Vegetable root cutting, weighing and grading device

A sorting device and root cutting technology, applied in sorting, metal processing and other directions, can solve the problems of long length of root cutting equipment and sorting equipment, increased processing cost, and large space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

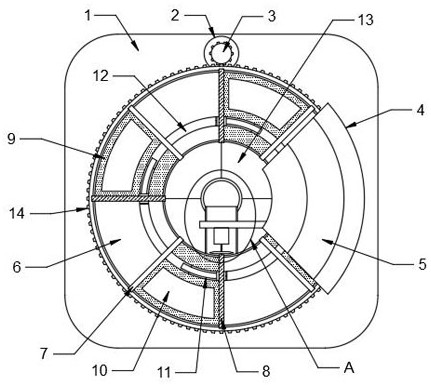

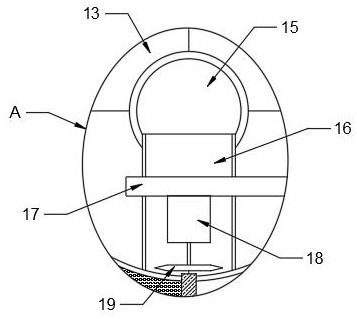

[0034] refer to Figure 1-7 , a device for weighing and grading vegetable cut roots, comprising a base 1, a rotatable feeding tray 6 is installed on the base 1, the center of the feeding tray 6 is open, and a root cutting mechanism is installed at the opening, The bottom of the feeding tray 6 is equipped with a fixed ring 35, and the bottom of the fixed ring 35 is rotated on the base 1 and is connected with a collection bucket 13 for collecting vegetable roots. A plurality of collection tanks 23 are fixed on the wall, and a weighing assembly 24 is installed on the bottom of the plurality of collecting tanks 23, and the weighing assembly 24 is composed of a bearing plate and a pressure sensor.

[0035] A top plate 4 is installed above the feeding tray 6, and a sorting device 5 is installed at the bottom of the top plate 4. The grading device 5 is composed of multiple high-resolution cameras and laser units, which can quickly scan and identify vegetables;

[0036] The upper gap...

Embodiment 2

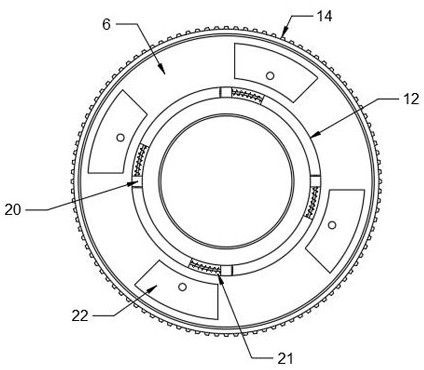

[0049] refer to Figure 6 The difference between this embodiment and Embodiment 1 is that the side wall of the slider 20 is provided with a groove, and the arc-shaped plate 11 extending into the annular groove 12 is slidably connected in the groove, and the arc-shaped plate 11 is rotatably connected There are a plurality of rotating rollers 25, an air bag 26 connected to the arc-shaped plate 11 is installed in the groove, a piston 29 is fixed on the top of the slide rod 30, the top of the sleeve 27 is connected with the air bag 26 through a trachea, and the fixed ring 35 corresponds to A plurality of third magnetic blocks 37 cooperating with the first magnetic blocks 31 are embedded in the position of the sorting device 5 .

[0050] When the vegetables after the root cutting passed below the grading device 5, because the first magnetic block 31 passed through a plurality of third magnetic blocks 37 successively, the opposite faces of the first magnetic block 31 and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com