Patents

Literature

160results about How to "Automatic clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

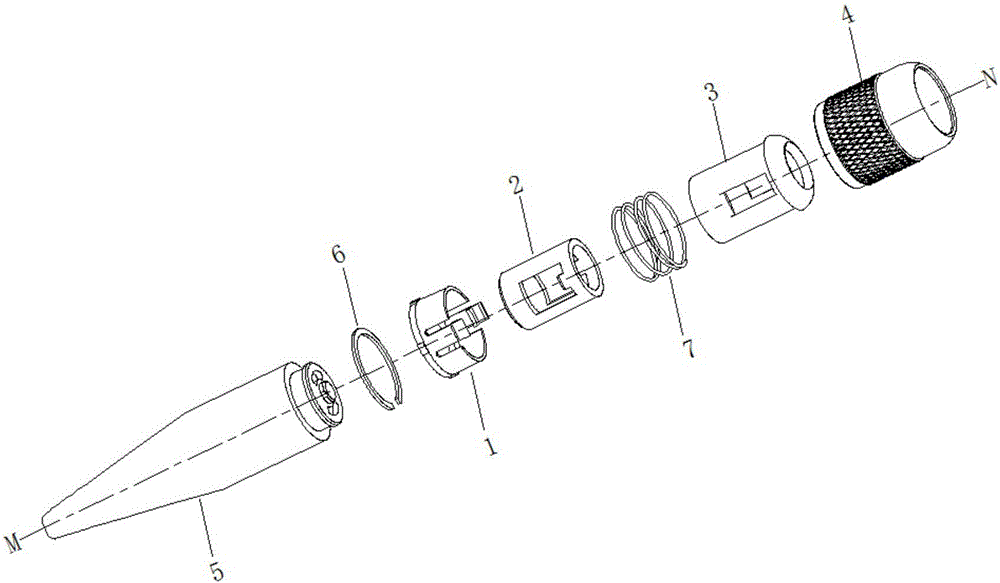

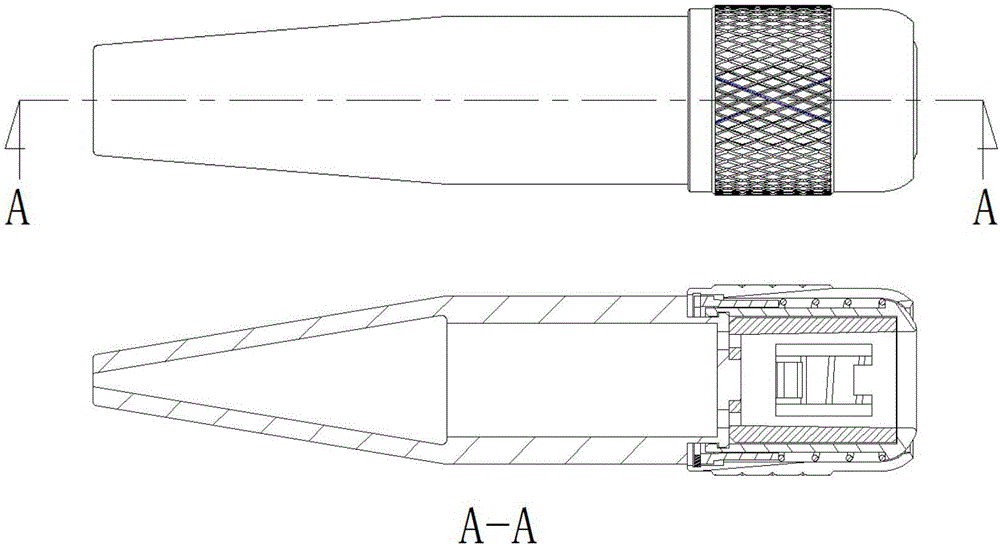

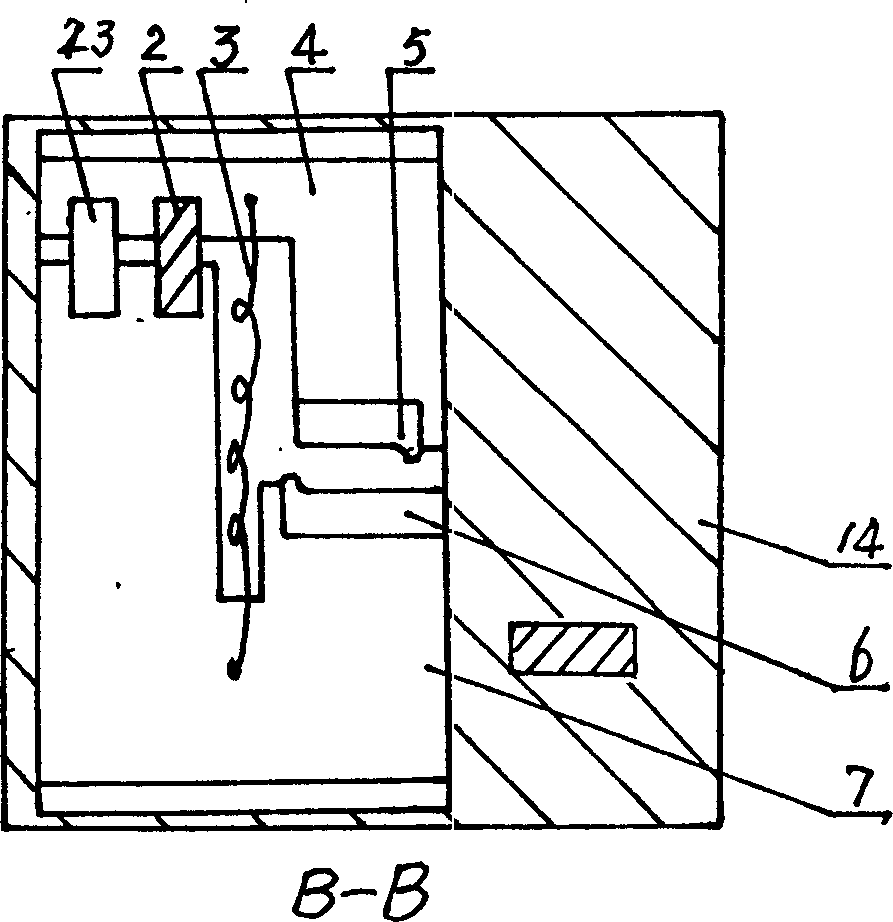

Device with automatic cigarette end withdrawal function

ActiveCN106174699AAutomatic clampingClamping is automatically releasedTobacco pipesEngineeringLow resistance

The invention discloses a device with an automatic cigarette end withdrawal function. The device comprises a cigarette clamping part (1), a cigarette stabilizing part (2), a supporting ring (3), a cigarette end withdrawal sliding ring (4), an air outlet end shell part (5), a metal meson (6) and a spring (7). By means of the device, a cigarette end left after a cigarette is burnt and smoked can be conveniently and rapidly withdrawn. The device has the advantages that the cigarette end left after the cigarette is burnt and smoked does not need to be pulled out manually, it can be achieved that a user can withdraw the cigarette end conveniently, rapidly, easily and smoothly withdrawn in a low resistance state without making contact with the cigarette end by hand.

Owner:CHINA TOBACCO YUNNAN IND

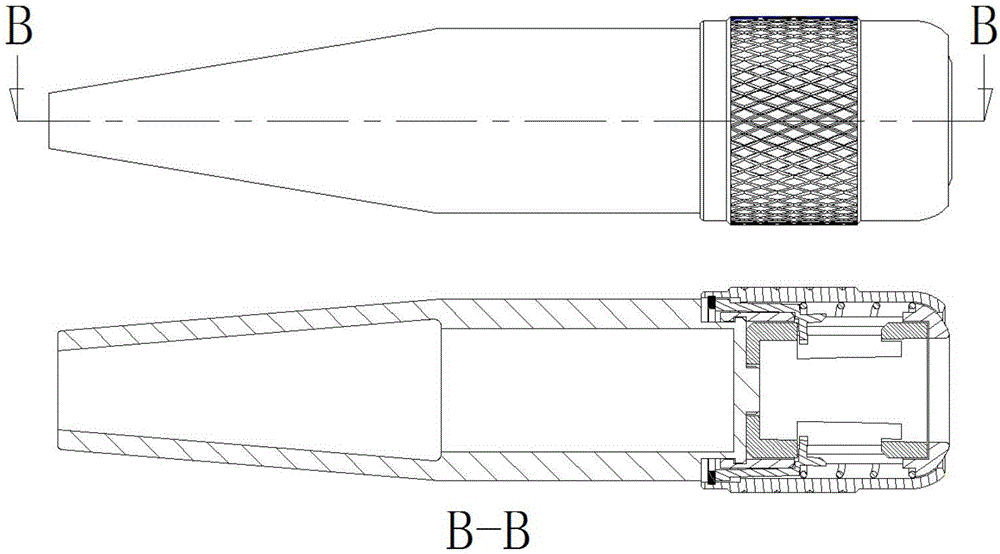

Disc cam driving type cylindrical workpiece centering and clamping fixture

InactiveCN105729148AReasonable designCompact structurePositioning apparatusMetal-working holdersEngineeringCam

The invention discloses a disc cam driving type cylindrical workpiece centering and clamping fixture which comprises a bottom plate, a bevel pushing head, a bent arm I, a bent arm II, a driving spring and a disc cam, wherein a sliding rod is mounted in the middle part of the bottom plate in a sliding manner through a sliding rod support; a roller is rotatably mounted at one end of the sliding rod; the bevel pushing head of which the front end has an ejecting block is fixedly mounted at the other end of the sliding rod; the driving spring is arranged on the sliding rod between the bevel pushing head and the sliding rod support in a sleeving manner; the disc cam tangential to the roller is rotatably mounted at one end of the bottom plate through a rotating shaft; and the bent arm I and the bent arm II which are mutually symmetrical are rotatably mounted on the upper side of the other end of the bottom plate. The disc cam driving type cylindrical workpiece centering and clamping fixture has the characteristics that the design is reasonable, the structure is simple, the excircle centering and clamping can be achieved, the disc cam is matched with the driving spring for utilization, the operation is convenient, the automation degree is high, and the service life is long.

Owner:XIAN ZHONGZHI HUIZE PHOTOELECTRIC TECH

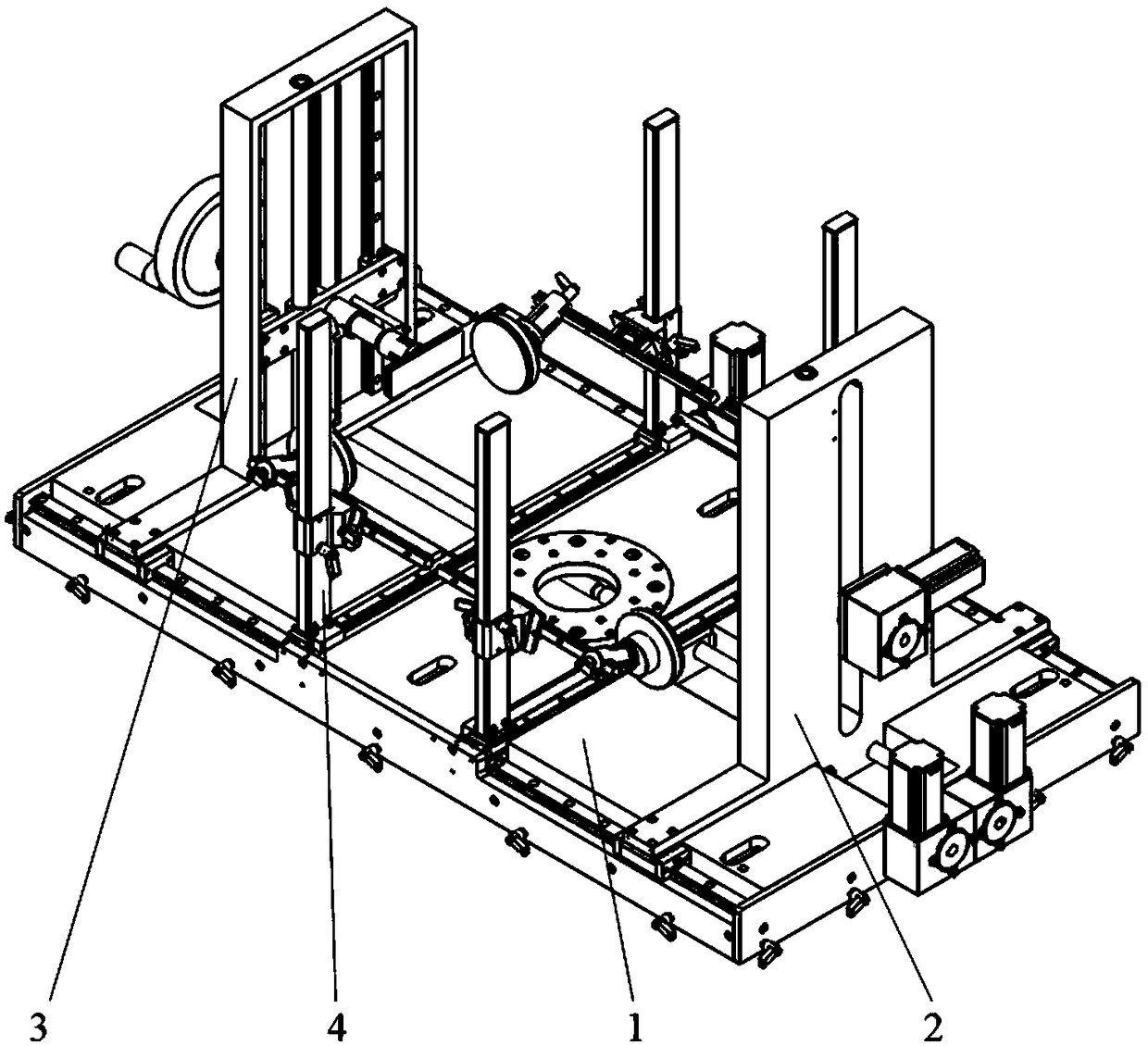

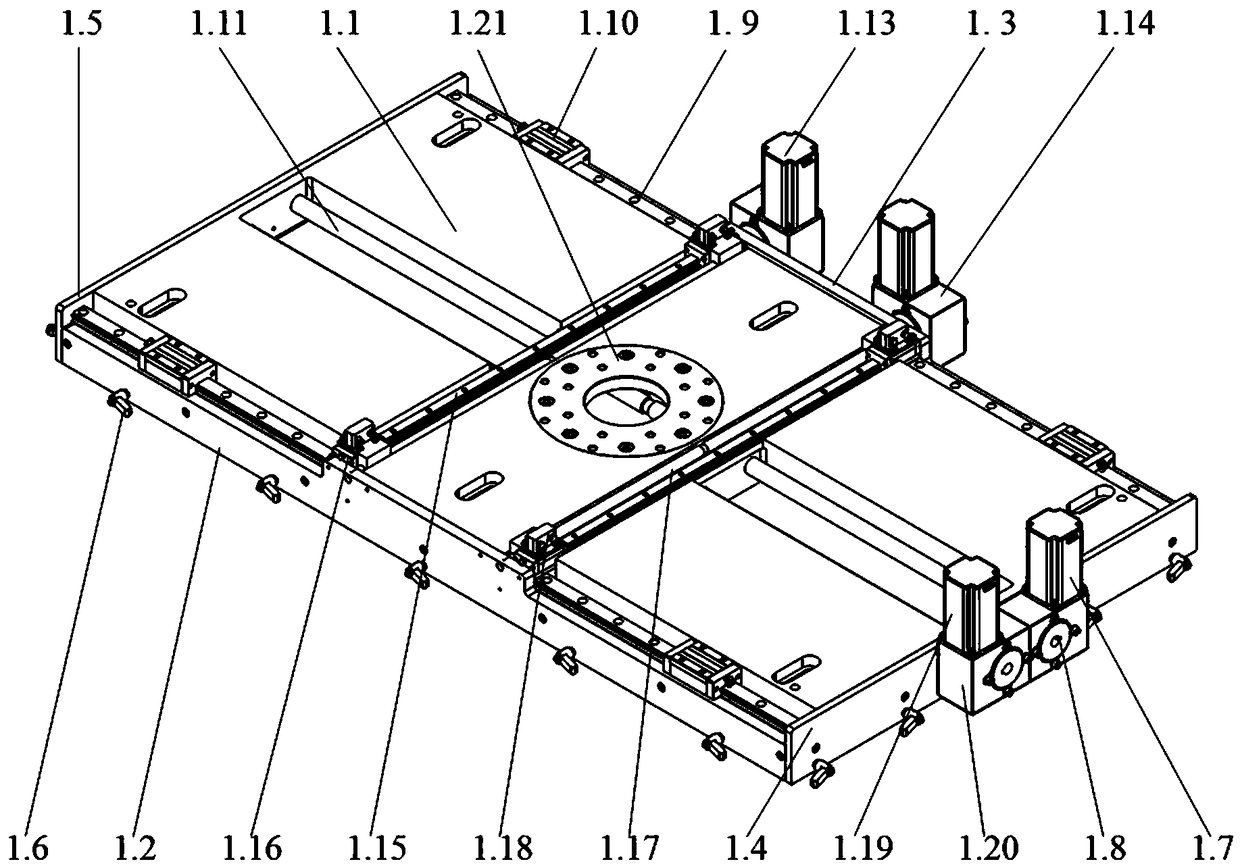

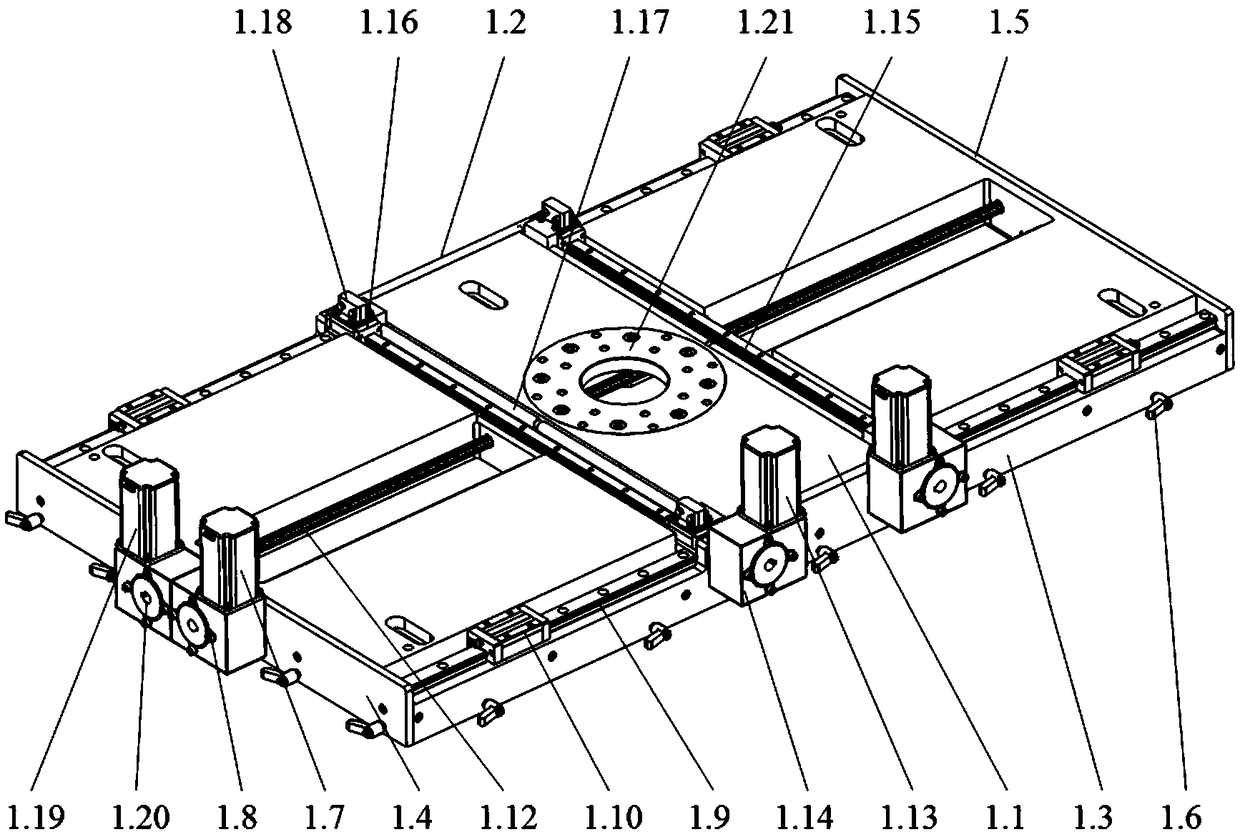

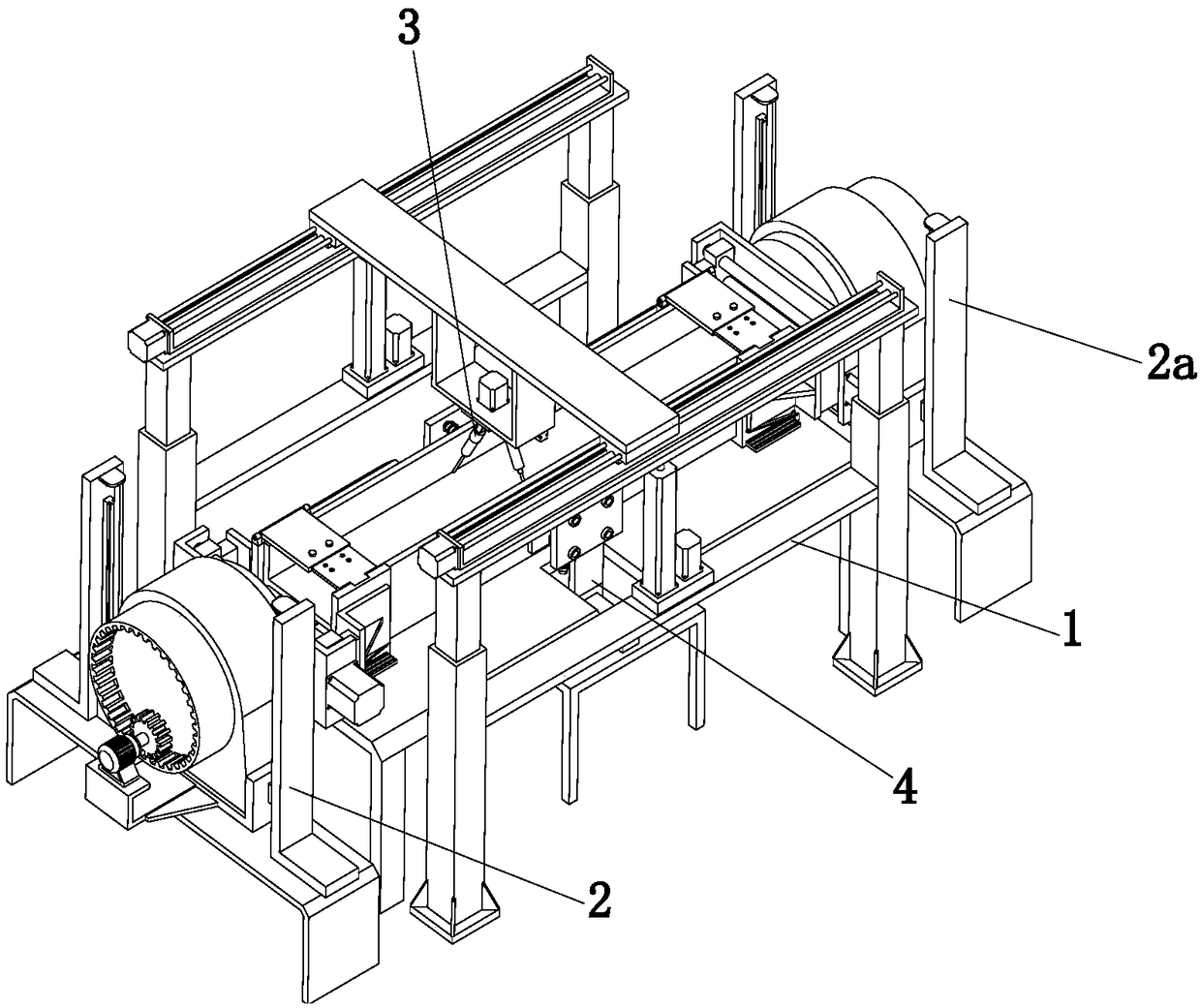

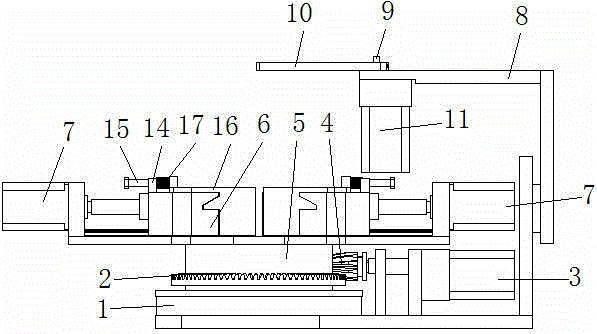

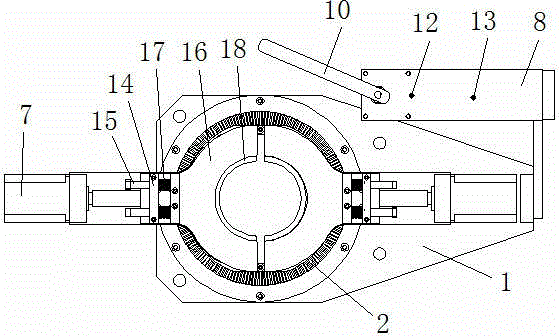

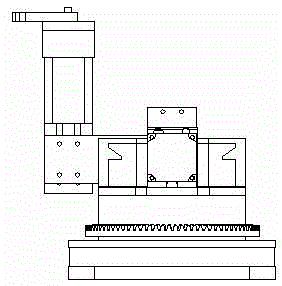

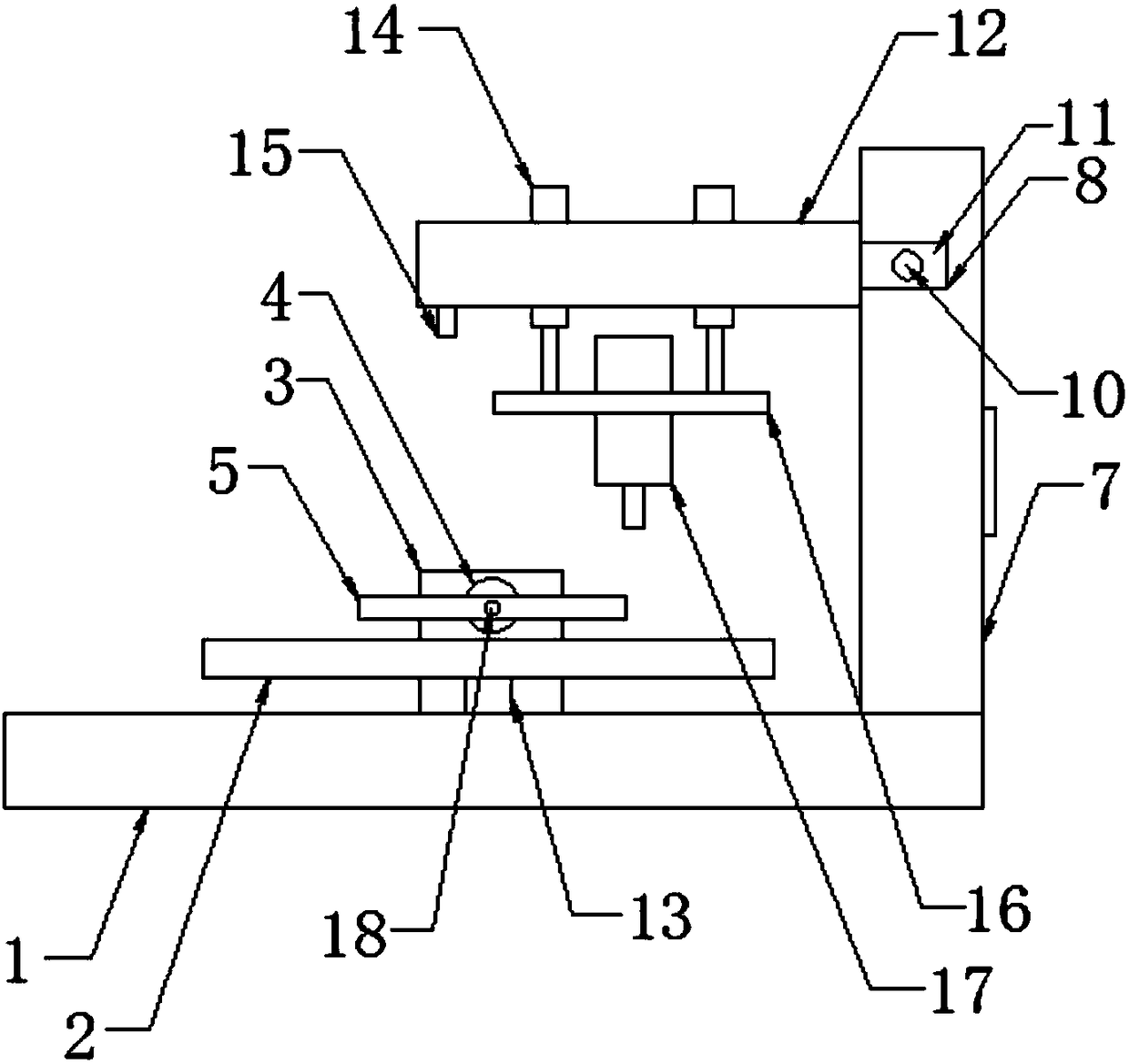

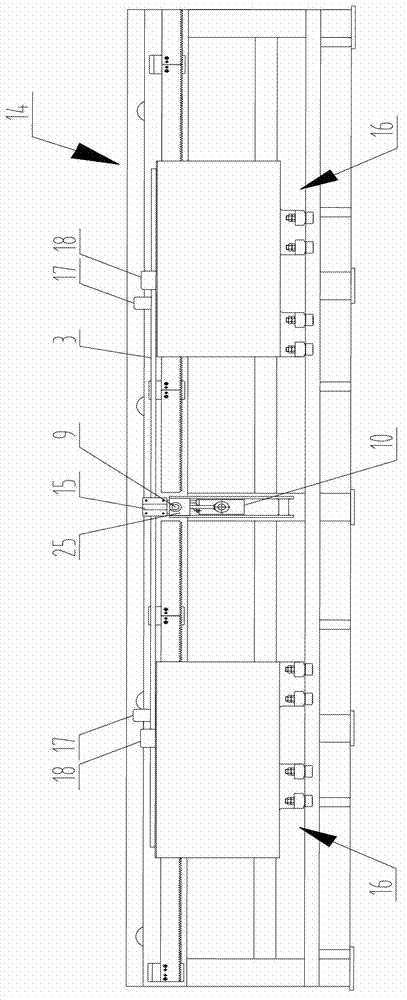

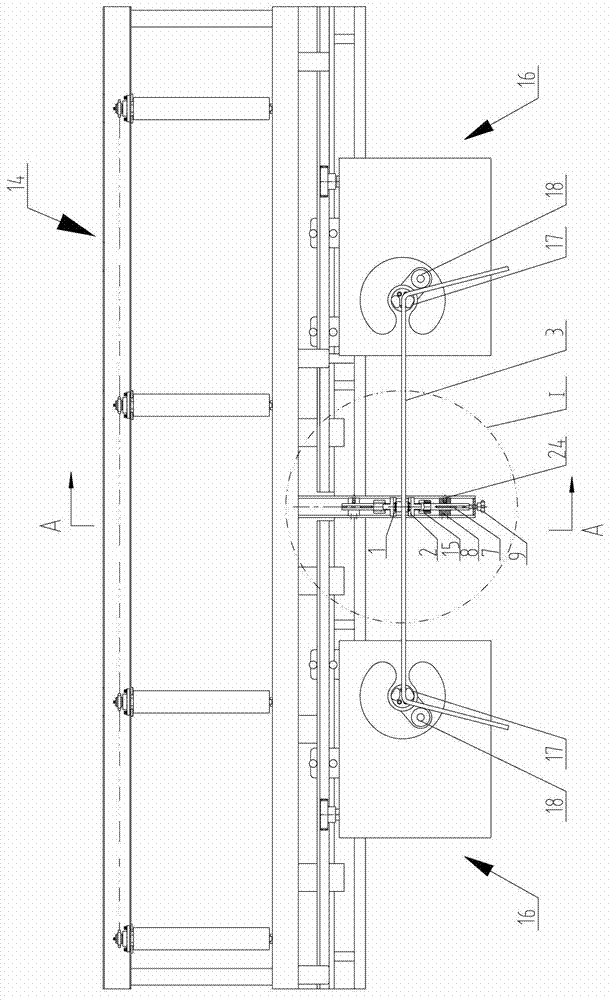

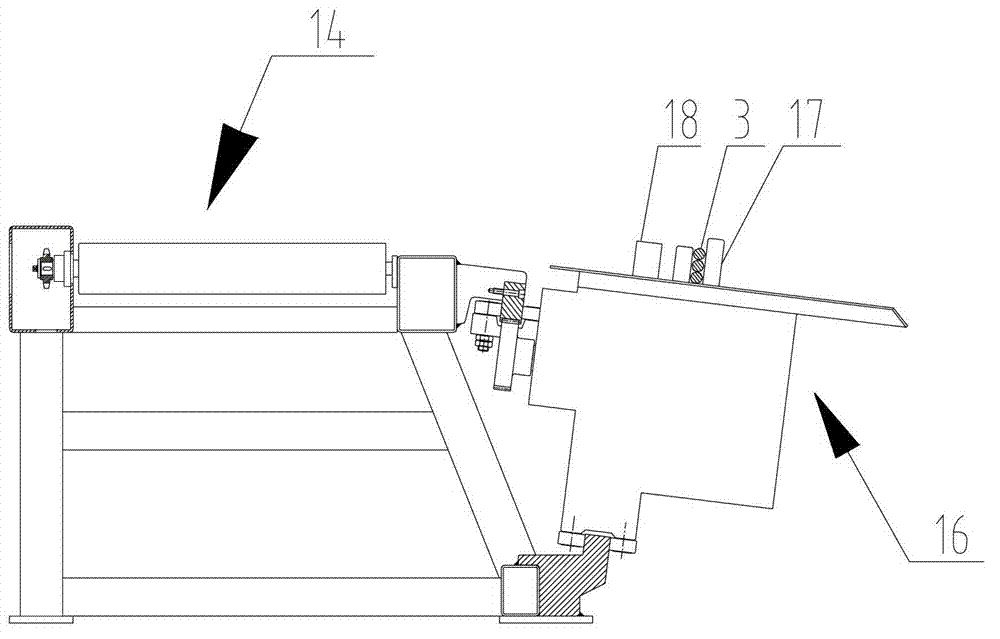

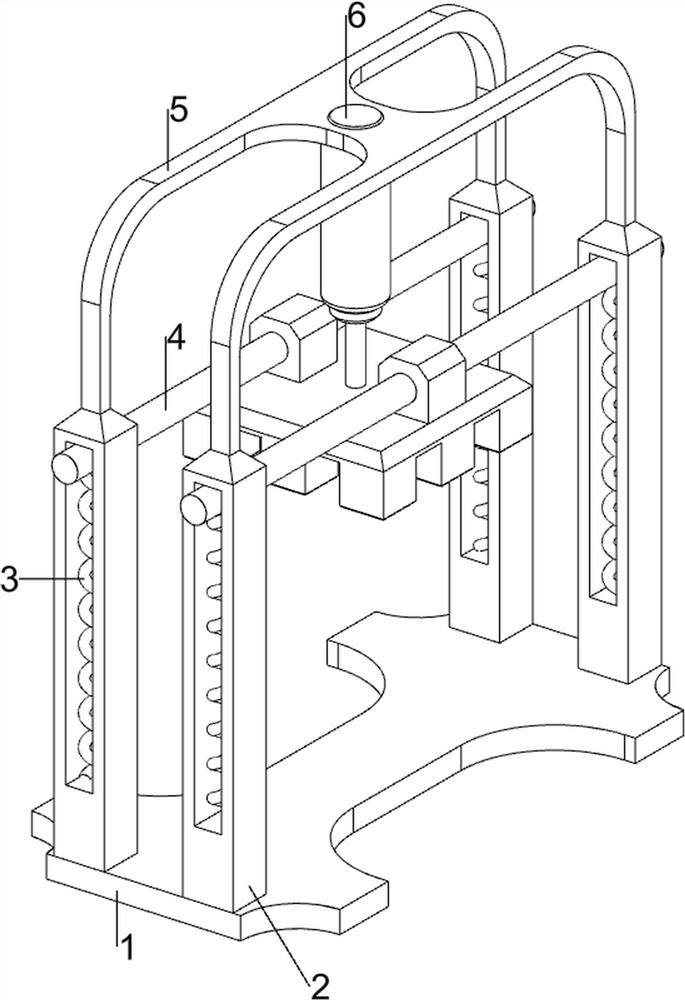

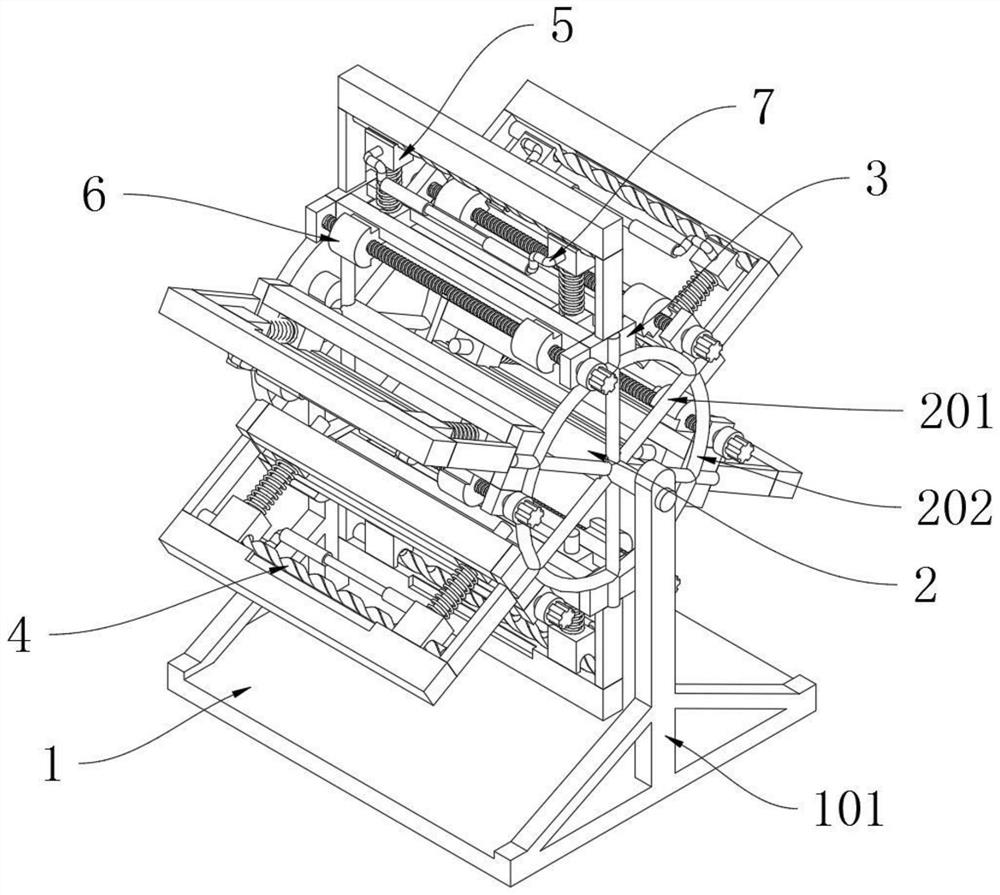

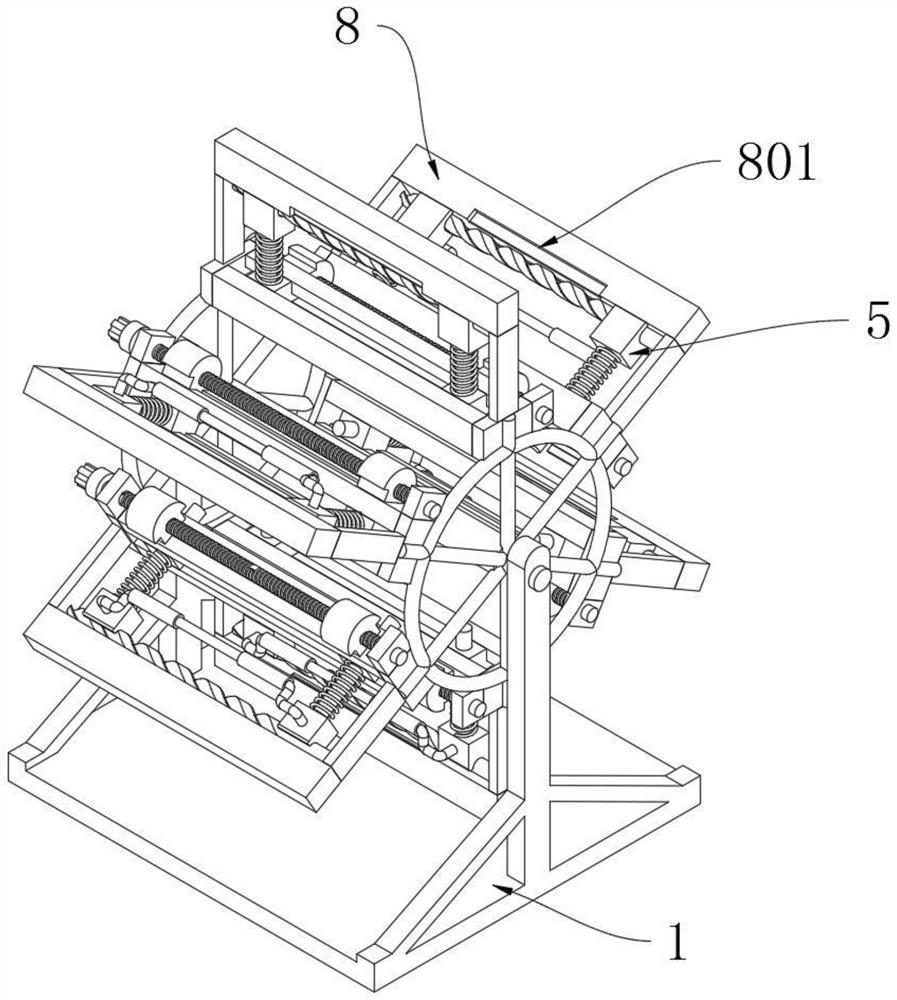

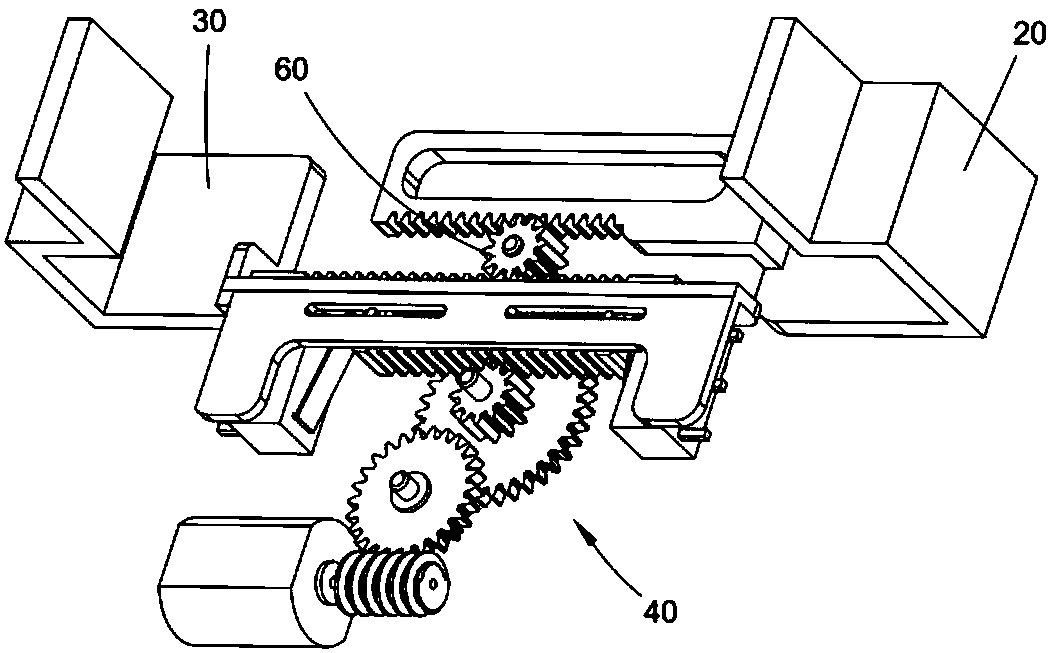

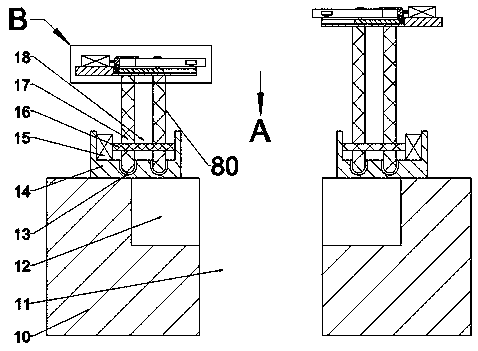

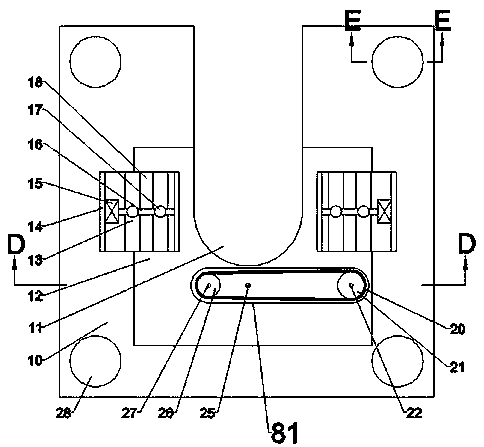

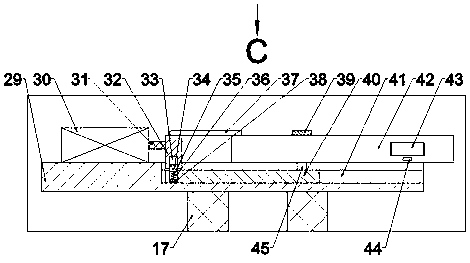

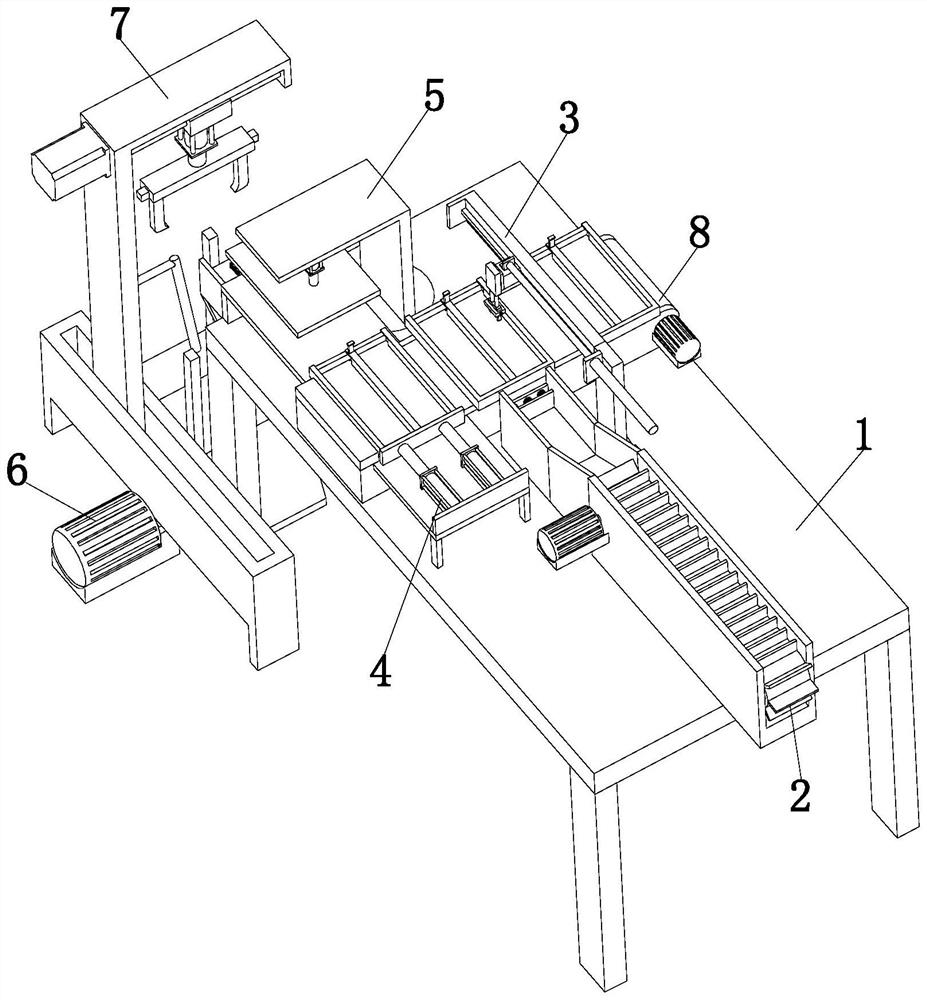

Pressing mechanism for airplane titanium alloy part processing tool table

ActiveCN108637724AGood repeatabilityImprove consistencyPositioning apparatusMetal-working holdersMotor driveEngineering

The invention relates to a pressing mechanism for an airplane titanium alloy part processing tool table, in particular to an auxiliary device for a machine tool processing part. The pressing mechanismcomprises four parts, which are separately a pedestal regulating and fixing mechanism, a left side lifting pressing mechanism, a right side lifting pressing mechanism and an X-direction pressing mechanism, wherein the left side lifting pressing mechanism and the right side lifting pressing mechanism are mounted and fixedly arranged on the pedestal regulating and fixing mechanism, and define a threaded-transmission and spline-transmission matching relationship with the pedestal regulating and fixing mechanism; and the X-direction pressing mechanism is mounted and fixed on the pedestal regulating and fixing mechanism. The pressing mechanism can be manually and quickly regulated, and a motor drives equipment to realize automatic regulation on a clamping dimension and a clamping position as well as clamping with set load; and the motor drives blank to lift and rotate, so that multi-surface processing is realized.

Owner:XIAN AIRCRAFT IND GROUP

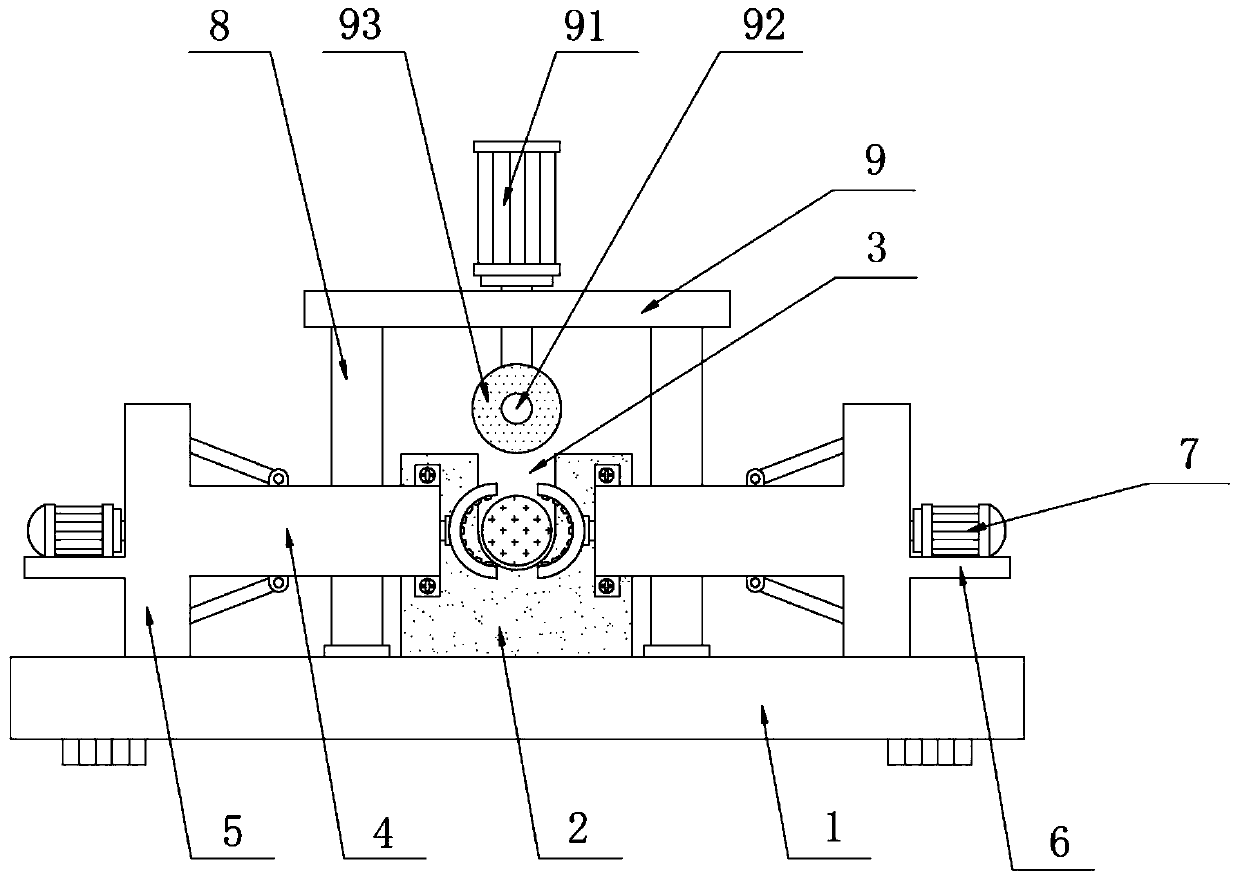

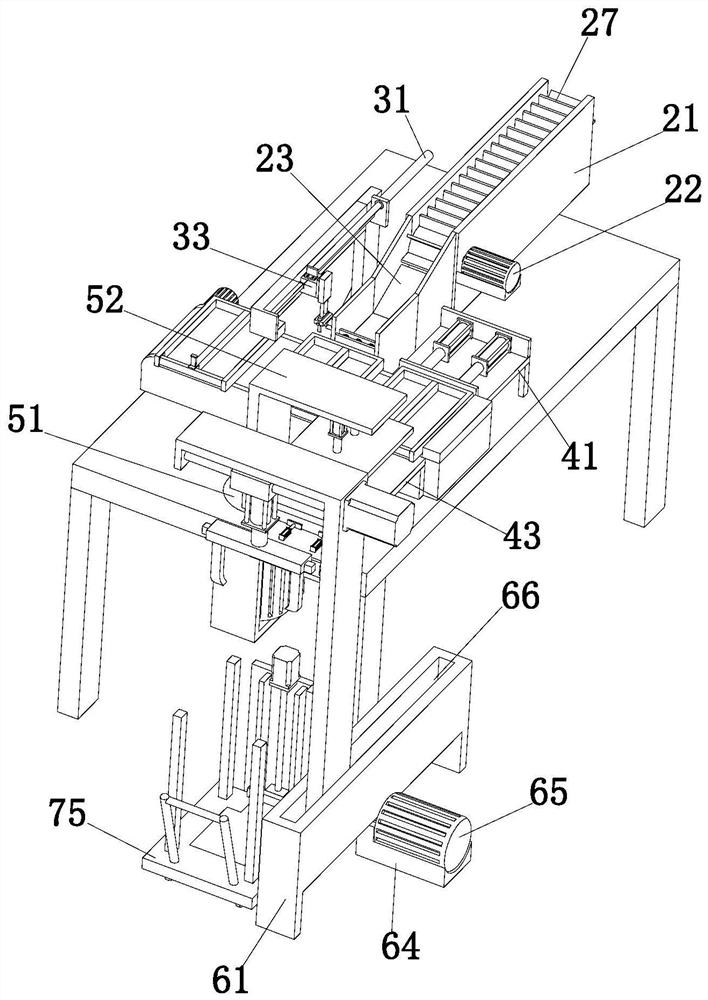

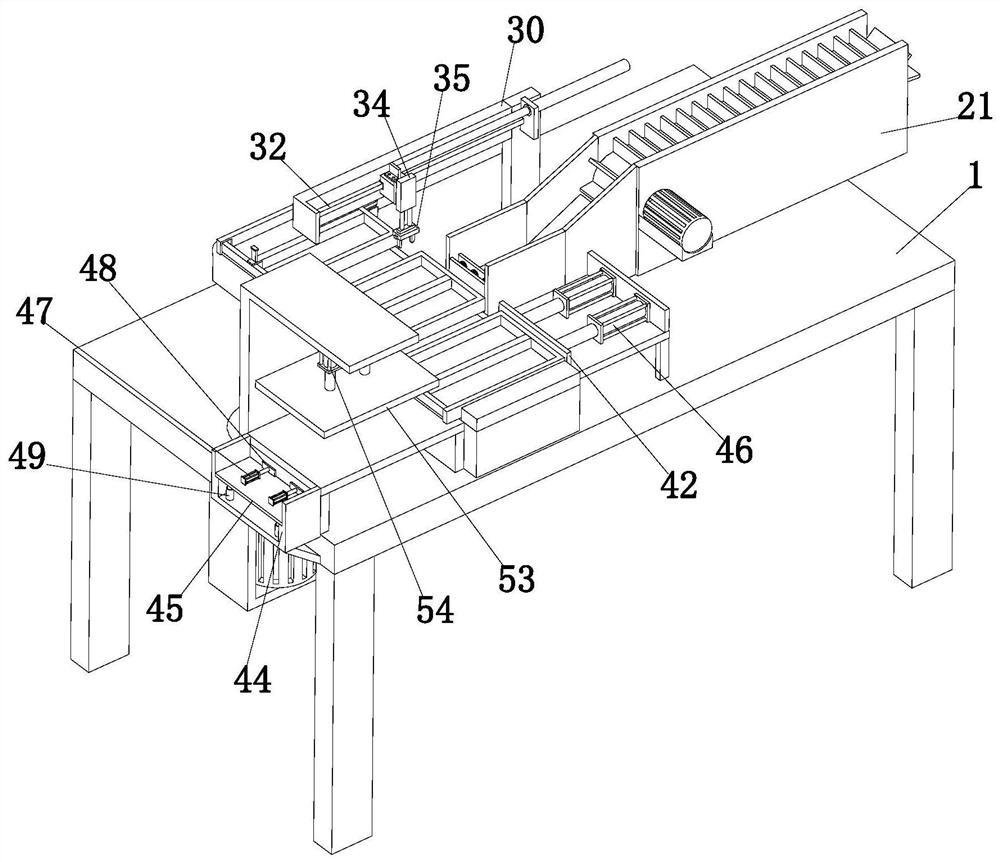

H-shaped steel automatic welding device

ActiveCN108890213AAutomatic clampingAutomatic flippingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringUltimate tensile strength

The invention relates to the field of steel structure processing, in particular to an H-shaped steel automatic welding device which comprises a working table, an overturning mechanism, an automatic welding mechanism and a limit mechanism. Two limit jigs can be movably arranged at the top of the working table at intervals, and the automatic welding mechanism comprises a welding component, a liftingcomponent, a rectangular mounting plate and two lead screw sliding tables. The H-shaped steel automatic welding device has the advantages that two edges of H-shaped steel can be simultaneously weldedby the automatic welding mechanism, the position of the H-shaped steel cannot be additionally adjusted by a worker, the H-shaped steel can be conveniently welded by the worker and automatically limited by the limit mechanism, so that offset of the H-shaped steel is omitted in the welding process, the H-shaped steel can be automatically overturned by the overturning mechanism, manual overturning of the worker is omitted, and the labor intensity of the worker is reduced.

Owner:九江市现代钢结构工程有限公司

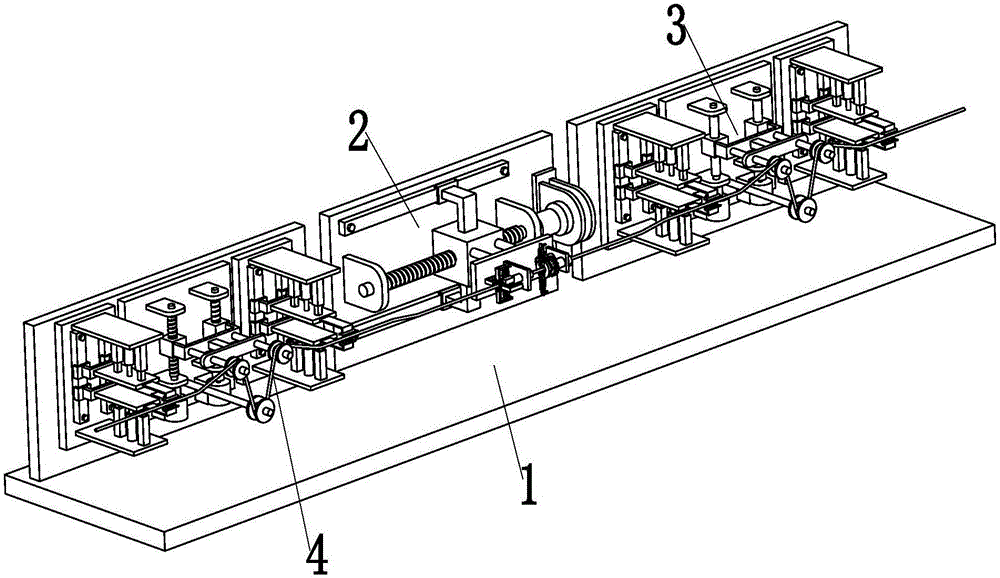

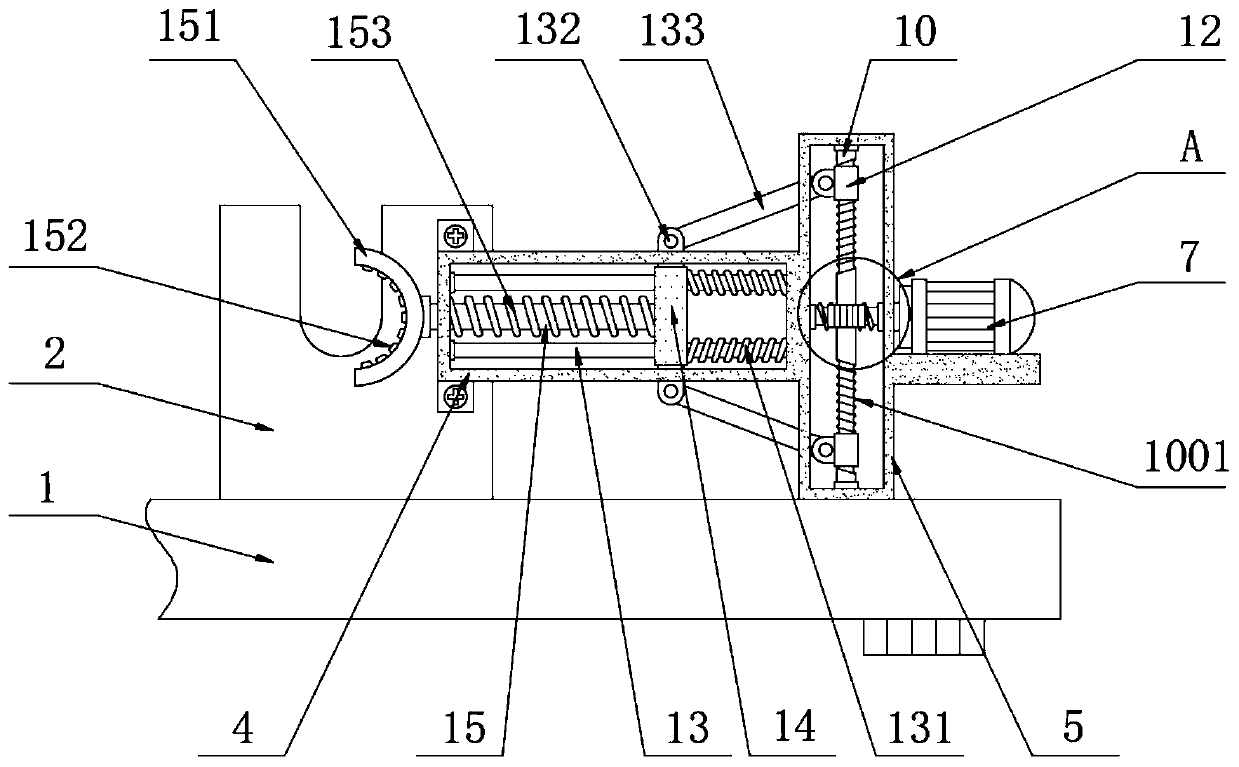

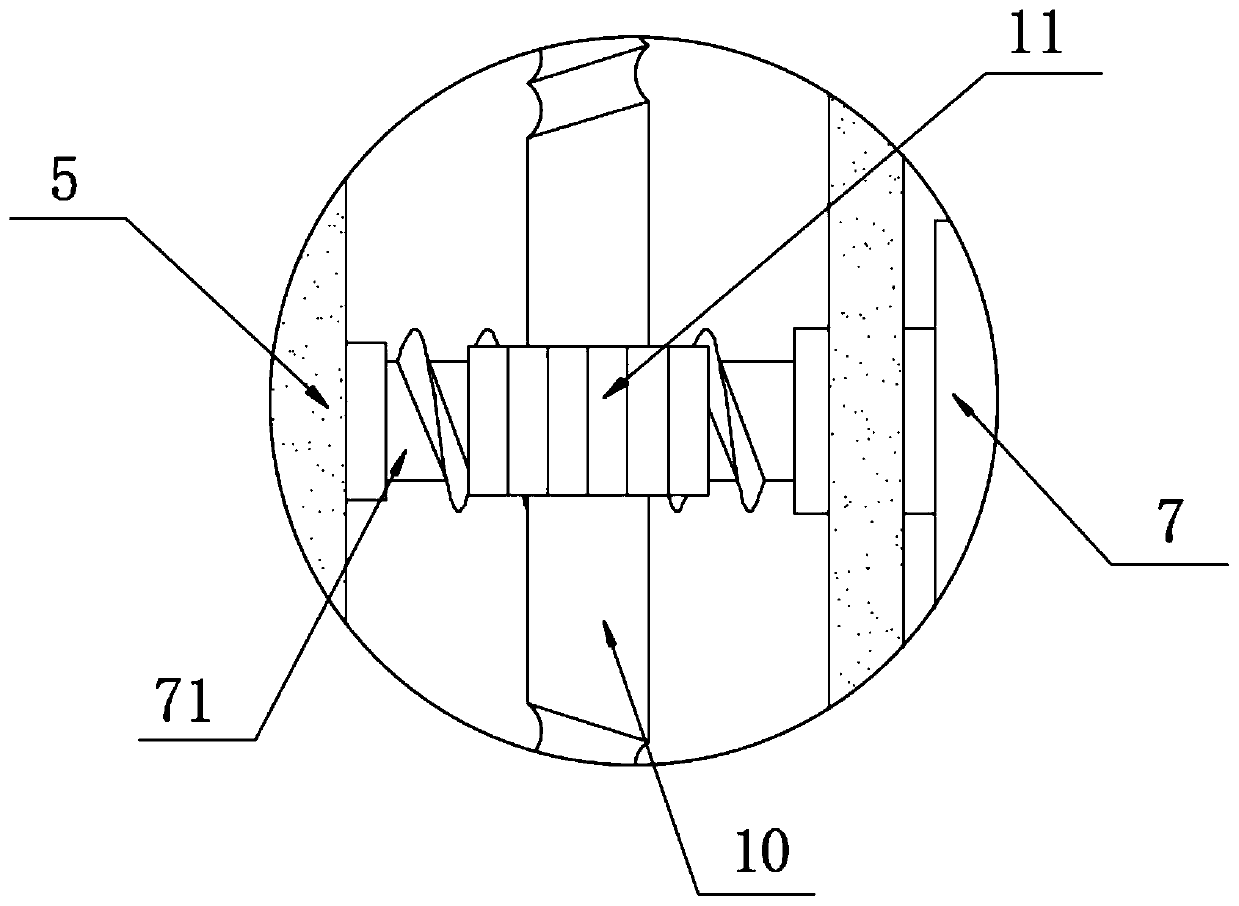

Vehicle wire harness full-automatic processing device

InactiveCN106129779AGood clamping effectFast and even automatic strippingVehicle connectorsLine/current collector detailsAutomatic processingCable harness

The invention relates to a fully automatic processing equipment for vehicle wire harnesses, comprising a base plate and a wire harness body, a ring cutting and stripping device is installed in the middle of the upper end surface of the base plate, and two clamping and tensioning devices are symmetrically installed on both sides of the upper end surface of the base plate; the wire harness body The two ends of the wire harness are passed through two clamping and tensioning devices respectively, and the middle part of the wire harness body is passed through the ring cutting and stripping device. The ring cutting and stripping device can realize the automatic ring cutting and wire stripping function during the processing of the wire harness body. The tensioning device can realize the automatic tensioning and clamping functions during the processing of the wire harness body. The invention can realize the integrated processing functions of automatic tensioning, clamping, ring cutting and wire stripping during the processing of vehicle wire harness, without manual operation, manual ring cutting, manual stripping, manual adjustment of tension force, and manual adjustment The clamping force has the advantages of good automatic ring cutting effect, good wire stripping quality, high wire stripping efficiency, good tension adjustment performance, good tension adjustment effect, poor clamping effect and high work efficiency.

Owner:YJH ELECTRICAL EQUIP

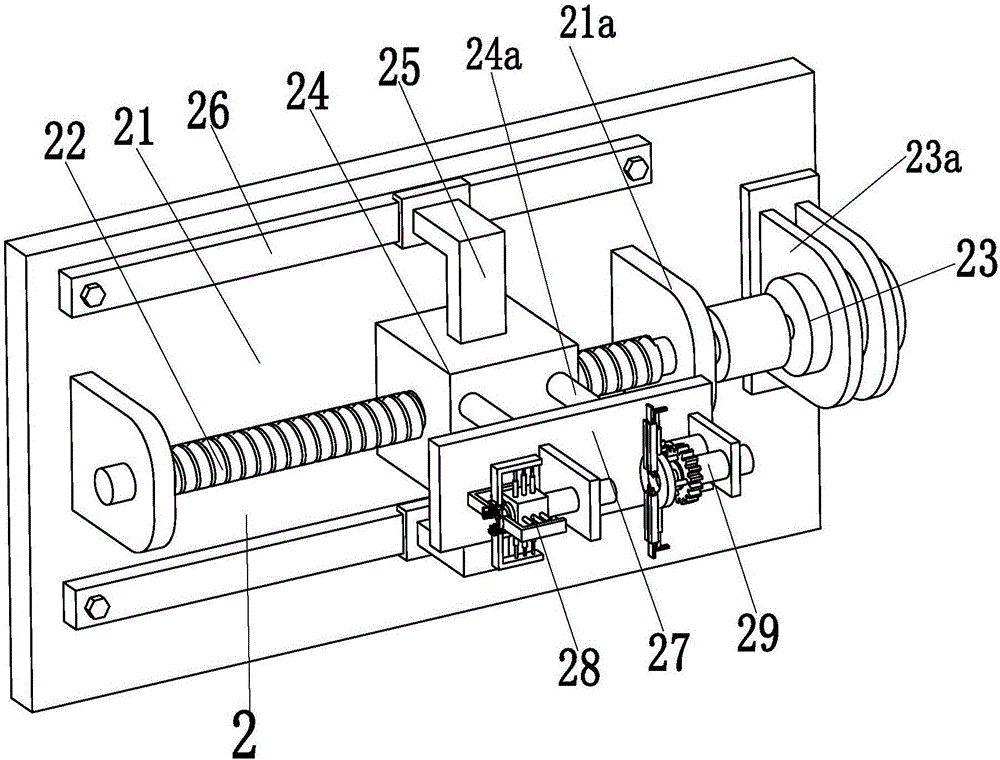

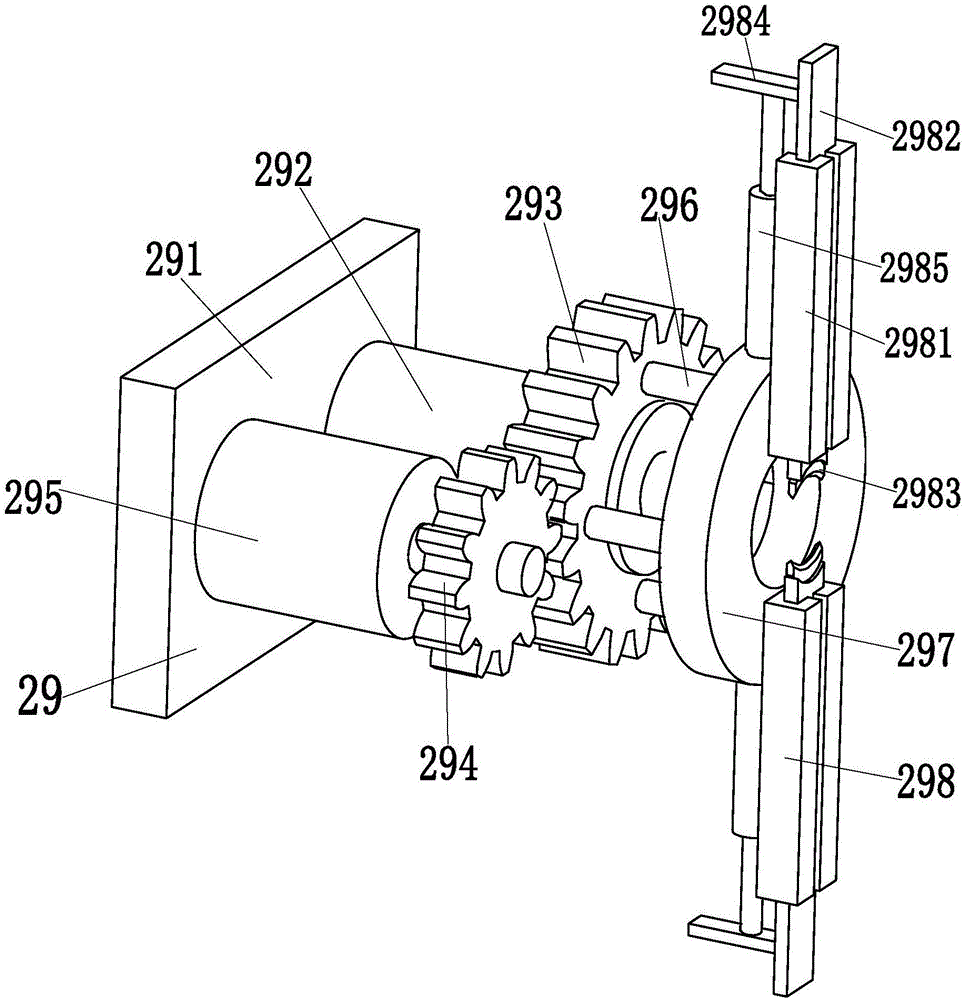

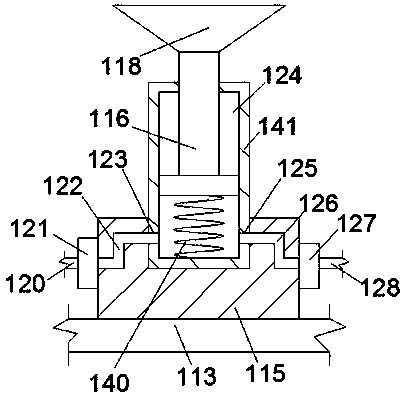

Chuck clamp for loading and unloading well logging exploring tube radiation source

InactiveCN103978354AAutomatic clampingAutomatic releaseWork holdersMetal working apparatusGear wheelElectric machinery

The invention discloses a chuck clamp for loading and unloading a well logging exploring tube radiation source. The chuck clamp comprises a base and a revolving shaft arranged on the base, wherein a rotary chuck gear is arranged at the upper end of the revolving shaft; a rotary stepping motor is meshed with the rotary chuck gear through a transmission conical gear to drive the rotary chuck gear and the revolving shaft to rotate; a tongs holder is arranged on the rotary chuck gear; two opposite tongs are arranged on the upper surface of the tongs holder through slide rails; the two tongs are connected with a clamping stepping motor respectively; a transverse rod bracket is arranged on the base; a pin shaft is arranged on the transverse rod bracket; a transverse rod and the pin shaft rotate synchronously; the transverse rod stepping motor is connected with the pin shaft to drive the pin shaft to rotate. By adopting the chuck clamp, clamping and loosening of the well logging exploring tube can be realized, and a series of actions such as opening of a cabin door, loading and unloading of the radiation source, closing of the cabin door and the like can be finished automatically during clamping, so that potential threat to human health due to current manual operation is avoided. The chuck clamp is simple in mechanism and low in maintenance cost, and works stably and reliably.

Owner:CHONGQING UNIV

Clamping device for producing transformer

ActiveCN112091359AAutomatic clampingImprove quality and efficiencyWelding/cutting auxillary devicesAuxillary welding devicesTransformerEngineering

The invention relates to the technical field of transformers, in particular to a clamping device for producing a transformer. The clamping device comprises a machining table, a conveying device, a feeding device, a turnover device and a clamping device body, wherein the machining table is arranged on the ground; the top of the machining table is provided with a rectangular groove in sliding fit with the clamping device body; the conveying device is arranged beside the machining table; the feeding device is arranged on the machining table and the conveying device and is located above the clamping device body; the turnover device is arranged above the clamping device body; and the clamping device body is arranged at the top of the machining table. According to the clamping device for producing the transformer, through the mutual operation among the arranged conveying device, the feeding device, the turnover device and the clamping device body, the transformer can be automatically clamped, and pins of the transformer can be welded while the transformer is clamped, so that the welding quality and the production efficiency are improved; and the clamping device can be automatically adjusted, and can clamp transformers with different specifications, so that the use range is enlarged, and wide application and use are facilitated.

Owner:常德创亿电子元件有限公司

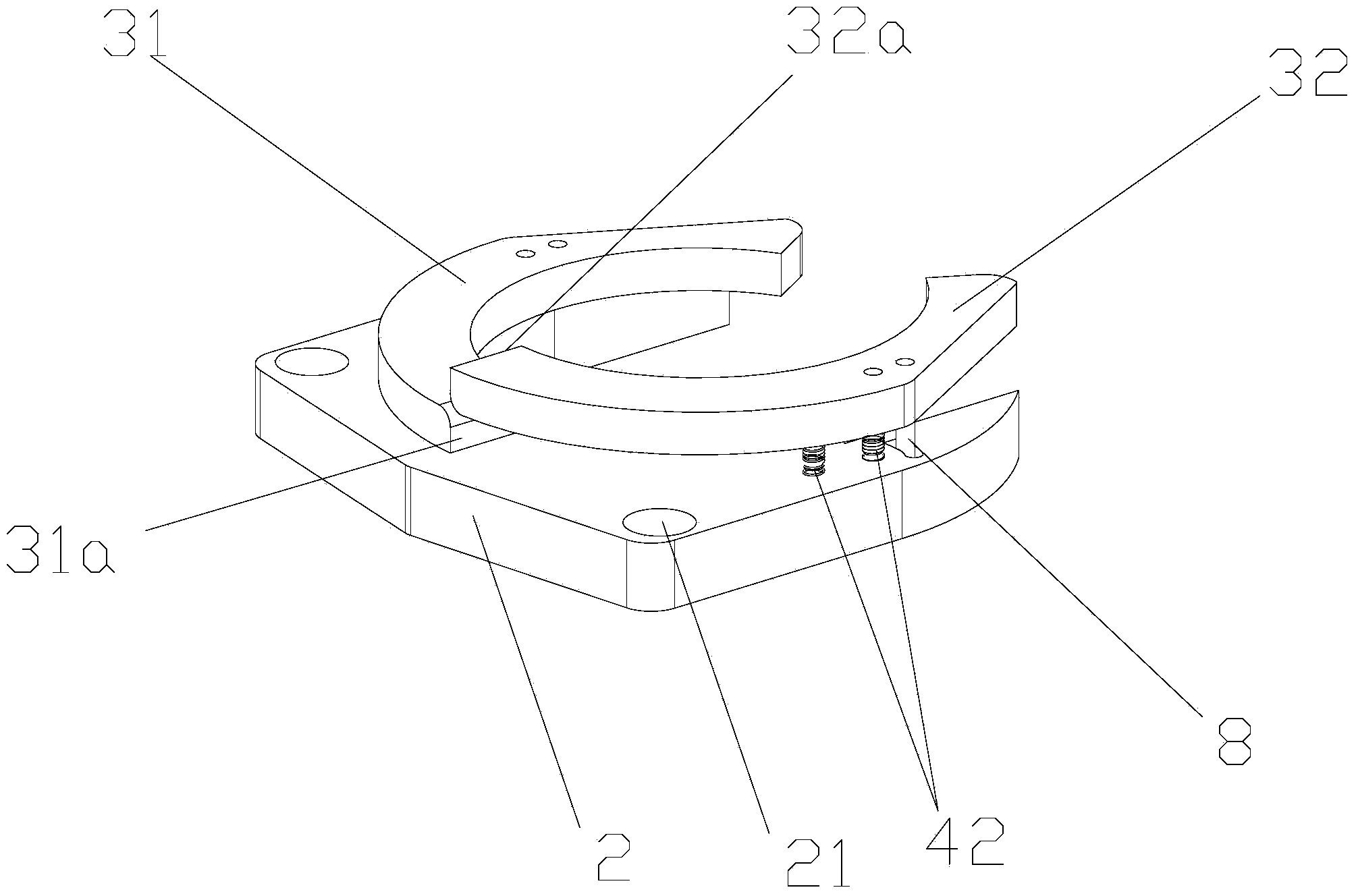

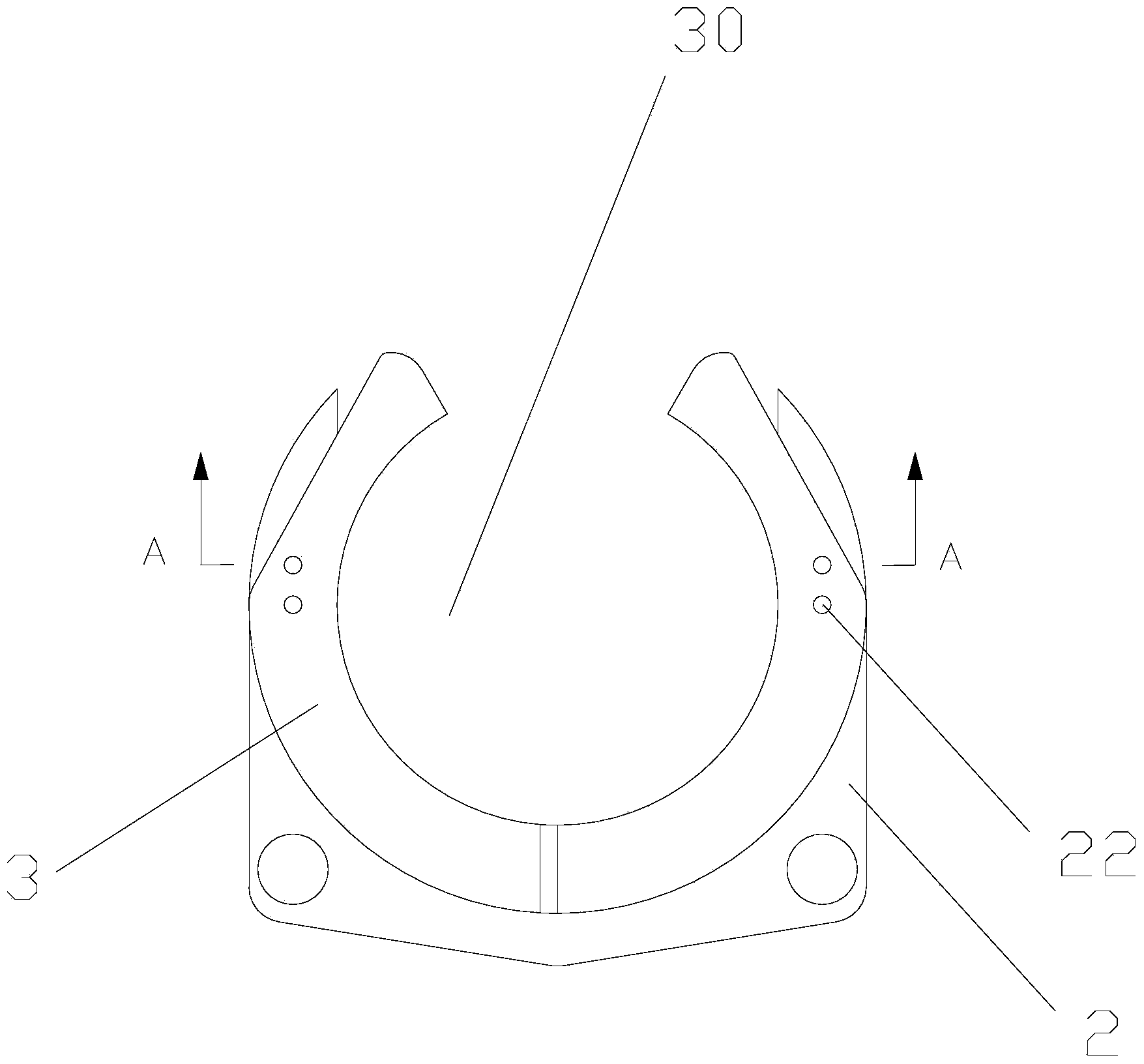

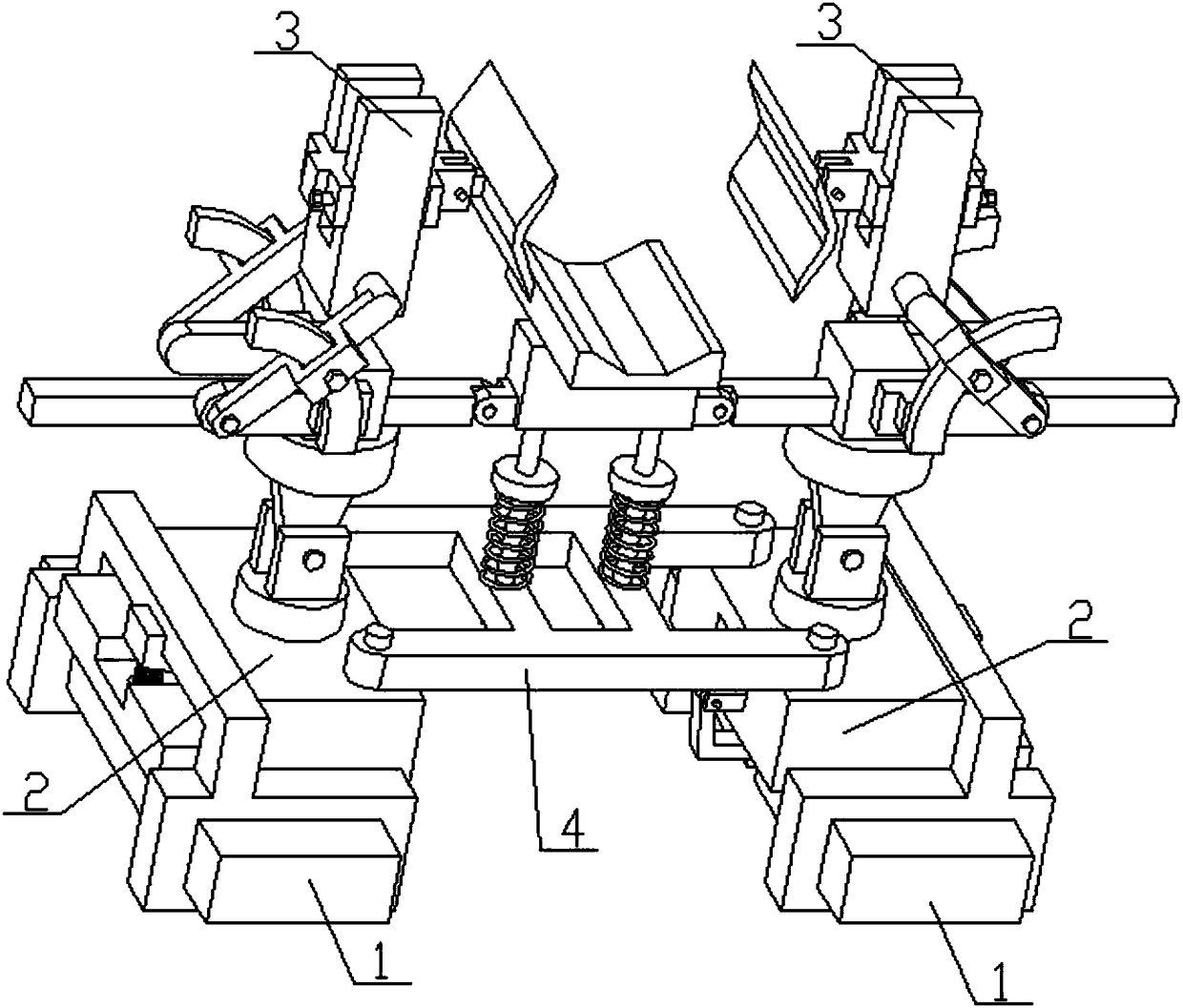

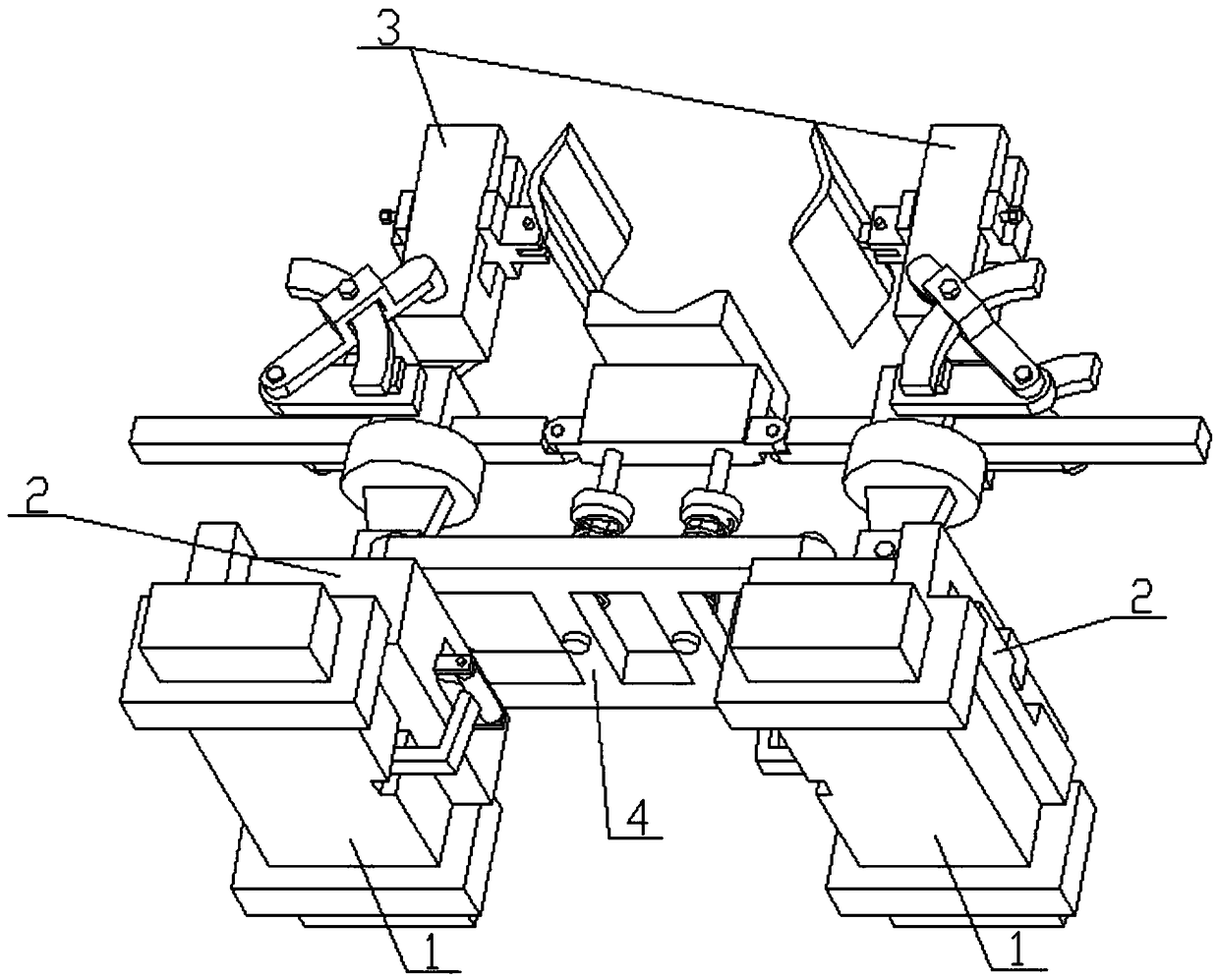

Clamping device for carrying barrel body

The invention discloses a clamping device for carrying a barrel body. The clamping device comprises at least two supporting pillars which are arranged in parallel and at least one group of clamping mechanisms which is fixed on the supporting pillars, wherein the clamping mechanisms comprise clamping plates and clamping claws which are connected to the clamping plates, are provided with arc-shaped openings which are matched with the outer surface shape of the barrel body and are used for clamping the outer wall of the barrel body; the clamping plates are provided with gaps which are used for the barrel body to enter and fixed holes which are used for fixedly connecting the clamping plates with the supporting pillars; the clamping claws comprise clamping claws I and clamping claws II which can be relatively clamped or loosened with each other; the clamping claws I and the clamping claws II are respectively hinged to the clamping plates; elastic reset pieces I which are used for making the clamping claws I, the clamping claws II and the clamping plates outwards open are arranged among the clamping claws I, the clamping claws II and the clamping plates; elastic reset pieces II which are used for making the clamping claws II and the clamping plates upwards move are arranged between the clamping claws II and the clamping plates. The clamping device is higher in strength, can be matched with delivery wagons of different types for use, and is suitable for various working sites, and the clamping mechanisms of the clamping device have self-locking functions when carrying is carried out.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

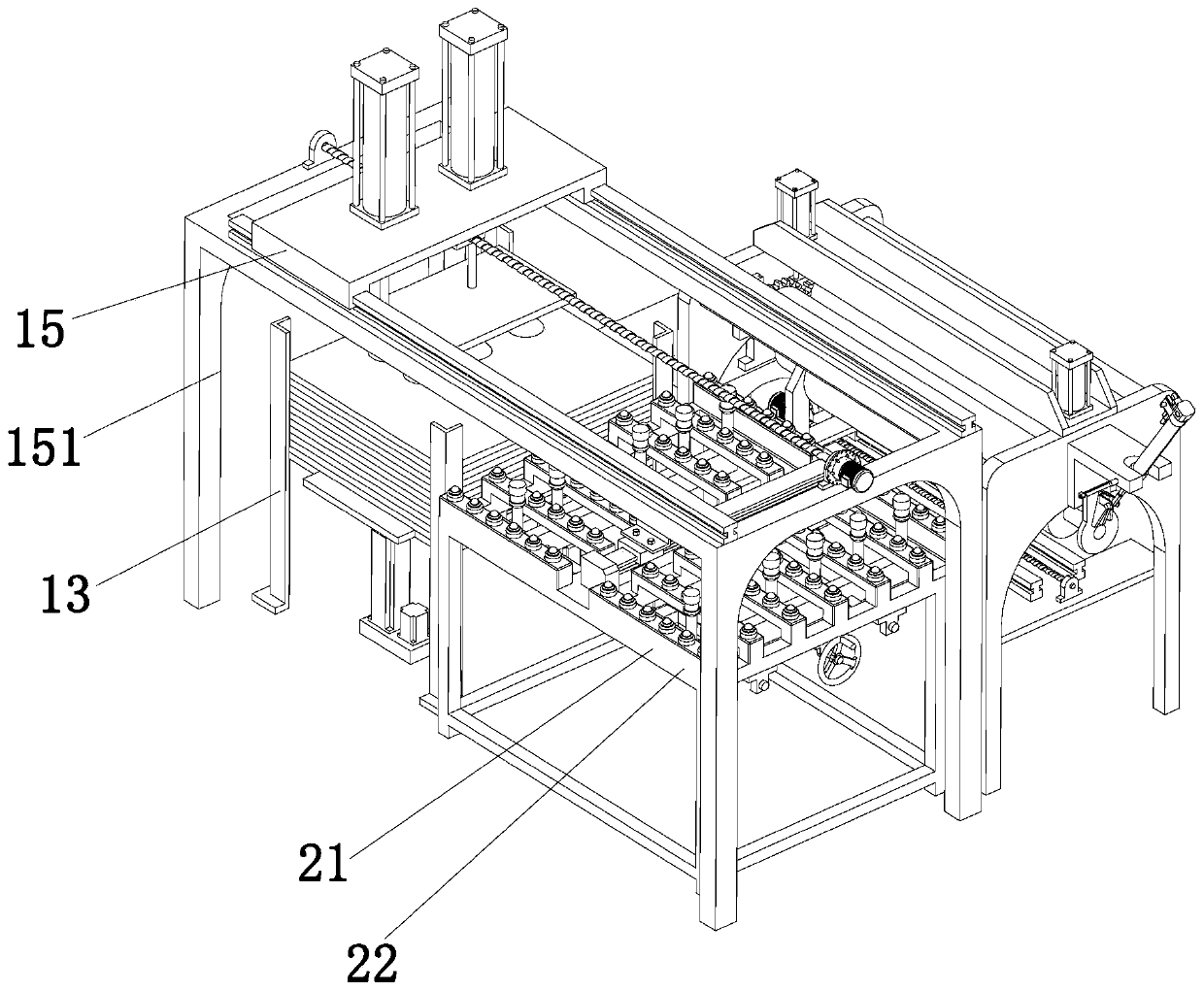

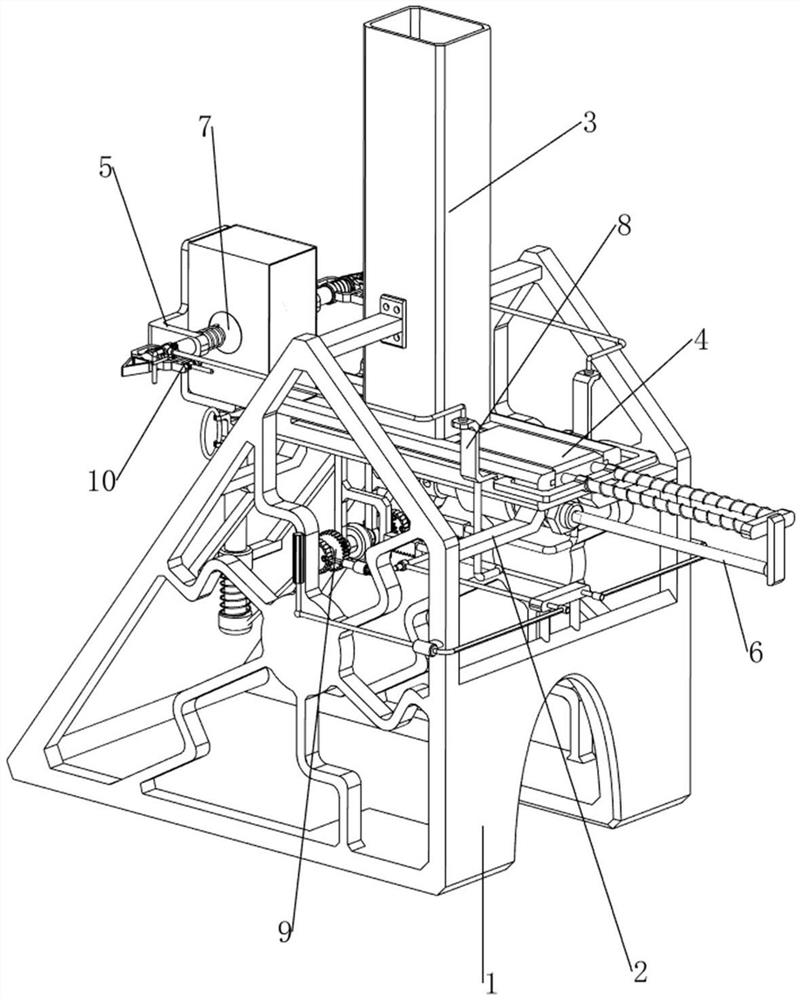

Marine engineering submarine pipeline erecting device

ActiveCN108397596AAutomatic clampingPipe supportsPipe laying and repairEngineeringMechanical engineering

The invention relates to the field of marine engineering, in particular to a marine engineering submarine pipeline erecting device. The marine engineering submarine pipeline erecting device comprisestrack assemblies, clamping sliding seat assemblies, clamping assemblies and a pressing assembly. The clamping sliding seat assemblies in the device can side on the track assemblies for position adjustment, so that different positions of a pipeline can be supported as needed. The device can clamp the pipeline and the device can adapt to erection of pipelines of different sizes. When the pipeline isplaced on a lower support to press the lower support, the device automatically clamps the pipeline. The two clamping sliding seat assemblies are arranged, the upper ends of sliding seats are fixedlyconnected with hinged seats, and the upper ends of the sliding seats are symmetrically and fixedly connected with two positioning inserting columns. The two clamping assemblies are arranged, and the upper ends of bottom rotating seats are fixedly connected with fixing blocks. Extension rods are fixedly connected to the front and rear ends of the fixing blocks, the outer ends of the two extension rods are connected with rotating rods in a hinged mode, and the two extension rods are fixedly connected with arc-shaped rods.

Owner:浙江立盛新型墙体材料有限公司

Industrial roller brush carrier roller automatic cutting device with high cutting efficiency

InactiveCN110394501AImprove safety performanceReduce labor intensityPositioning apparatusMaintainance and safety accessoriesElectric machineryEngineering

The invention discloses an industrial roller brush carrier roller automatic cutting device with high cutting efficiency. The industrial roller brush carrier roller automatic cutting device comprises aworkbench, two fixing blocks are symmetrically arranged on the upper surface of the workbench, containing grooves matched with a carrier roller are formed in the upper surfaces of the fixing blocks,moreover, first fixing cylinders are fixedly connected to the front surfaces of the two sides of the fixing blocks through bolts, and second fixing cylinders are arranged at one ends of the first fixing cylinders. The invention relates to the technical field of roller brush carrier roller cutting. According to the industrial roller brush carrier roller automatic cutting device with the high cutting efficiency, one ends of servo motors are installed on one side surfaces of the second fixing cylinders in an embedded and rotating mode, when the carrier roller is cut, the carrier roller can be automatically clamped and firmly fixed, so that the situation that the cutting effect is affected due to the fact that the carrier roller shakes during cutting is prevented, the industrial roller brush carrier roller automatic cutting device replaces the operation of manually holding the carrier roller by hands for fixing, so that the safety performance is improved, meanwhile, the labor intensity ofworkers is reduced, and the practicability is high.

Owner:潜山市志杰刷业有限公司

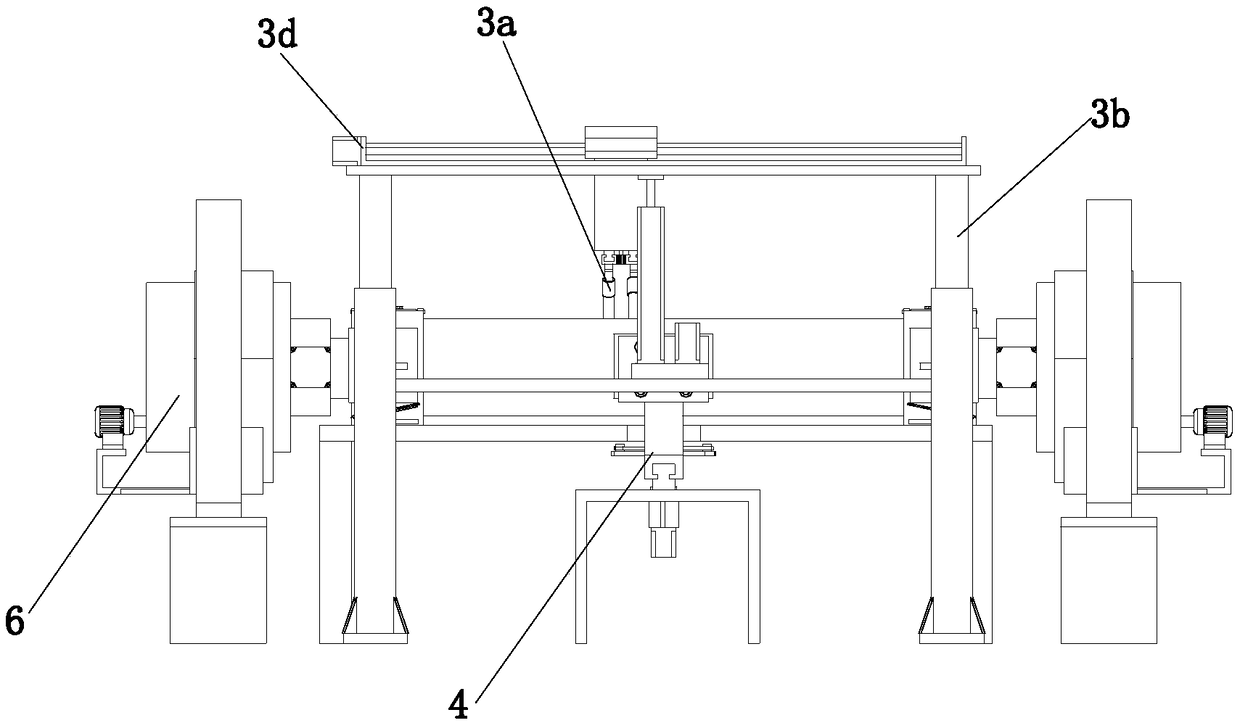

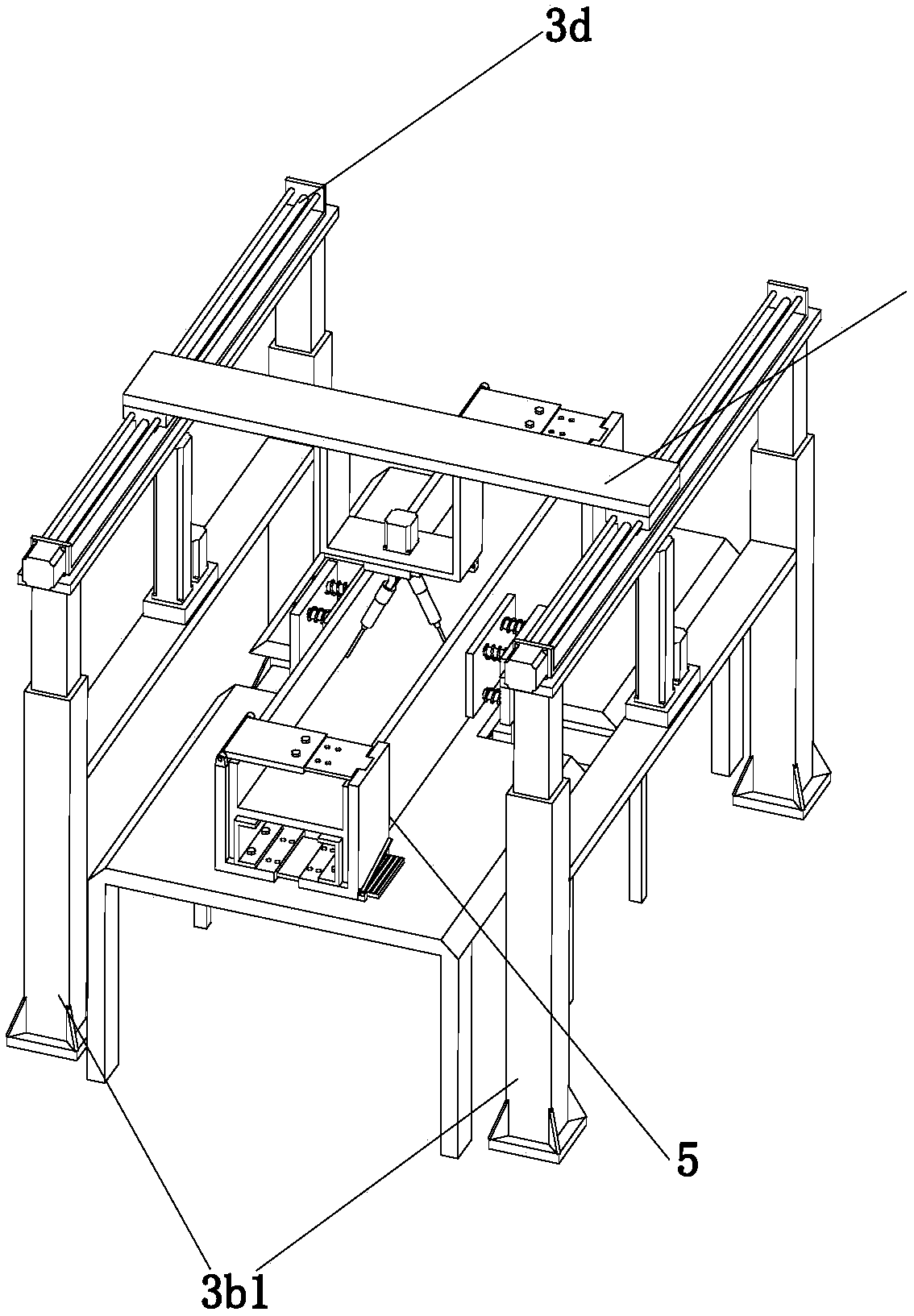

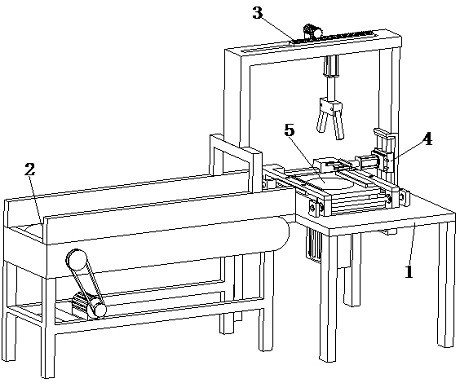

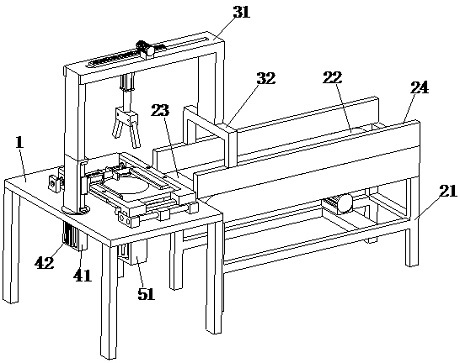

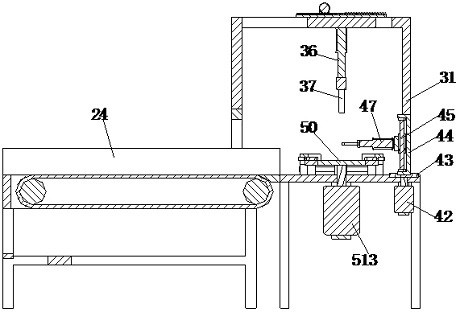

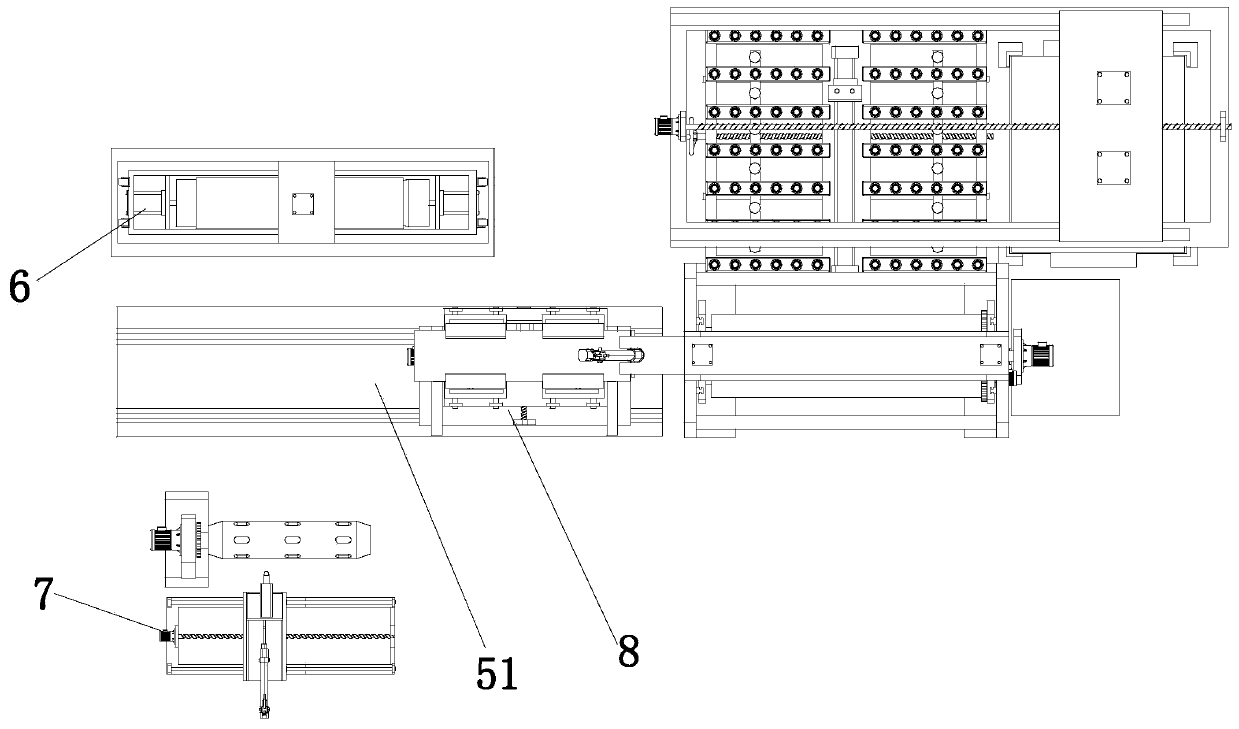

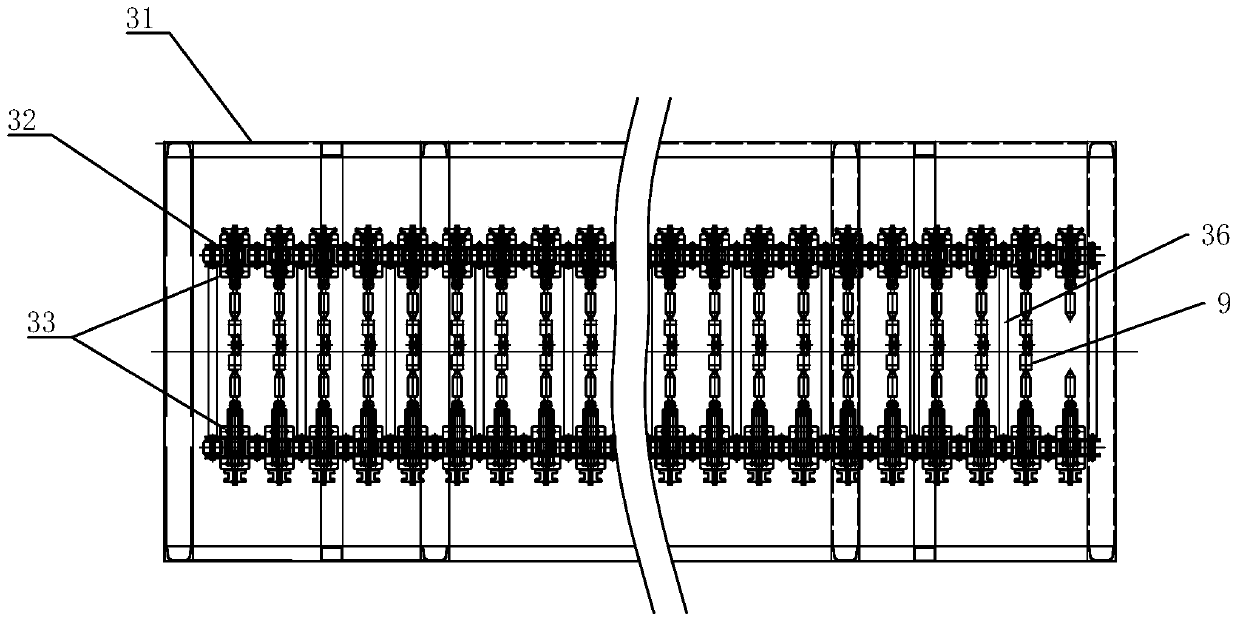

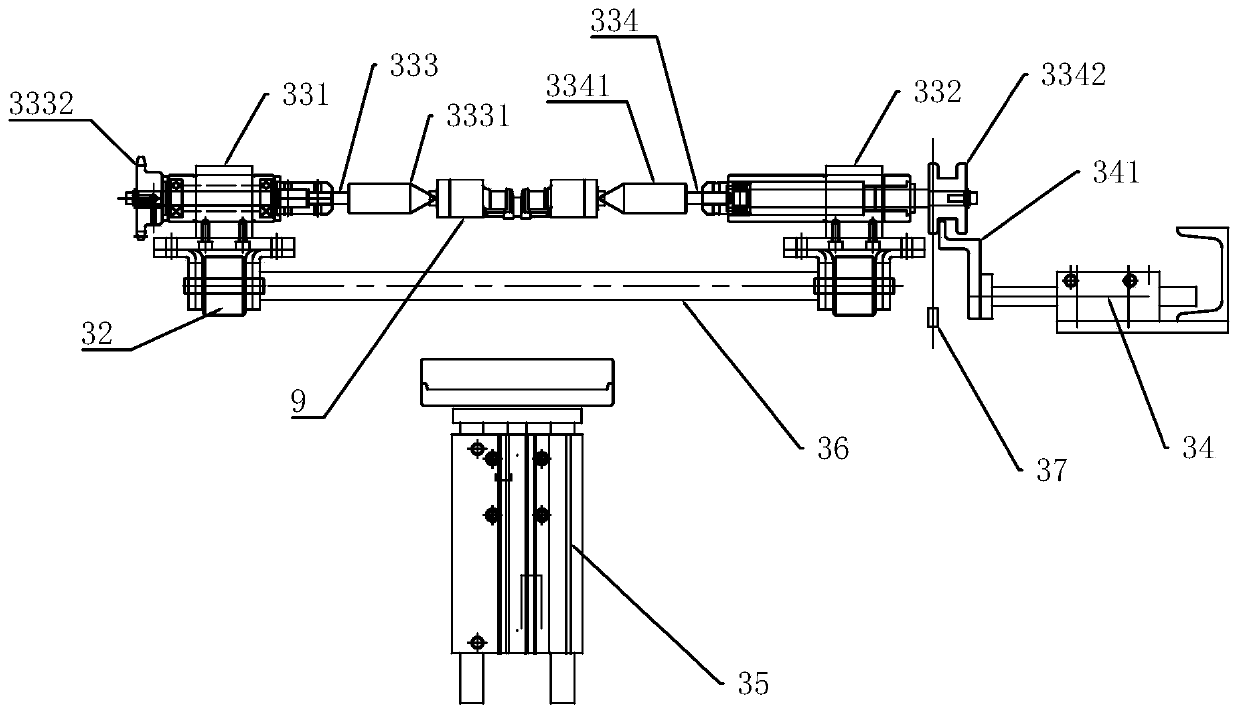

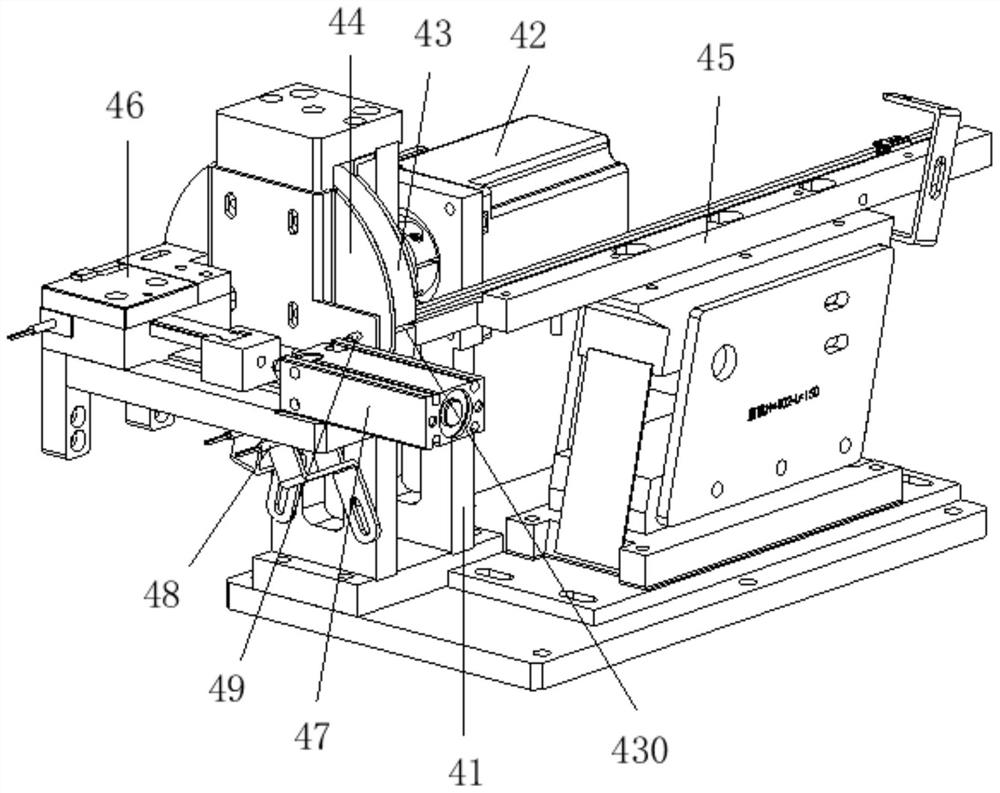

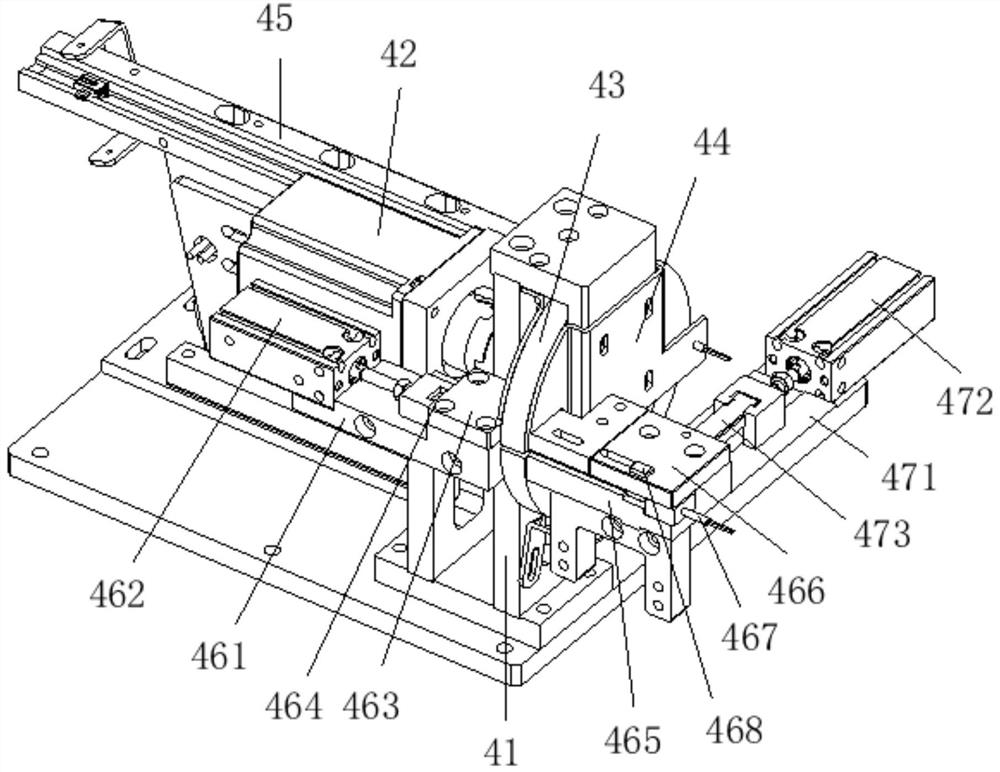

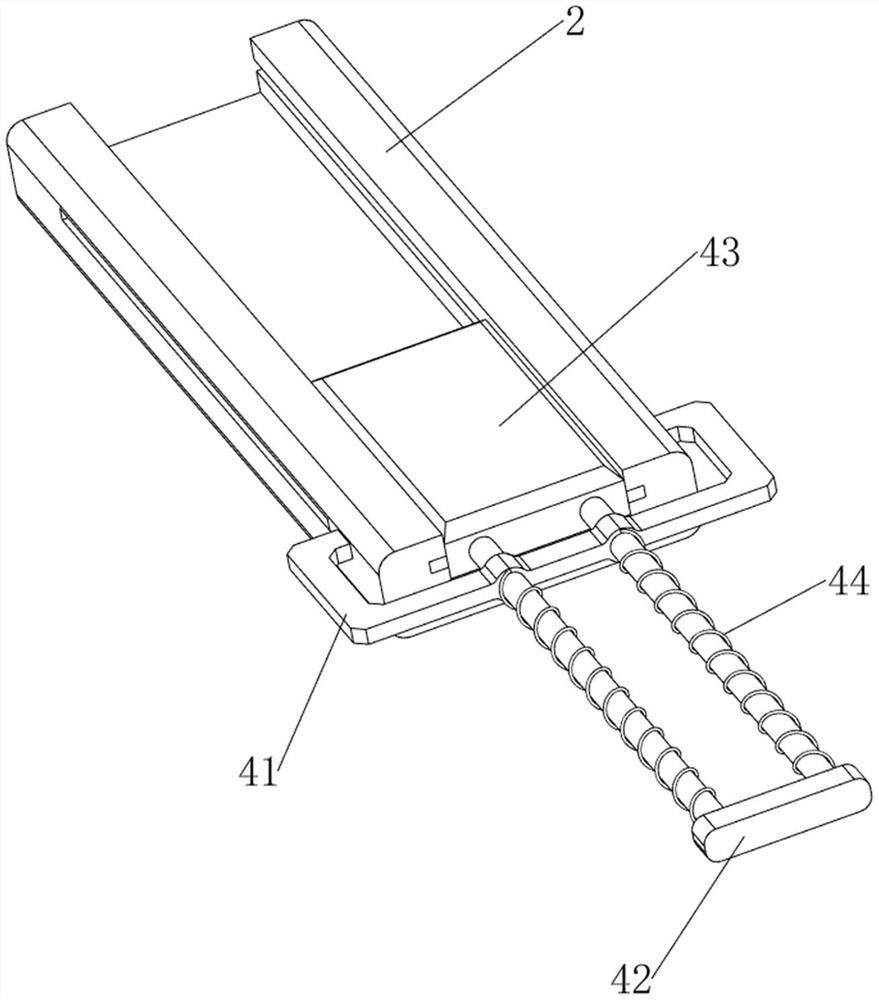

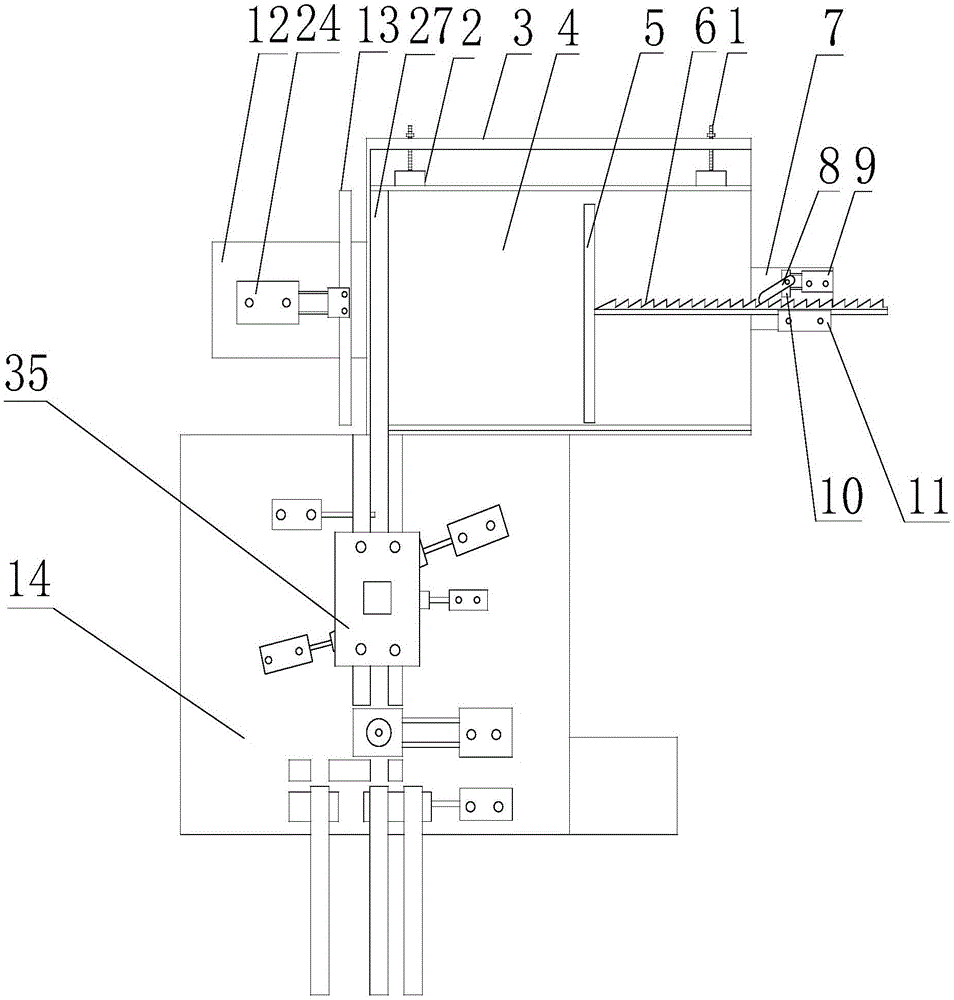

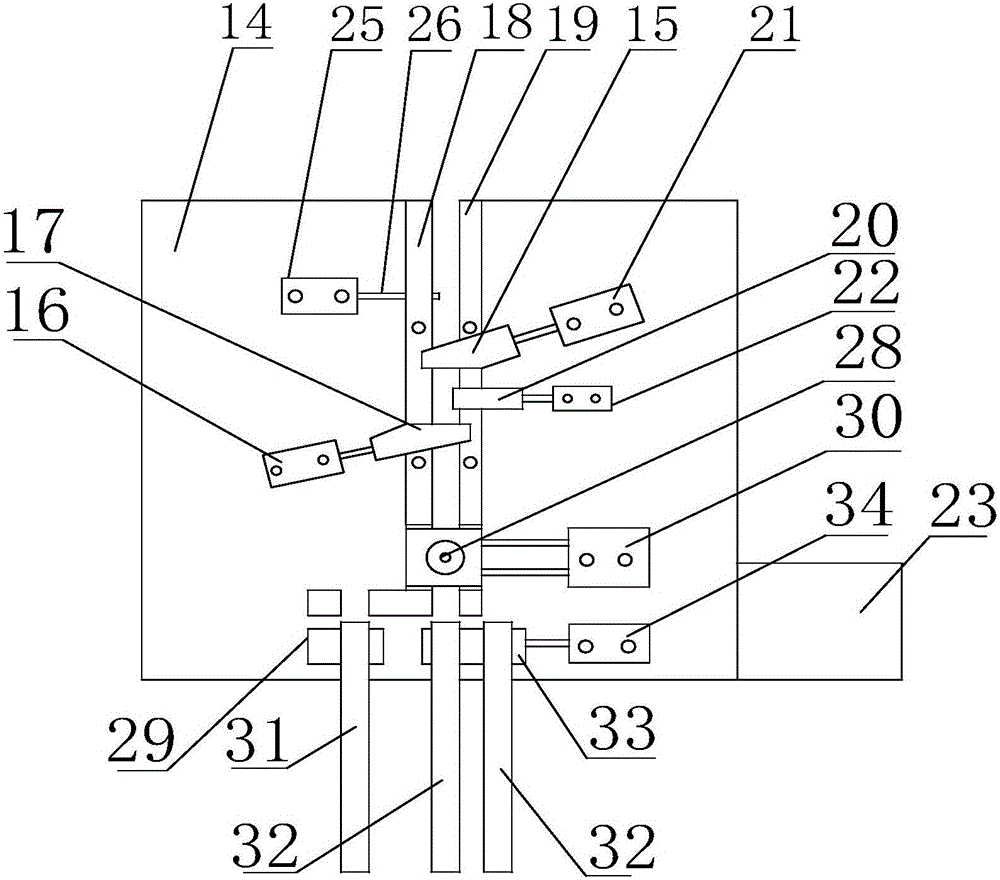

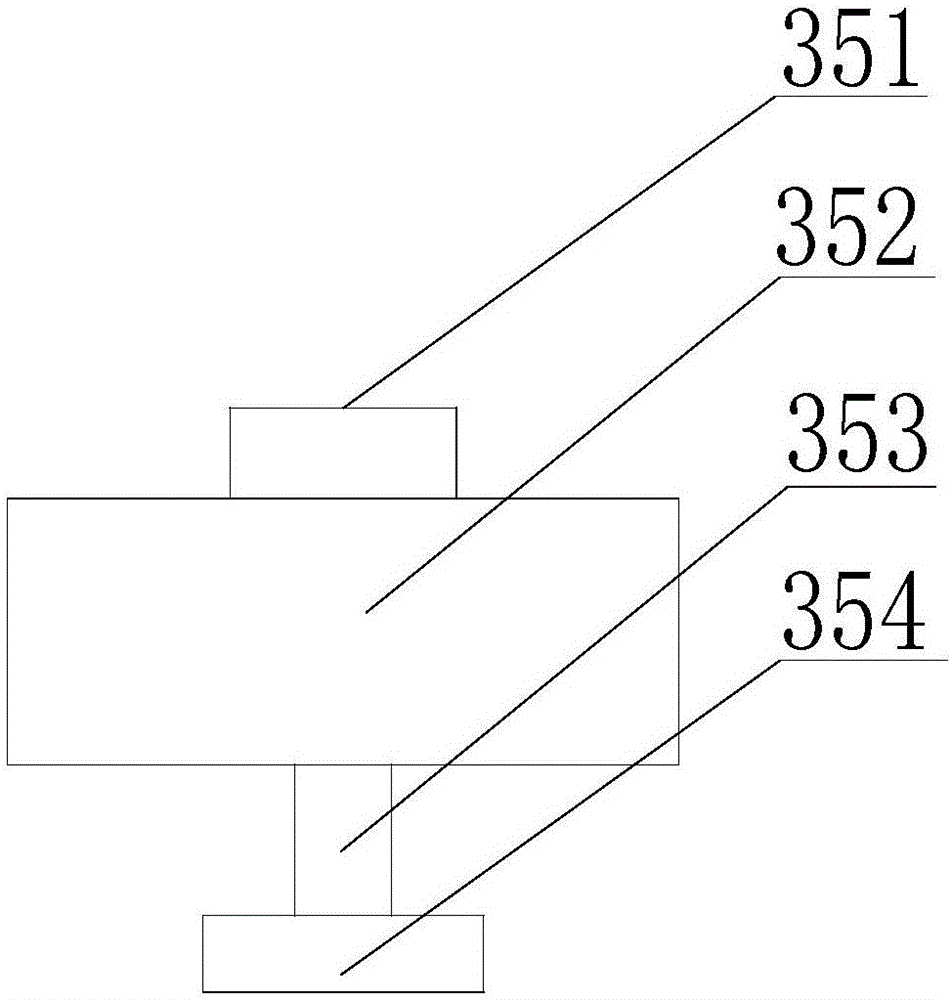

Sewing leak hunting mechanism of solar water heater water tank inner container rounding leak hunting machine and process thereof

ActiveCN111256378AAutomatic clampingAutomate welding operationsDetection of fluid at leakage pointSolar heating energySolar waterEngineering

The invention discloses a sewing leak hunting mechanism of a solar water heater water tank inner container rounding leak hunting machine, and belongs to the technical field of water heater processing.The sewing leak hunting mechanism comprising a pedestal, a leakage and pressure detecting mechanism, an automatic sewing mechanism and a workpiece feeding mechanism, wherein the workpiece feeding mechanism is arranged on the pedestal; and the workpiece feeding mechanism comprises a feeding table, a second lead screw sliding table, a rotary turning-around assembly and a workpiece clamping assembly, wherein two horizontally-arranged supporting rails are arranged at the top of the pedestal, the feeding table is arranged at the moving end of the second lead screw sliding table, the rotary turning-around assembly is arranged at the top of the feeding table, and the workpiece clamping assembly is arranged at the top of the rotary turning-around assembly. According to the sewing leak hunting mechanism of the solar water heater water tank inner container rounding leak hunting machine, pressure and leakage detecting operation can be automatically carried out on a welded inner container under action of the leakage and pressure detecting mechanism, clamping, feeding and turning-around placement operation on raw materials of the cylindrical inner container can be achieved under action of theworkpiece feeding mechanism, and welding operation on the raw materials of the cylindrical inner container can be achieved under action of the automatic sewing mechanism.

Owner:裘士兴

Apple processing device

ActiveCN111000264AReduced peeling cycle timeAvoid incomplete peelingFruit stoningVegetable peelingApple peelAgricultural engineering

The invention discloses an apple processing device and relates to the field of fruit processing. The apple processing device comprises an apple clamping mechanism, an adjusting base sliding frame, anadjusting base, a cutting mechanism, a driving mechanism, a coring mechanism and an ejection mechanism. The invention has the beneficial effects as follows: the problem that an existing apple peelingdevice cannot effectively peel the center parts of the upper and lower ends of an apple is solved; and an apple core can be separated from the apple in the apple peeling process, and the apple core can be ejected out of the coring mechanism, so that the peeling period of a single apple is shortened. The adjusting base sliding frame is arranged on the apple clamping mechanism; one end of the adjusting base is connected with the apple clamping mechanism, and the other end of the adjusting base is movably connected to the adjusting base sliding frame; the cutting mechanism is connected to the adjusting base in a matched mode; the driving mechanism is arranged on the apple clamping mechanism; the coring mechanism is connected with the driving mechanism in a matched mode; and the driving mechanism drives the coring mechanism to rotate and move up and down to separate apple cores from apples; and the ejection mechanism is arranged on the apple clamping mechanism.

Owner:洛川延刚经贸果业有限责任公司

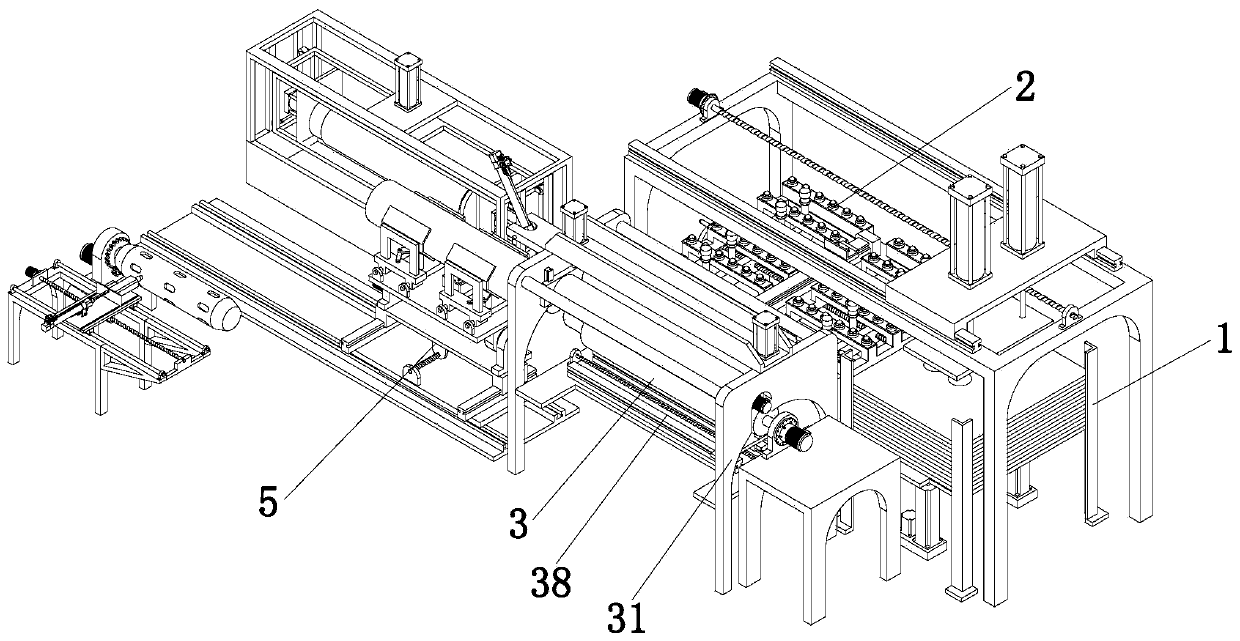

Horizontal spraying production line

The invention discloses a horizontal spraying production line. The horizontal spraying production line comprises a spraying chamber, a drying chamber and a spraying conveying device, wherein the spraying conveying device comprises a spraying machine frame, two spraying conveying chains which are arranged in parallel at intervals and a clamping jig; the clamping jig comprises a first mounting seatand a second mounting seat; the first mounting seat and the second mounting seat are oppositely positioned on the two spraying conveying chains respectively; the first mounting seat is connected witha main shaft; one end of the main shaft is provided with a fixed pressing block, and another end of the main shaft is provided with a driving wheel; the second mounting seat is connected with a drivenshaft; one end of the driven shaft is provided with a movable pressure block; the second mounting seat is provided with a return spring which can drive the driven shaft to return to one side close tothe main shaft; the spraying conveying chains are provided with feeding positions and discharging positions; the feeding positions and the discharging positions are both provided with second drivingdevices for pulling the driven shaft to slide; and the spraying chamber is provided with a rotary driving device for driving the driving wheel to rotate. The horizontal spraying production line not only can ensure uniform spraying for workpieces, but also has higher working efficiency and simple structure.

Owner:东莞市驰铭智能科技有限公司

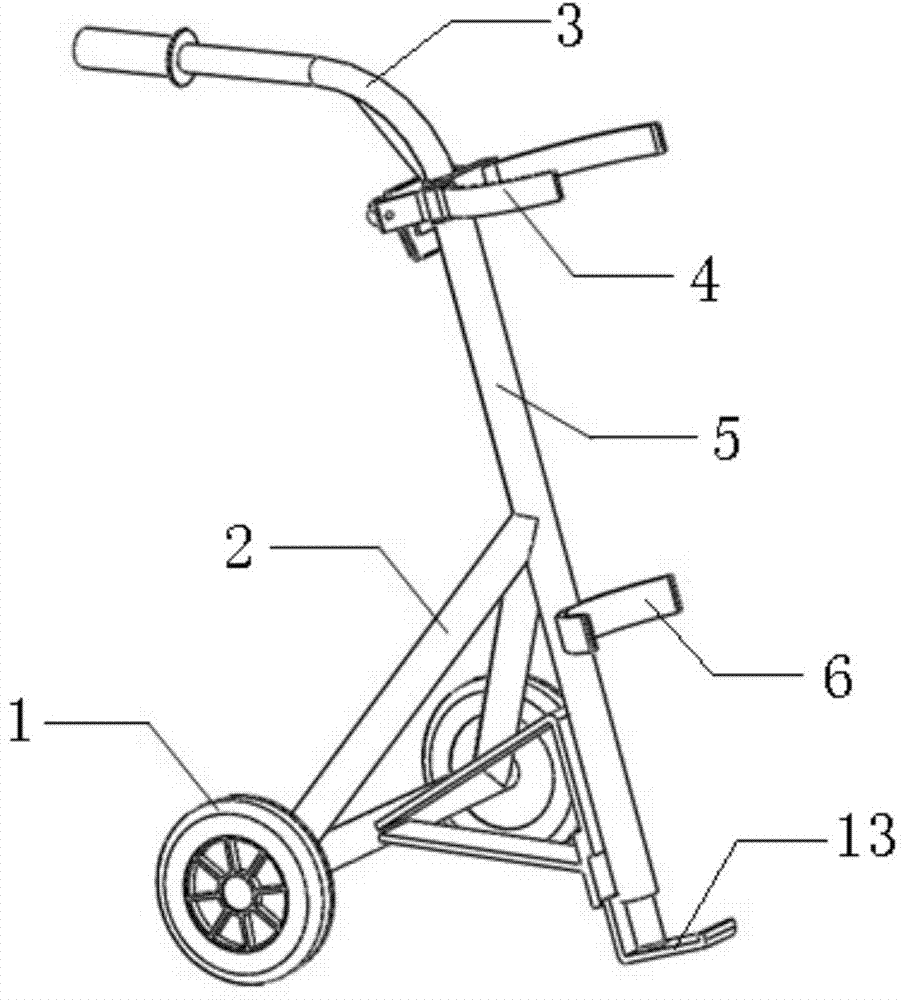

Oxygen bottle trolley

InactiveCN104325997AAutomatic clampingAutomatic releaseHand carts with one axisGas cylinderEngineering

The invention relates to an oxygen bottle trolley. The oxygen bottle trolley comprises a frame and a clamping device which is arranged on the frame, wherein the clamping device comprises holding claws which are arranged in pairs in an opening and closing manner; a carrying rod is movably assembled on the frame along a vertical guide direction; both the upper and lower ends of the carrying rod extend out of the frame; the upper end of the carrying rod is fixedly connected with a handle, and the lower end of the carrying rod is fixedly connected with an oxygen bottle carrying plate; the middle upper part of the carrying rod is fixedly connected with a wedged plate which moves vertically along with the carrying rod and of which the upper part is wider than the lower part; the holding claws are fixedly connected with force application arms which are positioned in a vertical movement stroke of the wedged plate and are ejected by the wedged plate. According to the oxygen bottle trolley, the carrying rod can move up and down with the gravity change caused by loading or unloading of an oxygen bottle, so that the wedged plate on the carrying rod can descend and push the force application arms on the movable claws to drive the movable claws to close so as to automatically clamp the oxygen bottle, and the wedged plate ascends without pushing the movable claws to enable the movable claws to be restored and opened when the carrying rod ascends; thus the clamping and loosening of the oxygen bottle are automatically realized, and the labor intensity of workers is reduced.

Owner:STATE GRID CORP OF CHINA +1

Part drilling device

InactiveCN108311725AAutomatic clampingAvoid deformationPositioning apparatusMetal working apparatusEngineeringDistance sensors

Owner:WUJIANG HEXIN MASCH FACTORY

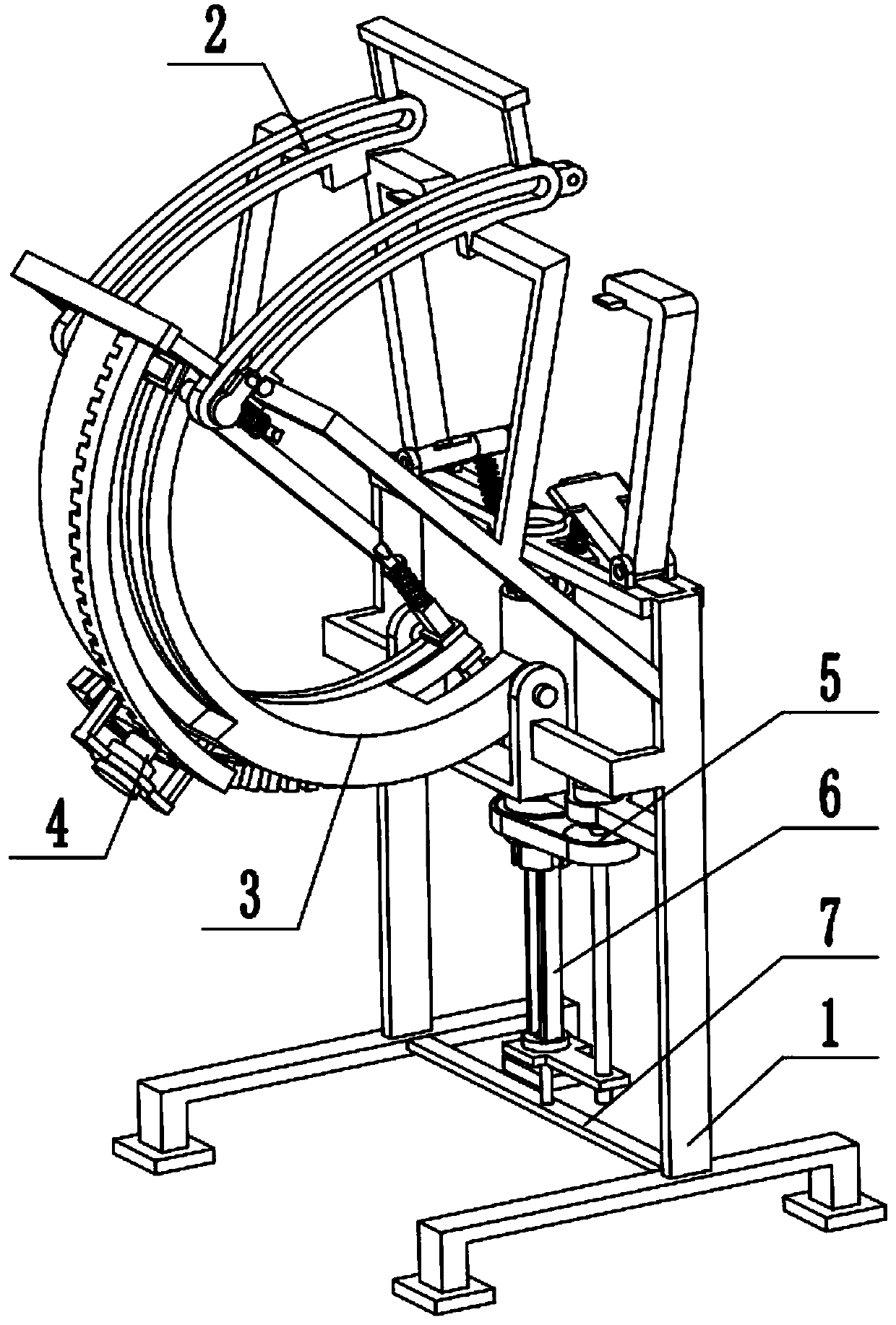

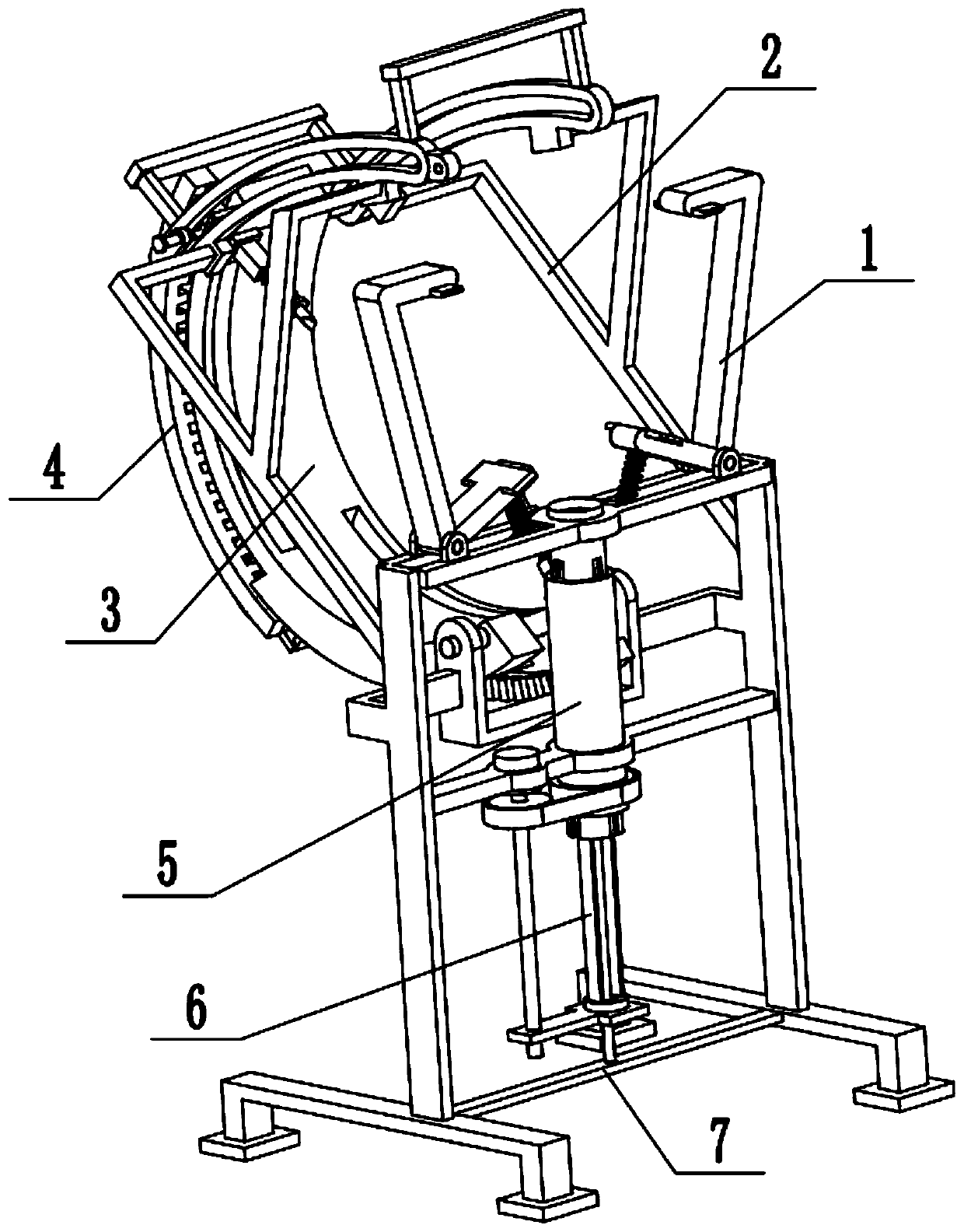

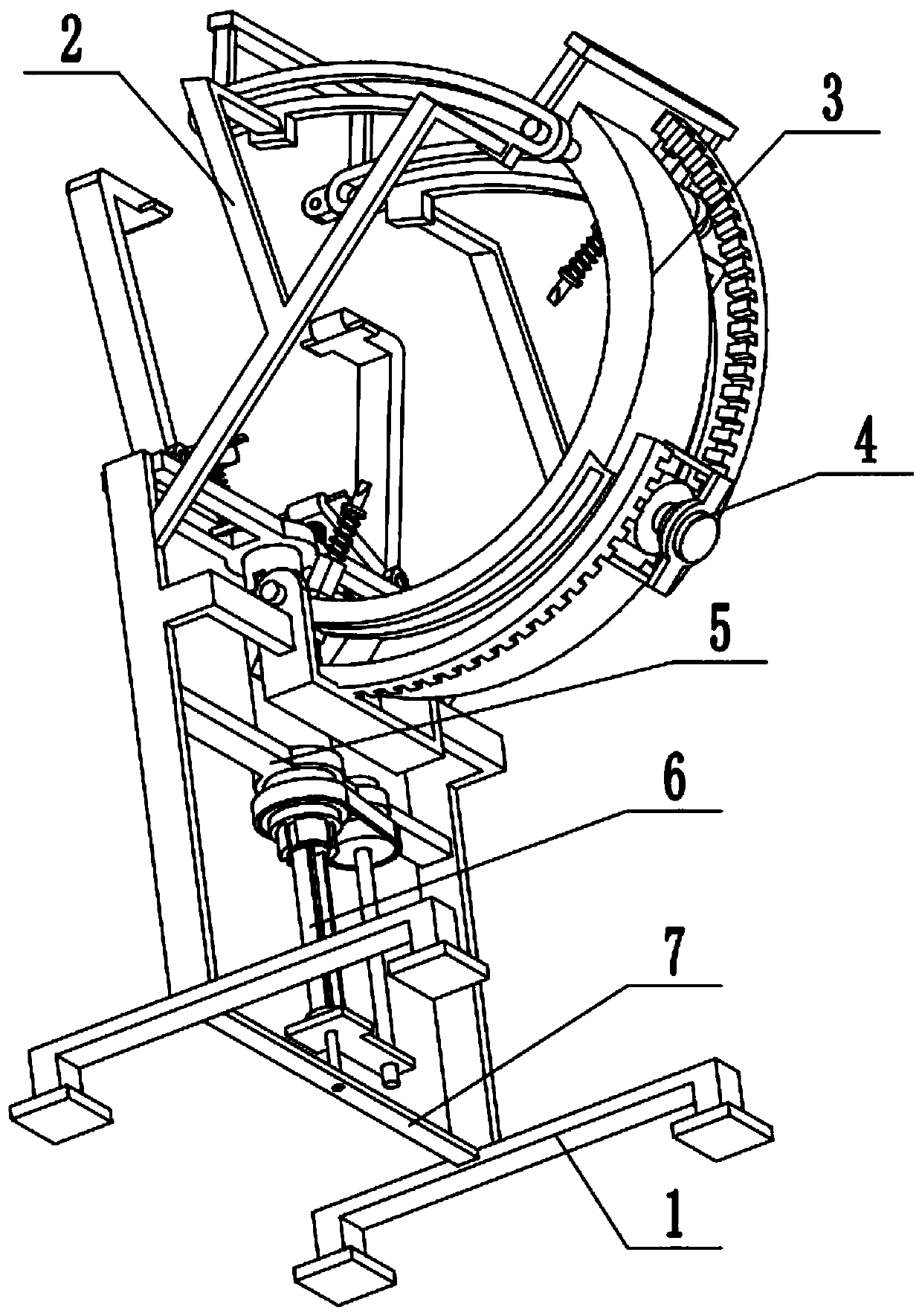

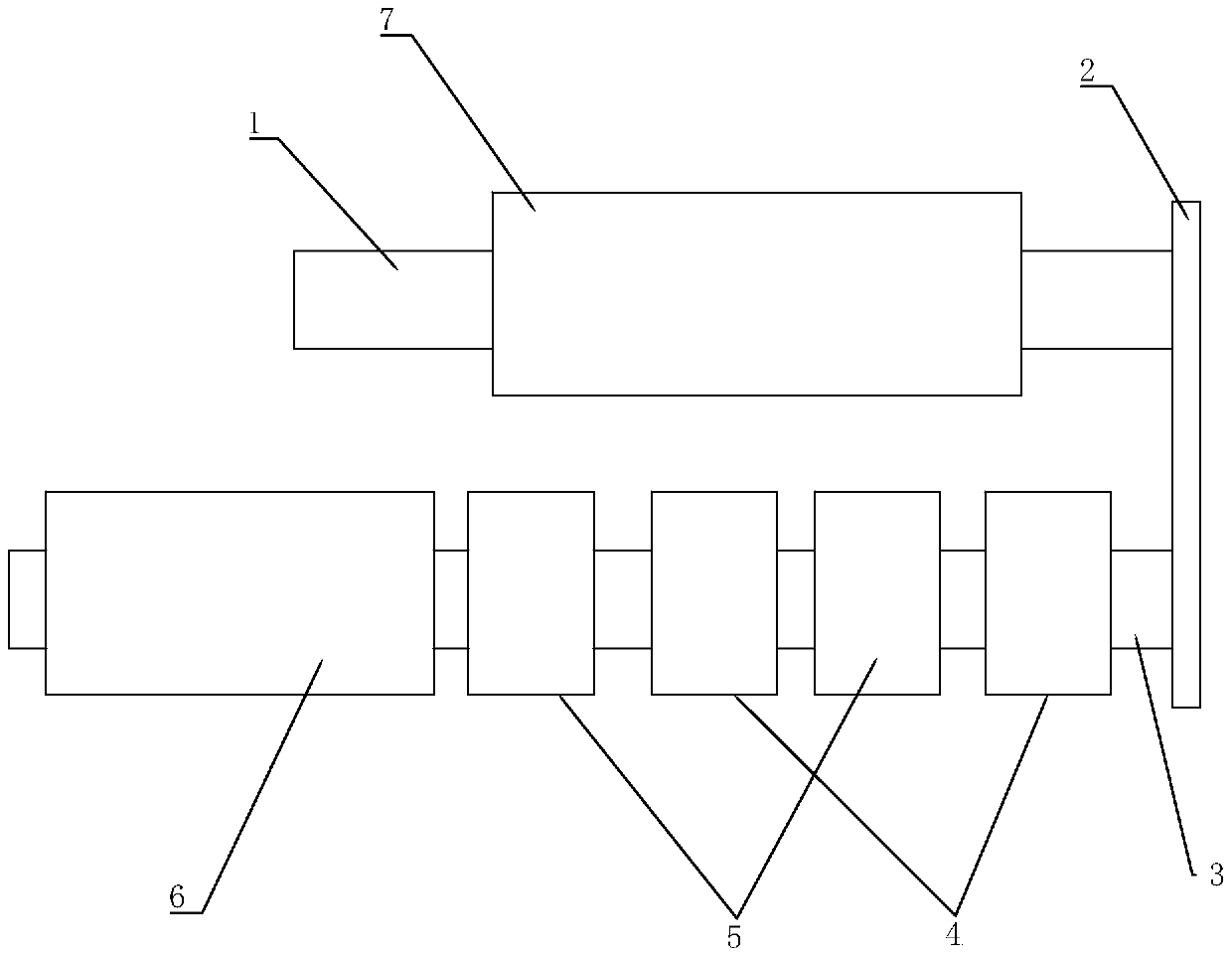

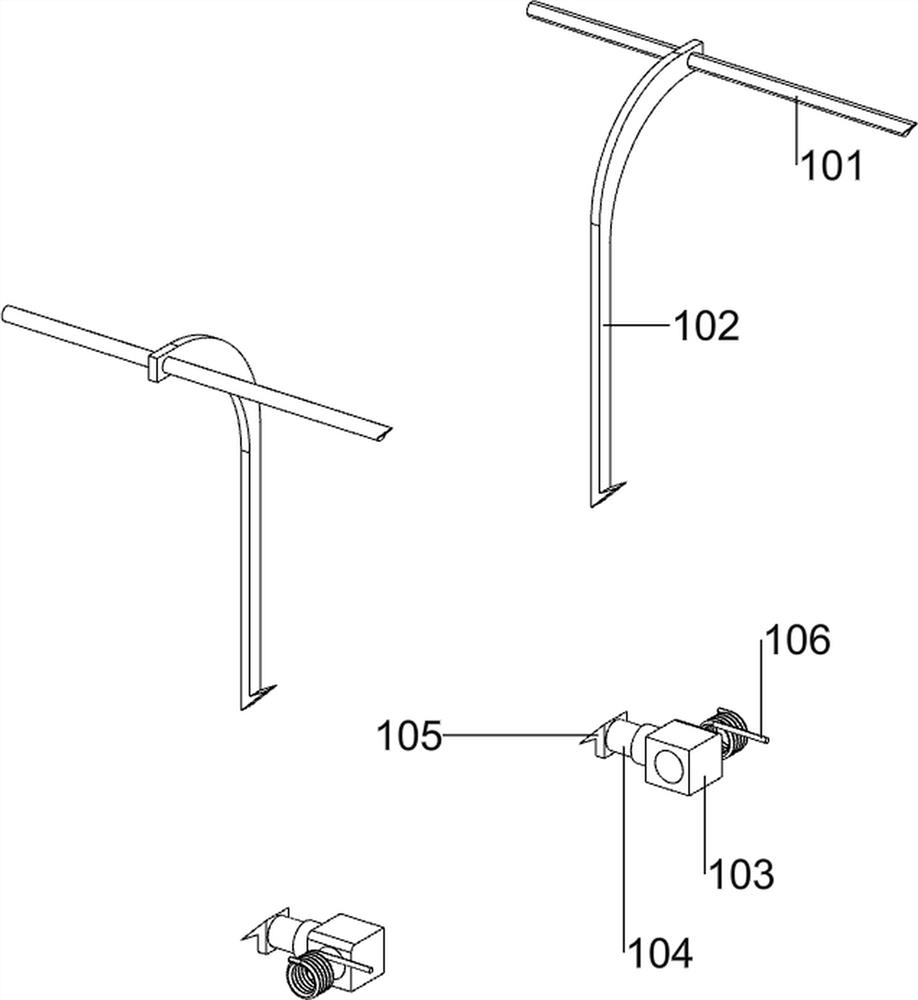

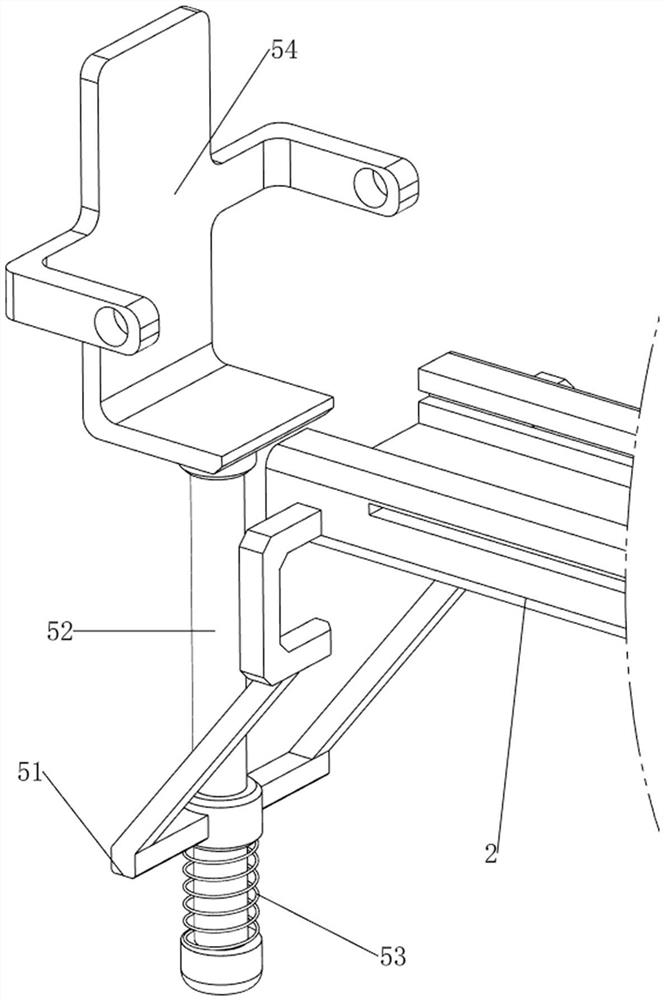

Automatic clamping mechanism in steel bar bender

The invention discloses an automatic clamping mechanism in a steel bar bender. The automatic clamping mechanism comprises a bending rack, wherein a circular track is supported on the bending rack; a bidirectional piston rod cylinder is fixed on the circular track; a bidirectional piston rod moving axis inside the bidirectional piston rod cylinder is parallel to the axis of the circular track; one ends of a pair of clamping arms of which the mirror symmetry structures are the same are fixed on the bidirectional piston rod of the bidirectional piston rod cylinder respectively; through holes of the pair of clamping arms are respectively in sliding match on the circular track; the other ends of the pair of clamping arms are respectively provided with clamping plates; the bidirectional piston rod cylinder drives the pair of clamping arms to slide along the circular track so as to make the clamping plates tightly clamp a reinforcing steel bar from two sides. The clamping mechanism has the beneficial effects that with the adoption of the automatic clamping mechanism of the steel bar bender, the reinforcing steel bar can be automatically clamped while being bent; the convenience is provided for operating personnel of the reinforcing steel bar machining equipment; and the clamping mechanism has the advantages of high automation degree, simple structure, stable working, time conservation and labor conservation and high working efficiency.

Owner:TJK MACHINERY TIANJIN

Manufacturing machine for square rubber cushion block for cabinet

InactiveCN113386183AHit free operationAutomatic clampingMetal working apparatusMachineIndustrial engineering

The invention relates to a manufacturing machine, and particularly relates to a manufacturing machine for a square rubber cushion block for a cabinet. The manufacturing machine for the square rubber cushion block for the cabinet can improve the working efficiency and reduce the production cost. According to the technical scheme, the manufacturing machine for the square rubber cushion block for the cabinet comprises a bottom plate, first sliding rails, first springs, a cutter, a placing frame, an air cylinder and a placing mechanism, wherein the first sliding rails are arranged on the four sides of the bottom plate, the placing frame is connected between the tops of the first sliding rails, the cutter is connected between the first sliding rails in a sliding mode, the first springs are arranged between the four sides of the bottom of the cutter and the first sliding rails on the same side, the air cylinder is arranged in the middle of the placing frame, the bottom of the air cylinder is connected with the cutter, and the placing mechanism is arranged on the bottom plate. Through the cooperation between the placing mechanism and an anti-clamping mechanism, materials can be automatically cut, so that the square rubber cushion block is formed.

Owner:李雪萍

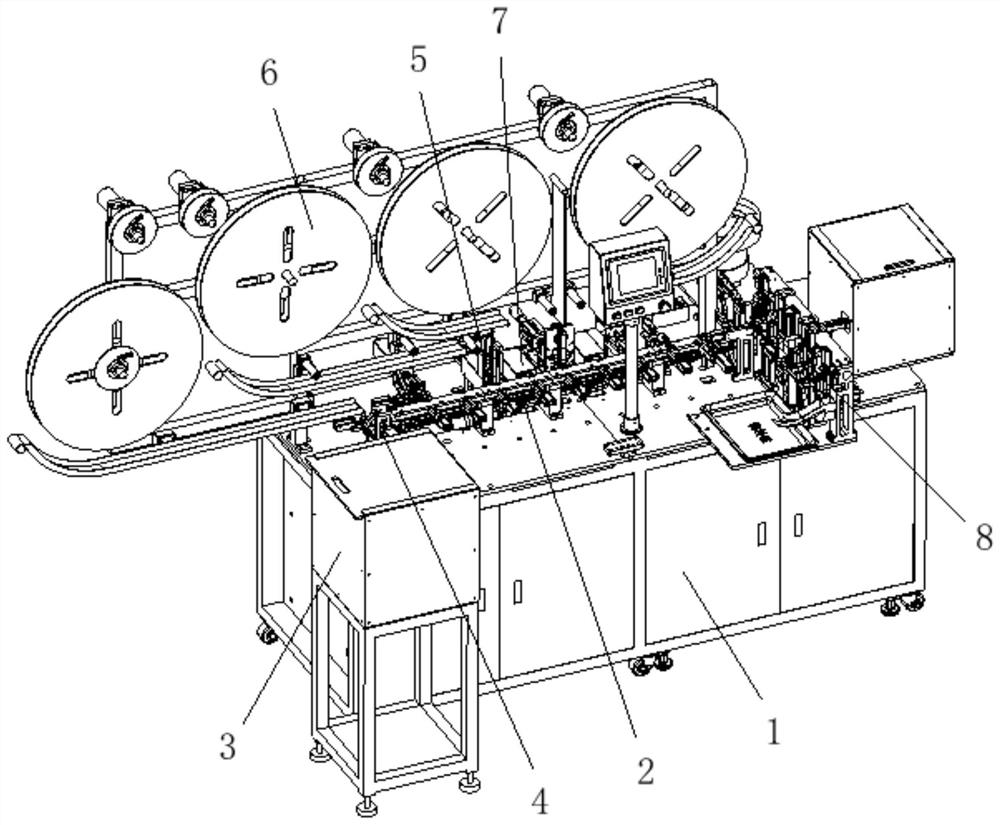

Novel automatic assembling equipment for power supply socket

PendingCN112072444ACompact structureGuaranteed uptimeContact member assembly/disassemblyStructural engineeringMachining

The invention discloses novel automatic assembling equipment for a power supply socket. The novel automatic assembling equipment comprises a rack, a linear machining flow channel, a rubber core vibration disc, a rotary overturning and staggering mechanism, a pin mechanism, a terminal discharging device, material sweeping belt structures and an assembling and testing mechanism, wherein the linear machining flow channel is arranged on the rack; the rubber core vibration disc is arranged on the left side of the linear machining flow channel and is conveyed to the linear machining flow channel through the rotary overturning and staggering mechanism; the pin mechanism is arranged on the rear side of the linear machining flow channel and comprises a positive terminal, a center pin and a negativeterminal pin; the terminal discharging device in butt joint with the rear side terminal of the pin mechanism is arranged on the rear side terminal; the next station of each terminal pin is provided with one material sweeping belt structure; and the right side of the linear processing flow channel is provided with the assembling and testing mechanism in a butt joint manner. By means of the mode, the novel automatic assembling equipment is compact in structure, stable in operation, capable of automatically assembling, detecting and classifying power sockets and high in assembling efficiency.

Owner:SUZHOU E CONN TECH

Drill bit storage device convenient for personnel to take for machining

InactiveCN111843607AEasy accessAutomatic clampingProtection and storage accessoriesWork tools storageMachining processDrill bit

The invention provides a drill bit storage device convenient for personnel to take for machining, relates to the technical field of machining, and aims to solve the problems that in the machining process, due to the fact that drill bits are placed in a storage box, when the drill bits are taken, the storage box needs to be opened for selection, moreover, the drill bits are placed in the box and also need to be clamped by a clamping mechanism, the drill bits are abraded due to collision, and in the machining process, the drill bits of different specifications and models need to be selected foruse according to the sizes of drilled holes, and due to the fact that the diameters and the lengths of the drill bits of different specifications are inconsistent, the drill bits are difficult to clamp through the same set of clamping tool. The drill bit storage device comprises a base; a rotating mechanism is transversely and rotationally mounted at the upper end of the middle of the base. According to the drill bit storage device, due to the fact that a bearing rod is vertically and fixedly mounted in the middle of the lower end of a bearing mechanism, the lower end of the bearing rod is inserted into a sliding assembly in a sliding mode, the drill bits can be conveniently taken and placed, the drill bits can be automatically clamped after being placed under the combined action of the bearing rod and a spring, and convenience and rapidness are achieved.

Owner:倪波者

Automatic packaging device for circuit breaker production

ActiveCN112849519AAvoid displacementRealize the push effectPackagingPackaging CaseControl engineering

The invention relates to a packaging device, and particularly relates to an automatic packaging device for circuit breaker production. The automatic packaging device for circuit breaker production can achieve automatic packaging, reduces labor force of workers and is convenient to use. The automatic packaging device for circuit breaker production comprises supporting feet, a sliding rail plate, a discharging frame, a pushing mechanism and a moving mechanism, wherein the sliding rail plate is arranged between the two sides of the supporting feet, the discharging frame is arranged between the two sides of the supporting feet, the pushing mechanism is arranged on the sliding rail plate, and the moving mechanism is arranged on the sliding rail plate. According to the automatic packaging device, a first sliding rod is manually pushed to slide leftwards, a first spring is compressed, and therefore a sliding block is driven to move leftwards, a circuit breaker can be pushed out through the sliding block, and the pushing effect is achieved; and after the circuit breaker is pushed to a packaging box again through the sliding block, people need to push a supporting plate to move downwards again, and therefore a second sliding rod is driven to continue to slide downwards, a second spring continues to reset, and the moving effect is achieved.

Owner:江西双宏科技电气有限公司

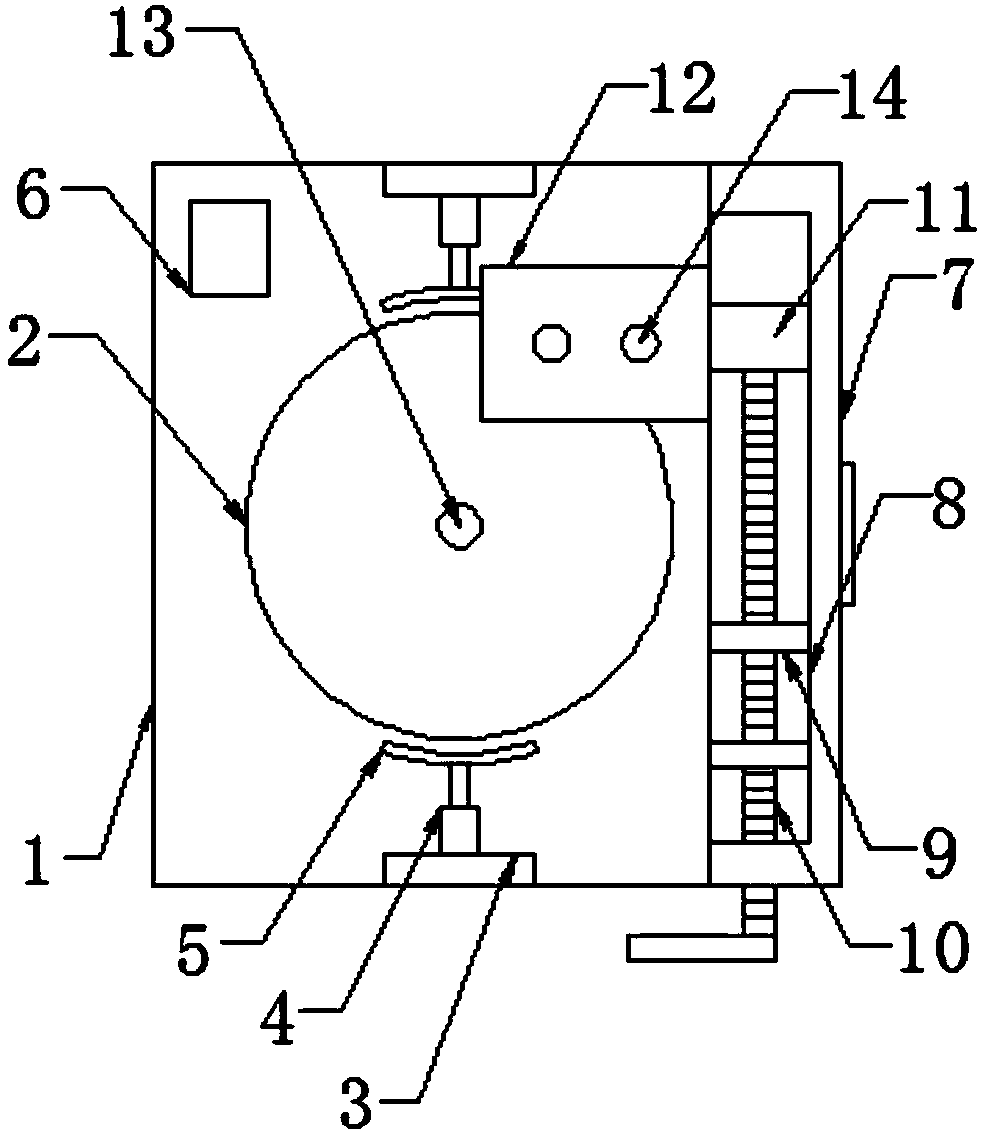

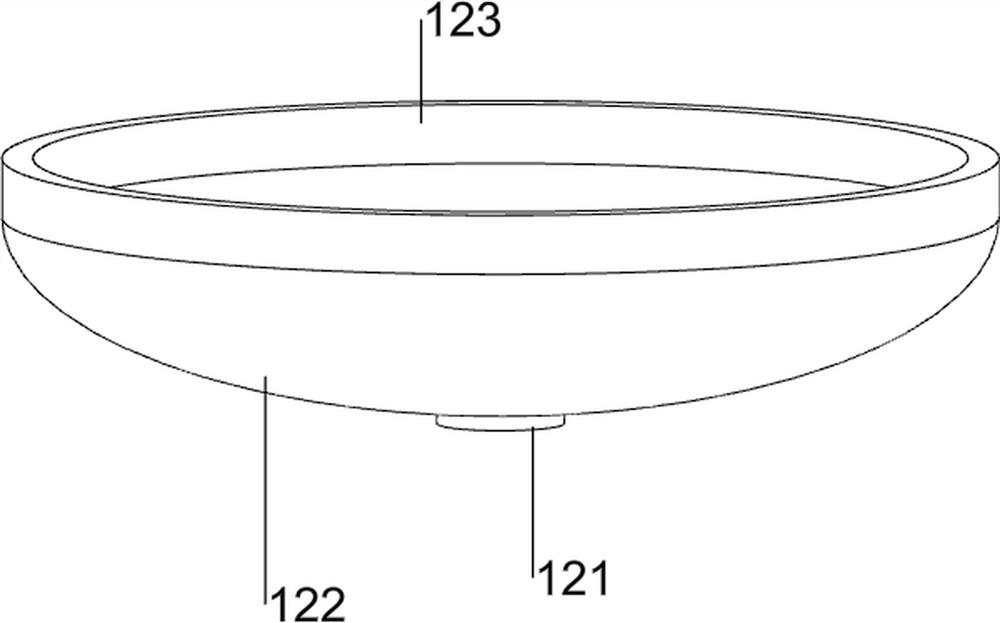

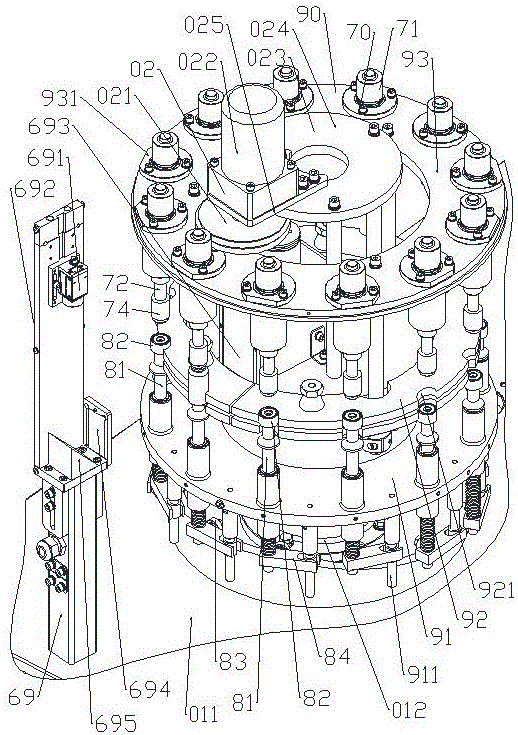

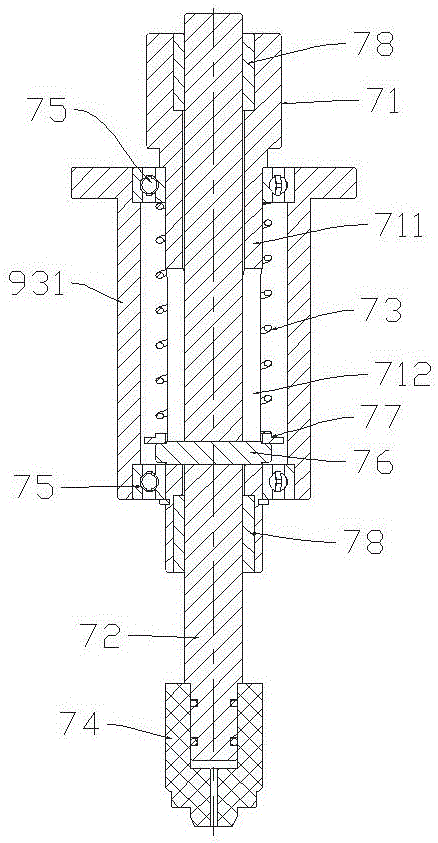

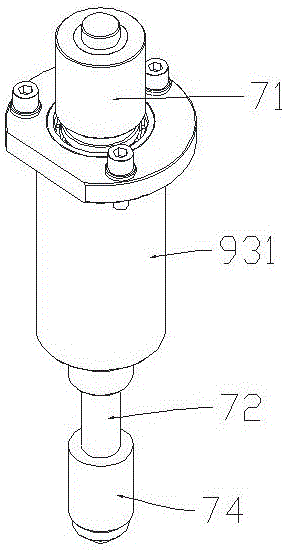

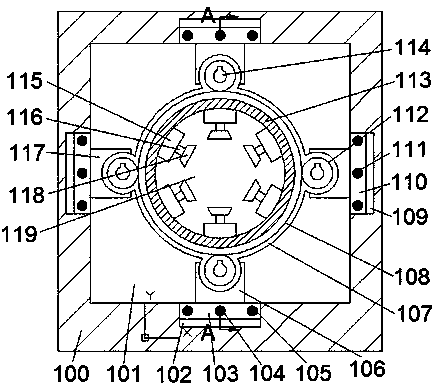

Automatic lamp detection device and detection device for bottle body thereof

PendingCN106323990AAutomatic clampingAutomatic releaseMaterial analysis by optical meansElastic componentCam

The invention discloses a detection device for a bottle body. The detection device comprises a frame, a bedplate, a cam, a turntable mechanism and a bottle body camera component, wherein the turntable mechanism comprises a lower turntable, a middle turntable and an upper turntable; bottle-accommodating grooves are uniformly distributed along the outer edge of the middle turntable; a bottle tray component comprises a support rod, a bottle tray and an idler wheel; the support rod is arranged on the lower turntable in the manner of sliding up and down; the bottle tray is rotatably arranged at the top of the support rod; the idler wheel is arranged on the lower part of the support rod and is matched with the cam; the bottle tray and the bottle-accommodating grooves are coordinately arranged; a bottle-pressing component comprises a first friction wheel, a rotating shaft and an elastic component for supplying a downward pre-tightening force to the rotating shaft; a bottle-pressing head is arranged on the lower part of the rotating shaft; a friction wheel driving component comprises a second friction wheel which is used for driving the first friction wheel on a detection position to rotate; an anti-swinging rod is arranged on the lower turntable; a swing arm is arranged on the lower part of the support rod; the other end of the swing arm is limited on the anti-swinging rod in the manner of sliding up and down. The detection device for the bottle body has the advantages of high working efficiency and high reliability. The invention also provides a lamp detection device adopting the detection device for the bottle body.

Owner:CHANGSHA ZHIYUAN TECH

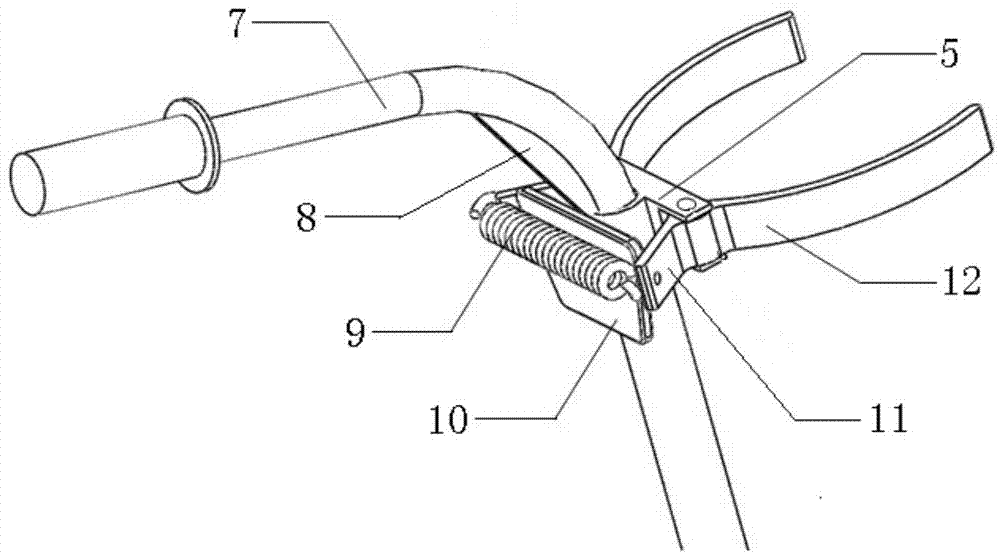

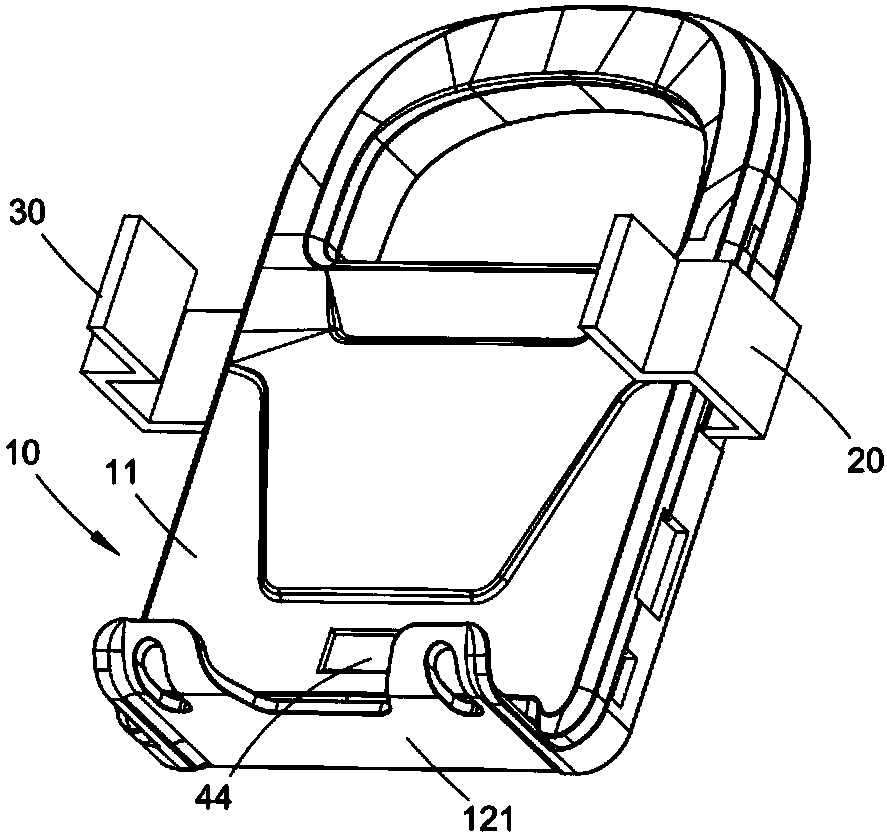

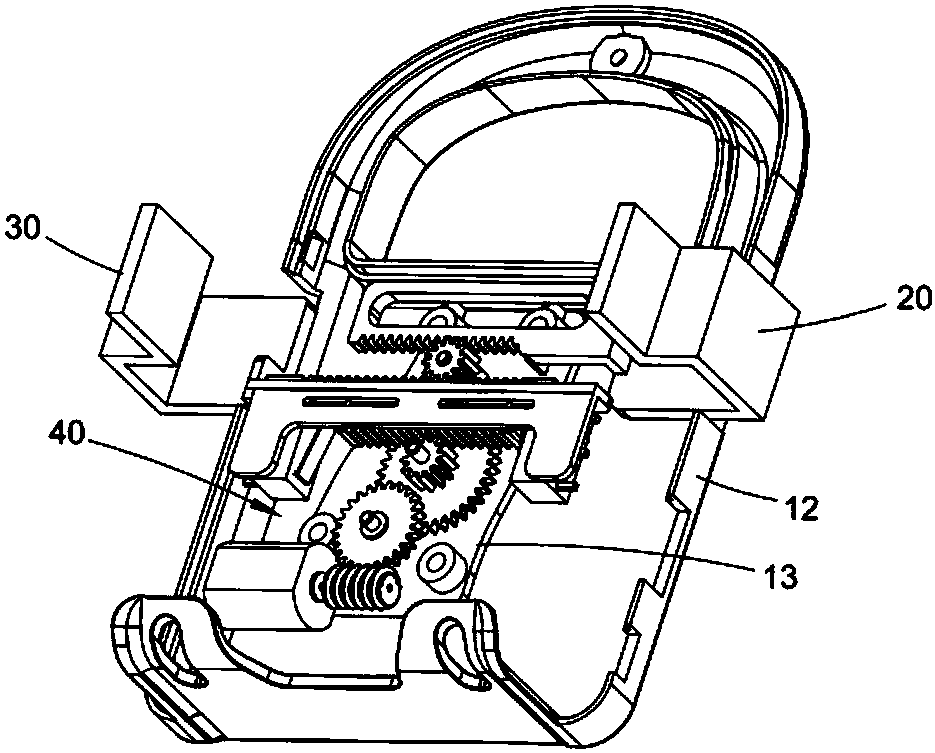

Multi-function handle

InactiveCN109333464AReduce the number of replacementsAutomatic clampingMulti-purpose toolsMetal-working hand toolsEngineeringMultiple function

The invention discloses a multi-function handle. The multi-function handle comprises a handle body, the handle body is internally provided with a working space with a forward opening, the working space is internally provided with a main body structure, and the main body mechanism comprises all components of the multi-function handle. The main body mechanism mainly comprises driving lead screw movable components, driven unthreaded rod movable components, a tooth meshing structure and a pneumatic clamping component. The upper and lower symmetrical driving lead screw movable components can be simultaneously driven by a same driving device. The driving lead screw movable components comprise intermediate transmission components. The multi-function handle can adapt to the disassembly or assemblyof objects in various shapes, effectively reduces the number of tool replacement by operators, can automatically realize clamping, moving and rotating and enhances work efficiency, in the movement process, belt drive, gear meshing drive and thread drive are used for ensuring a consistent direction of motion and stable transmission efficiency, and the reliability in the equipment moving process isenhanced.

Owner:马亚丽

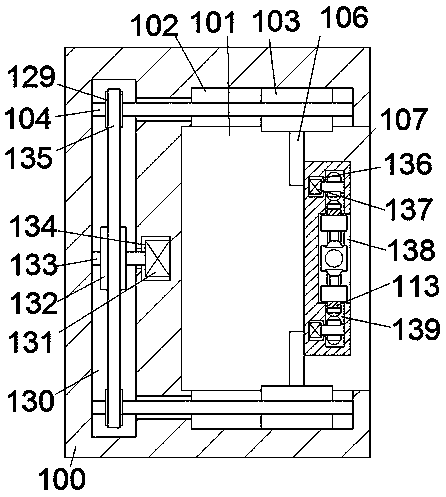

Double-opening mobile phone holder

InactiveCN108200256AFast and automatic clampingPrecise positioningTelephone set constructionsMobile phoneTriggering device

The invention discloses a double-opening mobile phone holder comprising a pair of clamping blocks arranged on a holder body, wherein the pair of clamping blocks are both movable clamping blocks, the first clamping block in the pair of the clamping blocks is driven by a drive system, and the second clamping block is linked with the first clamping block via a transmission mechanism. The drive systemcomprises a transmission piece elastically connected with the first clamping block, a power source used for driving the transmission piece to move towards or away from the second clamping block, anda passive triggering device arranged on the first clamping block, wherein the passive triggering device is connected with the power source. The power source drives the transmission piece, the transmission piece drives the pair of clamping blocks to move towards each other to clamp a mobile phone, the pair of clamping blocks are static, and the transmission piece overcomes an elastic force betweenthe transmission piece and the first clamping block to continuously move forwards until the passive triggering device is triggered, the power source stops providing power, the transmission piece stopsmoving, and the mobile phone is clamped at the middle part of the holder. The double-opening mobile phone holder provided by the invention can rapidly clamp the mobile phones with different widths.

Owner:DONGGUAN BEIYANG IND DESIGN CO LTD

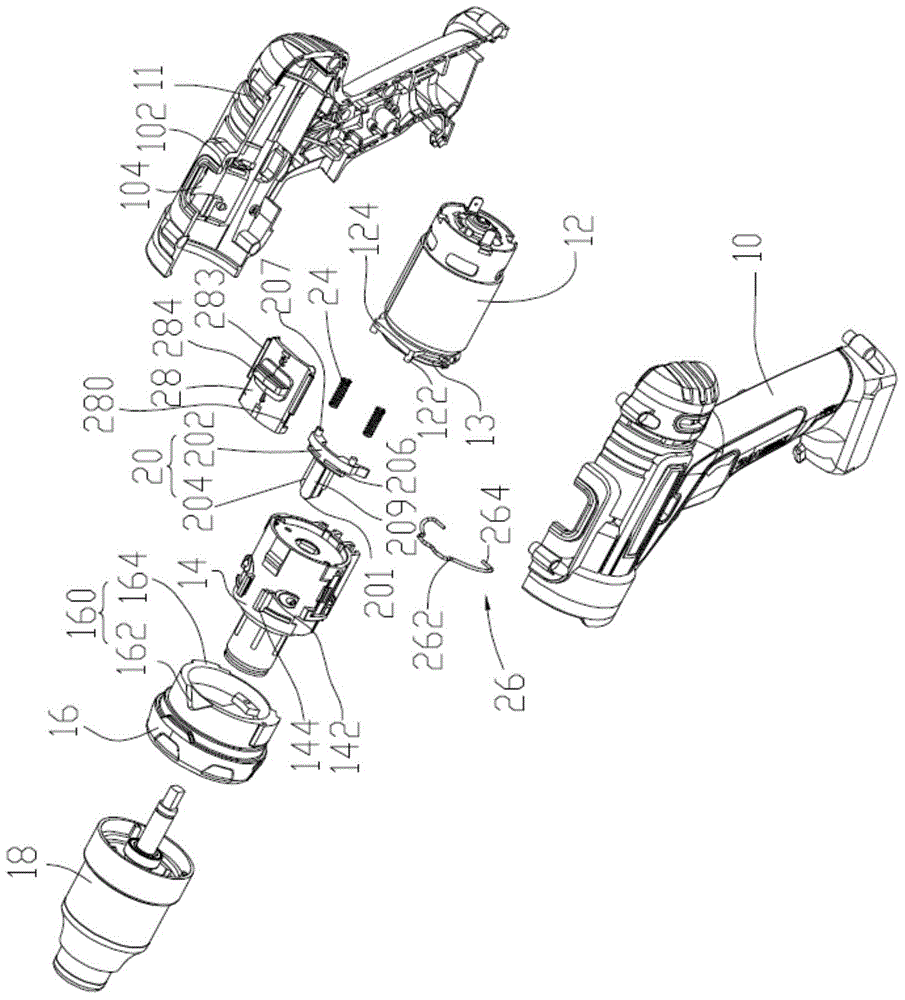

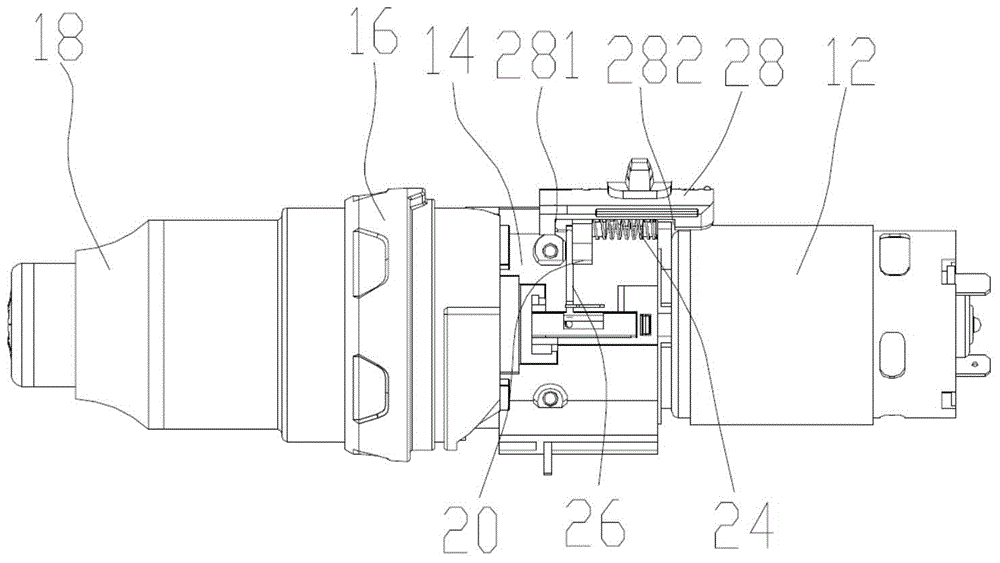

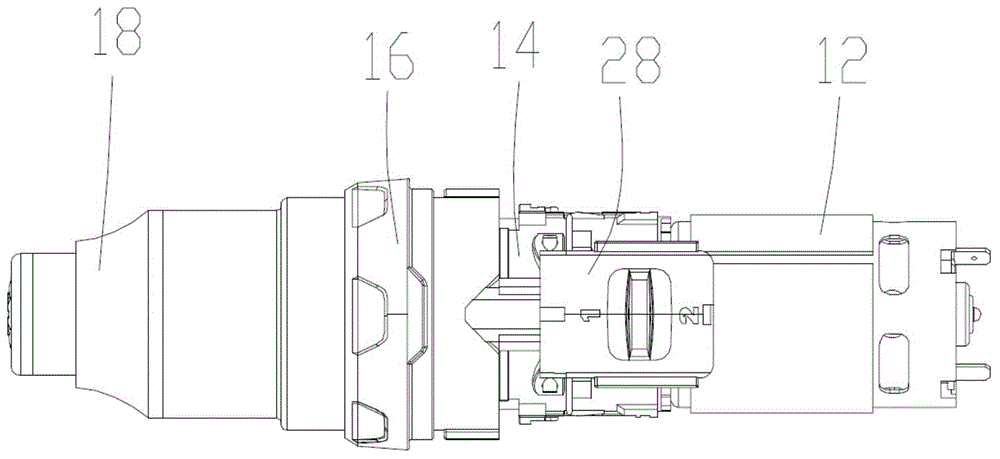

Gun drill and mode switching mechanism thereof

ActiveCN105772799AAutomatic clampingSimple structurePortable power-driven toolsPortable drilling machinesStress conditionsEngineering

The invention discloses a gun drill and a mode switching mechanism. The gun drill comprises a machine shell, a motor, a reducer casing, a rotatable mode selector switch, a clamping head and a linkage piece; the linkage piece is fixed relative to a gear shifting tooth ring of the reducer casing, the rotatable mode selector switch is rotationally arranged on the reducer casing in a sleeving manner, a cam part is arranged on the rotatable mode selector switch, and the linkage piece is matched with the rotatable mode selector switch; and the linkage piece comprises a matched end, in the rotating process of the rotatable mode selector switch, the cam part is matched with the matched end to drive the linkage piece to axially move along the reducer casing, and the gear shifting tooth ring of the reducer casing is further pushed to axially move along the reducer casing. The mode switching mechanism comprises the above the rotatable mode selector switch and the above linkage piece. The cam part is matched with the matched end, and circumferential motion of the rotatable mode selector switch can be easily switched into axial motion of the gear shifting tooth ring; and in addition, the structure is simple, the stress condition is good, motion is reliable, and the gun drill can be automatically clamped.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

Automatic positioning device

The invention provides an automatic positioning device. The automatic positioning device comprises a fixing support, a sliding rail, a first positioning mechanism, a second positioning mechanism and a sensor. The fixing support comprises a first support and a second support. The front end of the first support is fixedly connected with the top end of the second support. The sliding rail is arranged on the right side wall of the first support. The first positioning mechanism is arranged at the front end of the first support. The first positioning mechanism comprises a first air cylinder, a connecting block, a sliding block, a second air cylinder and a first positioning block. The second positioning mechanism and the sensor are arranged at the rear end of the first support. The second positioning mechanism comprises a third air cylinder and a second positioning block. The third air cylinder is arranged at the rear end of the first support and is connected with the second positioning block. The automatic positioning device can clamp and position a plastic packaging box automatically and rapidly without damaging or breaking down the plastic packaging box, so that the production efficiency of packaging is improved. In addition, the automatic positioning device is low in manufacturing cost, long in service life and easy to maintain.

Owner:QUANZHOU HUASHUO IND

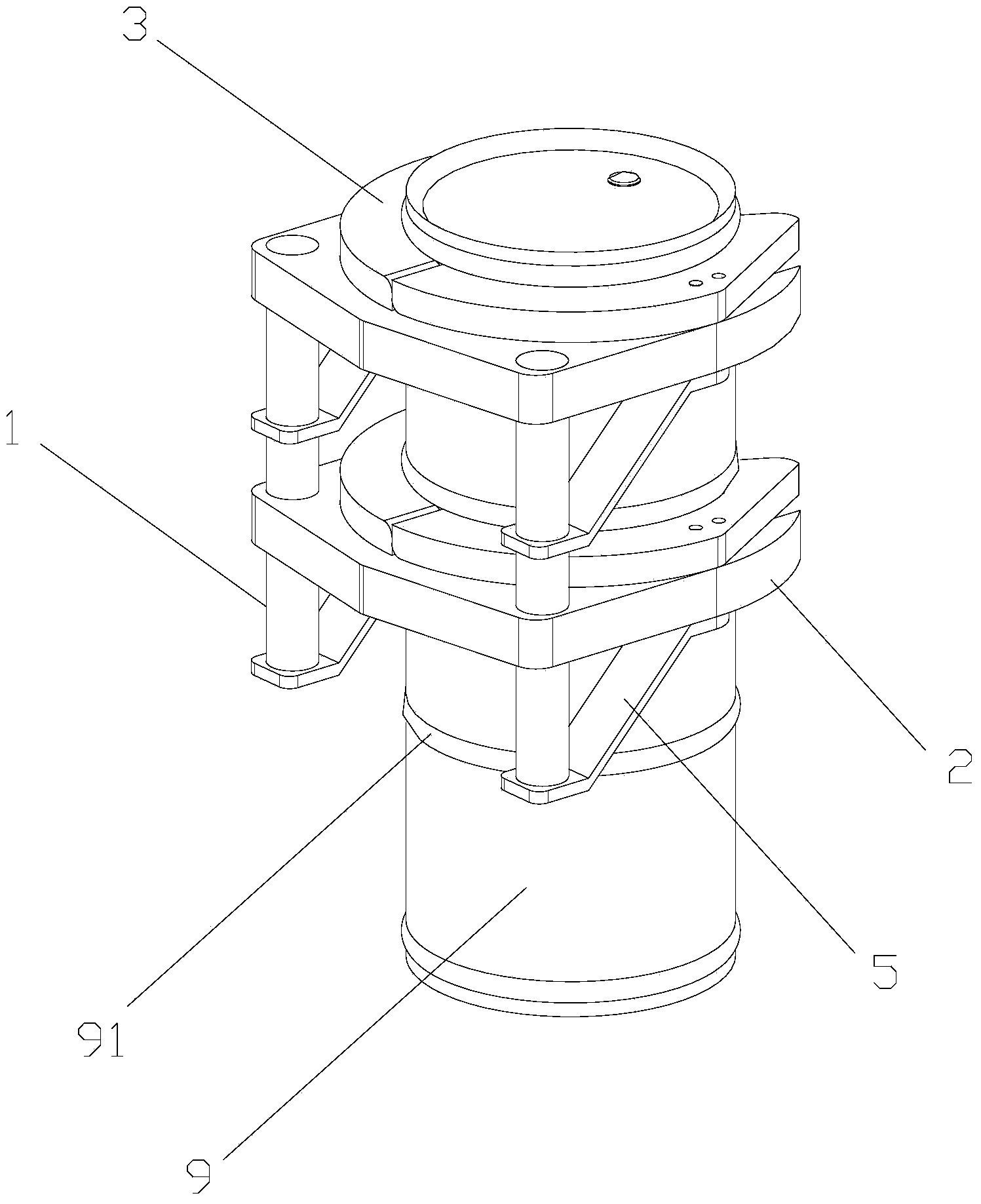

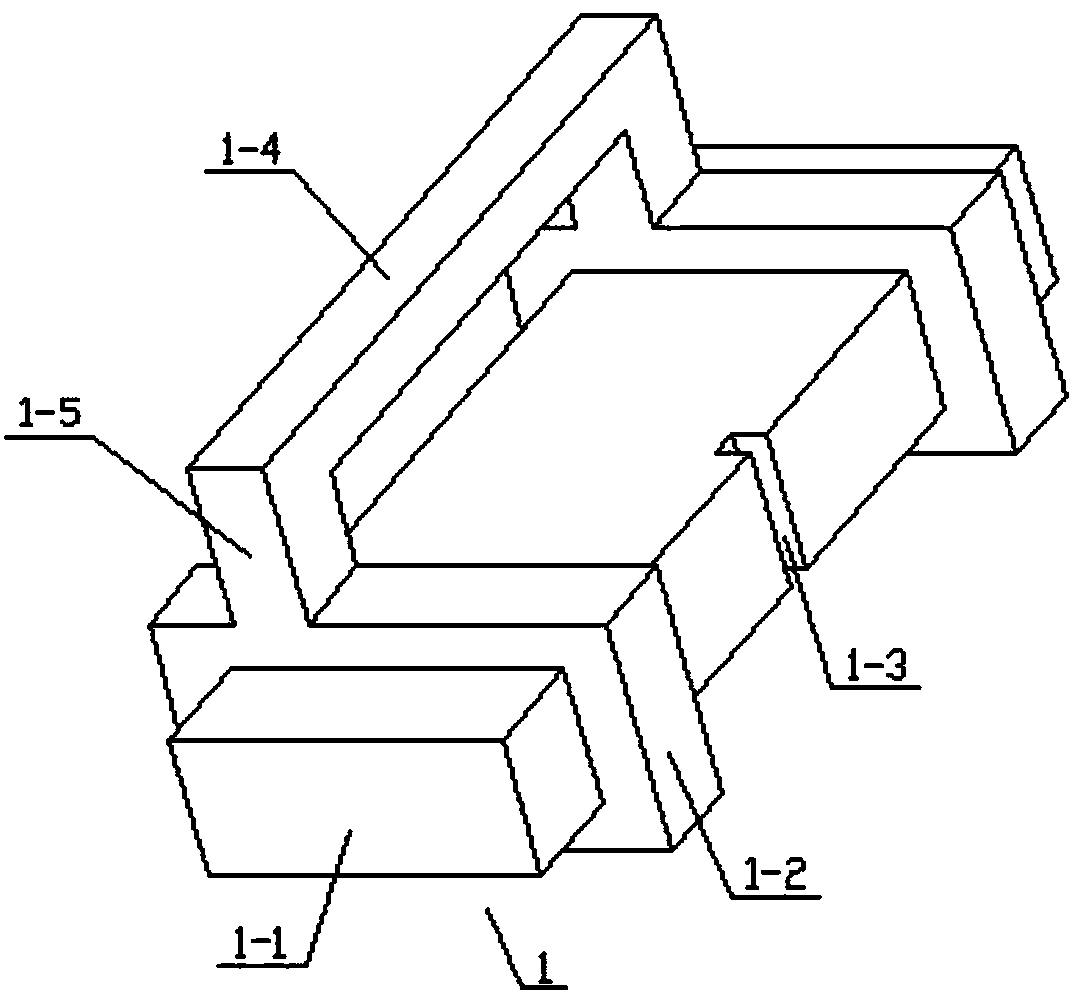

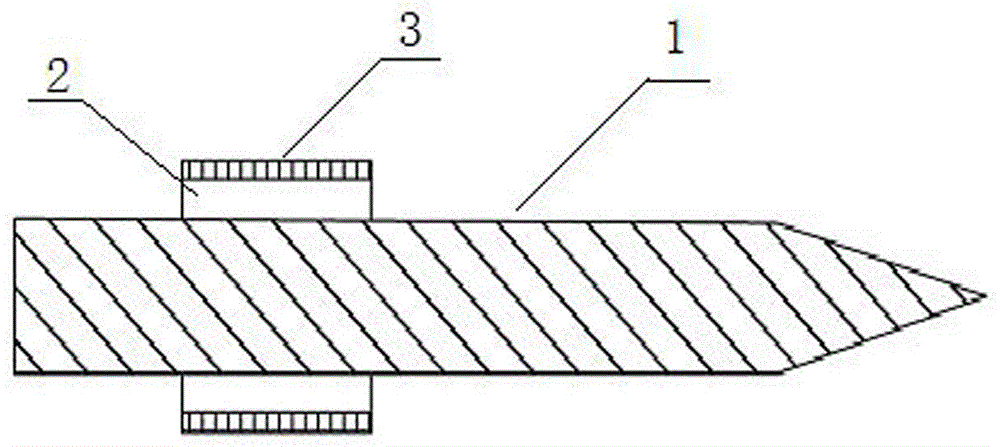

Three-valve separated expander

The invention discloses a three-valve separated expander and relates to the technical field of mineral anchorage clamping piece type products. The three-valve separated expander comprises a shaft (1) and is characterized in that one end of the shaft (1) is of a three-valve separated structure, an expanding core (2) sleeves each valve, an expanding sleeve (3) sleeves each expanding core (2), and a taper center is arranged at the other end of the shaft (1). The three-valve separated structure is in central symmetry relative to the shaft (1), and the valves are same in size. The three-valve separated expander is low in manufacturing cost, facilitates workpiece mounting and taking out, enables machine tools to completely execute automatic clamping and releasing actions, and greatly reduces the labor intensity of manpower.

Owner:HEFEI HAOCHENG IND & TRADE

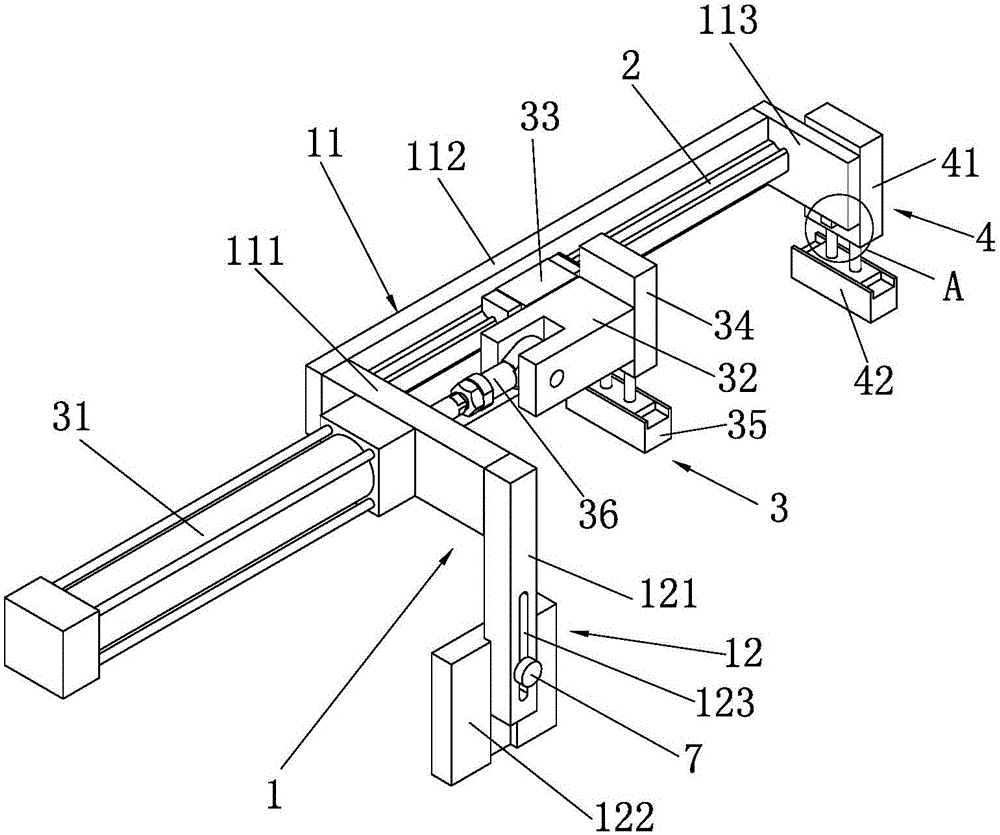

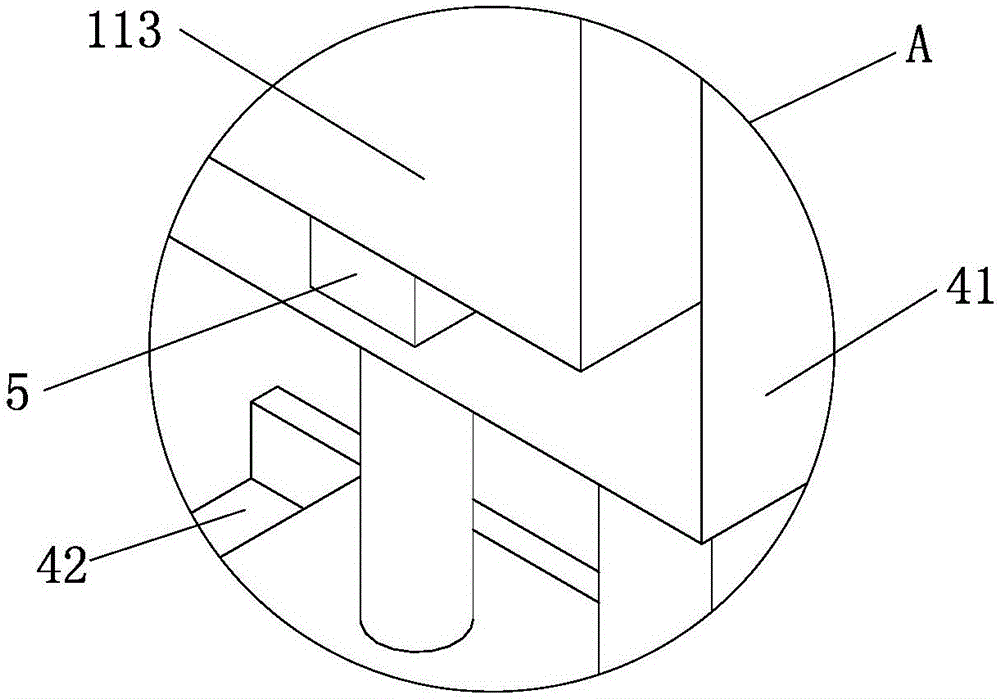

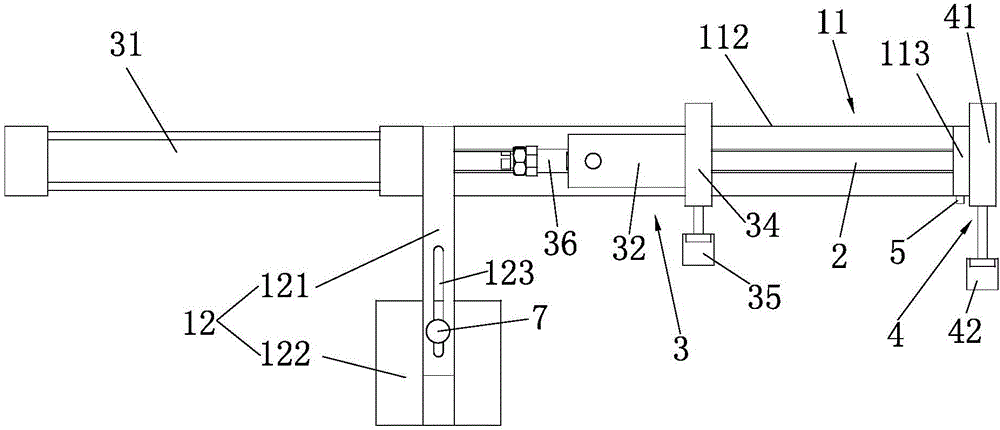

Device capable of rapidly correcting network transformer pins

InactiveCN106847490ALabor savingAutomatic clampingTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureBiochemical engineeringTransformer

The invention discloses a device capable of rapidly correcting network transformer pins. The device comprises a feed table and an inclined plate, a first fixing plate is arranged on the feed table, a first driving mechanism and a supporting block are arranged on the first fixing plate, a first connecting block is arranged on the first driving mechanism, a push broach is arranged on the first connecting block, a skew rack is arranged on the supporting block, a push rod is arranged on the skew rack, a plurality of driving mechanisms and fixing plates are arranged on the inclined plate, a screening device is arranged on a seventh driving mechanism, a movable block is arranged on an eighth driving mechanism, a finished product pipe is arranged on the movable block, waste pipes are arranged on the fixing plates, a first boss, a second boss and a controller are arranged on the inclined plate, detection devices are arranged on the first boss and the second boss, and pin openings are formed in detection blocks of the detection devices. The device can automatically feed and clamp, pins can be rapidly corrected, and unqualified products and qualified products can be separately collected.

Owner:ZHONGJIANG KAIXUN ELECTRONICS

Cutting device capable of achieving automatic tree sawing function

InactiveCN111216201AIncrease binding forceSave manpower and timeGripping devicesClamping devicesEngineeringIndustrial engineering

The invention discloses a cutting device capable of achieving the automatic tree sawing function. The cutting device comprises a base. A locating slot penetrating through the upper and lower end facesof the base is formed in the base. The rear end wall of the locating slot communicates with the external space. Two clamping mechanisms are mounted on the upper end face of the base in bilateral symmetry with the locating slot as the center. Two manipulator structures at different heights are driven by hydraulic cylinders and can automatically clamp a tree to be cut and provide stable clamping force. The cutting device can cut down and transport the cut tree through concentric shaft rotation, is fixed to the ground through a fixed pile structure, provides large constraining force, can complete cutting of large-diameter trees, automatically implements the cutting process, saves a great deal of manpower and time and avoids safety problems caused during manual operation.

Owner:温州市景润机械科技有限公司

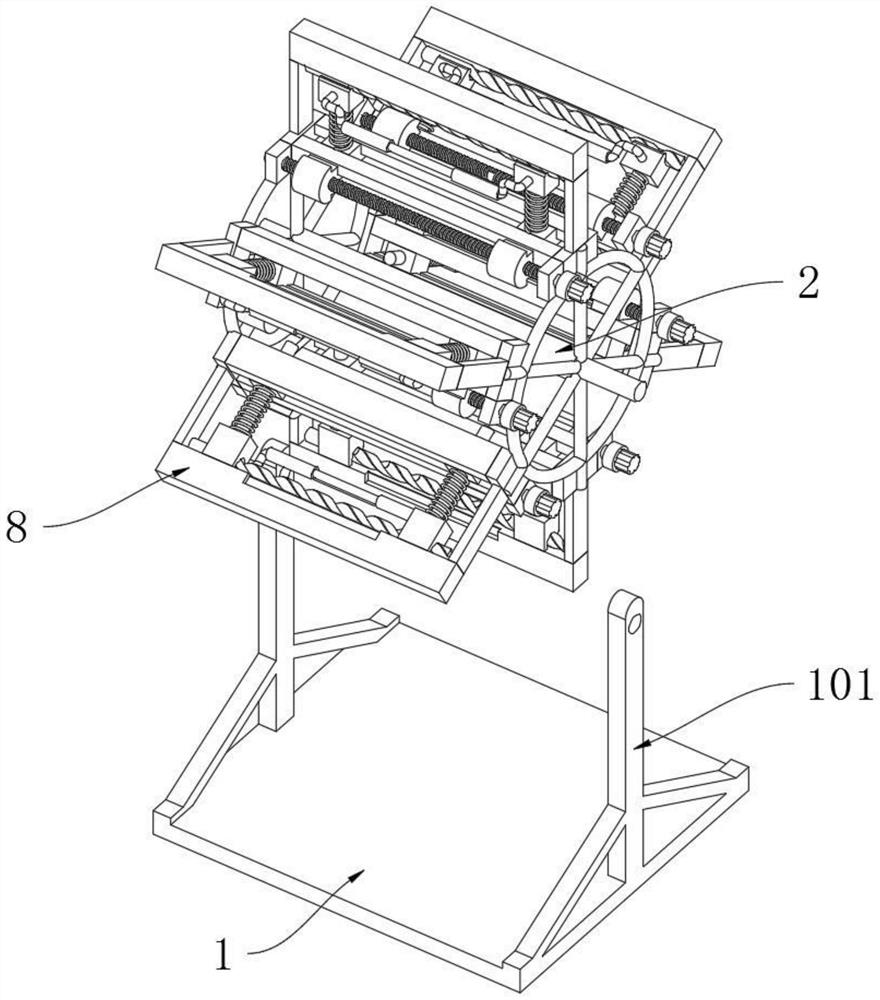

Automatic air conditioner cooling fin mounting and flattening equipment

InactiveCN112387888AImprove processing efficiencyPlay a buffer roleMetal-working feeding devicesHeat exchange apparatusMachiningEngineering

The invention relates to the technical field of air conditioner cooling fin assembling, in particular to automatic air conditioner cooling fin mounting and flattening equipment. The automatic air conditioner cooling fin mounting and flattening equipment comprises a machining table, a material arranging device, a conveying device, a feeding device, fixed clamping devices, a flattening device, a moving device and a discharging stacking device. The material arranging device is arranged on the top of the machining table. The conveying device is arranged at the tail of the material arranging device. The conveying device is provided with a plurality of cooling fin plate frames. The feeding device is arranged beside the material arranging device. The fixed clamping devices are arranged on the twosides of the conveying device. The flattening device is arranged beside the conveying device. The moving device is arranged on the ground. The discharging stacking device is arranged at the moving end of the moving device. According to the automatic air conditioner cooling fin mounting and flattening equipment, through the mutual cooperation work of the material arranging device, the conveying device, the feeding device, the fixed clamping devices, the flattening device, the moving device and the discharging stacking device, cooling fins are automatically mounted and flattened, automatic discharging and stacking are achieved, and the whole machining efficiency is improved.

Owner:余萍

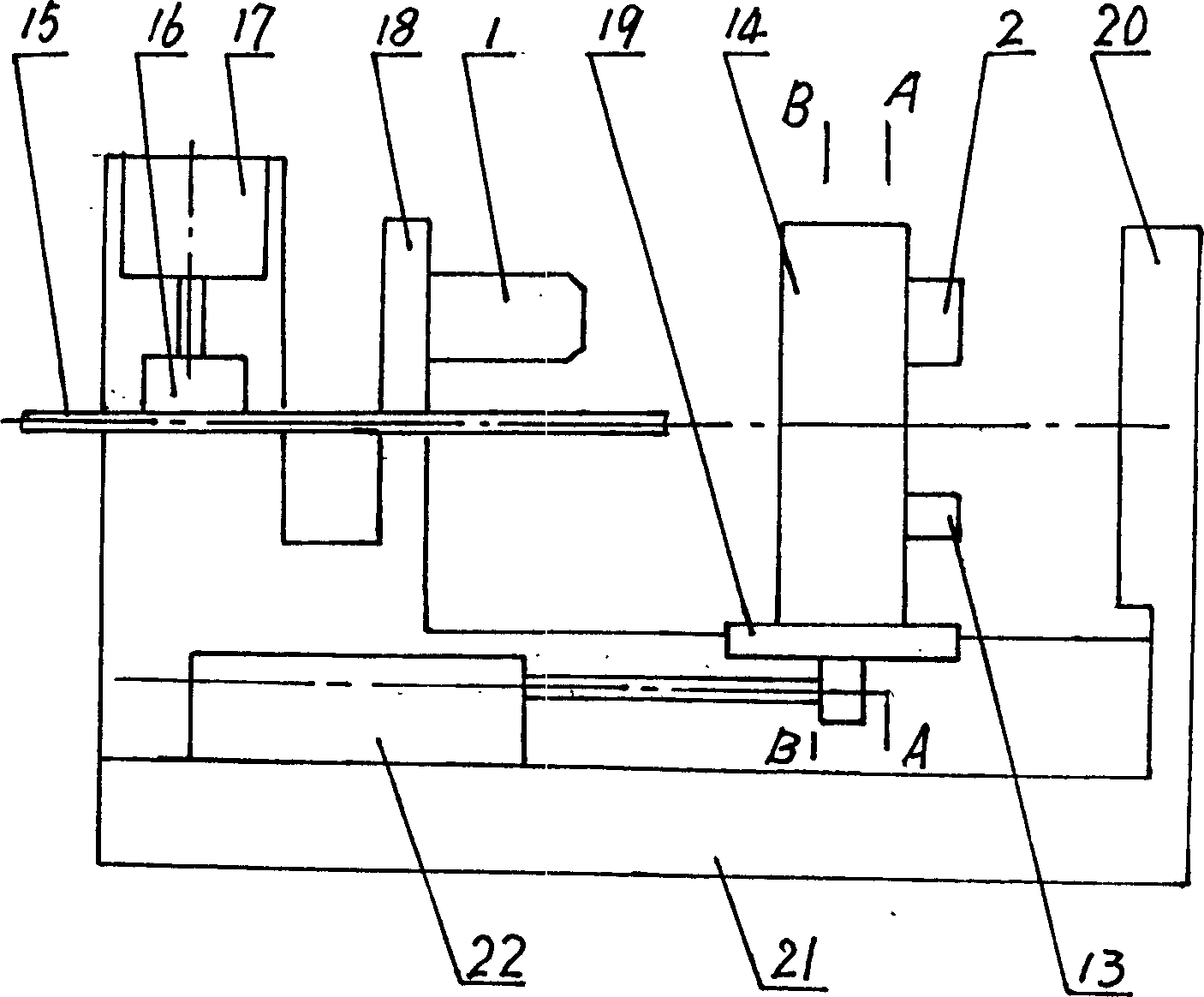

Electromagnetic wire stripping machine

InactiveCN1599154AImprove peeling qualityRealize semi-automatic peeling workLine/current collector detailsSpring forceEngineering

The invention relates to an electromagnetic wire barker machine and includes the machine frame 21, oil cylinder 22, oil cylinder 17, compacting block 16 and electromagnetic wire 15. There are an oil cylinder 22 at the upper part of the frame and an oil cylinder 17 is set at the top left part of the frame. There is a compacting block 16 at the end of the oil plug pole. There are a location limit board 18 at the left end of the frame 21 and a location limit board 20 at the right end of the frame 21. There is a shut-limiting bolt 1 on the location limit board 18. Between the location limit boards 18 and 20, the oil plug pole of the oil cylinder 22 connects with the slippery lingua 19, on which there is molding knife box 14. There are the electromagnetic wire fluctuating barker device and electromagnetic wire fore-and-aft barker device in the molding knife box 14. The invention is featured by high efficiency, safety, convenient use and high quality of peeling, can finish the semiautomatic peeling work of the automatic electromagnetic line, can choose corresponding bit according to the size of section of the electromagnetic wire to be peeled, adapts the spring force and realizes the quick peeling working of many electromagnetic wires.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com