Horizontal spraying production line

A production line, horizontal technology, applied in spray booths, spray devices, etc., can solve the problems of low operation efficiency, thick coating thickness, complicated steps, etc., and achieve the effects of simple structure, improved uniformity, and reduced manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

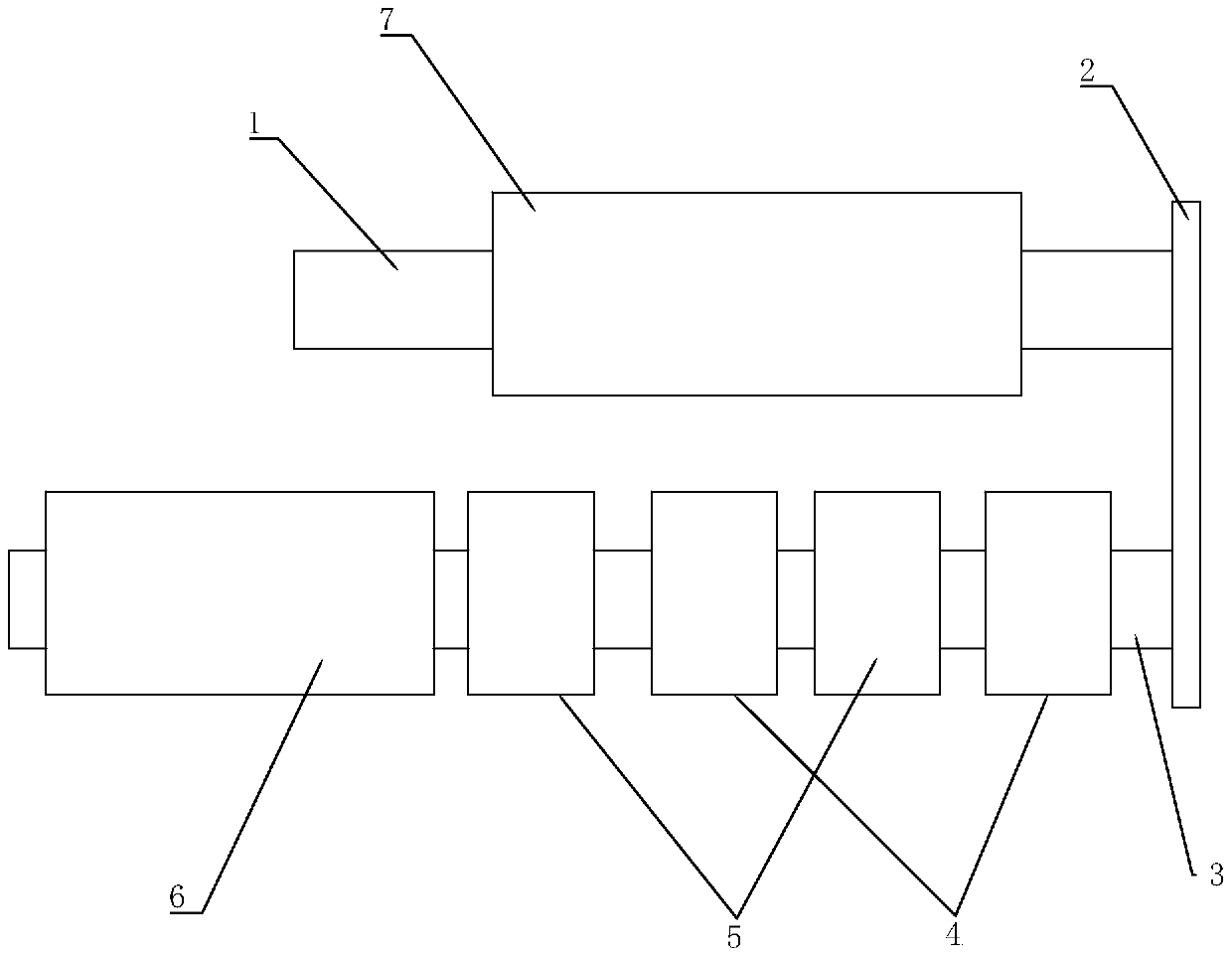

[0030] refer to figure 1 , the embodiment of the present invention provides a horizontal spraying production line, including a spraying chamber 4, a drying chamber 5, and a spraying conveying device 3 passing through the spraying chamber 4 and the drying chamber 5.

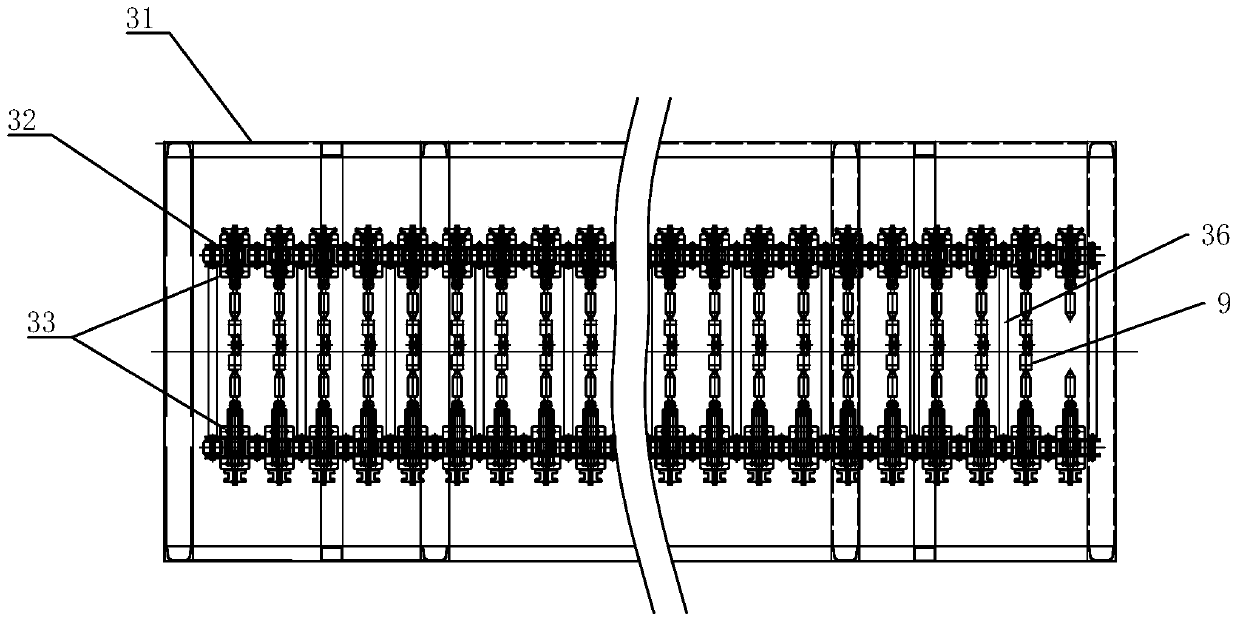

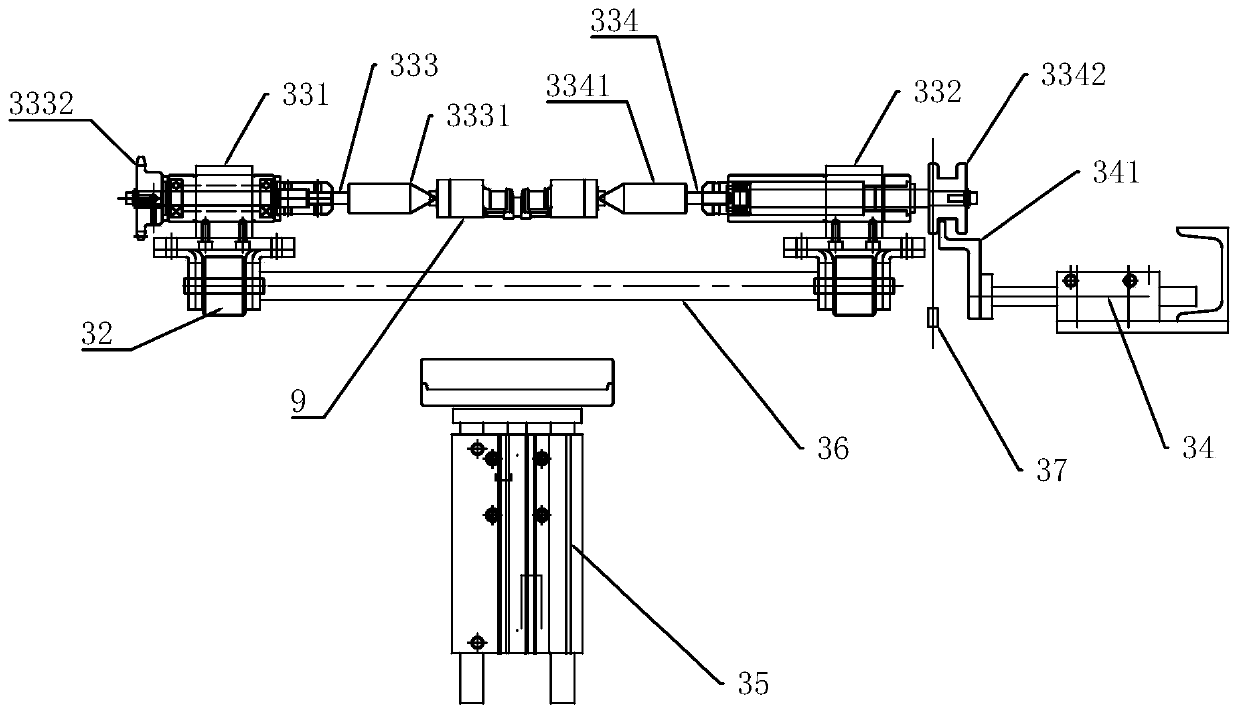

[0031] refer to Figure 2 to Figure 4, the spraying conveying device 3 includes a spraying frame 31, a spraying conveying chain 32 arranged on the spraying frame 31, a number of clamping fixtures 33 arranged on the spraying conveying chain 32, driving the spraying The first driving device (not shown in the drawings) of the conveyor chain 32 movement; in this embodiment, preferably, the first driving device includes a first motor and a driving sprocket and a driven sprocket, the The spraying conveyor chain 32 is wound on the driving sprocket and the driven sprocket. There are two spraying conveyor chains 32 arranged in parallel and at intervals; the clamping fixtures 33 all include a first mounting seat 331 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com