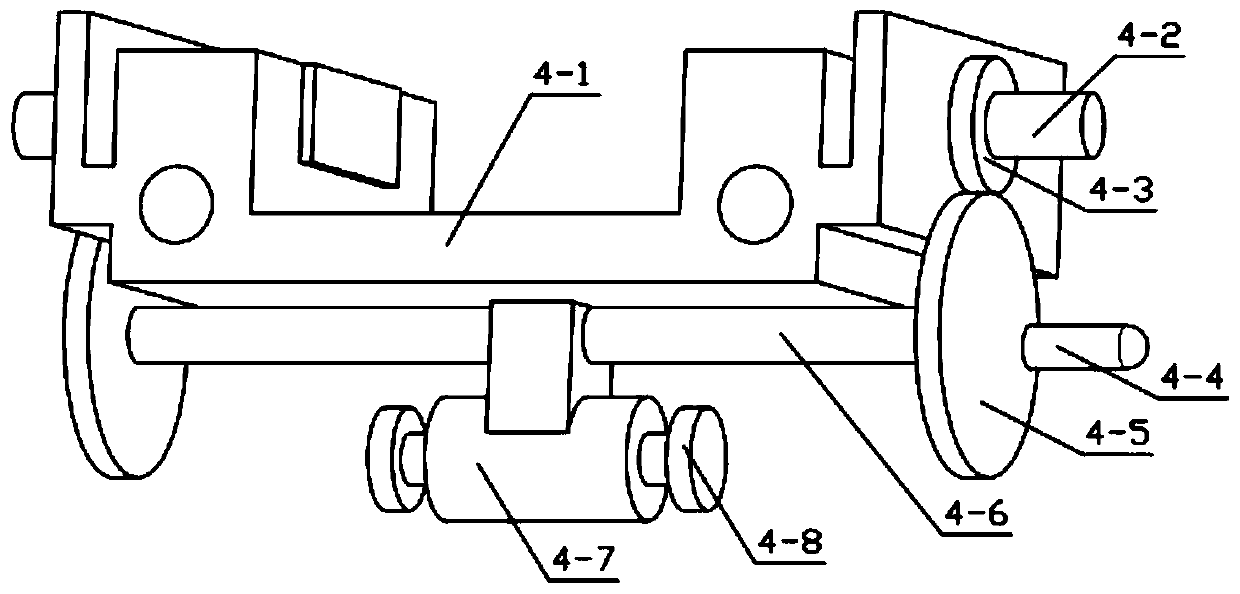

[0042] Combine below Figure 1-13 Describe this embodiment, this embodiment will further explain the second embodiment, the fixed mechanism 4 includes a U-shaped base 4-1, a threaded clamp block 4-2, an internal thread ring gear 4-3, a handle 4- 4. Main gear 4-5, connecting shaft 4-6, moving motor 4-7, displacement gear 4-8, threaded clamp block 4-2 is slidably installed on the through hole provided on U-shaped base 4-1, The U-shaped base 4-1 is slidably installed on the track rod 3, the internal thread ring gear 4-3 is rotatably installed on the U-shaped base 4-1, and the threaded clamp block 4-2 is threadedly connected with the internal thread ring gear 4-3, The internal thread ring gear 4-3 meshes with the main gear 4-5, the main gear 4-5 is fixedly connected with the handle 4-4, the main gear 4-5 is fixedly installed on the connecting shaft 4-6, and the connecting shaft 4-6 The rotation is installed on the U-shaped base 4-1, the mobile motor 4-7 is fixedly installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com