An automatic auxiliary bench for machining with automatic control of the clamping force

A machining and automatic technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of inconvenient automatic adjustment, insufficient structure of automatic control of top tightening force, inconvenient adjustment of fixed radian, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

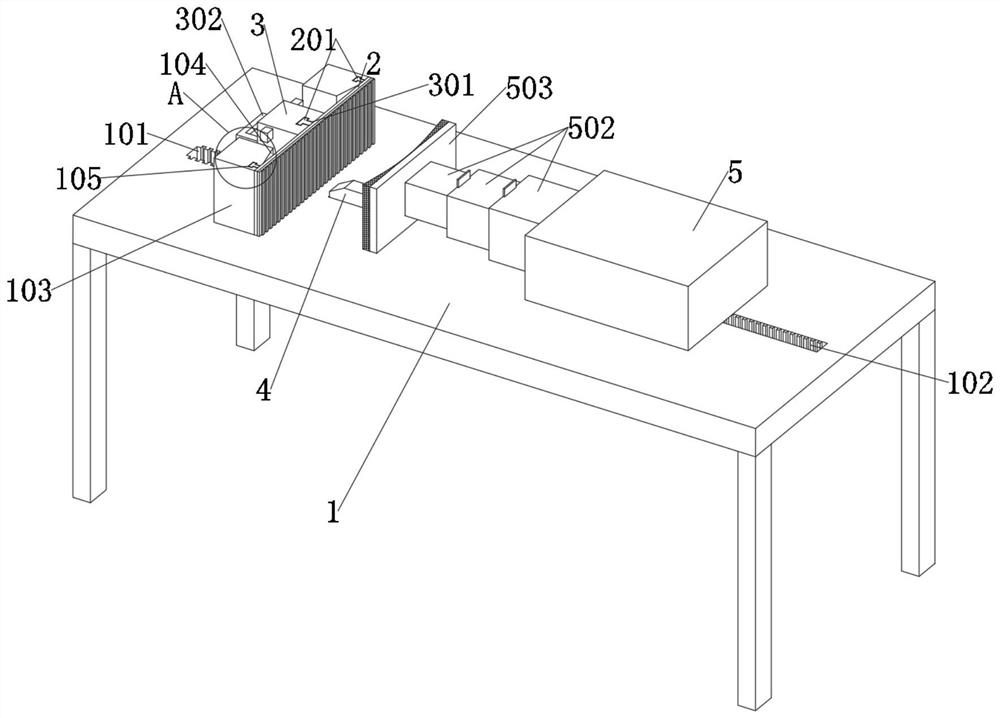

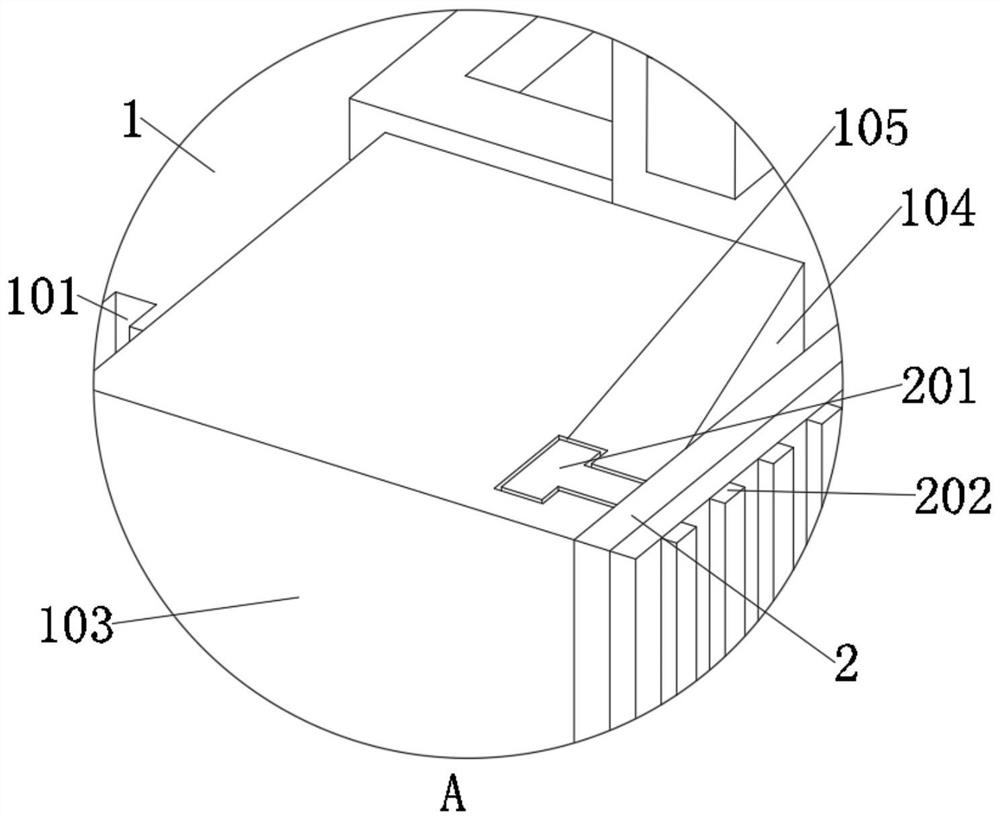

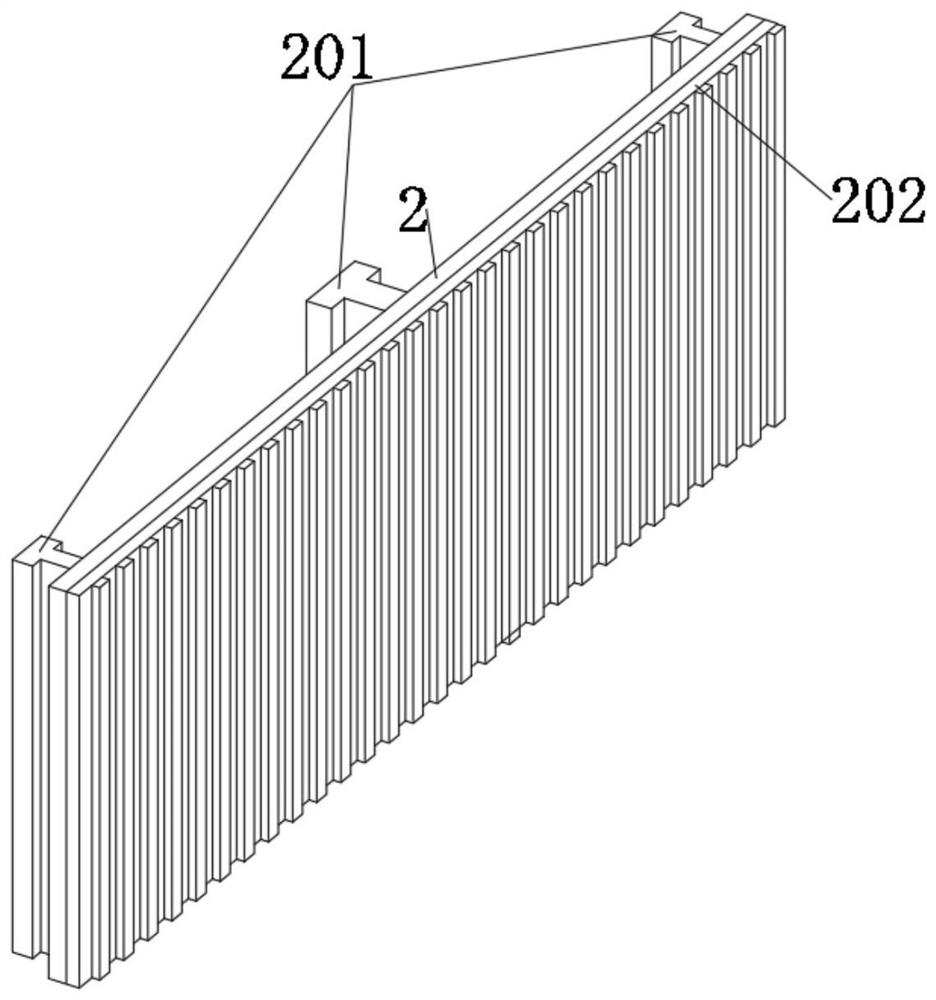

[0032] as attached figure 1 To attach Figure 8 Shown:

[0033]The present invention provides an automatic auxiliary bench for machining with automatic control of the jacking force. Chuck 201, anti-slip piece 202, moving piece 3, embedded groove 301, pulling piece 302, inner compartment 303, pressing piece 304, clamping piece 305, receiving piece 4, triggering piece 401, moving box 5, motor 501, telescopic piece 502 , a splint 503, a force member 6, a contact block 601, a trigger block 602 and a pressure plate 603; the main body 1 is a rectangular plate structure, and the bottom corner of the main body 1 is installed with a support rod of a rectangular structure by welding, and the main body 1 is provided with a moving slot 102 with a rectangular structure in the middle position on the right side of the top, and the gear at the bottom of the motor 501 is installed inside the moving slot 102; the right side of the mounting block 103 is provided with a T-shaped mounting slot 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com